低温烟气余热发电实验系统设计及性能

周乃君1,王晓元1,王志奇1, 2

(1. 中南大学 能源科学与工程学院,湖南 长沙,410083;

2. 湘潭大学 机械工程学院,湖南 湘潭,411105)

摘要:采用R123为工质,以热风炉产生的烟气模拟工业炉排放的烟气作为实验热源,通过设计和搭建基于有机朗肯循环的余热发电系统实验台,研究膨胀机输出功率、系统热效率以及 效率随系统状态参数的变化规律。实验结果表明:膨胀机输出功率随蒸发压力和热源温度的升高而增大,实验条件下的最大输出功率为645 W。系统热效率随工质蒸发压力的升高而增大,最大热效率为8.5%。系统

效率随系统状态参数的变化规律。实验结果表明:膨胀机输出功率随蒸发压力和热源温度的升高而增大,实验条件下的最大输出功率为645 W。系统热效率随工质蒸发压力的升高而增大,最大热效率为8.5%。系统 效率随蒸发压力和热源温度的升高而增大,实验条件下的最大

效率随蒸发压力和热源温度的升高而增大,实验条件下的最大 效率为3.5%。工质过热度的提高不利于提升系统的综合性能。

效率为3.5%。工质过热度的提高不利于提升系统的综合性能。

关键词:低温烟气余热;有机朗肯循环;热力性能实验;发电效率

中图分类号:TK11 文献标志码:A 文章编号:1672-7207(2014)01-0312-05

Experimental system and its performance on power generation equipment for low-temperature exhaust

ZHOU Naijun1, WANG Xiaoyuan1, WANG Zhiqi1, 2

(1. School of Energy Science and Engineering, Central South University, Changsha 410083, China;

2. Institute of Mechanical Engineering, Xiangtan University, Xiangtan 411105, China)

Abstract: An Organic Rankine Cycle (ORC) experimental system for low-temperature flue gas heat recovery was constructed. R123 was selected as the working fluid of the experimental system, and low-temperature flue gas produced by stove was treated as heat source to imitate the flue gas from industrial furnaces. The relationships among output power of expander, cycle efficiency and exergy efficiency and system parameters were researched. The results show that the output power of expander increases with the increase of evaporating pressure and temperature of heat source. The maximum of output power of expander efficiency is 645 W. The cycle efficiency increases with the increase of evaporating pressure and the maximum of cycle efficiency is 8.5%. The exergy efficiency increases with the increase of evaporating pressure and temperature of heat source. The maximum of exergy efficiency is 3.5%. Increase of the superheat degree has a bad influence on system performance.

Key words: waste heat from low-temperature exhaust; Organic Rankine Cycle; thermodynamic performance experiment; power generation efficiency

我国的工业余热资源丰富,各行业的工业余热总量占其燃料消耗总量的17%~67%,可回收利用的余热资源占余热总资源的60%[1]。目前,我国的中高温余热利用技术较为成熟[2-3],而对于中低品位余热的利用仍在技术研究阶段,特别对于节能潜力巨大的低温烟气余热,由于缺乏有效的技术手段没有得到有效利用,使得我国的能源利用效率偏低[4-5]。有机朗肯循环(Organic Rankine Cycle,简称ORC)是一种有效的低品位余热发电技术,具有蒸发压力和冷凝压力较低、设备相对简单等优点。围绕该技术开展相关的研究工作,对改善我国低温余热资源利用技术缺乏的现状具有重要的意义[6-7]。目前,国内外都有对有机朗肯循环技术研究的相关报道。Yamamoto 等[8]通过数值模拟和实验研究对建立的朗肯循环装置进行了研究,比较了采用水或R123作为工质的朗肯循环动力系统的性能,指出有机朗肯循环具有更高的循环性能。Quoilin等[9]对采用涡旋膨胀机的有机朗肯循环系统通过数学建模进行优化研究,并用实验验证了涡旋膨胀机在有机朗肯循环中的优势。Manolakos等[10]对太阳能ORC系统进行了实验研究,膨胀机的效率约为65%,膨胀机的最大输出电能2.05 kW。国内对于有机朗肯循环系统的实验研究较少,其中,王晓东[11]搭建了一个以R245fa为工质,采用8 mm管板式集热器的太阳能朗肯循环系统实验台,研究结果表明,集热器效率在运行中会发生阶跃式突变,且随太阳辐照度的增加而减小,随工质流量的增加而增大。罗琪[12]对利用热水作为低温热源的有机朗肯循环进行了实验研究,得到系统最大效率为3.7%,最大输出电功率为910 W。然而这些研究由于热源种类以及温度的限制,没有能够很好模拟工业中的废弃余热,本文作者在对有机朗肯循环理论研究的基础上,设计了低温烟气余热发电系统实验台,研究了蒸发压力、热源温度以及过热度对系统性能的影响,对基于有机朗肯循环的低温烟气余热利用技术在工程实际中的应用推广具有指导作用。

1 实验系统

1.1 实验系统概述

本文设计并构建的低温烟气余热发电实验台由热源、工质循环回路、冷却水回路以及润滑油循环回路4个部分组成,如图1所示。实验采用R123为循环工质,以热风炉产生的低温烟气为热源,采用整体翅片管式的蒸发器,冷凝器采用水冷却的方式,膨胀机则选用涡旋式膨胀机[13]。

1.2 实验主要设备

整个实验系统设计的输出功率为1 kW。通过设计计算,选用的主要设备如表1所示。

1.3 实验测量设备

本实验中主要的测量参数有温度、压力、流量、烟气的成分以及膨胀机转速等,各个测量点见图1。参数的采集采用XMR5000无纸记录仪。其主要的测量设备如表2所示。

图1 低温烟气余热发电实验系统

Fig. 1 Experimental system of power generation for low-temperature flue gas

表1 低温烟气余热发电系统主要设备

Table 1 Main instruments of power generation system

表2 实验装置的主要测量设备

Table 2 Main measuring equipment in experimental facility

2 实验数据处理

在对整个低温烟气发电系统进行分析时,主要以膨胀机输出功率、系统热效率以及 效率等几个指标来评估系统性能。

效率等几个指标来评估系统性能。

2.1 膨胀机输出功率

实验过程中,由于发电机效率较低,因此没有采用测量得到的电功率作为系统的输出功率,而利用膨胀机进出口参数计算膨胀机的输出功率。其计算公式如下:

(1)

(1)

式中:mf为工质的质量流量,kg/s;h3和h4分别为膨胀机进、出口的比焓,kJ/kg。

2.2 系统热效率

(2)

(2)

式中:Qe为烟气传给工质的热量,kJ/s;mg为低温烟气的质量流量,kg/s;cp为低温烟气的比定压热容,kJ/(kg·K);

2.3  效率

效率

(3)

(3)

式中:Eg为烟气中的有效能,kJ。

3 实验结果及分析

3.1 膨胀机输出功率的实验结果

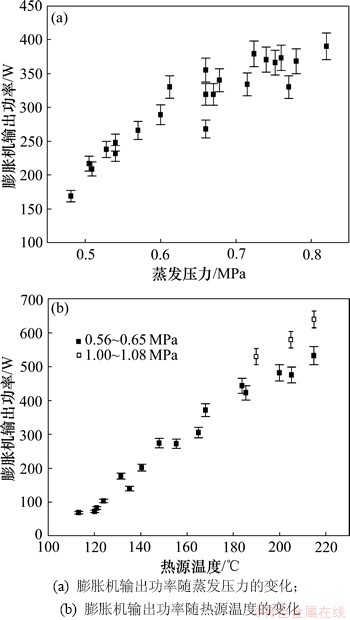

图2所示为膨胀机输出功率随系统蒸发压力和热源温度的变化规律。图2(a)所示为热源温度在164~ 168 ℃之间时,膨胀机输出功率随系统蒸发压力的变化规律。由图2(a)可以看出:实验系统的最大输出功率为392 W。虽然发电量较小,但这仅是初步的实验结果,可起到验证低温烟气余热发电的目的。图2(b)表明:膨胀机输出功率随着热源温度的升高而增大。在蒸发压力为0.56~0.65 MPa、热源温度为215 ℃时,实验装置的最大发电量为532 W;当蒸发压力提升到1.00~1.08 MPa时,系统的输出功率将进一步提高,最大输出功率为645 W。

图2 膨胀机输出功率的实验结果

Fig. 2 Results of output power of expander

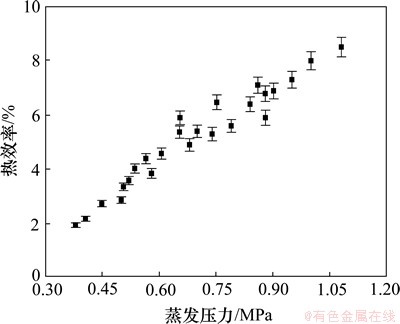

3.2 系统热效率的实验结果

图3所示为系统热效率的实验结果。由图3可见:当热源温度一定时,系统热效率随着蒸发压力的升高而增大。其最高热效率为8.5%,与相同工况下的理论结果相比,效率明显偏低,其原因主要是由于循环中膨胀机的效率偏低。由于此膨胀机是由7.5 kW的涡旋式压缩机改造而成,据分析,其效率仅为57%。若按膨胀机效率80%来推算,则循环热效率为11.9%。

3.3 系统 效率的实验结果

效率的实验结果

图4(a)所示为热源温度在164~168 ℃之间时,系统的 效率随蒸发压力的变化规律。根据

效率随蒸发压力的变化规律。根据 效率的定义式(3)可知:当系统中热源的

效率的定义式(3)可知:当系统中热源的 值变化较小时,

值变化较小时, 效率将随膨胀机输出功率的变化而变化。在该实验条件下,系统的最大

效率将随膨胀机输出功率的变化而变化。在该实验条件下,系统的最大 效率为3.5%,

效率为3.5%, 效率较低表明实验系统还需进一步的改进。图4(b)所示为当蒸发压力在0.56~0.65 MPa之间时,系统的

效率较低表明实验系统还需进一步的改进。图4(b)所示为当蒸发压力在0.56~0.65 MPa之间时,系统的 效率随热源温度的变化规律。随着热源温度的升高,热源中的有用能增大。由图4(b)可见:随着热源温度的升高,系统的

效率随热源温度的变化规律。随着热源温度的升高,热源中的有用能增大。由图4(b)可见:随着热源温度的升高,系统的 效率也逐渐提高。这主要是由于系统输出功率随着热源温度一同升高,且增长幅度大于烟气中有用能的增长幅度。

效率也逐渐提高。这主要是由于系统输出功率随着热源温度一同升高,且增长幅度大于烟气中有用能的增长幅度。

图3 系统热效率的实验结果

Fig. 3 Results of cycle efficiency

当热源温度为162~165 ℃,蒸发压力为0.44~0.46 MPa时,过热度对系统性能的影响如图5所示。

图4 系统 效率的实验结果

效率的实验结果

Fig. 4 Results of exergy efficiency

图5 过热度对系统性能的影响

Fig.5 Relationship between system performance and superheat degree

由图5可见:随着工质过热度的提高,输出功率、循环热效率和 效率都有不同程度的下降,这与理论分析结果一致[14-15]。

效率都有不同程度的下降,这与理论分析结果一致[14-15]。

根据过热度对系统性能的影响可知:实际工程应用中在保证系统安全、稳定运行的前提上,应适当控制工质进入膨胀机时的过热度,以提高系统的综合性能。

4 结论

(1) 膨胀机输出功率随着工质蒸发压力和热源温度的升高而增大,实验系统获得的最大输出功率为645 W。

(2) 系统热效率随着蒸发压力的升高而增大,实验系统循环的最大热效率为8.5%。系统 效率随着工质蒸发压力和热源温度的升高而增大,在实验条件下,系统的最大

效率随着工质蒸发压力和热源温度的升高而增大,在实验条件下,系统的最大 效率为3.5%。

效率为3.5%。

(3) 随着工质过热度的提高,输出功率、循环热效率和 效率有所下降,这是系统设计时需要注意的。

效率有所下降,这是系统设计时需要注意的。

参考文献:

[1] 周耘, 王康, 陈思明. 工业余热利用现状及技术展望[J]. 科技情报开发与经济, 2010, 20(23): 162-164.

ZHOU Yun, WANG Kang, CHEN Siming. The present utilization and the technical prospect of industrial waste Heat[J]. Sci-Tech Information Development & Economy, 2010, 20(23): 162-164.

[2] 赵钦新, 王宇峰, 王学斌, 等. 我国余热利用现状与技术进展[J]. 工业锅炉, 2009(5): 8-15.

ZHAO Qinxin, WANG Yufeng, WANG Xuebin, et al. Technical advances & status of China’s waste heat utilization[J]. Industrial Boiler, 2009(5): 8-15.

[3] 连红奎, 李艳, 束光阳子, 等. 我国工业余热回收利用技术综述[J]. 节能技术, 2011, 29(2): 123-128.

LIAN Hongkui, LI Yan, SHU Guangyangzi, et al. An overview of domestic technologies for waste heat utilization[J]. Energy Conservation Technology, 2011, 29(2): 123-128.

[4] 孟嘉. 工业烟气余热回收利用方案优化研究[D]. 武汉: 华中科技大学能源与动力工程学院, 2008: 1-8.

MENG Jia. The optimization research for recovery and utilization program of waste heat in industrial flue gas[D]. Wuhan: Huazhong University of Science and Technology. School of Energy and Power Engineering, 2008: 1-8.

[5] Hettiarachchia H D M, Golubovica M, Woreka W M, et al. Optimum design criteria for an Organic Rankine cycle using low-temperature geothermal heat sources[J]. Energy, 2007, 32(9): 1698-1706.

[6] Gu W, Weng Y, Wang Y, et al. Theoretical and experimental investigation of an Organic Rankine Cycle for waste heat recovery system[J]. Journal of Power and Energy, 2009, 223(5): 523-533.

[7] 顾伟, 孙绍芹, 翁一武, 等. 采用涡旋膨胀机的低品位热能有机物朗肯循环发电系统实验研究[J]. 中国电机工程学报, 2011, 31(11): 20-25.

GU Wei, SUN Shaoqin, WENG Yiwu, et al. Experimental study on low grade heat driven Organic Rankine Cycle by scroll expander[J]. Proceedings of the CSEE, 2011, 31(11): 20-25.

[8] Yamamoto T, Furuhata T, Arai N, et al. Design and testing of the Organic Rankine Cycle[J]. Energy, 2001, 26(3): 239-251.

[9] Quoilin S, Lemort V, Lebrun J. Experimental study and modeling of an Organic Rankine Cycle using scroll expander[J]. Applied Energy, 2010, 87(4): 1260-1268.

[10] Manolakos D, Papadakis G, Kyritsis S, et al. Experimental evaluation of an autonomous low-temperature solar Rankine Cycle system for reverse osmosis desalination[J]. Desalination, 2007, 203(1/3): 366-374.

[11] 王晓东. 太阳能低温朗肯循环系统适用工质的理论和实验研究[D]. 天津: 天津大学机械工程学院, 2008: 32-49.

WANG Xiaodong. Theoretical and experimental investigation on the working fluids for low temperature solar Rankine Cycle system[D]. Tianjin: Tianjin University. School of Mechanical Engineering, 2008: 32-49.

[12] 罗琪. 中低温热源有机物工质发电系统分析[D]. 上海: 上海交通大学机械与动力工程学院, 2010: 46-60.

LUO Qi. Analysis of power generation system based on Organic Rankine Cycles driven by low-grade heat[D]. Shanghai: Shanghai Jiaotong University. School of Mechanical and Power Engineering, 2010: 46-60.

[13] Lemort V, Quoilin S, Cuevas C, et al. Testing and modeling a scroll expander integrated into an Organic Rankine Cycle[J]. Applied Thermal Engineering, 2009, 29(14): 3094-3102.

[14] Hung T C, Shai T Y, Wang S K. A review of Organic Rankine Cycles (ORC) for the recovery of low-grade waste heat[J]. Energy, 1997, 22(7): 661-667.

[15] Dai Y, Wang J, Gao L. Parametric optimization and comparative study of Organic Rankine Cycle (ORC) for low grade waste heat recovery[J]. Energy Conversion and Management, 2009, 50(3): 576-582.

(编辑 杨幼平)

收稿日期:2012-10-27;修回日期:2013-01-11

基金项目:湖南省科技计划重点项目(2009GK2009);湖南省教育厅一般项目(12C0379)

通信作者:周乃君(1963-),男,湖南临澧人,教授,博士生导师,从事工业节能技术研究;电话:13973160806;E-mail: njzhou@csu.edu.cn