搅拌铸造竹叶灰铝基复合材料的显微组织和力学性能

来源期刊:中国有色金属学报(英文版)2017年第12期

论文作者:B. Praveen KUMAR Anil Kumar BIRRU

文章页码:2555 - 2572

关键词:Al-4.5Cu 合金;搅拌铸造;复合材料;竹叶灰;密度;孔隙度

Key words:Al-4.5Cu alloy; stir casting; composites; bamboo leaf ash; density; porosity

摘 要:以从农业废物中分离出的竹叶灰(BLA)为增强剂,当竹叶灰(BLA)含量分别为2%、4% 和 6%时,以Al-4.5%Cu合金为基体,采用搅拌铸造方法制备复合材料。该复合材料由于基体和增强粒子之间的有效结合,而具有优越的性能。采用各种试验确定该复合材料的力学性能,如密度、孔隙度、硬度和抗拉强度。将所得结果与基体合金相进行比较。采用OM、SEM-EDAX 和 XRD分析方法对所选基体合金中增强粒子的分散性进行分析。结果表明,复合材料中BLA颗粒均匀分布于晶体内。此外,还观察到BLA颗粒与基体合金有良好的结合,且界面清晰。随着BLA颗粒质量分数的增加,复合材料的密度降低,而孔隙度增大。当复合材料中BLA颗粒含量达到4%时,材料的硬度和抗拉强度都增加,而当BLA含量进一步增加时,硬度和抗拉强度都会降低。

Abstract: Al-4.5%Cu alloy was used as a matrix at 2%, 4% and 6% of bamboo leaf ash (BLA) which was extruded from agro waste and was used as reinforcement. The composite which was fabricated by stir casting method possessed superior properties due to an effective bonding between matrix and reinforcement particles. The fabricated composite specimens were subjected to various tests to determine the mechanical properties such as density, porosity, hardness and tensile strength. The results were compared with basic matrix alloy. Furthermore, the OM, SEM with EDAX and XRD analyses were carried out to analyze the dispersion of the reinforced particles in the selected matrix alloy. It was observed that the homogeneous distribution of BLA particles in composites was intragranular in nature. Moreover, it was also observed that BLA particles were well bonded with matrix alloy with clear interface. It was also found that the density decreased with increase in mass fraction of BLA particles and porosity increased with increase in mass fraction of BLA particles. The hardness and tensile strength were increased up to 4% of BLA in the composite, with a further increase in BLA content the hardness and tensile strength decreased.

Trans. Nonferrous Met. Soc. China 27(2017) 2555-2572

B. Praveen KUMAR, Anil Kumar BIRRU

Department of Mechanical Engineering, National Institute of Technology, Manipur 795004, India

Received 20 October 2016; accepted 16 April 2017

Abstract: Al-4.5%Cu alloy was used as a matrix at 2%, 4% and 6% of bamboo leaf ash (BLA) which was extruded from agro waste and was used as reinforcement. The composite which was fabricated by stir casting method possessed superior properties due to an effective bonding between matrix and reinforcement particles. The fabricated composite specimens were subjected to various tests to determine the mechanical properties such as density, porosity, hardness and tensile strength. The results were compared with basic matrix alloy. Furthermore, the OM, SEM with EDAX and XRD analyses were carried out to analyze the dispersion of the reinforced particles in the selected matrix alloy. It was observed that the homogeneous distribution of BLA particles in composites was intragranular in nature. Moreover, it was also observed that BLA particles were well bonded with matrix alloy with clear interface. It was also found that the density decreased with increase in mass fraction of BLA particles and porosity increased with increase in mass fraction of BLA particles. The hardness and tensile strength were increased up to 4% of BLA in the composite, with a further increase in BLA content the hardness and tensile strength decreased.

Key words: Al-4.5Cu alloy; stir casting; composites; bamboo leaf ash; density; porosity

1 Introduction

With a wide choice of materials which are available for engineers, they are posed with a big challenge of selecting the appropriate material and manufacturing process for their applications [1]. In the past few years, the global need for cost-effective, high performance and acceptable quality materials caused a shift in research from monolithic to composite materials [2]. Metal matrix composites (MMCs) have the potential to replace conventional materials in many engineering applications such as aerospace, automobile and marine industries as structural engineering materials [3-8]. Light metals such as aluminium, magnesium, copper and their alloys are the most widely used matrix materials in the production of MMCs. It is also well known that the properties of MMCs are related to the size, mass fraction of the reinforcements as well as the nature of the matrix- reinforcement interfaces [9-11].

Among the various MMCs, aluminium based alloys are widely utilized in the production of MMCs [12] and have reached the industrial production stage due to their aforementioned superior properties [13-16]. During the last three decades, TiC, AlN, B4C, Al2O3, TiB2, MoS2, SiC, Gr and mica, have widely used as the reinforcement particles at various mesh sizes in the aluminium matrix which improved the hardness, tensile strength, elastic modulus and wear resistance [17-25]. However, MMC’s technology is still in developing stage and several important combinations of reinforcement especially agro-based bamboo leaf ash (BLA) are yet to study.

The cost of aluminium metal matrix composite (AMMCs) remains high, which limits its applications. The use of inexpensive reinforcements such as natural material might reduce the overall cost of AMMCs and may also increase its functionality in different applications [26]. The search for low cost options in AMMC production has led to a number of efforts tailored at utilizing industrial and agro waste products as reinforcing materials [27]. In this regard, a number of researchers made attempts on agro waste ashes such as baggase ash, rice husk ash (RHA), coconut shell ash, palm kernel shell ash, groundnut shell ash (GSA) and bamboo leaf ash as complementing reinforcements. The agro waste ash contains a high content of silicon dioxide (SiO2) with the distribution of other elements such as Al2O3, Fe2O3, CaO, MgO and C [28-33]. There are several advantages in using the agro waste as reinforcements; these cost very less for processing, easily available in massive at an economical price and often lower densities in comparison with some ceramics (such as silicon carbide, boron carbide and alumina), benefit in conservation and protection of the environment [34].

Some studies on AMMCs reinforced with BLA particles were reported [35-37]. ALANEME et al [35] studied the aluminium hybrid composite (Al-Mg-Si/ BLA/Al2O3) with variations of BLA and Al2O3 as reinforcements in mass fraction by using stir casting method. They observed that the wear resistance increased significantly with 2% and 3% addition of BLA. It was concluded that using BLA as a complementing reinforcement would produce the high performance and low cost composites. ALANEME et al [36] compared the mechanical and corrosion resistance of Al-Mg-Si/SiC AMMCs and Al-Mg-Si/SiC-BLA aluminium hybrid metal matrix composites (AHMMCs) produced by stir casting. They observed that with the addition of BLA particles, the hardness, ultimate tensile strength and elongation of hybrid composite decreased and fracture toughness increased compared with Al-Mg-Si/SiC composite. It was also noticed that the margin of difference of specific strength between the Al-Mg-Si/ 10%SiC and Al-Mg-Si/2%BLA/8%SiC composites is less than 2%. The higher corrosion resistance was observed at 2% and 3% BLA containing hybrid composites in 3.5% NaCl solution as compared to Al-Mg-Si/10%SiC composite. ALANEME and ADEWUYI [37] prepared the Al-Mg-Si/Al2O3 and Al-Mg-Si/Al2O3/BLA composites using stir casting method. The tensile strength and hardness were slightly decreased with increase of BLA content as compared to Al-Mg-Si/Al2O3 composite. They also observed that specific strength at 4% of BLA in Al-Mg-Si/Al2O3/BLA hybrid composite is less than 9% in comparison with Al-Mg-Si/Al2O3. Fracture toughness in Al-Mg-Si/ Al2O3/BLA hybrid composite was observed to be superior as compared to Al-Mg-Si/Al2O3 composites. Still, it is necessity to characterize the potentials of agro waste ashes such as BLA, which is economical and also complementing reinforcement in AMMCs.

The present work is motivated by the prospects of developing high performance and low cost AMMCs in an effort in considering the potentials of BLA as complementing reinforcement, as bamboo trees are mostly found at large scale in Manipur, geographically located in North East India and the leaves often litter the environments where they are found. The Al-4.5%Cu alloys were selected as matrix material. Aluminium- copper alloy possesses vital mechanical properties, i.e., higher strength, fatigue resistance and tensile strength. It is the alloy which is used in aircraft structures, especially wing and fuselage structures under tension where high specific strength is prominent. It is also used in high temperature applications like as in automobile engines and in other rotating and reciprocating parts such as a piston, drive shafts, brake-rotors and in other structural parts [38,39]. For the production of AMMCs, different processes have their own merits and demerits. The manufacturer generally prefers the lowest cost route with adequate quality casting [40]. Therefore, stir casting method represents a substantial proportion of methodology used for the preparation of composites materials at cost effective with imputes quality. For stir casting method, in order to achieve the optimal properties of MMCs [41], the distribution of the reinforcement materials in the matrix has to be uniform and the wettability among the reinforcement and molten matrix should be optimized. The porosity level and the oxidation with cast MMCs have to be minimized and the chemical reaction between the reinforcements and the matrix material need to be avoided [42]. The stir casting method is used for fabrication of Al-4.5%Cu alloy reinforced with 0%, 2%, 4% and 6% of BLA.

2 Experimental

2.1 Materials

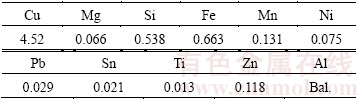

Aluminium with 4.5% Cu was selected as the matrix material for the present investigation and chemical composition of the aforesaid alloy is presented in Table 1. Bamboo leaf ash was processed as per the standard procedure. Magnesium in ingot form was used to improve wettability between the matrix alloy and the reinforcements during the production of the composite materials.

Table 1 Chemical composition of Al-4.5%Cu alloy (mass fraction, %)

2.2 Preparation of bamboo leaf ash

The bamboo leaf ash was prepared following procedures and precautions reported by ALANEME et al [35,43]. Dry bamboo leaves as shown in Fig. 1(a) were collected from farmlands having a large mass of bamboo trees within Manipur, North East India, which were used to prepare the ash. The bamboo leaves were placed in a metallic drum and fired in the open air to allow for complete combustion. The ash produced from the burning process was allowed to cool for 24 h before removal from the drum. The ash was then milled and conditioned using an electric muffle furnace at a temperature of 650 °C for 3 h to remove carbonaceous materials. A sieve shaker was used to sieve the bamboo leaf ash to obtain ashes with mesh size under 75 μm. Prepared BLA which was used as reinforcement is shown in Fig. 1(b). The average particle size was found to be 75 μm and chemical composition as per X-ray diffraction (XRD) investigation of BLA is depicted in Table 2.

Fig. 1 Dry bamboo leaves (a) and prepared bamboo leaf ash with particle size under 75 μm (b)

Table 2 Chemical composition of bamboo leaf ash (mass fraction, %)

2.3 Composite production

In the present investigation Al-4.5%Cu alloy was used as the matrix material and BLA particles were used as reinforcements and for fabricating the composites used stir casting process. The stir casting method was used for the production of the composite as it is relatively inexpensive and offers a wide selection of materials and processing conditions, experimental stir casting bottom pouring system setup as shown in Fig. 2. Stir casting method offers better matrix particle bonding due to stirring action of particles into melts [44]. The matrix and the reinforcement materials are pre-heated at a certain temperature before being mixed to release all the moisture and trapped air between the particles [45]. The Al-4.5%Cu alloy, which was in the form of ingot was cut into small pieces to accommodate in the crucible and was then melted in the induction electric resistance furnace, and heated to 800 °C till the entire alloy in the crucible melt in an argon atmosphere. The molten metal is allowed to cool in the furnace to a semi-solid state at a temperature of 620-650 °C [46]. The solidification range for Al-4.5Cu alloy is 548.2-660.452 °C [47].

Fig. 2 Bottom pouring type of stir casting experimental setup

The BLA particles at 0%, 2%, 4% and 6% were added respectively for all the castings and initially preheated for 1 h at a temperature of 350 °C to eliminate dampness and to promote the wettability with the molten Al-4.5%Cu alloy. For all the experiments, BLA particle sizes were maintained under 75 μm. The heat-treated BLA particles were injected by argon gas and the magnesium in ingot form approximately 0.1% is also added to promote wettability between the reinforcement and molten alloy into the semi solid state of alloy and stirring of the slurry is performed for 5-6 min. The composite slurry was then superheated at 750 °C and the secondary stirring process is performed using a mechanical four-blade graphite coated stainless steel stirrer, which is introduced into the melt to carry out stirring process. The coating of graphite to the blades of the stirrer is essential to prevent the migration of ferrous ions from the stirrer into the molten metal. The stirring is carried out at a speed of 600 r/min for 10 min to enhance uniform distribution of the BLA particles in the Al-4.5%Cu alloy, and simultaneously argon gas of high purity was used as a protective shroud on the melt surface. The current process was similar to that by PRABU et al [48] who fabricated composite by stir casting with stirring speed 600 r/min for 10 min and it was observed to produce better distribution reinforcement particles in the composite and hardness of the composite. After complete incorporation of the BLA reinforcement particles into Al-4.5%Cu alloy, the prepared composite poured into 350 °C preheated permanent steel mould of d 20 mm, length 200 mm, respectively. The fabricated composite material is fettled at room temperature from steel mould. The fabricated composite ingot was taken with various contents of BLA particles (0%, 2%, 4% and 6%). The fabricated composite materials were cut into samples for microstructure examination, density measurements, hardness and tensile tests.

2.4 Density and porosity measurements

Density measurement was carried out to evaluate the porosity levels of the composites produced by stir casting method and to study the effect of the BLA content on the density of the composites produced. Porosity can be determined by comparing the experimental and theoretical densities of each composite [4]. The experimental density for each composite was evaluated by weighing the test sample using a high precision electronic weighing balance with a tolerance of 0.1 mg. The measured mass in each case was divided by the volume of the respective sample.

The experimental density of composites was determined by water displacement technique (Archimedes’ principle) and is calculated using Eq. (1) [49]:

ρex=m/V (1)

where ρex is the experimental density of specimen, m is the mass of the specimen and V is the volume of water displaced.

Theoretical density (ρth) was measured by the rule of mixture [50,51]. The rule of mixture (Eq. (2)) for particulate composite is given as

ρth=ρmVm+ρrVr (2)

where ρm is the theoretical density of matrix, Vm is the volume fraction of the matrix, ρr is the theoretical density of reinforcement and Vr is the volume fraction of reinforcement.

During the fabrication of MMCs, porosity levels may be normal, because there are long particles which increase surface area in contact with air. The volume fraction of porosity, its size and distribution in cast MMCs play vital roles in controlling the mechanical properties. Porosity may not be fully avoided during the casting process, but it may be controlled. The porosity of the composites was determined using Eq. (3):

(3)

(3)

2.5 Microstructural and XRD characterization

The composites metallographic examination was carried out using an optical microscope (OM) and scanning electron microscope (SEM). FEI Quanta 250 SEM equipped with energy dispersive analysis of X-ray (EDAX) was used to study the microstructure of the composites. The samples of fabricated composites were sectioned for microstructure examination. All such samples were polished and etched with Keller’s reagent (95 mL water, 2.5 mL HNO3, 1.5 mL HCl, 1.0 mL HF), a widely used reagent for Al and Al alloys, was used as an etching agent [52] to analyze the fabricated composites. Buehler Omni Met image analysis software, in conjunction with an optical microscope, was used to study the microstructure and measure the grain size of the fabricated composites. Grain size calculations were performed by linear intercept method. In photo- micrograph, at any straight line, the length of the line divided by the average number of grains intercepted by it, gives the average grain size [53]. The grain sizes were measured at different locations for each specimen and the average grain size was determined. X-ray diffraction patterns of the BLA and all composite samples are done using a Bruker D8 advanced ECO X-ray diffractometer with Cu Kα radiation and Ni filter. The XRD analysis was carried out at a voltage of 40 kV and current intensity 25 mA.

2.6 Hardness and tensile test

Hardness and tensile test samples of the fabricated composite were prepared as per ASTM standards. The sample for hardness test prepared cylindrical in shape with d 12 mm and height 10 mm was polished to obtain a flat and smooth surface finish. Hardness tests were performed by taking the average of three readings for each sample using micro Vickers Hardness machine as per ASTM E384-11 with a load of 500 g for 15 s and Brinell hardness testing machine as per IS 1500-2005 consisting of ball indenter of 5 mm and a load of 250 kg. The tensile tests were performed on tensile samples prepared from the as-cast composites as per ASTM B557 standard.

The specimens for the tensile test were machined in round shape with d 9 mm and 36 mm gauge length, as shown in Fig. 3. The test was carried out by using a computerized universal testing machine. The strength and deformability parameters are determined from the tensile test are an ultimate tensile strength, yield strength, elongation and specific strength. The fracture surface of the tensile specimens was also observed using SEM.

Fig. 3 Tensile test specimens of fabricated composite with various mass fractions of BLA

3 Results and discussion

Al-4.5%Cu alloy reinforced with BLA particles was successfully fabricated using stir casting method. The microstructure and mechanical behavior of the fabricated Al-4.5Cu-BLA composites were discussed in detail in subsequent sections with different mass fractions of BLA.

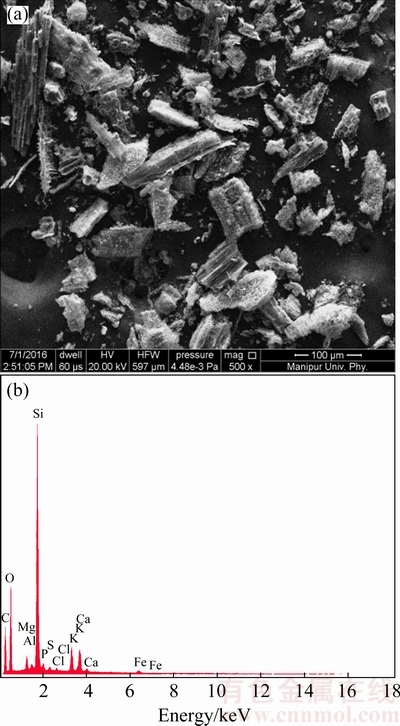

3.1 Characterization of bamboo leaf ash

The SEM image with EDAX and XRD pattern of the BLA particles are shown in Figs. 4 and 5. It is observed from SEM image that the BLA consists of different particles in various sizes. Figure 4(b) shows peaks of silicon (Si), aluminium (Al), carbon (C), oxygen (O), calcium (Ca), magnesium (Mg), potassium (K) and iron (Fe). From the synthesized BLA, further oxides combination revealed that elements, silicon dioxide (SiO2), alumina (Al2O3), carbon (C), calcium oxide (CaO), potassium oxide (K2O), ferric oxide (Fe2O3), and magnesium oxide (MgO) were detectable in the BLA particles. Figure 5 clearly indicates that the peaks of the major constituent belong to SiO2 as depicted in Table 2. It is confirmed from EDAX profile that silicon (Si) is the major constituent and oxygen (O) was also present in the BLA particles. The presence of silicon (Si) and oxygen (O) confirms that SiO2 is detectable in BLA particles as a major constituent [36].

Fig. 4 SEM image of synthesized BLA (a) and corresponding EDAX profile (b)

Fig. 5 XRD pattern of synthesized BLA particles

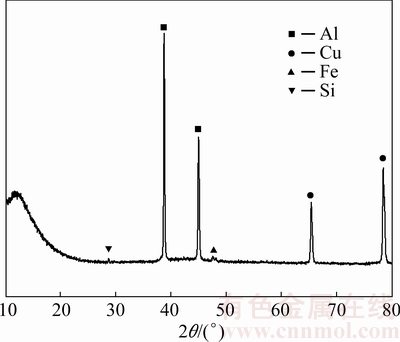

3.2 X-ray diffraction analysis of Al-4.5Cu-BLA in AMMCs

The XRD patterns of the fabricated composites are shown in Figs. 6-9. The diffraction peaks of SiO2 which is the major constituent in BLA particles are clearly observed and it confirms with EDAX profiles of the particulates in the fabricated composites. For most of the composite materials, the intensity of SiO2 peaks increases as BLA content increases in AMMCs. It is clear from Figs. 6-9 that the aluminium peaks in the composites are somewhat shifted to higher 2θ in comparison to Al-4.5%Cu alloy. The shifting of aluminium occurs due to the presence of BLA particles in the composite materials. Peaks of any other elements like alumina (Al2O3), ferric oxide (Fe2O3), potassium oxide (K2O) and magnesium oxide (MgO) along with SiO2 and aluminium were also detectable, but the peaks of the major constituent belong to SiO2 immediately after aluminium. This might be the integrity of BLA particles preserved during the formation of the composite. ALANEME and ADEWUYI [37] fabricated Al-Mg-Si/ Al2O3/BLA hybrid composite by stir casting method and observed the decomposition of BLA into Al2O3 and Si. It is noticed the presence of primary silicon single crystals in the vicinity of BLA. The BLA particles behave thermodynamically stable under the casting conditions employed in the present research work. BLA particles neither decompose nor interact with aluminium to form any sort of intermetallic compounds. This confirms that the interface between the aluminium matrix and BLA particles tends to be clean; if not then the reaction products usually accumulate at the interface and inhibit load transfer mechanism to operate during tensile loading [54]. It was also observed from earlier research work that when the molten composite was poured into a mold, within a shorter time after the complete incorporation of BLA particles which is the holding time. The time between incorporation of BLA particles into molten alloy and pouring of the molten composite into the mold is not sufficiently long enough to cause interfacial reactions between reinforcement and matrix material. It was also observed that interfacial reaction occurs only if the casting temperature exceeds 750 °C [55].

Fig. 6 XRD pattern of Al-4.5Cu matrix alloy

Fig. 7 XRD pattern of Al-4.5Cu-2BLA of aluminium composite

Fig. 8 XRD pattern of Al-4.5Cu-4BLA of aluminium composite

Fig. 9 XRD pattern of Al-4.5Cu-6BLA of aluminium composite

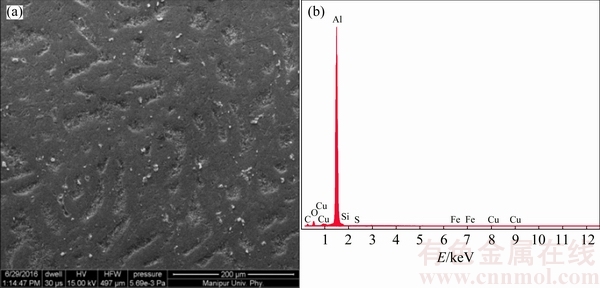

3.3 Microstructure analysis of Al-4.5Cu-BLA in AMMCs

The OM micrograph and SEM micrograph with EDAX profiles of the Al-4.5%Cu alloy and reinforce- ment with 2%, 4% and 6% BLA particles of composites are shown in Figs. 10-14. It was observed from Fig. 10(a) that typical dendritic structure was induced by rapid solidification. The cooling rate is very high and is known as supercooling, which forms the dendritic structure. The dendritic structure is characterized with elongated primary α(Al) dendritic arms which have high aspect ratios. Figure 11 shows the SEM micrograph of matrix alloy with EDAX analysis, the white phase in SEM micrograph is Al2Cu intermetallic phase. The alloying element of Al-4.5%Cu alloy, such as Cu is present at a level which is higher than their solubility limit. As a result, the intermetallic phase Cu is formed around the dendrites during stir casting. Figures 12-14 show the considerable amount of gas holes which were observed due to the sticking of environmental gasses and suction of air bubbles into the melt during stir casting. The observed porosity might be due to entrapped gasses in the molten metal as shown in Fig. 15. And it is also observed that longer stirring time might increase the number of air bubbles entrapped into molten metal as the BLA particles are prone to associate with these bubbles [56]. The porosity level in the fabricated composite is lower than 4% as depicted in Table 3, which is the maximum porosity level which might be acceptable in cast AMMCs [57]. The acceptable porosity demonstrates that the casting is of good quality and is a good indicator of the reliability of the stir casting process utilized for the production of the composites [58].

Fig. 10 Optical microphotographs of as-cast aluminium composites with various mass fractions of BLA

Fig. 11 SEM image (a) and EDAX profile (b) of Al-4.5Cu alloy

Fig. 12 SEM image (a) and EDAX profile (b) of Al-4.5Cu-2BLA composite

Fig. 13 SEM image (a) and EDAX profile (b) of Al-4.5Cu-4BLA composite

Fig. 14 SEM image (a) and EDAX profile (b) of Al-4.5Cu-6BLA composite

The dendritic structure is not present in the micrographs of the AMMCs and grain structure is formed in the composites as shown in Figs. 10(b)-(d) due to the presence of BLA particles, which alters the dendritic structure of the aluminium matrix. The solidification pattern of the composite is influenced by the presence of BLA particles. It is confirmed from the micrographs (Figs. 10(b)-(d)) that the BLA particles act as effective grain refiners. The matrix grain size decreases with the increase in a number of reinforcement particles and is confirmed by the average grain size measurement conducted by linear intercept method which is shown in Table 5. The grain refinement may take place due to BLA particles which act as grain nucleation sites and aluminium grains solidifies on grain refiner. The constitution under cooling zone in front of the BLA particles may cause it to act as a grain nucleation site. Formation of interfacial nucleation sites is increased in composite with an increased mass fraction of BLA particles. The spreading of BLA particles in the aluminium matrix restricts the growth of α(Al) grains during solidification. The higher the content of BLA particles, the more the grain nucleation sites are created as well as the more the resistance is offered to the freely growing α(Al) grains, therefore, the grains are further refined [59].

The distribution of reinforcement particles in the composite is significantly influenced by the production method. Figures 10(b)-(d) reveal that the distribution of BLA particles in composites is nearly homogeneous and the same homogeneous distribution of reinforcement particles is desirable to achieve good mechanical and tribological properties. The homogeneous distribution of reinforcement particles in the composite is influenced by distribution in the semi-solid melt and as a result of mixing, distribution in the semi-solid melt after mixing and during pouring, and redistribution as a result of solidification. The uniform distribution of BLA particles in composite helps to achieve very low agglomeration, segregation of particles and porosity. The vortex generated in the stirring process breaks solid dendrites due to higher friction between particles and Al matrix alloy, which further induces a uniform distribution of particles. However, air bubbles and all the other impurities on the surface of the melt are also sucked into the liquid. The pure argon gas is recommended for degassing [60]. Degassing liquid aluminium alloy is a usual step in the casting procedure. For the present investigation, pure argon gas was used as degassing purpose and formed a protective shroud on the melt surface to reduce the air entrapped into the melt.

The optical micrographs as shown in Figs. 10(b)-(d) and SEM micrographs shown in Figs. 12-14 confirm that the stirring was adequate to disperse the BLA particles throughout the aluminium matrix. With stir casting method it might achieve a homogeneous distribution of reinforcement particles. After the reinforcement mixing and during pouring there is a slight effect of a change in the distribution of particles in composite due to shorter holding time and rapid transfer of melt from the crucible to the mould. But the solidification pattern dictates the final distribution of BLA particles within the matrix. The density gradient between the aluminium matrix and the BLA particles is a key factor during solidification. The BLA particles have lower density compared with aluminium matrix, the particles will float or otherwise it will sink. Therefore, retaining the suspension of BLA particles in the composite melt for a longer duration is essential to homogeneously disperse the particles. Stir casting method offers another value-added advantage to obtain homogeneous distribution.

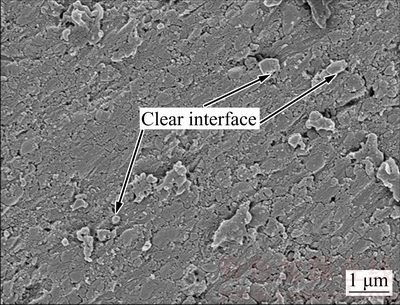

The BLA particles were added to the semi-solid matrix alloy. In this method due to the addition of the reinforcement particles into composite at the semi-solid state of the matrix, the movement of reinforcement particles within the semi-solid melt subsequent to mechanical stirring is minimized. The high viscosity of the semi-solid melt restricts the motion of particles and inhibits particle settling as well as floating [55,61]. During stirring, the particles mix with the semi-solid melt. The wetting of particles by the semi-solid melts was done by adding magnesium in ingot form at 0.1% in mass fraction. The wetting action also resists the free movement of BLA particles sequentially incorporated in the present investigation. The EDAX profiles of composite materials are shown in Figs. 12(b)-14(b). The peaks of aluminium (Al), silicon (Si), oxygen (O), carbon (C), iron (Fe) and traces of silver (Ag) were observed in Figs. 12(b)-14(b). The presence of these elements confirms the presence of silicon dioxide (SiO2), alumina (Al2O3) and ferric oxide (Fe2O3) in the composites. It was noted that SiO2, Al2O3 and Fe2O3 observed in the EDAX (Figs. 12(b)-14(b)) and XRD (Figs. 6-9) profiles are primary constituents found in BLA. From above result and micrograph of Al-BLA composite, as shown in Fig. 15, it is confirmed that the reinforcing particles are dispersed in the aluminium matrix. The SEM micrograph of Al-BLA composite at higher magnification is shown in Fig. 16. The clear interface between the aluminium matrix and the BLA particle is revealed and, it confirmed that the BLA particles were well bonded with the aluminium matrix.

Fig. 15 SEM image of Al-4.5Cu-6BLA composite showing BLA particles dispersibility

Fig. 16 SEM image of Al-4.5Cu-6BLA composite showing clear interface

3.4 Density and porosity

Table 3 shows the results of density and porosity in the fabricated composites with various contents in BLA particles. Figure 17 shows the variation in measured density and porosity of the composite material. The density of the composites was minimized with an increase in the mass fraction of BLA reinforcement. For the composite consisting of 2%, 4% and 6% of BLA particles, it was observed that there were reductions in density at 1.677%, 3.25% and 4.895% in comparison with Al-4.5%Cu alloy as shown in Table 4.

Table 3 Density and porosity of aluminium composites

Fig. 17 Variations in density and porosity at various mass fractions of BLA particles in aluminium composites

Table 4 Decrement percentage of density with addition of BLA in composites in comparison with Al-4.5%Cu alloy

The reduction of densities in the composites was due to the presence of low density BLA particles. The theoretical densities [50] are obtained from the rule of the mixture using Eq. (2). The theoretical density values of the composite decreased and experimental density also decreased linearly, the experimental density values are lower than those of the theoretical densities. The density measurements showed that the composites contained some porosity; the porosity was measured with Eq. (3) as known values of theoretical and experimental densities. It was observed from theoretical and experimental densities, the porosity of aluminium matrix and composites slightly increased with increase in BLA reinforcement as shown in Fig. 17.

The maximum porosity obtained is 2.512% at 6% BLA in the composite as shown in Fig. 17. The porosity level in the fabricated composite is lower than 4% which is the maximum porosity level and might be acceptable in cast AMMCs [62]. The low porosity level observed is a good indicator of the reliability of utilizing the stir casting method for the production of composites. ALANEME et al [43] and ALANEME and ALUKO [57] have reported that with stir casting method that porosity levels were lower than 4%, which were referred to as an acceptable level of porosity in cast composites. This indicates that in spite of higher porosity level, in the present research work the porosity level is up to 2.52%, which is considered as an acceptable and suitable for preparing the Al-BLA composite. As expected that the density of the composites decreased with increase in the mass fraction of BLA in comparison with Al-4.5%Cu alloy.

It seems that the obtained results depending on increasing mass fraction of BLA in the composite. The light mass AMMCs may be produced at significantly reduced cost. It also agreed with ALANEME et al [36] that the significantly decreased density was observed with increase in mass fraction of BLA. ALANEME et al [37] also noticed that with increasing mass fraction of BLA in composite, the density decreased and porosity increased. Similar to other agro wastage RHA which is a major constituent of SiO2 in compositions, as reinforcements, ALANEME and ADEWALE [63] used and studied the presence of RHA particles in the composites and observed that the density decreased and porosity increased slightly. And also APPARAO and BIRRU [64] studied the quality characteristics and significance density of aluminium based alloy.

3.5 Hardness measurement

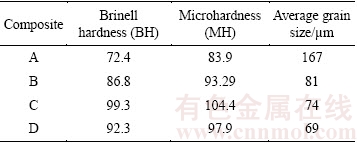

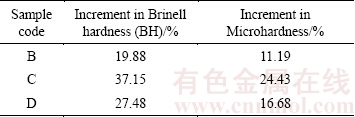

The hardness values of Al-4.5%Cu alloy and reinforced with 2%, 4% and 6% of BLA in composites are shown in Table 5. The Brinell hardness and microhardness increased with increase in BLA content in composite in comparison with Al-4.5%Cu alloy, as shown in Fig. 18.

The Brinell hardness values increased by 19.88%, 37.15 % and 27.48 % for composites containing 2%, 4% and 6% of BLA in composite respectively in comparison with Al-4.5%Cu alloy, as shown in Table 6. It was also observed that the highest value of Brinell hardness (BH 99.3) for the composite containing 4% BLA is confirmed in Fig. 18 and it is higher than 37.15% in comparison with the hardness value of Al-4.5%Cu alloy. And furthermore, it was observed that microhardness values increased by 11.19%, 24.43% and 16.68% for composites containing 2%, 4% and 6% of BLA in composites respectively in comparison with Al-4.5%Cu alloy as shown in Table 6. It was observed the highest value of microhardness (MH 104.4) for the composite containing 4% BLA confirms from Fig. 18 and it is higher than 24.43% in comparison with that of Al-4.5%Cu alloy.

Table 5 Hardness values and average grain size of aluminium composites

Fig. 18 Brinell hardness and microhardness of composites with different contents of BLA

Table 6 Increment percentage of hardness value with addition of BLA in composites in comparison with Al-4.5%Cu alloy

An increment in the hardness of composites indicates that the particles existing in the matrix have improved the overall hardness of the composite because the matrix is a soft material and the reinforcement particles hard and contribute positively to the hardness of the composites. The hardness of the MMCs increased or decreased linearly due to the increasing ceramic phase of the matrix alloy with the mass fraction of reinforcement particles [65]. Similar observations are reported by SARAVANAN and KUMAR [66] who fabricated AlSi10Mg-RHA composite by stir casting route and reported that the hardness increased with increase in mass fraction of RHA. USMAN et al [67] reported that the hardness increased initially with an increase in bagasse ash content and with further increased bagasse ash the hardness decreased. ALANEME et al [68] also observed that the hardness increased with increase in mass fraction of GSA and silicon carbide in composite compared with Al-Mg-Si alloy. The RHA, bagasse ash and GSA are the agro wastages and SiO2 is the major constituent. The increment in the hardness of the composites which obtained a complementary result with cost advantage agro waste BLA using in composites as reinforcement and to produce the appraisable performance with economical composite materials.

From the optical micrographic examination shown in Table 5, it was observed that the average grain size was minimized with increase of BLA content in composites. The grain refinement might have taken place due to BLA particles acting as grain nucleation sites. The grain refinement promotes to achieve the enhancement mechanical and tribological properties of the composite materials. The hardness increased with decrease in the average grain size of aluminium composites as shown in Figs. 19 and 20. It is also confirmed according to the Hall-Petch relation that the hardness increased with a decrease in grain size [69].

Fig. 19 Brinell hardness and average grain size of aluminium composites

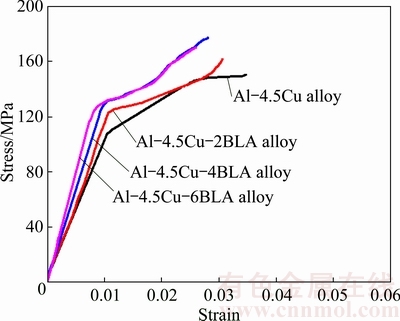

3.6 Tensile behaviour of composite material

From the present investigation, the ultimate tensile strength, yield strength, elongation and specific strength of composites are depicted in Table 7. The ultimate tensile and yield strength of composite with different BLA contents in the composites were observed that the tensile and yield strength increased with increase in BLA content in the composites as shown in Fig. 21. The ultimate tensile strengths were 7.46%, 17.7% and 12.9%, and yield strengths were 6.61%, 11.67% and 9.8% increased respectively with an increment of reinforcement at 2%, 4% and 6% of BLA content in composites and compared with Al-4.5%Cu alloy as shown in Table 8. The increase in the strengthening capacity of composite expected from the tensile load is effectively transferred from the matrix to the BLA particles. From the results, it is clear that the BLA particles strengthen the AMMCs with respect to mass ratio compared with Al-4.5%Cu alloy. ALANEME and ADEWALE [63] developed Al-Mg-Si/RHA/SiC hybrid composite by stir casting method and observed that the tensile strength increased with the addition of RHA along with SiC particles in comparison with Al-Mg-Si alloy. ALANEME et al [68] also reported that the tensile and specific strength increased with incorporation of GSA along with SiC particles in Al-Mg-Si/GSA/SiC hybrid composite in comparison with Al-Mg-Si alloy.

Fig. 20 Microhardness and average grain size of aluminium composites

Table 7 Tensile behaviour of aluminium composites

Several theories and mechanisms have been suggested to explain the strengthening of MMCs. However, the strength of the composites does not depend on a unique mechanism but several mechanisms may act simultaneously. It was observed that the hard ceramic particles used as reinforcements in metal matrix composite might improve strength due to the synergy of direct and indirect strengthening mechanisms [70]. CHAWLA and SHEN [71] have reported that direct strengthening arises in the composites as a result of the transfer of load from the matrix to hard and stiffer particulates through the matrix particulate interface; this may result in increased resistance to plastic deformation and a higher work hardening capacity in MMCs [72]. Indirect strengthening may also occur due to high thermal mismatch arising from uneven cooling between the matrix phase materials which have a higher coefficient of thermal expansion and ceramic phase reinforcement material with a lower coefficient of thermal expansion [43,73].

Fig. 21 Ultimate tensile strength and yield strength of aluminium composites

It is well known that when the motion of dislocations is hindered or delayed, the strengthening takes place. Indirect strengthening occurs due to high thermal mismatch arising from uneven cooling between the metallic matrix and ceramic particles. The coefficient of thermal expansion between aluminium matrix and BLA particles is different, the coefficient of thermal expansion of aluminium alloy is higher than the embedded ceramic particles [74]. The differences in coefficient of thermal expansion set up strain fields around BLA particles during solidification. These strain fields hinder the motion of dislocations during tensile load and the higher applied load may require to pass the dislocations around the strain fields. As discussed earlier the BLA particles refine the grains (see Table 5) of the matrix alloy. According to the Hall-Patch relationship [69,75], the average grain size is inversely proportional to tensile strength. As the grains are refined, the area resists the tensile or external force and the number of boundaries increases. The motion of dislocation is retarded due to frequent change in direction of dislocations at grain boundaries. Higher refine in grain size improves the grain boundaries (appraisable bonding) between BLA particles and matrix material, which might delay the detachment of BLA particles from the matrix material while applying the tensile load. The applied tensile load is effectively transferred to the BLA particles, due to improving the indirect strengthening with thermal mismatch results. The scenario where the particles are not sufficiently strong to induce direct strengthening for load transfer from matrix alloy to reinforcement particles but the indirect strengthening might lead to induce some strength improvements of the monolithic alloy.

In the present investigation, the tensile strength was observed with stress-strain curves as shown in Fig. 22, at 6% BLA in the composite decreased when compared with 4% of BLA composites. The reduction of strength at 6% BLA might be due to direct strengthening capacity of BLA which contains predominantly silicon dioxide. The elastic modulus of silicon dioxide is about the same of aluminium (elastic modulus of aluminium is 69000 MPa and silicon dioxide that of is 60000-72000 MPa [43,76] and it has a low coefficient of thermal expansion and low density, and it is lower than aluminium alloys [77]. Other causes for UTS and specific strength decrease at 6% BLA in composite might be due to increase in ash particles in the matrix which produces more sites for crack initiation and hence lowers the load bearing capacity of the composites thus reducing the strength. Besides, if the number of contacts between silicon dioxide (SiO2) and alumina (Al2O3) particulates increases, the particles are no longer isolated by the ductile aluminium alloy matrix. Therefore, cracks may not get arrested by the ductile matrix and would propagate easily between the silicon dioxide and alumina particulates. Furthermore, the elastic stresses generated due to the thermal mismatch putting the particles into compression and the matrix into tension. These residual stresses affect the material properties in and around the crack tips and the fracture toughness values would be altered. Consequently, these residual stresses might probably contribute to the brittle nature of the composites [78].

Fig. 22 Stress-strain curves of Al-4.5Cu alloy and aluminium composites with various contents of BLA (yield strength with 0.2% offset)

From the XRD characterisation, as shown in Figs. 8 and 9, it was observed that SiO2 which is a major constituent might reduce the coefficient of thermal expansion in the present investigated composite materials. In the present work, the strengthening effect may mainly occur through an increased dislocation density arising from a thermal mismatch between the matrix and reinforcements particles. Strength of the material is attributed to its typical crystal structure, i.e., effective barriers to slip are provided by the fine structure or the increase in dislocation density. The dislocations are generated in the alloy matrix upon cooling or quenching from the processing or solutionizing temperature, due to a mismatch of the coefficient of thermal expansion (CTE) between the matrix and BLA particles [79]. The higher dislocation density increases the strength of the alloy [80]. The amount of dislocation generation is affected by CTE, particle size, particle content and matrix strength [81]. From the experimental results, appraisable strength to mass ratios may be achieved using economical agro waste BLA as a complementing reinforcement for fabrication of cost-effective aluminium metal matrix composites might be achieved.

It is observed that the specific strength of composites is slightly increased with increase in BLA content compared with Al-4.5%Cu alloy, as shown in Fig. 23. The specific strength of fabricated composite increased by 10.44%, 21.94% and 19.04% with 2%, 4% and 6% BLA respectively in comparison with Al-4.5%Cu alloy as presented in Table 8. It might be recommended to the industries to produce high specific strength composites with cost-effective. Figure 24 shows the ductility (elongation) at 2%, 4% and 6% BLA in composites. The ductility is dependent on factors such as fabrication method, particles adhesion to matrix and particle cohesion [82].

Fig. 23 Specific strength of aluminium composites

Table 8 Increment of ultimate tensile strength, yield strength and specific strength with addition of BLA in composites in comparison with Al-4.5%Cu alloy

The addition of reinforcement content decreases the elongation fracture of the composites. The fracture of reinforcement particles and localization of matrix deformation are considered as the main factor to be responsible for the decrease of the ductility of composites [83]. The mass fraction of reinforcement is increased conversely, the geometric slip distance of the dislocation decreased, the microcracks occurred at relatively low elongation and the elongation fracture decreased consequently [84]. And also, the ductility decreased with increase in BLA content in the composites in comparison to the Al-4.5%Cu alloy due to increment in hardness and tensile strength. Similar results are stated by SUDARSHAN and SURAPPA [85] for various contents of fly ash reinforcement.

Fig. 24 Elongation of aluminium composites

The SEM micrographs of the fracture surfaces of tensile specimens of Al-4.5%Cu alloy and composites with 2%, 4% and 6% BLA particles are shown in Fig. 25. The effect of BLA content in the composite on the fracture morphology of the tensile tested samples was examined. And it is observed that uniformly distributed and bigger size voids are presented in the fracture morphology as shown in Fig. 25(a). It may be that the fracture morphology of Al-4.5%Cu alloy revealed typical ductile fracture characteristic, consisting of numerous dimples over the entire surface.

Fig. 25 Tensile fracture morphologies of Al-4.5Cu-BLA AMMCs with different contents of BLA

The fracture morphologies of composite shown in Figs. 25(b)-(d) indicate that the composite specimen has different contents of BLA. In the composites, the size of voids is decreased with increase in BLA content in the composites. The grain refinement in the AMMCs causes the voids in size to shrink. The dimples might result in the void nucleation and subsequent coalescence by strong shear deformation, and fracture process on the shear plane. While the fracture and decohesion of the BLA particles may be explained by work hardening and the fragmentation of the ceramic phase caused by high stress concentration. The presence of hard reinforcement particles in the soft matrix causes a plastic flow localisation at the particle-matrix interface [86]. Also, the stress concentration at the matrix particles interfaces produces high levels of damages, which included particle fracture [87]. The ductile shear bands on the fracture surface indicate that some amount of ductility is retained by BLA particles. BLA particles remain intact in several places for evidence as shown in Figs. 25(b) and (c) for the existence of good interfacial bonding between the aluminium matrix and BLA particles. The fracture of the composites is macroscopically brittle and microscopically ductile. The furthermore increased BLA content in composite might create more sites for crack initiation and would lower the load bearing capacity of the composite, as shown in Fig. 25(d).

The reason for the brittle fracture nature in the composites may be the presence of weak intermetallic phases. The existence of this detrimental intermetallic phase activates a different fracture mechanism, the material failing by the nucleation growth and coalescence of voids, and these subsequently grow by plastic straining and as result, final fracture occurs suddenly by localized necking of the intervoid matrix. From the earlier researches [88,89], it was demonstrated that generally three modes of failures typically occur in metal matrix composites. Firstly, cracking of the reinforcing particles, secondly, particles debonding at the particle-matrix interface which might result in the nucleation of voids and thirdly the growth and coalescence of voids in the matrix. The particular failure modes were observed and the process of evolution of the failure depended broadly on processing, matrix microstructure and reinforcement morphology and distribution in addition to the stress state.

4 Conclusions

1) The BLA particles were synthesized successfully under 75 μm, it was found that SiO2 was a major constituent in BLA with major peaks of Si and O along with other trace elements in BLA particles which were detected by particle examination with EDAX and XRD.

2) The SEM micrographs revealed good interfacial bond between matrix and BLA particles. The BLA particles were thermodynamically stable at the high temperature and may not be interfacial reaction between Al-4.5%Cu alloy and BLA particles.

3) The density of the fabricated composites reduced with an increase in BLA content in comparison with Al-4.5%Cu alloy. The maximum porosity observed in the prepared composite is 2.512% with 6% BLA. The porosity level in prepared composite is lower than 4% which was the maximum porosity level and might be acceptable in Al-4.5Cu-BLA composites.

4) The hardness of the composites increases with increase in BLA content compared with the matrix. The maximum hardness attained at 4% BLA in the fabricated composites.

5) In the fabricated composites the tensile and yield strength of the composites with 2%, 4% and 6% BLA increased in comparison with the matrix. Similarly, the highest tensile and yield strengths were observed at 4% BLA particle. Conversely, the ductility of composite material in terms of elongation decreased in comparison with the matrix. The fracture mode of the composites revealed that the macroscopically brittle and microscopically ductile in nature was observed.

Acknowledgments

Authors would like to acknowledge the National Institute of Technology, Manipur, Imphal-India for financial support to carry out the experiment by Mr. B. Praveen Kumar, full time research scholar, enrolment number (15PME004), under the guidance of Dr. Anil Kumar Birru, assistant professor and head of Department of Mechanical Engineering, NIT MANIPUR.

References

[1] SANJAY K M. Composites manufacturing materials, product, and process engineering [M]. CRC press: Taylor & Francis group, 2001.

[2] HAGHSHENAS M. Metal–matrix composites [J]. Reference Module in Materials Science and Materials Engineering, 2017, 10.1016/B978-0-12-803581-8.03950-3.

[3] ASHOK KUMAR B, MURUGAN N, DINAHARAN I. Dry sliding wear behavior of stir cast AA6061-T6/AlNp composite [J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 2785-2795.

[4] KHOSRAVI H, BAKHSHI H, SALAHINEJAD E. Effects of compocasting process parameters on microstructural characteristics and tensile properties of A356-SiCp composites [J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 2482-2488.

[5] DONG Pu-yun, ZHAO Hai-dong, CHEN Fei-fan, LI Jun-wen. Microstructures and properties of A356-10%SiC particle composite castings at different solidification pressures [J]. Transactions of Nonferrous Metals Society of China, 2013, 23: 2222-2228.

[6] HU Yuan, CHEN Yi-qing, LI Li, HU Huan-dong, ZHU Zi-ang. Microstructure and properties of Al/Cu bimetal in liquid-solid compound casting process [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 1555-1563.

[7] MOKHNACHE El Oualid, WANG Gui-song, GENG Lin. Wearing resistance of in-situ Al-based composites with different SiO2/C/Al molar ratios fabricated by reaction hot pressing [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 917-923.

[8] RADHIKA N, RAGHU R. Development of functionally graded aluminium composites using centrifugal casting and influence of reinforcements on mechanical and wear properties [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 905-916.

[9] PRAMANIK A. Effects of reinforcement on wear resistance of aluminum matrix composites [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 348-358.

[10] LI Hai-peng, FAN Jia-wei, KANG Jian-li, ZHAO Nai-qin, WANG Xue-xia, LI Bao-e. In-situ homogeneous synthesis of carbon nanotubes on aluminum matrix and properties of their composites [J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 2331-2336.

[11] IIZUKA Tateoki, OUYANG Qiu-bao. Microstructures and mechanical properties of MgAl2O4 particle-reinforced AC4C aluminum composites [J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 2337-2345.

[12] ABBASIPOUR B, NIROUMAND B, VAGHEFI S M M. Compocasting of A356-CNT composite [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 1561-1566.

[13] ERTURUN V, KARAMIS M B. Effects of reciprocating extrusion process on mechanical properties of AA 6061/SiC composites [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 328-338.

[14] HU Cheng-jin, YAN Hong-ge, CHEN Ji-hua, SU Bin. Microstructures and mechanical properties of 2024Al/Gr/SiC hybrid composites fabricated by vacuum hot pressing [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 1259-1268.

[15] VASANTHA KUMAR C A, RAJADURAI J S. Influence of rutile (TiO2) content on wear and microhardness characteristics of aluminium-based hybrid composites synthesized by powder metallurgy [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 63-73.

[16] DEVARAJU A, KUMAR A, KOTIVEERACHARI B. Influence of addition of Grp/Al2O3p with SiCp on wear properties of aluminum alloy 6061-T6 hybrid composites via friction stir processing [J]. Transactions of Nonferrous Metals Society of China, 2013, 23: 1275-1280.

[17] LIJAY K J, SELVAM J D R, DINAHARAN I, VIJAY S J. Microstructure and mechanical properties characterization of AA6061/TiC aluminum matrix composites synthesized by in situ reaction of silicon carbide and potassium fluotitanate [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 1791-1800.

[18] ASHOK KUMAR B, MURUGAN N. Metallurgical and mechanical characterization of stir cast AA6061-T6-AlNp composite [J]. Materials and Design, 2012, 40: 52-58.

[19] TAN Xiao-fen, ZENG Fan-hao, WANG Shu-qiu, ZHOU Fei, XIONG Xiang. Effects of heat treatment on phase contents and mechanical properties of infiltrated B4C/2024Al composites [J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 2359-2365.

[20] JIANG Xiao-song, WANG Nai-juan, ZHU De-gui. Friction and wear properties of in-situ synthesized Al2O3 reinforced aluminum composites [J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 2352-2358.

[21] ZHONG Long-hua, ZHAO Yu-tao, ZHANG Song-li, CHEN Gang, CHEN Shuai, LIU Yong-hong. Microstructure and mechanical properties of in situ TiB2/7055 composites synthesized by direct magnetochemistry melt reaction [J]. Transactions of Nonferrous Metals Society of China, 2013, 23: 2502-2508.

[22] ALIDOKHT S A, ABDOLLAH-ZADEH A, SOLEYMANI S, ASSADI H. Microstructure and tribological performance of an aluminium alloy based hybrid composite produced by friction stir processing [J]. Materials and Design, 2011, 32: 2727-2733.

[23] PUGACHEVA N B, MICHUROV N S, BYKOVA T M. Structure and properties of the Al/SiC composite material [J]. The Physics of Metals and Metallography, 2016, 117: 634-640.

[24] MAHDAVI S, AKHLAGHI F. Effect of the graphite content on the tribological behavior of Al/Gr and Al/30SiC/Gr composites processed by in situ powder metallurgy (IPM) method [J]. Tribology Letters, 2011, 44: 1-12.

[25] NATH D, BHATT R T, BISWAS S K, ROHATGI P K. Mechanical properties of Al-mica particulate composite material [J]. Journal of Engineering Materials Technology, 1980, 102: 78-84.

[26] MARIN E, LEKKA M, ANDREATTA F, FEDRIZZI L, ITSKOS G, MOUTSATSOU A, KOUKOUZAS N, KOULOUMBI N. Electrochemical study of aluminum-fly ash composites obtained by powder metallurgy [J]. Materials Characterization, 2012, 69: 16-30.

[27] PRAKASH K S, KANAGARAJ A, GOPAL P M. Dry sliding wear characterization of Al 6061/rock dust composite [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 3893-3903.

[28] AIGBODION V S, HASSAN S B, DAUDA E T, MOHAMMED R A. Experimental study of ageing behaviour of Al-Cu-Mg/bagasse ash particulate composites [J]. Tribology in Industry, 2011, 33: 28-35.

[29] ALLWYN KINGSLY G J, MOHAMED S N, DINAHARAN I J, DAVID R S J. Production and characterization of rich husk ash particulate reinforced AA6061 aluminum alloy composites by compocasting [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 683-691

[30] ANKESH K, KANHAIYA K, SUMAN S, SIVA S R R. Study of physical, mechanical and machinability properties of aluminium metal matrix composite reinforced with coconut shell ash particulates [J]. Imperial Journal of Interdisciplinary Research, 2016, 2: 151-157.

[31] OLADELE I O, OKORO A M. The effect of palm kernel shell ash on the mechanical properties of as-cast aluminium alloy matrix composites [J]. Leonardo Journal of Sciences, 2016, (28): 15-30.

[32] ALANEME K K, EZE H I, BODUNRIN M O. Corrosion behaviour of groundnut shell ash and silicon carbide hybrid reinforced Al-Mg-Si alloy matrix composites in 3.5% NaCl and 0.3M H2SO4 solutions [J]. Leonardo Electronic Journal of Practices and Technologies, 2015, 26: 129-146.

[33] COCINA E V, MORALES E V, SANTOS S F, SAVASTANO H Jr, MOISES F. Pozzolanic behavior of bamboo leaf ash: Characterization and determination of the kinetic parameters [J]. Cement & Concrete Composites, 2011, 33: 68-73.

[34] BAHRAMI A, SOLTANI N, PECH-CANUL M I, GUTIERREZ C A. Development of metal-matrix composites from industrial/agricultural waste materials and their derivatives [J]. Critical Reviews in Environmental Science and Technology, 2015, 46: 143-208.

[35] ALANEME K K, OLUBAMBI P A, AFOLABI A S, BODURIN M O. Corrosion and tribological studies of bamboo leaf ash and alumina reinforced Al-Mg-Si alloy matrix hybrid composites in chloride medium [J]. International Journal of Electrochemical Science, 2014, 9: 5663-5674.

[36] ALANEME K K, ADEMILUA B O, BODUNRIN M O. Mechanical properties and corrosion behaviour of aluminium hybrid composites reinforced with silicon carbide and bamboo leaf ash [J]. Tribology in Industry, 2013, 35: 25-35.

[37] ALANEME K K, ADEWUYI E O. Mechanical behaviour of Al-Mg-Si matrix composites reinforced with alumina and bamboo leaf ash [J]. Metallurgy Material Engineering, 2013, 19: 177-187.

[38] LI Xiao-bing, ZU Guo-yin, WANG Ping. Microstructural development and its effects on mechanical properties of Al/Cu laminated composite [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 36-45.

[39] XIU Zi-yang, WANG Xu, HUSSAIN M, FENG Chao, JIANG Long-tao. Effect of heat treatment on microstructure and thermophysical properties of diamond/2024 Al composites [J]. Transactions of Nonferrous Metals Society of China, 2013, 23: 3584-3591.

[40] EZATPOUR H R, TORABI-PARIZI M, SAJJADI S A. Microstructure and mechanical properties of extruded Al/Al2O3 composites fabricated by stir-casting process [J]. Transactions of Nonferrous Metals Society of China, 2013, 23: 1262-1268.

[41] MOSES J J, DINAHARAN I, JOSEPH S S. Prediction of influence of process parameters on tensile strength of AA6061/TiC aluminum matrix composites produced using stir casting [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 1498-1511.

[42] ANTHYMIDIS K, DAVID K, AGRIANIDIS P, TRAKALI A. Production of Al metal matrix composites by the stir-casting method [J]. Key Engineering Materials, 2014, 592-593: 614-617.

[43] ALANEME K K, AKINTUNDE I B, OLUBAMBI P A, ADEWALE T M. Fabrication characteristics and mechanical behaviour of rice husk ash—Alumina reinforced Al-Mg-Si alloy matrix hybrid composites [J]. Journal of Materials Research and Technology, 2013, 2: 60-67.

[44] LI Yu, LI Qiu-lin, LI Dong, LIU Wei, SHU Guo-gang. Fabrication and characterization of stir casting AA6061-31%B4C composite [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 2304-2312.

[45] HAHSINS J, LOONAY L, HASHNI M S J. Metal matrix composites production by stir casting method [J]. Journal of Materials Processing Technology, 1999, 92-93: 1-7.

[46] GENG Lin, ZHANG Hong-wei, LI Hao-ze, GUAN Li-na, HUANG Lu-jun. Effects of Mg content on microstructure and mechanical properties of SiCp/Al-Mg composites fabricated by semi-solid stirring technique [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 1851-1855.

[47] CHOI S W, CHO H S, KUMAI S. Effect of the precipitation of secondary phases on the thermal diffusivity and thermal conductivity of Al-4.5Cu alloy [J]. Journal of Alloys and Compounds, 2016, 688: 897-902.

[48] PRABU S B, KARUNAMOORTHY L, KATHIRESAN S, MOHAN B. Influence of stirring speed and stirring time on distribution of particles in cast metal matrix composite [J]. Journal of Materials Processing Technology, 2006, 171: 268-273.

[49] GUPTA M, LAI M O, SOO C Y. Effect of type of processing on the microstructural features and mechanical properties of Al-Cu/SiC metal matrix composites [J]. Materials Science and Engineering A, 1996, 210: 114-122.

[50] HULYA K, NECIP U,  M L, HANI H. Comparative processing-structure-property studies of Al-Cu matrix composites reinforced with TiC particulates [J]. Composites: Part A, 2011, 42: 812-824.

M L, HANI H. Comparative processing-structure-property studies of Al-Cu matrix composites reinforced with TiC particulates [J]. Composites: Part A, 2011, 42: 812-824.

[51] ZHAI Wei-chen, ZHANG Zhao-hui, WANG Fu-chi, SHEN Xiang-bo, LEE Shu-kui, WANG Lu. Effect of Si content on microstructure and properties of Si/Al composites [J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 982-988.

[52] MAZAHERY A, SHABANI M O. Characterization of cast A356 alloy reinforced with nano SiC composites [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 275-280.

[53] BIRRU A K, KARUNAKAR D B. Effects of grain refinement and residual elements on hot tearing of A713 aluminium cast alloy [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 1783-1790.

[54] RAJAN T P D, PILLAI R M, PAI B C, SATYANARAYANA K G, ROHATGI P K. Fabrication and characterisation of Al-7Si- 0.35Mg/fly ash metal matrix composites processed by different stir casting routes [J]. Composites Science and Technology, 2007, 67: 3369-3377.

[55] LLOYD J. Particle reinforced aluminium and magnesium matrix composites [J]. International Materials Reviews, 1994, 39: 1-23.

[56] AMIRKHANLOU S, NIROUMAND B. Synthesis and characterization of 356-SiCp composites by stir casting and compocasting methods [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: s788-s793.

[57] ALANEME K K, ALUKO A O. Production and age-hardening behaviour of borax premixed SiC reinforced Al-Mg-Si alloy composites developed by double stir-casting technique [J]. The West Indian Journal of Engineering, 2012, 34: 80-85.

[58] ZHOU W, XU Z M. Casting of SiC reinforced metal matrix composites [J]. Journal of Materials Processing Technology, 1997, 63: 358-363.

[59] HAN Y, LIU X, BIAN X. In situ TiB2 particulate reinforced near eutectic Al-Si alloy composites [J]. Composites: Part A, 2002, 33: 439-444.

[60] PAI B C, PILLAI R M, SATYANARAYANA K G. Prospects for graphite aluminium composites in engineering industries [J]. Indian Journal of Engineering & Materials Sciences, 1994, 1: 279-283.

[61] AKHLAGHI F, LAJEVARDI A, MAGHANAKI H M. Effects of casting temperature on the microstructure and wear resistance of compocast A356/SiCp composites: A comparison between SS and SL routes [J]. Journal of Materials Processing Technology, 2004, 155-156: 1874-1880.

[62] KOK M. Production and mechanical properties of Al2O3 particle reinforced 2024 aluminum composites [J]. Journal of Materials Processing Technology, 2005, 161: 381-387.

[63] ALANEME K K, ADEWALE T M. Influence of rice husk ash – silicon carbide weight ratios on the mechanical behaviour of Al-Mg-Si alloy matrix hybrid composites [J]. Tribology in Industry, 2013, 35: 163-172.

[64] APPARAO K Ch, BIRRU A K. QFD-Taguchi based hybrid approach in die casting process optimization [J]. Transactions of Nonferrous Metals Society of China, 2017, 27: 2345-2356.

[65] RAJMOHAN T, PALANIKUMAR K, RANGANATHAN S. Evaluation of mechanical and wear properties of hybrid aluminium matrix composites [J]. Transactions of Nonferrous Metals Society of China, 2013, 23: 2509-2517.

[66] SARAVANAN S D, KUMAR M S. Mechanical behaviour of aluminium (AlSi10Mg)-RHA composite [J]. International Journal of Engineering and Technology, 2014, 5: 4834-4840.

[67] USMAN A M, RAJI A, WAZIRI N H, HASSAN M A. Production and characterisation of aluminium alloy-bagasse ash composites [J]. Journal of Mechanical and Civil Engineering, 2014, 11: 38-44.

[68] ALANEME K K, BODUNRIN M O, AWE A A. Microstructure, mechanical and fracture properties of groundnut shell ash and silicon carbide dispersion strengthened aluminium matrix composites [J]. Journal of King Saud University—Engineering Sciences, 2016, 10.1016/j.jksues.2016.01.001.

[69] SURYANARAYANA C, MUKHOPADHYAY D, PATANKAR S N, FROES F H. Grain size effects in nanocrystalline materials [J]. Journal of Materials Research, 1992, 7: 2114-2118.

[70] ALANEME K K, ALUKO A O. Fracture toughness (K1C) and tensile properties of as-cast and age-hardened aluminium (6063)-silicon carbide particulate composites [J]. Scientia Iranica, 2012, 19: 992-996.

[71] CHAWLA N, SHEN Y. Mechanical behaviour of particle reinforced metal matrix composites [J]. Advanced Engineering Material, 2001, 3: 357-370.

[72] MILAN M T, BOWEN P. Tensile and fracture toughness properties of SiCp reinforced Al alloys: Effects of particle size, particle volume fraction and matrix strength [J]. Journal of Materials Engineering and Performance, 2004, 13: 775-783.

[73] FEI W D, HU M, YAO C K. Thermal expansion and thermal mismatch stress relaxation behaviours of SiC whisker reinforced aluminum composite [J]. Materials Chemistry and Physics, 2002, 77: 882-888.

[74] OBERG E, JONES F, HORTON H, RYFFEL H, MCCAULEY C. Machinery’s Handbook [M]. 30th ed. New York: Industrial Press, 2016.

[75] MORRIS J W Jr. The influence of grain size on the mechanical properties of steel [J]. Lawrence Berkeley National Laboratory, 2001, https://escholarship.org/uc/item/88g8n6f8.

[76] COURTNEY T H. Mechanical behaviour of materials [M]. 2nd ed. Long Grove, Illions: Waveland Press, 2005.

[77] BADIH E K. Fundamental of semiconductor processing technologies [M]. US: Springer, 1995.

[78] HAMOUDA A M S, SULAIMAN S, VIJAYARAM T R, SAYUTI M, AHMAD M H M. Processing and characterisation of particulate reinforced aluminium silicon matrix composite [J]. Journal of Achievements in Materials and Manufacturing Engineering, 2007, 25: 11-16.

[79] FLOM Y, ARSENAULT R J. Deformation in Al-SiC composites due to thermal stresses [J]. Materials Science and Engineering, 1985, 75: 151-167.

[80] VOGELSANG M, ARSENAULT R J, FISHER R M. An in situHVEM study of dislocation generation at Al/SiC interfaces in metal matrix composites [J]. Metallurgical Transactions A, 1986, 17: 379-389.

[81] AIKIN R M. The mechanical properties of in-situ composites [J]. The Journal of the Minerals, Metals & Materials Society, 1997, 49: 35-39.

[82] ADEOSUN S O, AKPAN E I, GBENEBOR O P, BALOGUN S A. Ductility and hardness of chloride cleaned AA6011/SiCp composites [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 339-347.

[83] CHENG Su-ling, YANG Gen-cang, ZHU Man, WANG Jin-cheng, ZHOU Yao-he. Mechanical properties and fracture mechanisms of aluminum matrix composites reinforced by Al9(Co, Ni)2 intermetallics [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 572-576.

[84] SONG M, HUANG D W. Experimental and modeling of the coupled influences of variously sized particles on the tensile ductility of SiCp/Al metal matrix composites [J]. Metallurgical and Materials Transactions A, 2007, 38: 2127-2137.

[85] SUDARSHAN, SURAPPA M K. Synthesis of fly ash particle reinforced A356 Al composites and their characterization [J]. Materials Science and Engineering A, 2008, 480: 117-124.

[86] de SANCTIS A M, EVANGELISTA E, FORCELLESE A, WANG Y Z. Hot formability studies on 359/SiC/20p and their application in forging optimization [J]. Applied Composite Materials, 1996, 3: 179-198.

[87] HAO Shi-ming, XIE Jing-pei, WANG Ai-qin, WANG Wen-yan, LI Ji-wen, SUN Hao-liang. Hot deformation behaviors of 35%SiCp/2024Al metal matrix composites [J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 2468-2474.

[88] YIGEZU B S, MAHAPATRA M M, KUMAR J P. Influence of reinforcement type on microstructure, hardness, and tensile properties of an aluminum alloy metal matrix composite [J]. Journal of Minerals and Materials Characterization and Engineering, 2013, 1(4): 124-130.

[89] LI Y, RAMESH K T, CHIN E S C. Comparison of the plastic deformation and failure of A359/SiC and 6061-T6/Al2O3 metal matrix composites under dynamic tension [J]. Materials Science and Engineering A, 2004, 371: 359-370.

B. Praveen KUMAR, Anil Kumar BIRRU

Department of Mechanical Engineering, National Institute of Technology, Manipur 795004, India

摘 要:以从农业废物中分离出的竹叶灰(BLA)为增强剂,当竹叶灰(BLA)含量分别为2%、4% 和 6%时,以Al-4.5%Cu合金为基体,采用搅拌铸造方法制备复合材料。该复合材料由于基体和增强粒子之间的有效结合,而具有优越的性能。采用各种试验确定该复合材料的力学性能,如密度、孔隙度、硬度和抗拉强度。将所得结果与基体合金相进行比较。采用OM、SEM-EDAX 和 XRD分析方法对所选基体合金中增强粒子的分散性进行分析。结果表明,复合材料中BLA颗粒均匀分布于晶体内。此外,还观察到BLA颗粒与基体合金有良好的结合,且界面清晰。随着BLA颗粒质量分数的增加,复合材料的密度降低,而孔隙度增大。当复合材料中BLA颗粒含量达到4%时,材料的硬度和抗拉强度都增加,而当BLA含量进一步增加时,硬度和抗拉强度都会降低。

关键词:Al-4.5Cu 合金;搅拌铸造;复合材料;竹叶灰;密度;孔隙度

(Edited by Xiang-qun LI)

Corresponding author: Anil Kumar BIRRU; Tel: +91-8331866984; E-mail: anilbirru@gmail.com

DOI: 10.1016/S1003-6326(17)60284-X