基于SimHydraulics的水力凿岩机冲击系统动态仿真

李志国,李夕兵,王斌

(中南大学 资源与安全工程学院,湖南 长沙,410083)

摘要:以自行研发的后控式SYYG65型水力凿岩机冲击系统为研究对象,在Matlab中应用SimHydraulics工具箱,建立水力凿岩机冲击系统动态仿真模型,实现流体/机械的混合仿真。建模过程不考虑系统运行状态的转换,简单有效地实现了活塞和阀芯在水压力作用下的耦合计算。在泵供水流量为120 L/min,减压阀卸荷压力为16 MPa时,对系统进行仿真计算,获得了在此条件下冲击机构运动与活塞前后腔压力变化典型曲线,并与实测结果进行比较。同时,运用这一动态仿真模型对蓄能器参数进行优化计算。研究结果表明:在有效容积为0.24~0.27 L和充气压力为5.00~5.75 MPa的最优工作参数下,SYYG65型水力凿岩机冲击系统能量利用率有显著提高。该SimHydraulics仿真模型对水力凿岩机冲击系统参数设计和优化匹配研究是有效的。

关键词:SimHydraulics仿真;水力凿岩机;优化设计

中图分类号:TD431 文献标志码:A 文章编号:1672-7207(2011)12-3835-09

Dynamical simulation of impact system of water-powered percussive rock drill based on SimHydraulics

LI Zhi-guo, LI Xi-bing, WANG Bin

(School of Resources and Safety Engineering, Central South University, Changsha 410083, China)

Abstract: The dynamical simulation model of water-powered percussive rock drilling system was built by SimHydraulics toolbox of Matlab code, based on the self-researched SYYG65 rock drilling system. And then the fluid/mechanical hybrid simulation was realized. The simple and effective coupling calculation of piston and the valve core under the water pressure was carried out by avoiding the transition of the running state of the system. With the 120 L/min in pump water supply and 16 MPa in unloading pressure, the typical curve was drawn by simulation computation, which coincided with the measured data. Furthermore, the optimization calculation of the accumulator was carried out by the simulation model. The results show that the utilization of the impact system is increased significantly when the effective volume is 0.24-0.27 L and the inflation pressure is 5.00-5.75 MPa. SimHydraulics dynamical simulation on water-powered percussive rock drilling system is effective.

Key words: simulation based on SimHydraulics; water powered percussive rock drill; optimization

冲击凿岩机是矿山开采、隧道掘进的主要设备。根据活塞加速运动的动力源不同,冲击凿岩机分为气动、液压、电动、内燃等。目前普遍采用液压或气动(风压)冲击凿岩机,而随着岩体工程安全开掘和环境保护的要求越来越高及开掘作业节能、高效的需要,用高压水代替压缩空气或矿物油作为凿岩机工作介质,即水力凿岩机的研制越来越引起人们的广泛关注[1-3]。水力凿岩机是以纯水为传递能量介质的阀控液缸系统,其工作过程服从流体运动和机械运动规律,且受多种因素的影响与制约,运动规律十分复杂。传统的设计方法不仅研制周期长、费用高,而且所设计的产品性能有很大的随意性,难以达到性能最优的要求。随着计算机技术的飞速发展,用计算机对系统特性进行数字仿真与优化设计研究,具有成本低,迅速快捷的优点,能方便地分析各参数对系统特性的影响。对于水力凿岩机冲击机构运动仿真的研究,国际上尚无统一试验标准。参照以往液压冲击器运动仿真经验,常用的冲击器运动仿真方法有以下几种:准匀加速度 法[4-5],该方法校正计算相对较难,有时难以达到理想的计算精度;基于Matlab/Simulink的液压冲击器动态仿真法[6-7],该方法不但可以方便地分析各个参数对冲击器性能的影响,还可以优化设计参数,但需利用Simulink仿真环境下的Stateflow 实现系统状态转换;基于AMESim的新型数字控制液压冲击器仿真法[8],该方法计算过程有高位压力跳跃的现象产生,降低了仿真精度;基于功率键合图法的液压冲击器动态特性数字仿真研究法[9-11],功率键合图的突出优点是可对所研究的各种典型动态影响因素予以较全面的考虑和描述,与系统实际特征较为符合,可全面、准确地揭示系统的动态特性及其各部分的动态变化规律,然而其运算过程需借助其他应用软件进行状态方程简化与计算,如Matlab等平台;基于虚拟样机技术的方 法[12-13],该方法将实体设计软件CAXA创建好的样机几何模型转换和导入到Adams/View环境中,对样机几何模型添加约束、载荷,进行机构运动学和动力学特性仿真,该仿真分析方法仅进行了机构各构件运动学和动力学仿真,未能实现机构运动与液压传动融合。以上各仿真平台建模均使用单向信号流,不足以表达液压系统网络中的流体运动,其中压力会发生传递并且流动方向也会改变。而SimHydraulics是液压传动和控制系统的建模和仿真专业工具,扩展了Simulink的功能。使用这个工具可以建立通常所见的控制系统单向信号流框图,而模型中信号则是双向传递。并且可以将该部分模型同使用传统Simulink 模块建立的物理对象模型和其他Simulink工具箱建立的物理对象模型部分连接起来,可以建立起含有液压和机械元件的物理网络模型,用于跨专业领域系统的建模。本文作者基于SimHydraulics建立水力凿岩机流体/机械混合实物模型,对自行研制的SYYG65型水力凿岩机的性能、结构及活塞运动等参数进行了计算验证,并针对水力凿岩机高压蓄能器有效容积及充气压力开展了优化计算,得到了较为理想的匹配参数。

1 水力凿岩机的工作原理及特点

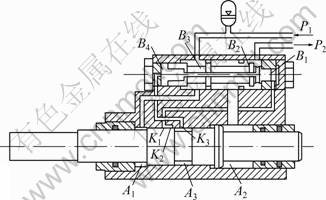

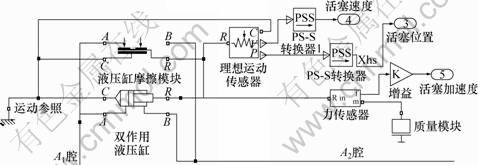

以后控式SYYG65型水力凿岩机为研究对象,图1所示为SYYG65型水力凿岩机的冲击及换向机构工作原理图。

图1 水力冲击及换向机构原理图

Fig.1 Principle of water-powered impact and reverse mechanism

图1所示为上一次冲程结束、活塞回程开始的状态。从高压水泵站输送来的高压水P1经高压蓄能器进入到冲击器缸体配流阀中,高压水P1经配流阀B3腔直接进入活塞的前腔A1,推动活塞向右作回程加速运动,当活塞台肩边缘越过K1控制口时,高压水P1经活塞前腔由K1口进入阀芯的右端控制腔B1,推动阀芯迅速左移并停靠在左位,这时活塞前后腔都通高压水,实现差动联接。因活塞前后腔受力面积不同A2>A1,活塞在压力差的作用下作回程减速运动,直到速度为0 mm/s,回程结束。活塞在压力差的作用下换向,并产生向左的冲程加速运动,当活塞前部台肩后边缘越过K2控制口时(K1口已关闭),这时阀芯右端控制腔B1的高压水经过K2和K3控制口和回水口P2相通,阀芯右端失压,阀芯在左端水压力(常压腔)的作用下,阀芯迅速右移换向,此时活塞正好冲击钎尾,冲程结束。系统重新进入图示工作状态,开始活塞的下一个工作循环。这样通过活塞运行过程中依次打开K1和K2口,从而实现活塞的往复运动,不断冲击钎尾,输出冲击能。

水力凿岩机的运动过程具有如下的特点:活塞和阀芯正常运动可以分成有限的状态[7];各个状态按照一定的条件转换,但由于传动介质的特殊性,各个状态的转换并不能由活塞或阀芯的位置简单界定,活塞和阀芯的运动具有高度耦合。SimHydraulics建立的水力凿岩机冲击系统运动实物模型恰好可以真实地反映水利凿岩机冲击与换向机构的相互耦合作用。

2 水力凿岩机的SimHydraulics模型

水力凿岩机的SimHydraulics模型主要由活塞及阀芯运动模型、液体配流模型,腔体、管路、传感器等其他模块组成。

2.1 活塞及阀芯运动模型

由水力凿岩机运行原理,活塞或阀芯可以建立统一动力平衡方程:

(1)

(1)

式中:m为活塞/阀芯质量,kg;F(p)为活塞/阀芯受到的有效液压推力,N;f为活塞/阀芯受到的其他合力,包括摩擦力、液体黏性阻力、液动力等,N; 为活塞/阀芯的加速度,m/s2。

为活塞/阀芯的加速度,m/s2。

该方程由双作用往复液压缸模块、液压缸摩擦模块及质量模块共同描述。

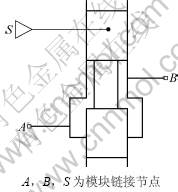

其中,液压缸摩擦模块(图2)描述函数如下:

(2)

(2)

(3)

(3)

式中:vth为速度阀值,一般取10-4~10-6 m/s;F为总摩擦力,N;FC为库仑摩擦力,N;Fpr为预载荷,N;fcfr为库仑摩擦因数,N/Pa;pA,pB为水压缸内腔压力,Pa;Kbrk为静摩擦力增长系数;cv为迁移系数,s/m;v为C端与R端相对速度,m/s;vR,vC为R端和C端绝对速度,m/s;fvfr为黏性摩擦因数,N·s/m。

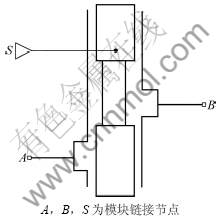

流量平衡由SimHydraulics模型网络自动保证,增加相应的位移参照及传感器模块后建立的活塞运动模型如图3所示。

阀芯运动模型与活塞模型类似,仅模块参数的设置不同。

图2 液压缸摩擦模块

Fig.2 Cylinder friction

2.2 液体配流模型

该部分实现活塞与阀的相互控制功能,模拟A1—K1和A3—K1各腔间压力水流动,A1和A2腔外泄漏以及B2—B3,B3—B5各腔(图1)压力水互通。其中A1—K1,A3—K1,B2—B3,B3—B5由变面积槽式孔口模块(图4)模拟。

其描述方程如下:

(4)

(4)

(5)

(5)

(6)

(6)

p=pA-pB (7)

(8)

(8)

(9)

(9)

(10)

(10)

式中:q为流量,m3/s;p为压差,Pa;pA,pB为A,B点压力,Pa;CD为流量系数;A(h)为孔口面积,m2;b为开口槽宽度,m;x0为孔口初始开度,m;x为滑阀位置(相对初始位置),m;h为孔口开度,m;or为符号量,若滑阀正向移动增大开口量,则or取+1;反正,or取-1;ρ为流体密度,kg/m3;DH为瞬时孔口水力直径,m;α为流体动黏滞系数,Pa·s;Aleak为滑阀完全关闭后泄漏面积,m2;A1和A2腔(图1)外泄漏由环形节流器(图5)描述。

图3 活塞运动模型

Fig.3 Piston model

图4 变面积槽式孔口

Fig.4 Orifice with variable area slot

图5 环形节流器

Fig.5 Annular orifice

该节流器流量按照Hagen-Poiseuille 公式[14]计算:

(11)

(11)

(12)

(12)

式中:R为阀套半径,m;r为阀体半径,m;e为偏心距,m;ε为偏心率。

2.3 SYYG65型水力凿岩机冲击系统模型

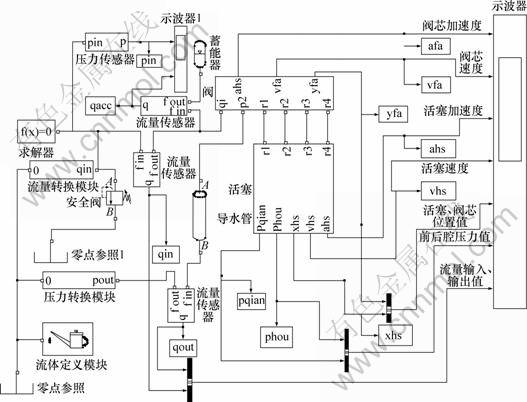

基于以上模块分析,针对自行设计的GYYG65型导轨式水力凿岩机冲击系统建立了SimHydraulics实物模型,模型由活塞运动子系统、配流阀运动子系统、理想定量泵、减压阀、传感器等组合而成,图6所示为系统顶层模型图。

该模型假设输入流量为定值,摩擦力、液体黏性阻力、液动力、液体传热、缸体刚度等因素在模型中均有相应模块参数反映。

模型从Matlab工作空间读入参数,并向工作空间输出活塞和阀芯的位移、速度、加速度,活塞前、后腔压力,回水流量,进出蓄能器流量等数据,并可采用Matlab脚本语言方便定制相应输出变量,以供后续分析使用。

3 仿真实验

3.1 SYYG65型水力凿岩机仿真模型参数

SYYG65型水力凿岩机活塞(图1)主要基本参数如下:活塞质量为4.97 kg,活塞前端台肩直径为43 mm,活塞前腔后台阶直径为47 mm,后端直径为38 mm;活塞最大位移为56 mm,K1开口距前腔前端39 mm,K2到K1距离为21 mm;密封间隙为50 μm;设置活塞库仑摩擦因数、黏性摩擦因数、静摩擦力增长系数、迁移系数等(式(2)、(3)中相应参数)。

配流阀(图1)的主要基本参数:阀芯质量为0.2 kg,阀套内径为34 mm,阀芯外径为30 mm,阀套B2腔宽度为20 mm,B3腔宽度为23 mm,B5腔宽度为23 mm;阀芯台肩宽度为5 mm;最大位移为9 mm;阀芯两端摩擦副配合间隙为20 μm;阀芯前腔B4台肩直径为29 mm,后腔B1后台阶直径为13 mm;设置相应摩擦因数。

A2到B2腔水路管径为10 mm,其余内部管路直径均为8 mm。凿岩机进水管直径为18 mm,出水管直径为20 mm。

其他参数,如活塞前腔有效面积、活塞后腔有效面积、水缸前腔体积、后腔体积等参数均由以上参数计算得出。

Simulink版本为7.1(R2008a),设置流体介质为纯水(water),求解器选取适用于刚性方程的ode15s变步长求解器,该求解器是基于数值微分公式(NDFs)的变阶多步求解器,能有效求解该模型。打开求解器的过零检测选项,设置自适应过零监测,以保证对水介质传动的有效仿真。

图6 SYYG65型水力凿岩机冲击系统仿真模型

Fig.6 Simulation model of water-powered percussive rock drill SYYG65

3.2 仿真结果及与实测结果分析对比

3.2.1 系统运行实验

参照实物系统,设定泵供水流量为120 L/min,减压阀设定卸荷压力为16 MPa,蓄能器充气压力为4.5 MPa,容积为0.15 L,运行仿真模型。该凿岩机基本性能如表1所示。

表1 SYYG65型水力凿岩机性能

Table 1 Performance of SYYG65 water powered percussive rock drill

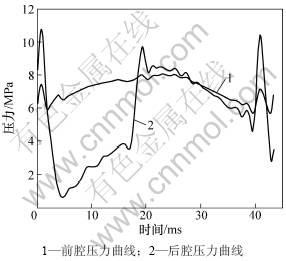

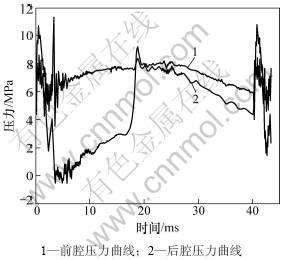

图7和8所示分别为活塞前后腔压力仿真和实验曲线。

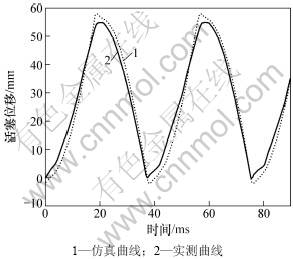

对比图7与图8发现:仿真曲线与实测曲线前后腔压力波动趋势基本一致,压力相符,由于仿真模型对部分因素采取了理想假设,故仿真曲线比实测曲线显得平滑。活塞位移曲线如图9所示。对比图7和图9可见:仿真与实测曲线基本重合,但由于活塞与缸体的接触计算采用理想黏弹性模型[14]计算,计算结果与真实接触有差异,故活塞的最大与最小位移仿真值与实测结果有少许偏离。

图7 前后腔压力仿真曲线(单个运动循环)

Fig.7 Simulated pressure curves of front and back cavity of rock drill (single cycle)

图8 前后腔压力实测曲线(单个运动循环)

Fig.8 Measured pressure curves of front and back cavity of rock drill (single cycle)

图9 活塞位移曲线

Fig.9 Displacement curves of piston

由表1可见:仿真输出参数与实测数据基本一致,相比实测结果最大偏离不超过6%。该模型较真实地再现了水力凿岩机冲击机构内部的运动规律,为冲击系统参数设计及验证提供了经济、有效的途径与工具。

3.2.2 蓄能器参数优化

高压蓄能器是凿岩机最重要的部件之一,通常由气腔和液腔2部分组成,有气腔充气压力和液腔有效容积2项主要参数。它主要用以吸收活塞运动循环中水泵供给的多余流量,以补偿冲程后期活塞运动所需的峰值流量;吸收系统压力波动,延长系统使用寿命,提高凿岩机冲击系统的能量利用率。

水力凿岩机冲击系统的能量利用率η是衡量凿岩机性能优劣的一项重要指标:

(13)

(13)

式中:Ee为冲击活塞移动到最前端具有的动能,J;Ew为冲击机构输入的水压能,J;λ为冲击频率,Hz;m为冲击活塞质量,kg;v为冲击活塞打击钎杆时的速度,m/s;p为冲击机构有效工作压力,Pa;q为冲击机构工作流量,m3/s;

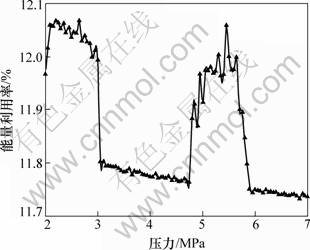

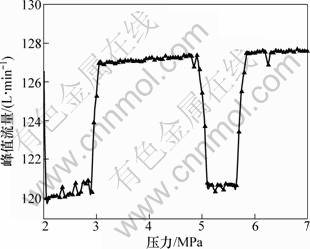

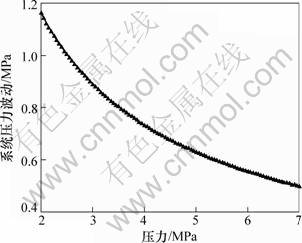

下面以能量利用率η为优化目标,以蓄能器进出口峰值流量、系统压力波动情况来确定水力凿岩机蓄能器最佳充气压力和有效容积。在仿真基础上,首先循环计算蓄能器充气压力2~7 MPa,每隔0.05 MPa做一组仿真实验。编制Matlab脚本文件,运行仿真模型,结果如图10~12所示。

从图10可以看出:蓄能器充气压力为2~7 MPa时,冲击机构能量利用率有2组较大值,其充气压力范围分别为2~3 MPa和4.75~5.80 MPa,且能量利用率随充气压力增大有总体降低的趋势;由文献[15]知:相对较小的蓄能器进出口流量峰值可降低系统能量损失,则蓄能器参数的选取应遵循最小流量峰值原则。由图11可知:蓄能器峰值流量Q具有2组较小值,分别对应蓄能器充气压力2~3 MPa和5.00~5.75 MPa。结合图12发现:充气压力的减小使系统的压力波动显著增强,不利于系统的稳定工作,影响系统使用寿命,故充气压力的选取不宜过小。

图10 能量利用率与充气压力的关系

Fig.10 Relationship between energy efficiency and inflation pressure of accumulator

图11 峰值流量与充气压力的关系

Fig.11 Relationship between peak flow and inflation pressure of accumulator

图12 系统压力波动与充气压力的关系

Fig.12 Relationship between pressure fluctuation and inflation pressure of accumulator

充气压力在取2~3 MPa时,蓄能器基本没有起到作用,峰值流量较小(图11),系统压力波动严重(图12),故该组参数不宜选取;图10中,系统得到较高的能量利用率,是由于模型计算时设置输入流量较大,基本满足了活塞冲程加速段的峰值流量需求,故该充气压力下能量利用率也取得了相对较大值。

综上所述,蓄能器最佳充气压力选定为5.00~5.75 MPa,系统具有相对理想的工作状态,具有较高的能量利用率(11.9%≤η≤12.07%)、较低的峰值流量 (Q<121.0 L/min)、相对小的压力波动范围(Δp< 0.68 MPa)。

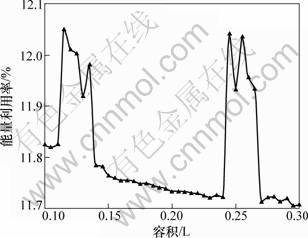

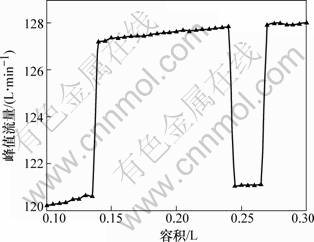

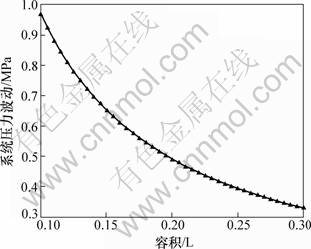

模型设置蓄能器有效容积范围为0.1~0.3 L,每隔5 mL做一组仿真实验。重新运行仿真模型,结果如图13~15所示。

由图13可见:蓄能器有效容积为0.1~0.3 L时,冲击机构能量利用率亦有2组较大值,其有效容积范围分别为0.11~0.14 L和0.24~0.27 L,且能量利用率随有效容积增大有总体降低的趋势;由图14可知:蓄能器峰值流量Q具有2组较小值,分别对应蓄能器有效容积为0.1~0.14 L和0.24~0.27 L;结合图15发现:有效容积的减小同样使系统的压力波动显著增强,不利于系统稳定工作及系统寿命,故有效容积的选取不宜过小。

可见,有效容积在取较小值0.11~0.14 L时,蓄能器基本没有起到作用。峰值流量随有效容积减小趋势更加明显(图14),系统压力波动严重(图15),故该组参数亦不宜选取。所以,蓄能器有效容积应选定为0.24~0.27 L,系统具有相对理想的工作状态,具有较高的能量利用率(11.9%≤η≤12.05%)、较低的峰值流量(Q<121.1 L/min)、相对小的压力波动范围(Δp<0.42 MPa)。

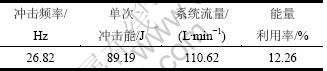

参照图10和图13,在已得到的最佳充气压力及有效容积范围内,选取最高能量利用率下的最优有效容积(0.255 L)及充气压力(5.5 MPa)参数,通过自行研发的SYYG65型导轨式水力凿岩机对上述优化结论做实测验证。置换有效容积为0.255 L的高压蓄能器,并预充氮气压力为5.5 MPa,其他工作参数同上节实测实验参数设定。实测结果表明:该型水力凿岩机能量利用率达到12.26%,活塞单次冲击能达到89.19 J(表2)。与表1中实测结果相比,能量利用率与单次冲击能均有明显提高。

图13 能量利用率与有效容积的关系

Fig.13 Relationship between energy efficiency and effective volume of accumulator

图14 峰值流量与有效容积的关系

Fig.14 Relationship between peak flow and effective volume of accumulator

图15 系统压力波动与有效容积的关系

Fig.15 Relationship between pressure fluctuation and effective volume of accumulator

表2 SYYG65型水力凿岩机性能测试结果(0.255 L)

Table 2 Measured performance of SYYG65 (0.255 L) water powered percursive rock drill

4 结论

(1) 基于SimHydraulics建立的水力凿岩机冲击系统运动实物模型,建模过程中不考虑系统运行时的复杂状态转换,综合考虑了活塞及阀芯所受的液压力、库仑摩擦力、液体黏性阻力等,简单有效地实现了活塞和阀芯在水压力作用下的耦合仿真计算。

(2) 通过对自行研制的SYYG65型导轨式水力凿岩机的仿真实验,得到活塞前、后腔压力以及位移的变化规律,仿真实验数据与实测数据吻合较好,证明了用SimHydraulics完全可以对水力凿岩机冲击系统运动规律进行仿真,为水力凿岩机冲击系统参数设计和匹配提供了有效的验证工具和评价手段。

(3) 以系统能量利用率为优化目标,以蓄能器进出口峰值流量和系统压力波动指标得到SYYG65型水力凿岩机的高压蓄能器最佳充气压力为5.00~5.75 MPa,有效容积为0.24~0.27 L,并通过了室内试验 验证。

参考文献:

[1] Paraszczak J, Planeta S, Ouellet H. Comparative experiment between water-powered jackleg drill and pneumatic drills[J]. Mining Engineering, 1994(8): 999-1002.

[2] 周梓荣, 李夕兵, 刘迎春. 支腿式水压凿岩机的研究与试验[J]. 中国机械工程, 2004, 15(14): 1236-1239.

ZHOU Zi-rong, LI Xi-bing, LIU Ying-chun. Research and experiment of water-powered rock drill with supporting leg[J]. China Mechanical Engineering, 2004, 15(14): 1236-1239.

[3] 伍先明, 刘德顺. 水压凿岩机的研究和设计[J]. 机床与液压, 2007, 35(4): 123-124.

WU Xian-ming, LIU De-shun. The research and design of hydraulic-rock drill[J]. Machine Tool & Hydraulics, 2007, 35(4): 123-124.

[4] 赵宏强. 新型液压冲击器仿真与优化研究[J]. 凿岩机械气动工具, 2001(1): 12-26.

ZHAO Hong-qiang. Study on simulation and optimize of new hydraulic impactor[J]. Rock Drilling Machinery & Pneumatic Tools, 2001(1): 12-26.

[5] 刘万灵, 高澜庆. 液压凿岩机换向阀的动特性分析[J]. 有色金属: 矿山部分, 1987(2): 46-54.

LIU Wan-ling, GAO Lan-qing. The dynamic characteristics of reversing valve of the hydraulic rock drill[J]. Nonferrous Metals: Mining, 1987(2): 46-54.

[6] 杨务滋, 邱海灵, 苗润田. 基于Simulink的液压冲击器动态仿真[J]. 凿岩机械气动工具, 2005(3): 40-45.

YANG Wu-zi, QIU Hai-ling, MIAO Run-tian. Dynamic simulation of hydraulic impactor based on Simulink[J]. Rock Drilling Machinery & Pneumatic Tools, 2005(3): 40-45.

[7] 唐伟. 无阀液压凿岩机动态过程的仿真研究[D]. 西安: 西安科技大学机械工程学院, 2004: 34-44.

TANG Wei. Simulation research in dynamic process of valveless hydraulic drill[D]. Xi’an: Xi’an University of Science and Technology. School of Mechanical Engineering, 2004: 34-44.

[8] 吴万荣, 孟莹, 杨矗, 等. 基于AMESim的新型数字控制液压冲击器的仿真[J]. 机械制造与自动化, 2008(3): 105-107.

WU Wan-rong, MENG Ying, YANG Chu, et al. Simulation of a new type of digital hydraulic breaker controlled by the high speed on-off solenoid valves based on AMESim[J]. Machine Building & Automation, 2008(3): 105-107.

[9] 孙树礼, 田树军, 徐冬梅, 等. 基于功率键合图法的液压破碎冲击器动态特性数字仿真研究[J]. 凿岩机械气动工具, 1997(3): 23-27.

SUN Shu-li, TIAN Shu-jun, XU Dong-mei, et al. Digital simulation and study of the hydraulic hammer based on power bond graph[J]. Rock Drilling Machinery & Pneumatic Tools, 1997(3): 23-27.

[10] 田树军, 杨国权, 刘能宏. YYGJ90型液压凿岩机动态性能仿真研究[J]. 凿岩机械气动工具, 1994(3): 51-55.

TIAN Shu-jun, YANG Guo-quan, LIU Neng-hong. Dynamical simulation of the hydraulic rock drill YYGJ90[J]. Rock Drilling Machinery & Pneumatic Tools, 1994(3): 51-55.

[11] 张庆功, 周建强, 吴镇江. 基于虚拟样机技术的气动凿岩机设计与仿真研究[J]. 煤矿机械, 2007, 28(7): 37-38.

ZHANG Qing-gong, ZHOU Jian-qiang, WU Zhen-jiang. Research on design and simulation of pneumatic rock drill based on virtual prototype technology[J]. Coal Mine Machinery, 2007, 28(7): 37-38.

[12] 张庆功, 张瑛, 谢慧萍. 基于虚拟样机技术的气动凿岩机建模与运动学仿真[J]. 煤矿机械, 2008, 29(10): 40-41.

ZHANG Qing-gong, ZHANG Ying, XIE Hui-ping. Modeling and kinematics simulation of pneumatic rock drill based on virtual prototype technology[J]. Coal Mine Machinery, 2008, 29(10): 40-41.

[13] 张庆功, 马晓丽, 王涛. 基于CAXA的YO18型气动凿岩机建模与运动仿真[J]. 科技资讯, 2006(19): 5-6.

ZHANG Qing-gong, MA Xiao-li, WANG Tao. Modeling and kinematics simulation of pneumatic rock drill YO18 based on CAXA[J]. Science & Technology Information, 2006(19): 5-6.

[14] Manring N D. Hydraulic control systems[M]. New York: John Wiley & Sons, 2005: 56-98.

[15] 刘海昌, 姜继海, Okoye C. 基于数值方法的液压蓄能器能量损失分析[J]. 中国机械工程, 2006, 17(12): 1283-1285.

LIU Hai-chang, JIANG Ji-hai, Okoye C. Energy loss analysis of hydraulic accumulator during energy storage using numerical method[J]. China Mechanical Engineering, 2006, 17(12): 1283-1285.

(编辑 赵俊)

收稿日期:2010-11-21;修回日期:2011-04-29

基金项目:国家高技术研究发展计划(“863”计划)项目(2006AA06Z134);国家自然科学基金资助项目(50934006);国家重点基础研究发展计划(“973”计划)项目(2010CB732004)

通信作者:李志国(1980-),男,河北灵寿人,博士研究生,从事流体机械、采矿工程方面的研究;电话:15827566859;E-mail:iamlizhiguo@163.com