文章编号:1004-0609(2016)-04-0844-08

梯度微纳米复合陶瓷刀具材料的力学性能和微观结构

郑光明1,赵 军2,程 祥1,徐汝锋1,李 丽1

(1. 山东理工大学 机械工程学院,淄博255000;

2. 山东大学 机械工程学院,济南250061)

摘 要:针对高速切削航空难加工材料镍基高温合金时对高性能刀具的迫切需求,采用热压烧结工艺,制备sialon梯度微纳米复合陶瓷刀具材料,研究烧结温度、保温时间、梯度层数对刀具材料力学性能及显微组织的影响。利用X射线衍射仪分析材料的物相组成,通过扫描电子显微镜和透射电子显微镜对微观形貌进行分析。结果表明:在1750 ℃烧结、压力35 MPa、保温60 min的条件下,成功合成了β-sialon。具有7层梯度结构的刀具材料在此工艺条件下可获得最优的力学性能:抗弯强度σf =840 MPa,表层维氏硬度HV为17.32 GPa,表层断裂韧性KIC = 8.96 MPa×m1/2,表层残余应力σr=-423 MPa,满足刀具材料的使用要求。微纳米颗粒的同时加入和合理的梯度结构是获得较高力学性能的主要原因。

关键词:微纳米复合;残余应力;梯度陶瓷刀具;热压烧结;力学性能

中图分类号:TQ174 文献标志码:A

梯度功能材料(Functionally graded material, FGM)是一种非均质类的复合材料,材料成分和微观结构呈现阶梯状或连续的变化[1]。FGM已经在航天飞机、武器装备、切削刀具、生物医学移植等领域得到推广和应用[2-4]。其中,在陶瓷刀具材料的设计和制备过程中引入FGM的概念,可为刀具材料热-力学性能的提高提供一种有效的工具。

近年来,针对淬火钢、高强钢、高温合金等航空难加工材料,相继研制了Al2O3 /(W,Ti)C、Al2O3 /TiCN、Al2O3/TiC/CaF2、Si3N4/TiCN、Si3N4/(W,Ti)C /Co等梯度陶瓷刀具材料[5-9],并对其力学性能和切削性能进行了分析。研究发现:与均质陶瓷刀具材料相比,梯度陶瓷刀具材料拥有更高的韧性和抗热震性[10];在高速切削难加工材料时,梯度刀具表现出更好的切削性能和耐磨性能[11]。可见,在高速切削时,梯度刀具更具有切削优势。

镍基合金是高温强度最高、应用最广的一类高温合金[12-13],常选用综合力学性能优越的sialon基陶瓷刀具对其进行高速加工[14-15]。随着梯度刀具材料的研究日趋深入,将不同性能材料进行梯度复合成为其发展方向之一。根据FGM的概念,利用α-sialon和β-sialon性能差异,制备表层为α-sialon材料、里层嵌入β-sialon材料的梯度陶瓷材料[16],发现材料整体的力学性能提高显著,可用作刀具材料或制作耐磨零部件等。随着梯度层数的增加,梯度sialon陶瓷材料的各向应力有减小的趋势[17]。研究还发现,叠层法可根据需求控制梯度层厚度,是一种制备梯度材料的有效方法[16]。

因此,本文作者针对航空镍基高温合金的高速切削特征,提出将硬度和耐磨性较高的sialon材料作为表层,将强度和韧性较好的Si3N4材料作为中间层,将微纳米复合与组分梯度分布相结合,研制新型的梯度刀具材料,有望在高速切削中得到应用。

1 实验

1.1 材料设计

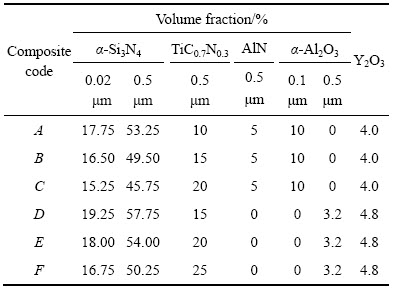

表1所列为微纳米复合材料的成分。本材料体系利用了Si3N4、Al2O3和AlN进行高温固相反应合成β-sialon。

实验选用中位粒径为0.02 μm的α-Si3N4颗粒(纯度99%(质量分数))和0.5 μm的α-Si3N4颗粒(纯度99%),中位粒径为0.1 μm的α-Al2O3颗粒(纯度99.6%)和0.5 μm的α-Al2O3颗粒(纯度99.9%),中位粒径为0.5 μm的AlN颗粒(纯度99%)。中位粒径为0.5 μm的TiC0.7N0.3颗粒(纯度99%)作为增强相,选用分析纯Y2O3作为烧结助剂。

TiC0.7N0.3具有较高的断裂强度和抗氧化性能,以及较高的导热系数和热膨胀系数。适量地添加TiC0.7N0.3和合理的组分设计,在有效地提高陶瓷刀具材料抗弯强度的同时,热压烧结后可使刀具材料表面形成压应力,有利于刀具表面硬度的提高,从而提高其耐磨性。

梯度材料选用对称型结构形式,总厚度为h=4 mm,借鉴课题组前期研究成果[5,7],设计相邻层间的厚度比为0.3。以获得高的力学性能和高的表层压应力为目标,设计了不同层数的梯度陶瓷材料,分别为S-1、S-3、S-5、S-7,如图1所示。

表1 微纳米复合材料的组成

Table 1 Composition of micro-nano-composites

图1 不同层数的梯度陶瓷材料

Fig. 1 Graded ceramic material with different layer numbers

1.2 材料制备

根据表1中的微纳米复合材料的组成,分别选用聚乙二醇(分子量为4000)和无水乙醇作为分散剂和分散介质对纳米颗粒进行分散。纳米α-Si3N4颗粒分散时分散剂加入量为纳米颗粒质量的0.5%,而纳米α-Al2O3颗粒分散时此值为1.5%。

采用超声振动结合机械搅拌(15 min)的方法制备微纳米悬浮液,将装入悬浮液的混料桶放在球磨机上球磨48 h后,取出放入ZK-40型真空干燥箱中烘干,然后过筛、封装待用。

根据图1中的设计,利用叠层法逐层填充,在ZRC85-25T型多功能高温热压烧结炉中真空烧结。受石墨模具高温强度的制约,本研究固定烧结压力为35 MPa。

1.3 性能测试

采用J5060E1型自动内圆切片机将烧结成的陶瓷圆饼(d 42 mm×4.2 mm)切割成试条,经研磨抛光后制成3 mm×4 mm×30 mm的试样。材料抗弯强度测量采用三点弯曲法,在WDW-50E型万能实验机上进行,选择20 mm的跨距,采用0.5 mm/min的加载速率,沿垂直于梯度层的方向加载。材料表层硬度和断裂韧性的测量采用压痕法,在HV-120型Vickers硬度计上对梯度材料表层进行测量,选择196 N的加载载荷,保持15 s。

陶瓷材料表面残余应力的测量采用压痕裂纹法[18-20]。如果在材料表面存在残余应力,断裂韧性与载荷大小、裂纹长度和应力大小有关[18-20]:

KIC=Xpl1-3/2 + Yσrl11/2 (1)

式中:KIC为材料断裂韧性;X为无量纲常数(对于陶瓷材料大约为0.016(E/HV)1/2,E为弹性模量,可通过物性参数计算获得,HV为材料硬度);p为加载载荷;l1为材料表面压痕裂纹长度;Y为裂纹几何因子(对于半圆形表面裂纹约为1.26)[19];σr为材料表面残余应力。

根据压痕法获得材料表面硬度HV、断裂韧性KIC、压痕裂纹长度l1,通过式(1)可以计算表层残余应力σr。

采用阿基米德排水法,选用GH-300C型密度计测量试样体积密度。借助简单混合法,计算整个材料的理论平均体积密度[5],从而得到材料的相对密度。

选用D/max-rB型X射线衍射仪(XRD)分析试样的物相组成,采用JSM-6380LA型数字化扫描电子显微镜(SEM)和Hitachi H-800 型透射电子显微镜(TEM)分析材料的显微结构。

由于刀具表层硬度及应力对其耐磨性产生重要影响[21],对于非均质的梯度结构材料,本文作者主要对其表层的硬度、韧性和应力、整体强度,以及微观结构进行检测与分析。

2 结果与讨论

2.1 物相分析

对S-1材料的初始粉末和S-5材料烧结样品的表层进行XRD分析,其结果如图2所示。由图2(a)可见,S-1初始粉末中Si3N4和Al2O3均为α相,碳氮化钛粉末中C与N的摩尔比为0.7:0.3。S-5材料经过1750 ℃和35 MPa条件烧结60 min后,表层材料主相变为Si4Al2O2N6和TiC0.7N0.3,表明在此烧结条件下,Si3N4、Al2O3和AlN间发生了化学反应(4Si3N4+2Al2O3+ 2AlN=3Si4Al2O2N6),生成了β-sialon相,与设计要求相一致。

图2 1750 ℃、35 MPa条件下烧结60 min S-1初始粉末和S-5烧结样品表层XRD谱

Fig. 2 XRD patterns of initial powder of S-1(a) and surface layer of S-5(b) sintered at 1750 ℃ and 35 MPa for 60 min

2.2 烧结温度

图3所示为烧结温度对S-5性能的影响。不同烧结温度的S-5材料表层断口微观形貌如图4所示,材料经过了400 ℃熔融的NaOH腐蚀1 min的处理。

图3 35 MPa下烧结60 min烧结温度对S-5抗弯强度、维氏硬度、断裂韧性和残余应力的影响

Fig. 3 Effect of sintering temperature on flexural strength and Vicker’s hardness(a) and fracture toughness and residual stress(b) of S-5 sintered at 35 MPa for 60 min

结合图3和4可见,烧结温度较低时(1650 ℃),由于所提供的材料烧结动力不足,使得晶粒生长不完全,表现为晶粒细小(见图4(a)),相对密度较低(95.27%),致使强度和韧性较低(见图3)。随着烧结温度的升高,材料各组分烧结充分,相对密度较高(98.88%),表明各组成相间界面结合紧密,可获得较高的力学性能。但当烧结温度过高时(1800 ℃),相对密度反而较低(94.19%),从图4(b)可见,晶粒粗化严重,个别晶粒出现异常长大情况,致使强度和硬度降低(见图3)。

另外,由于TiC0.7N0.3的含量由表及里逐层增大,在制备的冷却过程中,S-5材料表层形成了残余压应力(见图3),在1750 ℃烧结时获得的应力绝对值最大。因此,此材料体系在1750 ℃烧结时获得较高的综合力学性能。

图4 35 MPa下烧结60 min不同烧结温度的S-5表层断口微观形貌

Fig. 4 Fracture microphologies of surface layer of S-5 at 1650 ℃(a) and 1800 ℃(b) under 35 MPa for 60 min

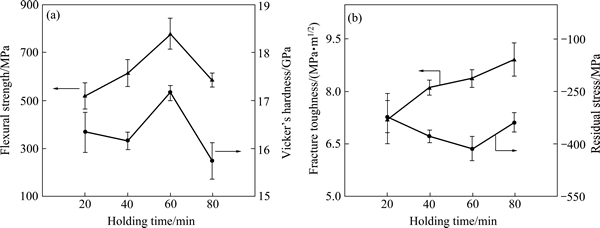

2.3 保温时间

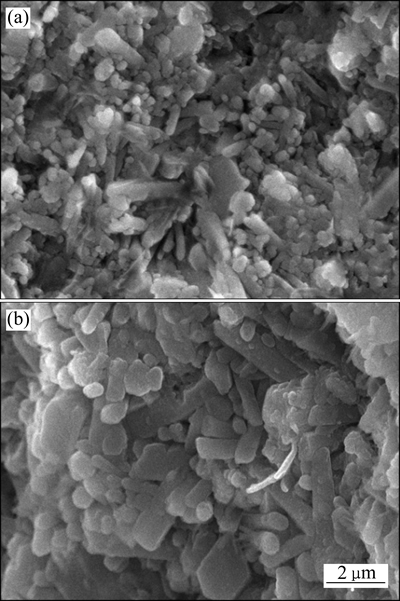

图5所示为保温时间对S-5性能的影响。不同保温时间的S-5材料表层断面微观形貌如图6所示。由图5可见,材料强度和表层残余应力绝对值随着保温时间的延长,先升高后降低,保温时间为60 min时取得较高值。表层维氏硬度和断裂韧性分别在60 min和80 min取得较大值。

在保温时间较短时(20 min),明显发现分布比较均匀的细针状的β-sialon晶粒(见图6(a)),这主要是由于晶粒没有足够的时间长大,致使生长不充分、各组织结构烧结不足,材料相对密度较低(95.89%),从而导致材料的力学性能较低(见图5)。随着保温时间的延长(60 min),各组成元素扩散加剧,材料烧结良好,相对密度较高(98.88%)。由于纳米和亚微米初始颗粒的同时加入,热压烧结后生成了不同尺寸的β-sialon晶粒。当保温时间延长到60 min时,发现在大的β-sialon晶粒中镶嵌着许多小的β-sialon晶粒,呈现纵横交错的结构,增加了烧结驱动力,提高了材料性能。由以上分析可见,在保温时间为60 min时,此材料体系可获得较高的综合力学性能。

图5 1750 ℃、35 MPa时烧结时保温时间对S-5抗弯强度、维氏硬度、断裂韧性和残余应力的影响

Fig. 5 Effect of holding time on flexural strength and Vicker’s hardness(a), fracture toughness and residual stress(b) of S-5 sintered at 1750 ℃ under 35 MPa

图6 1750 ℃、35 MPa下不同保温时间的S-5表层断口微观形貌

Fig. 6 Fracture micrographs of surface layer of S-5 at 1750 ℃ under 35 MPa for 20 min(a) and 60 min(b)

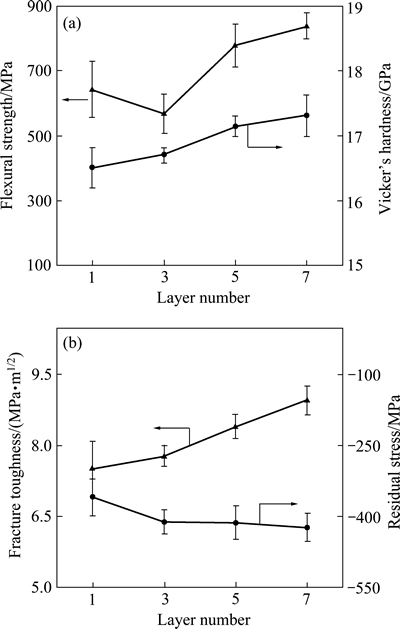

2.4 梯度层数

根据图1的设计,制备不同层数的梯度陶瓷材料,梯度层数对材料性能的影响如图7所示。S-7材料表层为sialon基材料,其厚度较小,硬度较高;里层为Si3N4基材料,其强度较高,对整体的强度提高起着主导作用,故S-7材料的抗弯强度较高。

梯度陶瓷材料硬度和断裂韧性主要受组成、结构及残余应力大小及分布的影响[5]。各梯度材料表层成分相同,由于各梯度层之间的热胀失配,使得层与层之间产生不同的应力,由图7可见,表层残余压应力值随着层数的增加有减小的趋势,从而导致表层材料硬度和韧性的提高。由于S-5和S-7两种材料第二层组分也相同,对表层的应力作用相差不大,故随着层数的继续增加,表层残余压应力值减小趋势变缓。由于组成分布及显微结构沿梯度方向的阶梯变化,表层维氏硬度和断裂韧性继续提高除了受应力影响以外,还与材料梯度结构(层厚、层数)的变化有关。

图8(a)所示为S-7材料表层断口微观形貌。由图8(a)可见,S-7表层断口同样观察到生长充分的长柱状晶粒,展现出纵横交叉的微观结构,与S-5的微观结构相一致。其相对密度达到99.01%,与S-5材料相差不大。由此可见,S-7的性能在S-5性能的基础上进一步提高主要是由梯度层数的增加引起的。

2.5 增韧补强机理

图8(b)和(c)所示为S-7表层微观结构的TEM像,图9(a)和(b)所示分别为白色区域(图8(b)中区域A)和黑色区域(图8(b)中区域B)的物相电子衍射图。由图9可见,白色晶粒为β-sialon,黑色晶粒为TiC0.7N0.3。

图7 1750 ℃、35 MPa烧结60 min时梯度层数对陶瓷材料抗弯强度、维氏硬度、断裂韧性和残余应力的影响

Fig. 7 Effect of layer number on flexural strength and Vicker’s hardness(a), fracture toughness and residual stress(b) of ceramic material sintered at 1750 ℃ under 35 MPa for 60 min

由图8(c)可见,β-sialon晶粒和TiC0.7N0.3晶粒接触界面比较光滑,界面结合良好(区域C)。TiC0.7N0.3晶粒处于β-sialon晶粒的内部(区域D)或边界处(区域E),形成了明显的晶内-晶间混合型的微观结构。其中,内晶型的TiC0.7N0.3颗粒的形状为类圆形,其晶粒直径在200 nm以内。

由于增强相颗粒的热膨胀系数和弹性模量都分别高于基体的热膨胀系数和弹性模量,在烧结的冷却过程中在材料内部产生残余热应力,其中TiC0.7N0.3颗粒易处于拉应力状态,β-sialon晶粒径向处于拉应力状态,切向处于压应力状态。当界面结合处的局部应力值足够大时,致使晶粒滑移面开始滑移并逐渐扩展到晶粒内部,从而形成如图8(b)所示的位错结构。当裂纹延伸至位错区域时,可通过自身的变形吸收部分断裂能,对裂纹起到“钉扎”的作用,从而提高材料的强度和韧度。

图8 1750 ℃、35 MPa烧结60 min后S-7材料表层SEM和TEM微观形貌

Fig. 8 Micrographs of surface layer of S-7 sintered at 1750 ℃ under 35 MPa for 60 min

综上所述,本研究采用7层结构设计的微纳米复合陶瓷刀具材料获得最优的力学性能:σf =840 MPa,HV=17.32 GPa,KIC=8.96 MPa×m1/2,σr =-423 MPa。另外,在相同烧结工艺条件下均质材料S-1的力学性能(见图7):σf =645 MPa,HV=16.59 GPa,KIC=7.80 MPa×m1/2,σr =-359 MPa。对比可见,合理梯度结构构建可显著提高材料力学性能。

微纳米颗粒的同时加入,使得材料呈现长柱状颗粒纵横交错的微观结构,增加了烧结驱动力,有利于材料力学性能的提高。合理的梯度结构设计,在表层引入了残余压应力,在高速切削时,这种压应力可以抵消部分切削抗力和摩擦力,从而提高刀具的抗摩擦磨损性能。而在断续切削时,这种残余压应力可以抵抗部分周期性的热载荷和机械载荷冲击,提高刀具的抗热冲击能力。

图9 S-7表层材料的物相电子衍射图

Fig. 9 Electron diffraction patterns of TiC0.7N0.3 phase [411](a) and β-sialon phase [001](b)

3 结论

1) 在1750 ℃、35 MPa烧结60 min的条件下烧结,具有7层梯度结构的刀具材料获得最优的力学性能: σf =840 MPa,HV=17.32 GPa,KIC =8.96 MPa×m1/2,σr =-423 MPa,满足刀具材料的使用要求。

2) 微纳米颗粒的同时加入,形成纵横交错的微观结构,增加材料烧结驱动力,有利于材料力学性能的提高;梯度结构的合理设计,在表层引入了残余压应力,提高刀具材料的耐磨性和抗热冲击能力。

3) 材料呈现晶内-晶间混合型的微观结构,其中位错结构的形成,可吸收部分断裂能,也有利于材料强度和韧性的提高。

4) Sialon梯度微纳米复合陶瓷刀具模型的建立,丰富了梯度刀具的种类,有望在高速/超高速切削难加工材料中得到推广和应用。

REFERENCES

[1] LOW I M. Ceramic matrix composites: microstructure, properties and applications[M]. Cambridge: Woodhead Publishing Limited, 2006: 575-596.

[2] QIAN Ting-ting, LIU Dong, TIAN Xiang-jun, LIU Chang-meng, WANG Hua-ming. Microstructure of TA2/TA15 graded structural material by laser additive manufacturing process[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(9): 2729-2736.

[3] HUSSAIN M A, MAQBOOL A, KHALID F A, BAKHSH N, HUSSAIN A, RAHMAN J U, PARK J K, PARK T G, HYUN L J, KIM M H. Mechanical properties of CNT reinforced hybrid functionally graded materials for bioimplants[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(S1): s90-s98.

[4] 苏 斌, 严红革, 陈吉华, 陈 刚, 杜嘉庆. 硅含量对喷射沉积 SiCp/Al-Si 功能梯度复合材料摩擦磨损性能的影响[J]. 中国有色金属学报, 2013, 23(1): 201-211.

SU Bin, YAN Hong-ge, CHEN Ji-hua, CHEN Gang, DU Jia-qing. Effect of silicon content of substrate on wear properties of spray-deposited SiCp/Al-Si functionally gradient composites[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(1): 201-211.

[5] 赵 军. 新型梯度功能陶瓷刀具材料的设计制造及其切削性能研究[M]. 北京:高等教育出版社, 2005: 71-125.

ZHAO Jun. Design and fabrication of functionally gradient ceramic tool materials and their cutting performance [M]. Beijing: Higher Education Press, 2005: 71-125.

[6] GAO Zhong-jun, ZHAO Jun, ZHENG Guang-ming. Processing and characterization of an Al2O3 /TiCN micro-nano-composite graded ceramic tool material[J]. Key Engineering Materials, 2012, 499: 132-137.

[7] ZHENG Guang-ming, ZHAO Jun, ZHOU Yong-hui, GAO Zhong-jun, CUI Xiaobin, LI An-hai. Fabrication and characterization of Sialon-Si3N4 graded nano-composite ceramic tool materials[J]. Composites Part B, 2011, 42(7): 1813-1820.

[8] TIAN Xian-hua, ZHAO Jun, WANG Yin-tao, GONG Feng, QIN Wen-zhen, PAN He-lin. Fabrication and mechanical properties of Si3N4/(W,Ti)C/Co graded nano-composite ceramic tool materials[J]. Ceramics International, 2015, 41(3): 3381-3389.

[9] XU Chong-hai, XIAO Guang-xiao, ZHANG Yong-lian, FANG Bin. Finite element design and fabrication of Al2O3/TiC/CaF2 gradient self-lubricating ceramic tool material[J]. Ceramics International, 2014, 40: 10971-10983.

[10] 董 颖. 梯度陶瓷刀具材料抗机械冲击与抗热冲击性能研究[D]. 济南: 山东大学, 2014: 33-42.

DONG Ying. Mechanical impact and thermal shock resistance of graded composite ceramic tools materials[D]. Jinan: Shandong University, 2014: 33-42.

[11] ZHENG Guang-ming, ZHAO Jun, ZHOU Yong-hui. Friction and wear behaviors of Sialon–Si3N4 graded nano-composite ceramic materials in sliding wear tests and in cutting processes[J]. Wear, 2012, 190/191: 41-50.

[12] 敖三三, 罗 震, 单 平, 步贤政, 刘为东. Inconel 601 镍基高温合金激光焊焊缝的显微组织[J]. 中国有色金属学报, 2015, 25(8): 2099-2107.

AO San-san, LUO Zhen, SHAN Ping, BU Xian-zheng, LIU Wei-dong. Microstructure of Inconel 601 nickel-based superalloy laser welded joint[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(8): 2099-2107.

[13] 谢 君, 于金江, 孙晓峰, 金 涛. 含铪高钨 K416B 镍基铸造高温合金的组织与蠕变行为[J]. 中国有色金属学报, 2015, 25(6): 1490-1497.

XIE Jun, YU Jin-jiang, SUN Xiao-feng, JIN Tao. Microstructure and creep behavior of Hf-containing K416B as-cast Ni-based superalloy with high W content[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(6): 1490-1497.

[14] VAGNORIUS Z,  . Effect of high-pressure cooling on life of SiAlON tools in machining of Inconel 718[J]. The International Journal of Advanced Manufacturing Technology, 2011, 54(1/4): 83-92.

. Effect of high-pressure cooling on life of SiAlON tools in machining of Inconel 718[J]. The International Journal of Advanced Manufacturing Technology, 2011, 54(1/4): 83-92.

[15] ZHENG Guang-ming, ZHAO Jun, SONG Xin-yu, CAO Qing-yuan. Ultra high speed turning of Inconel 718 with Sialon ceramic tools[J]. Advanced Materials Research, 2010, 126/128: 653-657.

[16]  , KARA F, MANDAL H. Functionally graded SiAlON ceramics[J]. Journal of the European Ceramic Society, 2004, 24(12): 3387-3393.

, KARA F, MANDAL H. Functionally graded SiAlON ceramics[J]. Journal of the European Ceramic Society, 2004, 24(12): 3387-3393.

[17] CAROLINE S L, AHN S H, DEJONGHE L C, THOMAS G. Effect of functionally graded material (FGM) layers on the residual stress of polytypoidally joined Si3N4-Al2O3[J]. Materials Science and Engineering A, 2006, 434(1/2): 160-165.

[18] PORTU D G, MICELE L, PEZZOTTI G. Laminated ceramic structures from oxide systems[J]. Composites Part B, 2006, 37(6): 556-567.

[19] CAI P Z, GREEN D J, MESSING G L. Mechanical characterization of Al2O3/ZrO2 Hybrid Laminates[J]. Journal of the European Ceramic Society, 1998; 18 (14): 2025-2034.

[20] 员冬玲, 邓建新, 段振兴. Al2O3-(W,Ti)C/Al2O3-TiC对称型叠层陶瓷的结构设计和力学性能[J]. 硅酸盐学报, 2008, 36(8): 1148-1152.

YUN Dong-ling, DENG Jian-xin, DUAN Zhen-xing. Structural desing and mechanical properties of Al2O3-(W,Ti)C/Al2O3-TiC symmetric laminated ceramic materials[J]. Journal of the Chinese Ceramic Socirty, 2008, 36(8): 1148-1152.

[21] DENG Jian-xin, Duan Zhen-xiong, Yun Dong-ling, ZHANG Hui, AI Xing, ZHAO Jun. Fabrication and performance of Al2O3/(W, Ti)C+Al2O3/TiC multilayered ceramic cutting tools[J]. Materials Science and Engineering A, 2010, 527(4/5): 1039-1047.

Mechanical properties and microstructure of graded micro-nano-composite ceramic tool material

ZHENG Guang-ming1, ZHAO Jun2, CHENG Xiang1, XU Ru-feng1, LI Li1

(1. School of Mechanical Engineering, Shandong University of Technology, Zibo 255000, China;

2. School of Mechanical Engineering, Shandong University, Ji’nan 250061, China)

Abstract: In view of the urgent need for high-performance tools when high-speed machining aviation difficult-to-cut material nickel-based super alloy, a sialon graded micro-nano-composite ceramic tool material was prepared by hot-pressing sintering. The effects of sintering temperature, holding time and layer number on the mechanical properties and microstructure of the tool material were investigated. The phase identification was carried out by X-ray diffraction (XRD), and the fracture surface microstructure of the composites was characterized by scanning electron microscopy (SEM) and transmission electron microscopy (TEM). The results show that β-sialon phase is formed at 1750 ℃ and 35 MPa for 60 min. The optimum mechanical properties of the ceramic material with 7 layer numbers are gotten: a flexural strength σf is 840 MPa, a surface layer Vickers hardness HV is 17.32 GPa, a surface layer fracture toughness KIC is 8.96 MPa×m1/2, a surface layer residual stress σr is -423 MPa, which meet the requirements for cutting tool materials. The high properties can be attributed to the addition of micro and nano grains and the suitable graded structure.

Key words: micro-nano-composite; residual stress; graded ceramic tool; hot-pressing; mechanical property

Foundation item: Projects(51505264, 51475273) supported by the National Natural Science Foundation of China; Project(BS2014ZZ005) supported by the Scientific Research Foundation for Outstanding Youth Scientists of Shandong Province of China; Project supported by the Youth Teacher Development Support Program of Shandong University of Technology

Received date: 2015-01-21; Accepted date: 2015-10-26

Corresponding author: ZHENG Guang-ming; Tel: +86-15966961938; E-mail: zhengguangming@sdut.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51505264,51475273);山东省优秀中青年科学家科研奖励基金资助项目(BS2014ZZ005);山东理工大学青年教师发展支持计划项目

收稿日期:2015-01-21;修订日期:2015-10-26

通信作者:郑光明,讲师,博士;电话:15966961938;E-mail: zhengguangming@sdut.edu.cn