文章编号:1004-0609(2011)05-1074-06

高压处理对La62.0Al15.7(Cu, Ni)22.3非晶合金

显微组织和腐蚀行为的影响

万小军1, 2, 王锋华2, 林建国2

(1. 湖南城市学院 物理与电信工程系,益阳 413000;2. 湘潭大学 材料与光电物理学院,湘潭411105)

摘 要:采用电弧熔炼铜模吸铸法制备La62.0Al15.7(Cu, Ni)22.3非晶合金,在室温下对该非晶合金进行高压处理(压力为3~5 GPa),研究高压处理对非晶合金显微组织的影响;并对非晶合金在3.5%NaCl溶液中的电化学性能进行测试。结果表明:室温下的高压处理使该非晶合金发生结构驰豫,从而导致其玻璃转变温度、第一晶化温度及驰豫激活体积发生改变;高压处理后,非晶合金的自腐蚀电位增加,自腐蚀电流密度减小,临界点蚀电位下降,因此,高压处理提高该了非晶合金的抗均匀腐蚀能力,但降低了其抗点蚀的能力。

关键词:非晶合金;高压处理;电化学腐蚀

中图分类号:TG146.4 文献标志码:A

Effects of high pressure treatment on microstructure and corrosion behavior of La62.0Al15.7(Cu, Ni)22.3 amorphous alloy

WAN Xiao-jun1, 2, WANG Feng-hua2, LIN Jian-guo2

(1. Department of Physics and Telecommunication Engineering, Hunan City University, Yiyang 413000, China;

2. Faculty of Material and Photoelectronic Physics, Xiangtan University, Xiangtan 411105, China)

Abstract: The La62.0Al15.7(Cu, Ni)22.3 amorphous alloy was prepared by the injection of liquid alloy into a copper mould. The alloy was treated under high pressures in the range of 3.0-5.0 GPa at room temperature, and the effects of the high pressure treatment on the microstructure of alloys were investigated. The corrosion behavior of the alloy electrolyte was measured in 3.5% NaCl by the electrochemical method. The results indicate that the high pressure treatment at room temperature causes the structural relaxation of alloy, which results in the changes of the glass transition temperature, the first crystallization temperature and the relaxation activation volume of the alloy. Compared with the as-cast alloy, the alloy treated by high pressure exhibits high self-corrosion potential, low self-corrosion current and low critical pitting potential. This implies that high pressure treatment promotes the uniform corrosion resistance, but deteriorates the pitting resistance of the alloy.

Key words: amorphous alloy; high pressure treatment; electrochemical corrosion

非晶合金具有优异的力学性能,独特的物理和化学性能,已成为当今材料领域的研究热点之一[1-2]。非晶合金在结构上没有晶界、位错及相界面等结构缺陷,同时其化学成分均匀,这些特征使其具有良好的抗腐蚀性能[3-4]。近些年来,人们对于非晶的腐蚀机理以及影响因素进行了大量研究,研究结果认为,非晶优异的抗腐蚀性能不仅与非晶的结构有着密切的关系[5],而且与合金成分有关,在合金中增加某些组元可能形成一种更好的保护膜[6-7],或者改变在局部位置腐蚀的动力学[8]。非晶合金是一种非平衡态材料,当外界给予合金一定的热激活能,非晶合金会向其平衡态-晶态合金转变,形成纳米晶组织。外界压力作为一个重要的热力学参数,对非晶组织的转变起着重要的作用。已有的研究结果表明[9-10],在一定温度下,对非晶合金进行高压处理,可以有效地调整非晶合金的原子间距及原子间作用关系,改变非晶合金的显微组织,从而影响合金的性能。高压处理会引起非晶合金内部结构的变化,从而引起抗腐蚀性能的改变。然而,有关高压处理对非晶合金腐蚀性能影响的研究还未见报道,因此,本文作者拟在室温下对La62.0Al15.7(Cu, Ni)22.3非晶进行高压处理(压力为3~5 GPa),研究高压处理对该非晶显微组织的影响,并探讨高压处理对非晶显微组织的变化及其对非晶合金腐蚀性能的影响。

1 实验

本研究以La62.0Al15.7(Cu,Ni)22.3为研究对象,该合金具有较低的玻璃转变温度和较强的非晶形成能 力[11]。用真空熔炼炉熔炼成分为La62.0Al15.7(Cu,Ni)22.3的合金。将合金在熔炼炉中反复熔炼5次,以获得成分均匀的母合金锭。在高真空条件下将母合金锭熔化并进行铜模吸铸,得到尺寸为d 3×60 mm的铸态试棒,并采用六面顶压砧型加压装置对非晶合金进行室温高压处理,为了使样品受压均匀,样品周围用BN粉末包埋,样品处于近似静水压力下。用X射线衍射方法(XRD)对铸态和经过不同压力处理后的样品进行结构表征。XRD实验在D/MAX衍射仪上完成,采用Cu Kα靶,管压为50 kV,电流为100 mA,扫描速度为0.02(°)/s。热分析实验是在TA Instruments Q10差热扫描量热仪(DSC)上进行,用纯In和纯Zn的熔化分别校准仪器温度和热焓(温度测量精度为±0.02 K,热流的测量精度为0.01 mW)。实验样品和标样都使用铝坩锅,并用高纯N2气流保护,每次测试样品质量为8~12 mg。将铸态和经过高压处理后的LaAlCuNi非晶合金做成腐蚀电极,其方法是采用导电胶和防水胶布粘连导线和样品,并将试样表面清洗干净并封裹,只留下d 3.0 mm截面,然后用万用电表欧姆档检查其导电性,保证每个电极导电稳定。对样品表面进行机械抛光,最终使用粒径1?m的金刚石抛光液将其抛光成镜面,并用丙酮清除表面油污后用蒸馏水清洗并在空气中晾干。用Solartron1287电化学测试仪对非晶合金试样的动电位极化曲线进行测试。实验中采用三电极法,所用的参比电极是饱和甘汞电极,辅助电极为铂电极,腐蚀液为浓度3.5%NaCl的溶液,实验温度为室温(295 K)。为了使得开路电压稳定,腐蚀前将每个样品在腐蚀液中浸泡30 min。用动电位的方法测得电极的极化曲线,相对于开路的扫描电压范围为-1.0~1.5 V,扫描速率为5 mV/s。每次腐蚀实验都采用新鲜的腐蚀液。腐蚀后将样品清洗并晾干,通过扫描电镜和能谱对样品表面进行测试和分析。

2 结果和讨论

2.1 高压处理对非晶合金微结构的影响

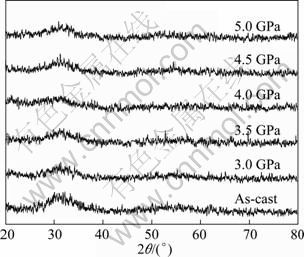

图1所示为铸态和在室温下经不同压力(3~5 GPa)处理后La62.0Al15.7(Cu,Ni)22.3非晶合金的XRD谱。由图1可以看出:在铸态合金的XRD谱上,只存在一个漫散射峰,表明所制备的合金为完全非晶态合金;经过高压处理后,该合金的XRD谱依然保持着非晶合金的衍射峰特征,未发现明显的晶化峰。这一结果表明,在室温下,3~5 GPa的高压处理未导致非晶合金的晶化,其显微组织依然保持完全的非晶态。但仔细比较其XRD谱可以发现,各试样的漫散射峰的高度和宽度略有不同。与铸态合金相比,当压力从3.0 GPa增至4.0 GPa时,合金的漫散射峰依次变宽,强度变低;而当压力进一步增至5.0 GPa时,漫散射峰的宽度变窄,强度增大。

图1 铸态和高压处理后非晶合金的XRD谱

Fig.1 XRD patterns of amorphous alloy in as-cast and high pressure pre-treated states at room temperature

这一实验现象在其它经过高压处理的非晶合金系也已经观察到[9-10]。通常认为,XRD漫散射峰的宽度和强度变化,与非晶合金的结构驰豫有关的,这一点在后面对试样的热分析中得到了证明。

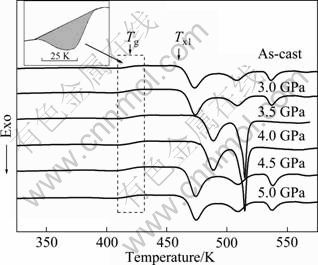

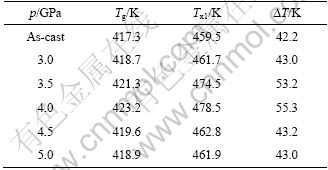

为了进一步分析高压处理对La62.0Al15.7(Cu, Ni)22.3非晶合金微结构的影响,本文作者对采用示差热分析仪(DSC)对铸态和经过不同压力处理后非晶合金的热力学性能进行了测试。图2所示为铸态和经过不同压力处理后非晶合金的DSC曲线(加热速率20 K/min)。从DSC曲线,可得到各试样的玻璃转变温度(Tg)和晶化温度(Tx)。表1列出了不同压力处理后非晶合金的玻璃转变温度Tg、第一晶化温度Tx1(出现第一个晶化峰的开始起始温度)和过冷液相区?T (?T= Tx1-Tg)。由表1可知,铸态La62.0Al15.7(Cu, Ni)22.3非晶合金的玻璃转变温度和第一晶化温度分别是417.3和459.5 K,经过高压处理后,非晶合金的热力学特性发生了变化。当压力由3.0 GPa增至4.0 GPa时,非晶合金的玻璃转变温度Tg略有增加,在压力为4.0 GPa时,Tg增至423.2 K,比铸态合金的玻璃转变温度提高6 K。而当压力继续增加至5 GPa时,其玻璃转变温度反而下降,接近铸态合金的玻璃转变温度。

图2 铸态和高压处理后非晶合金的DSC曲线

Fig.2 DSC curves of amorphous alloy in as-cast and high pressure pre-treated states at room temperature

表1 非金合金的玻璃转变温度Tg、晶化温度Tx1、过冷液相区?T和压力p

Table 1 Glass transition temperature Tg, crystallization temperature Tx1, supercooled liquid region ?T and pressure p of amorphous alloy

进一步比较各试样的DSC曲线可以发现,高压处理对该非晶合金的晶化温度(主要是第一晶化温度Tx1)和过冷液相区的大小也有较大影响。经4.0 GPa处理后,第一晶化温度增加到最大值478.5 K,比铸态的(459.5 K)增加19 K。当压力继续增加到5.0 GPa,第一晶化温度却减小到461.9 K。与第一晶化温度的变化趋势相似,该非晶合金的过冷液相区?T随压力变化也呈现先增加而减小的规律。当压力为4.0 GPa时,合金的过冷液相区?T为55.2 K,比铸态增加13 K;而当压力继续增加到5.0G Pa时,合金的过冷液相区的大小又降至43 K。

上述结果表明,高压处理使得La62.0Al15.7(Cu, Ni)22.3合金热力学特性发生了改变,即非晶合金的热稳定发生了改变,而非晶合金的热稳定是与非晶合金的微结构密切相关的。结合高压处理后试样的XRD分析结果可知,在室温下对合金进行高压处理,在3~5 GPa的高压下,虽然合金依然保持着非晶态,但合金中原子发生了驰豫,可以反映到非晶中自由体积上的变化,这一变化可由非晶合金DSC曲线上玻璃转变温度附近 “焓弛豫峰”的变化来描述(见图2中小插图)。焓弛豫峰的高度和宽度对应玻璃转变的焓变,其焓变正比于玻璃的自由体积,即峰的高度越高,焓越低,对应的自由体积越小。根据自由体积模型,文献[12]引入激活体积(?Tp)来描述非晶合金的结构弛豫与玻璃转变温度的关系。通常情况下,非晶合金的结构弛豫时间随温度的变化符合Vogel-Fulcher- Tammann(VFT)公式[12]:

(1)

(1)

式中:τ0为在极高温度下液体的弛豫时间;B和T0均为材料和粘度η有关的特征常数;p为外加压力;?Vp为弛豫的激活体积;k为常数;T为绝对温度。

假设在不同的压力p1和p2作用下,样品的玻璃转变温度分别为Tg1和Tg2,且测量的升温(或降温)速率完全相同。那么在压力p1作用下,其玻璃转变温度为Tg1时,样品的弛豫时间为

(2)

(2)

同样,在压力p2作用下,其玻璃转变温度为Tg2时,样品的弛豫时间为

(3)

(3)

由于测量玻璃转变温度时的升温(降温)速度相同,因而在这两个不同压力下,不同玻璃转变温度时的弛豫时间完全相同,即

(4)

(4)

于是,由式(2)、(3)和(4)可以得到弛豫的激活体积?Tp, 即

(5)

(5)

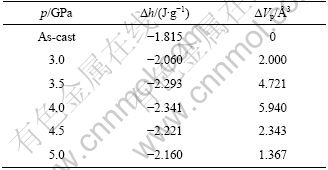

对于LaAlCuNi非晶合金, B和T0的近似值分别为2 613 K/s和359 K[13],而该合金在常压下的玻璃转变温度Tg0为417.3 K。将表1的数据代入式(5),可计算得到不同压力处理后LaAlCuNi非晶合金的弛豫激活体积?Vp,如表2所示。由表2可以看出,随着压力的增加,非晶合金的激活体积明显增大,当压力为4.0 GPa时,达到最大值;而当压力继续增加,激活体积不再增大,反而减小。 这一结果与DSC测试结果一致,这从理论上解释La62.0Al15.7(Cu, Ni)22.3非晶合金在高压处理过程中,合金的玻璃转变温度随压力变化的规律。进一步分析发现,在压力为4.0 GPa时,LaAlCuNi非晶合金的驰豫体积?Vp的值为5.940 ?3 (3.578 cm3/mol)。显然,非晶合金的驰豫激活体积?Vp比氧化物非晶态材料的(约为102 cm3/mol)小很多,因此,LaAlCuNi非晶合金的Tg随压力变化不及其它氧化物玻璃体系的变化明显。

表2 LaAlCuNi非晶合金的焓?h、激活体积?Vp和压力p

Table 2 Enthalpy ?h,activation volume ?Vp and pressure p of LaAlCuNi amorphous alloy

2.2 高压处理对非晶合金腐蚀行为的影响

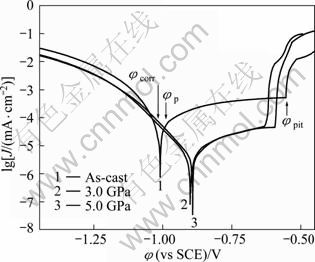

图3所示为在室温下,铸态和经过3.0和5.0 GPa压力处理后的非晶合金在3.5% NaCl溶液中的动电位极化曲线。从图3可以看出,两种试样的电化学极化行为相似,在特定的电位下,两种试样的阳极电流密度都会呈现急剧增加的现象,这表明合金表面的钝化膜发生破裂,亦即发生了点蚀,其对应的电位称之为临界点蚀电位φpit。点蚀主要发生在特殊离子的介质中,如Cl-属于活性阴离子,会破坏金属的钝化膜而引起点腐蚀[14]。

从两种试样的极化曲线上可以得到合金的自腐蚀电流密度Jcorr、自腐蚀电位φcorr,点蚀电位φpit,临界钝化电位φp等电化学腐蚀参数,如表3所示。从图3和表3可以看到,铸态合金和经过3.0和5.0 GPa高压处理的合金,自腐蚀电流密度分别为190.35、24.16和22.53 mA/m2,自腐蚀电位分别为-1.015、-0.904和-0.894 V。一般来说,腐蚀电流越小,腐蚀电位越大,其抗腐蚀能力越强[15-16]。经过高压处理后,非晶合金的自腐蚀电流密度急剧减小了一个数量级左右;自腐蚀电位增加约0.12 V,这表明经过高压处理后,非晶合金的抗电化学腐蚀能力增强。

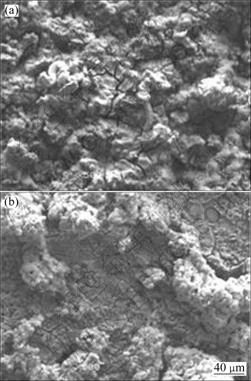

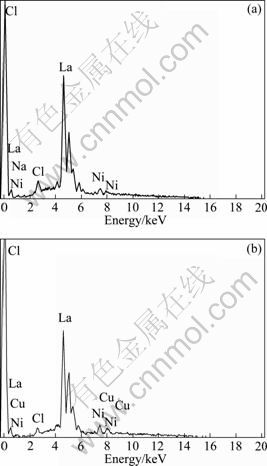

对电化学腐蚀样品的表面进行观察,发现非晶合金的表面覆盖一层黑色均匀的腐蚀产物膜,而且轻轻擦拭即可脱落。表明非晶合金已经发生了全面腐蚀,且腐蚀产物膜不能起到保护的作用。但在扫描电镜观察可以发现,铸态和经过5.0 GPa高压处理非晶合金的腐蚀表面形貌存在一些差异。两种样品腐蚀表面均存在裂纹,但铸态的裂纹比较大而少,而经过5.0 GPa高压处理的裂纹细而多(见图4),表明经过高压处理后,非晶合金空位逐渐消失,原子之间结合更紧密,能量降低,结构趋于“平衡”,抗腐蚀能力更强。对两种试样腐蚀表面的能谱(EDS)分析发现,在电化学腐蚀之后,两种试样的腐蚀表面成分主要是La和Cl两种元素,其表面成分几乎没有发生明显变化,表明高压处理没有影响非晶合金腐蚀产物,如图5所示。

图3 铸态和高压处理后La62.0Al15.7(Cu, Ni)22.3非晶合金在3.5%NaCl溶液中的电化学腐蚀曲线

Fig.3 Potentiodynamic polarization curves of La62.0Al15.7(Cu, Ni)22.3 in as-cast and high pressure pre-treated states at room temperature in 3.5%NaCl solution

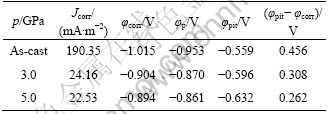

表3 铸态和高压处理后非晶合金的电化学腐蚀参数

Table 3 Electrochemical corrosion data collected from potentiodynamic scans of amorphous alloy in as-cast and high pressure pre-treated states

图4 铸态和经5.0 GPa压力处理的非晶合金电化学腐蚀后的表面形貌

Fig.4 Surface morphologies of amorphous alloy in as-cast (a) and 5.0 GPa high pressure pre-treated states (b) at room temperature

综上所述,高压处理对非晶合金的电化学腐蚀产生了重要影响,表现在其自腐蚀电位增加,自腐蚀电流密度减小,抗腐蚀能力增强,但在含Cl-溶液中的抗点蚀能力下降,虽然高压处理引起该非晶合金的电化学腐蚀变化原因还不是很清楚,但高压处理导致了非晶合金空位逐渐消失,能量降低,结构趋于“平衡”。非晶合金微结构的变化必然会影响非晶合金钝化膜的形成及其稳定性,从而改变非晶合金的电化学性能。

图5 铸态和5.0 GPa高压处理非晶合金腐蚀表面的EDS谱

Fig.5 EDS spectra of as-cast (a) and high pressure treated under 5.0 GPa (b) alloys

3 结论

1) 高压处理未导致该非晶合金晶化,但却使其发生了结构驰豫,从而引起合金的玻璃转变温度、第一晶化温度及驰豫激活体积改变,且随着压力的增加,这些参数先增后减,在压力为4 GPa时达到最大值。

2) 对La62.0Al15.7(Cu, Ni)22.3非晶合金在3.5%NaCl溶液中的电化学性能测试结果表明,经过室温高压处理后,该非晶合金自腐蚀电流密度减小,自腐蚀电位增加,临界点蚀电位φpit降低。因此,高压处理提高了该非晶合金的抗均匀腐蚀能力,但同时也降低了其抗点蚀的能力。

REFERENCES

[1] SCHUH C, HUFNAGEI T C, RAMAMRTY U. Mechanical behavior of amorphous alloys[J]. Acta Materialia, 2007, 55(12): 4067-4109.

[2] WU Yuan, XIAO Yue-hua, CHEN Guo-liang, LIU Chain-tsuan, LU Zhao-ping. Bulk metallic glass composites with transformation-mediated work-hardening and ductility[J]. Adv Mater, 2010, 22(25): 2770-2773.

[3] QIN C L, ZHANG W, ZHANG Q S, ASAMI K, INOUE A. Electrochemical properties and surface analysis of Cu-Zr-Ag-Al-Nb bulk metallic glasses[J]. Journal of Alloys and Compounds, 2009, 483(1/2): 317-320.

[4] 李 翔, 严 彪, 董 鹏, 王宇鑫, 杜春风. Fe基非晶合金的晶化及其在NaCl溶液中的电化学腐蚀行为[J]. 中国有色金属学报, 2010, 20(1): 156-162.

LI Xiang, YAN Biao, DONG Peng, WANG Yu-xin, DU Chun-feng. Crystallization and electrochemical corrosion behaviors of amorphous Fe-based alloys in NaCl solution[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(1): 156-162.

[5] ARCHER M D, CORKE C C, HARJI B H. Electrochemical properties of metallic glasses[J]. Electrochim Acta, 1987, 32(1): 13-26.

[6] 刘 兵, 柳 林, 孙 民, 邱春雷, 谌 祺. 微量Cr对Cu基块体非晶合金的形成能力及耐蚀性能的影响[J]. 金属学报, 2005, 41(7): 738-742.

LIU Bing, LIU Lin, SUN Min, QIU Chun-lei, CHEN Qi. Influence of Cr micro-addition on the glass formation ability and corrosion resistance of Cu-based bulk metallic glass[J]. Acta Metallurgica Sinica, 2005, 41(7): 738-742.

[7] PADHY N, NINGSHEN S, KAMACHI MUDALI U. Electrochemical and surface investigation of zirconium based metallic glass Zr59Ti3Cu20Al10Ni8 alloy in nitric acid and sodium chloride media[J]. J Alloys and Compounds, 2010, 503(1): 50-56.

[8] FRANKEL G S, NEWMAN R C, JAHNES C V, RUSSAK M A. On the pitting resistance of sputter-deposited aluminum alloys[J]. J Electrochem Soc, 1993, 140(8): 2192-2197.

[9] PAN Ming-xiang, WANG Jing-guo, YAO Yu-shu, ZHAO De-qian, WANG Wei-hua. Phase transition of Zr41Ti14Cu12.5Ni10Be22.5 bulk amorphous below glass transition temperature under high pressure[J]. Appl Phys Lett, 2001, 78(5): 601-603.

[10] ZHANG H W, ZHOU T J. Pressure effect on the crystallization behavior of Zr46.7Ti8.3Cu7.5Ni10Be27.5 bulk metallic glass[J]. Phys Lett A, 2006, 350(3): 297-301.

[11] INOUE A, ZHANG T, MASUMOTO T. The structural relaxation and glass-transition of La-Al-Ni and Zr-Al-Cu amorphous-alloys with a significant supercooled liquid region[J]. J Non-Cryst Solids, 1992, 150: 396-400.

[12] JIN Hai-jun, WEN Ping, LU Ke. Pressure effect on the structural relaxation and glass transition in metallic glasses[J]. Acta Materialia, 2003, 51: 6219-6231.

[13] JIANG Q K, ZHANG G Q, YANG L, WANG X D, SAKSL K, FRANZ H, WUNDERLICH R, FECHT H, JIANG J Z. La-based bulk metallic glasses with critical diameter up to 30 mm[J]. Acta Mater, 2007, 55: 4409-4418.

[14] RAJU V R, K?HN U, WOLFF U. Corrosion behavior of Zr-based bulk glass-forming alloys containing Nb or Ti[J]. Mater Lett, 2002, 57(20): 173-177.

[15] WANG X F, WU X Q, LIN J G, MA M. The influence of heat treatment on the corrosion behavior of as-spun amorphous Al88Ni6La6 alloy in 0.01 M NaCl solution[J]. Mater Lett, 2007, 61(8/9): 1715-1717.

[16] LIN J G, WANG W W, WU X Q, LEI J H, YIN S. Crystallization and corrosion resistance of as-spun (Al86Ni9La5)98Zr2 amorphous alloy[J]. J Alloys and Compounds, 2009, 478(1/2): 763-766.

(编辑 龙怀中)

基金项目:湖南省科技计划资助项目(2010FJ3132)

收稿日期:2010-11-30;修订日期:2011-03-10

通信作者:万小军,副教授;电话:0737-6353128;E-mail: yhqwxj@163.com