液压打桩锤主控阀换向性能的动态特性分析

胡均平,郭勇,张政华,刘成沛,代建龙

(中南大学 机电工程学院,湖南 长沙,410083)

摘要:为满足液压打桩锤高频工作下对换向快速性的要求,设计采用主控阀控制的快速换向柔性冲击系统。该阀通过4个控制口压力的变化控制阀芯的运动,通过内部反馈油孔实现对换向状态的记忆。根据主控阀换向工作基本原理,建立主控阀换向过程的动态数学模型,采用Stateflow处理换向过程的状态转换结合Simulink建立换向过程的仿真模型。结合实验的相关参数对主控阀换向过程进行仿真分析,仿真得到的换向所需时间和实验结果基本一致。利用仿真模型,分析内腔直径,内部反馈孔直径和长度以及弹簧刚度4个主要因素对主控阀换向性能的影响。研究结果表明:主控阀内腔直径对主控阀换向快速性的影响最大,内部反馈油孔直径和长度次之,弹簧刚度影响最小。

关键词:液压打桩锤;主控阀;换向性能;打桩;Stateflow

中图分类号:U415.5 文献标志码:A 文章编号:1672-7207(2012)07-2622-07

Dynamic analysis of main control valve reversing performance for hydraulic pile hammer

HU Jun-ping, GUO Yong, ZHANG Zheng-hua, LIU Cheng-pei, DAI Jian-long

(School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China)

Abstract: To make hydraulic pile hammer work at high frequencies when control system rapidly reverses, the main control valve was designed to realize the flexible control of the system with rapid reversing. The spool movement was controlled by pressure variation on four ports and the state of spool movement was remembered through inner feedback hole. According to the working principle of main control valve, the dynamic mathematic model of main control valve reversing was established. Using Stateflow to manage the state transfer of spool movement, the simulation model was presented in combination with Simulink. The simulation was done with parameters in the experiment and the reversing time required is in accord with the results of experiment. The effects of main parameters to reversing performance of main control valve were analyzed. The results show that inner chamber diameter has the greatest effects on reversing performance, the diameter of feedback hole was the second, the length of the feedback hole follow and the spring stiffness is the smallest.

Key words: hydraulic pile hammer; main control valve; reversing performance; pile driving; Stateflow

液压打桩锤的打击能量大,能量传递效率高,打击能可以调节,并且在施工中产生的噪声和污染小[1],它已经成为柴油锤的环保替代品,在打桩工程中得到越来越广泛的使用。液压打桩锤控制系统作为打桩锤的核心得到了广泛的研究。Patrick等[2]提出了一种通过电磁铁控制打桩机打击能和打击频率的方案。James[3]采用纯液压控制提出了水下打桩锤的控制方法,但是打桩锤的能量和频率无法调节。Iskander[4]详细地论述了单作用电液打桩锤的设计和控制。吕景忠等[5]提出了采用气液联合控制打桩锤工作的方法,但其打击能量只能通过行程阀有级调节。液压打桩锤的打桩频率高,对换向的平稳和快速性要求高[6-8],采用行程开关或接近开关控制电磁阀控制打桩锤工作产生的换向冲击大,导致系统故障率高,可靠性较差[9-12]。液压柔性冲击控制系统克服了电磁阀换向时产生的刚性冲击,使液压打桩锤的换向过程更加平稳可靠,同时也使冲击能和冲击频率实现了无级调节,增加了液压打桩锤的适用范围。主控阀是液压桩锤避免换向时刚性冲击,实现平稳可靠换向的关键部件,它的主要作用是实现桩锤换向的先导控制。液压打桩锤要保持在高频率下工作,要求主控阀具有很高的换向性能。

1 主控阀工作原理及结构

1.1 主控阀工作原理

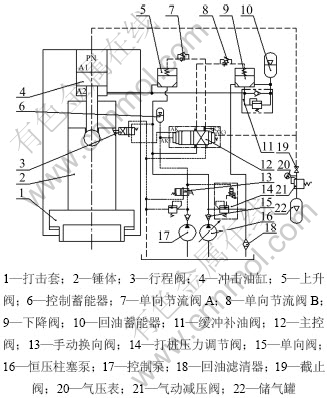

图l所示为液压打桩锤柔性冲击控制系统液压原理图。初始状态下,锤体2处于下位,行程控制阀3处于右位,主控阀12在油缸氮气腔压力和弹簧力的作用处于右位。当操作阀13时,主控阀12左端的环形面AK作用有系统压力ps,左端的圆形面AK1作用有控制压力pk,而右端的环形面AK2与高压油接通,右端圆形面AK3与油缸上的氮气腔接通,在这几个压力的作用下,主控阀12处于左位。上升阀5的控制腔通过主控阀12的B口和T口与回油接通,上升阀5打开。下降阀9的控制腔通过主控阀12的A口和P口与高压油接通,下降阀9关闭。单向节流阀A7和单向节流阀B8实现了上升阀5和下降阀9的先关后开,避免了误动作。锤体2上升触动行程阀3换向,使左端的环形面AK和右端环形面AK2与回油接通。锤体2继续上升压缩氮气腔,氮气腔压力升高。当氮气腔压力大于控制压力pk时,主控阀12换向处于右位。上升阀5的控制腔通过主控阀12的B口和P口与高压油接通,上升阀5关闭。下降阀9的控制腔通过主控阀12的A口和T口与回油接通,下降阀9打开。油缸4下腔与回油通,锤体2在氮气压力和自重的作用下下落。此时,主控阀12左端的环形面AK与回油通,左端的圆形面AK1作用用控制压力pk,而右端的环形面AK2作用有系统压力ps,右端环形面AK3与油缸的氮气腔接通。随着锤体2的下落,油缸的氮气腔压力减小,当触动行程阀3换向时,主控阀左端的环形面与高压油接通,主控阀换向。如此循环,实现连续打桩。缓冲补油阀11实现油缸缓冲腔的补油和缓冲腔的安全保护。

图1 液压打桩锤柔性控制系统工作原理

Fig.1 Scheme of flexible control system for hydraulic pile hammer

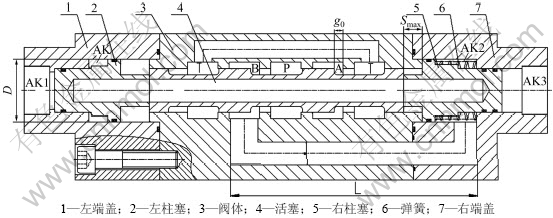

1.2 主控阀结构

主控阀的结构比普通二位四通液控换向阀复杂,其主要特点是阀芯左端有2个液压控制口,阀芯右端有一气压控制口,在阀体内部还有一反馈腔与阀芯右端相通。通过几个控制口中压力的变化即可实现阀芯的换向功能,如图2所示。为加工制造的方便将活塞做成三段,即左柱塞2,活塞4和右柱塞5。右端盖7与右柱塞5的环形腔通过反馈油孔与B口相通,这使得主控阀具有记忆功能,即一旦主控阀接受行程阀传递的信号换向至左位,它将一直使阀芯处于左位,直到氮气腔压力大于控制压力的换向信号传来,此后主控阀将一直处于右位,直到再次触动行程阀。装配时,阀芯4在弹簧6的预压缩力作用下处于右位。阀芯4和阀体3采用正开口形式,避免了压力反馈换向时高频高压信号的干扰。当系统压力作用于AK处,控制压力作用于AK1处时,阀芯移动并保持在左位;当AK3处的气压值超过AK1的控制压力时,阀芯移动并保持在右位直到桩锤下落行程到位。通过调节AK1的压力pk即可实现对打桩锤打击能的调节。

图2 主控阀结构

Fig.2 Structure of main control valve

2 主控阀换向性能试验

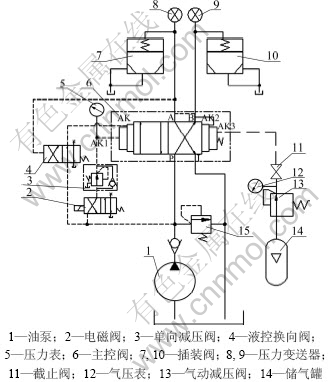

为完成主控阀换向快速性,平稳性的测试,最直接的测试方案是测量主控阀阀芯的位移时间曲线。但是,主控阀两端都接有控制回路,位移传感器的安装不方便,因此本文采用插装阀控制腔的压力突变来判断主控阀是否换向,在打桩锤系统的基础上设计了采用测量压力来测试主控阀性能的方案,如图3所示。忽略管道的影响,插装阀控制腔压力突变的时刻可以认为是主控阀换向完毕的时刻,即控制腔压力发生压力突变所需时间为主控阀换向时间。

图3 主控阀换向性能试验原理图

Fig.3 Experiment scheme for reversing performance of hydraulic pile hammer

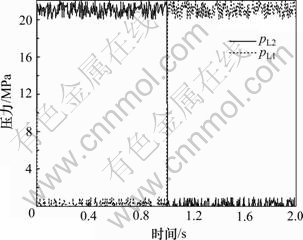

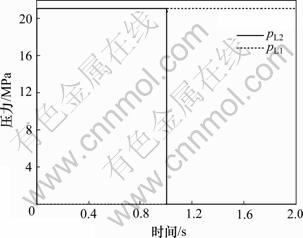

在主控阀换向性能测试的参数设定时,先调节阀右端圆形面积AK3作用的压力至1.7 MPa,它通过调节减压阀13和截止阀12,观察压力表11读数实现。调节溢流阀15将系统压力调至21 MPa。使电磁阀2得电,调节单向减压阀3,观察压力表5使左端圆形面积AK1作用压力为2.2 MPa。实验操作时,电磁阀2得电1 s后断开,然后保持该状态。传感器8和9所测压力分别为插装阀7控制腔压力pL1和插装阀10控制腔压力pL2,所得2 s内的曲线如图4所示。

图4 pL1和pL2测试曲线

Fig.4 Test curves of pL1 and pL2

测试的数据表明:主控阀在0~1 s向右运动至左位时,压力pL1在2 ms左右达到系统设定压力,在4 ms左右开始下降,主控阀完成左位换向,在5 ms附近时压力稳定在0 MPa附近波动;压力pL2在4 ms左右开始上升,在5 ms左右稳定在21 MPa附近波动。主控阀在1~2 s向左运动至右位时,压力pL1在1.028 s左右开始上升,主控阀完成右位换向,在1.03 s左右稳定在21 MPa附近波动。压力pL2在1.028 s左右开始下降,在1.03 s时稳定在0 MPa附近波动。

3 主控阀换向的数学模型及仿真

3.1 主控阀换向的数学模型

由牛顿定理可知,主控阀阀芯的运动方程如式(1)所示:

(1)

(1)

(2)

(2)

(3)

(3)

(4)

(4)

其中:m为阀芯质量,kg;S为阀芯位移,m;pAK为左端面环形面积上作用的压力,Pa; 为环形面积,D为内腔大径,dsp为阀芯直径;pAK2为右端面环形面积上作用的压力,Pa;

为环形面积,D为内腔大径,dsp为阀芯直径;pAK2为右端面环形面积上作用的压力,Pa; 为端面圆形面积,m2;pK为左端圆形面积上作用的压力,Pa;pN为右端面圆形面积上作用的压力,Pa;K为弹簧刚度,N/m;x0为弹簧初始压缩量,mm;f为阀芯与阀体之间的摩擦力,N;Fs为稳态液动力,N;Ft为瞬态液动力,N;μ为油液动力黏度,Pa×s;Lf为阀芯凸肩长度,m;rc为阀芯与阀体的径向间隙,m;Δp为阀口压差,Pa;Cd为阀流量系数;ρ为油液质量密度,kg/m3;g0阀芯初始状态开口量。

为端面圆形面积,m2;pK为左端圆形面积上作用的压力,Pa;pN为右端面圆形面积上作用的压力,Pa;K为弹簧刚度,N/m;x0为弹簧初始压缩量,mm;f为阀芯与阀体之间的摩擦力,N;Fs为稳态液动力,N;Ft为瞬态液动力,N;μ为油液动力黏度,Pa×s;Lf为阀芯凸肩长度,m;rc为阀芯与阀体的径向间隙,m;Δp为阀口压差,Pa;Cd为阀流量系数;ρ为油液质量密度,kg/m3;g0阀芯初始状态开口量。

忽略油管的液容效应,对主控阀的AK腔供油口应用连续性方程有:

(5)

(5)

其中: ,ps为系统压力,Pa;dL1为供油管直径,m。

,ps为系统压力,Pa;dL1为供油管直径,m。

(6)

(6)

其中: ,

, ;

;

V1为Ak腔体积,m3;E为油液的体积弹性模量,Pa。

对主控阀的AK2腔供油口应用连续性方程有:

(7)

(7)

其中:

(8)

(8)

dr1为反馈油孔直径,m; ,L为反馈油孔长度,m。

,L为反馈油孔长度,m。

对插装阀7的控制腔应用连续性方程有:

(9)

(9)

其中: ;pA为主控阀A口压力,Pa;pL1为插装阀控制腔压力,Pa。

;pA为主控阀A口压力,Pa;pL1为插装阀控制腔压力,Pa。

(10)

(10)

其中:VL1为插装阀7控制腔的体积,m3。

对插装阀10的控制腔应用连续性方程有:

(11)

(11)

(12)

(12)

其中:VL2为插装阀10控制腔的体积,m3。

3.2 主控阀换向的仿真模型

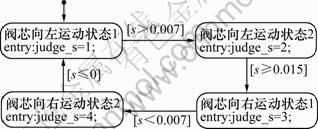

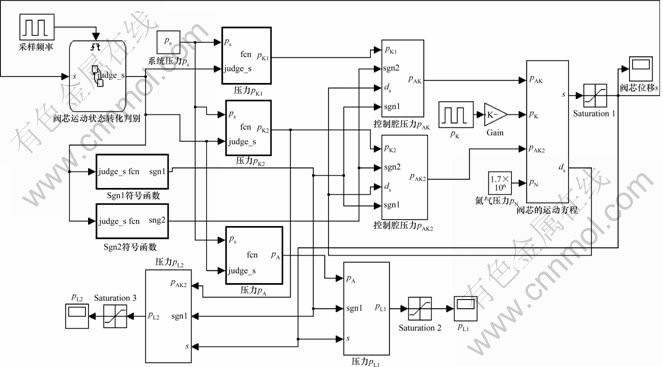

主控阀换向过程包含4个运动状态,这几个状态是按一定条件转换循环进行的。在Simulink中实现主控阀换向过程模拟仿真的关键是解决状态转换问题。使用Stateflow生成监控逻辑,嵌入到Simulink中,可以方便的解决Simulink中的状态转换问题[13-14]。在Stateflow中建立的主控阀运动状态转换图如图5所示。结合主控阀换向运动的数学模型,在Simulink中建立的模型如图6所示。

图5 主控阀阀芯运动状态转化图

Fig.5 States transfer for spool movement of main control valve

图6 主控阀换向过程的仿真模型

Fig.6 Simulation model for main control valve reversing

3.3 仿真结果

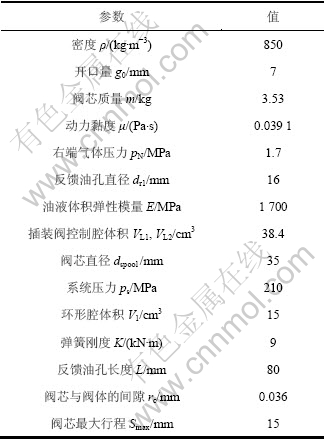

用矩形波模拟左端控制压力变化,仿真参数如表1所示。采用ode15s(stiff/NDF)算法对模型进行求解,所得pL1和pL2的曲线如图7所示。

图7的仿真数据表明:主控阀在0~1 s向右运动至左位时,压力pL1在2.1 ms后达到21 MPa,在4.5 ms后开始下降,在5.4 ms时压力pL1稳定在0 MPa;压力pL2在3.9 ms时开始上升,在5.2 ms时稳定在21 MPa。主控阀在1~2 s向左运动至右位时,压力pL1在1.004 2 s时开始上升,在1.058 6 s时稳定在21 MPa。压力pL2在1.003 6 s时开始下降,在1.005 4 s时稳定在0 MPa。在0~1 s内,仿真结果与实验结果完全相同。但是在1~2 s内,主控阀向左运动的过程中,仿真结果与测量结果差了大约24 ms。实验采用的电磁阀动作的延时时间为0~30 ms[15-16],而仿真过程的控制压力由矩形波模拟没有考虑电磁阀动作的延时,因此忽略电磁阀动作的影响仿真结果和实验结果是完全符合的,该模型可以用来模拟主控阀的换向过程。

图7 pL1和pL2仿真曲线

Fig.7 Simulation curve of pL1 and pL2

表1 主控阀换向的仿真参数

Table 1 Simulation parameters of main control valve reversing

4 换向性能影响因素

实现主控阀对柔性冲击换向系统的快速控制,主控阀的最大流量要求达到400~600 L/min。而主控阀的最大通流量由阀芯直径dsp,开口g0和阀芯最大位移Smax决定,因此为保证对主控阀通流能力的要求,不考虑这3个因素对主控阀换向性能的影响。对主控阀向右运动换向至左位进行仿真,通过插装阀7控制腔压力pL1的变化考察内腔大径D,弹簧刚度K,阀体内反馈油孔直径dr1和油孔长度L对主控阀换向快速性的影响。

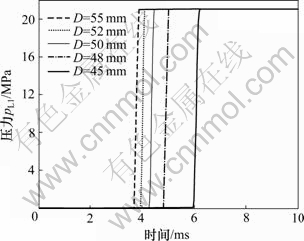

图8所示为内腔直径D对主控阀换向的影响。随着直径D的增大,pL1变化提前,换向时间减短,但是D的增大对换向阀换向时间缩短的作用越来越小。直径D对换向阀换向时间影响很大,主控阀的换向时间在D=55 mm的情况下比D=52 mm提前了0.2 ms。

图8 内腔大径D对主控阀换向性能的影响

Fig.8 Effects of inner chamber diameter D on reversing performance of main control valve

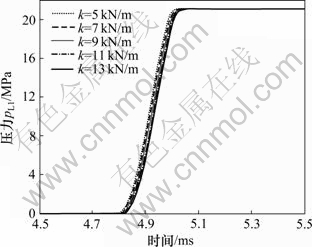

图9所示为弹簧刚度K对主控阀换向的影响。随着弹簧刚度K的减小,pL1变化提前,换向时间减短,但是弹簧刚度K对主控阀换向时间的影响较小。

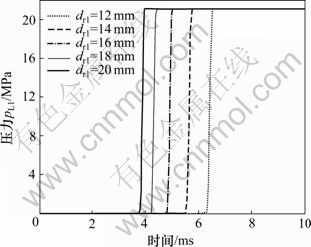

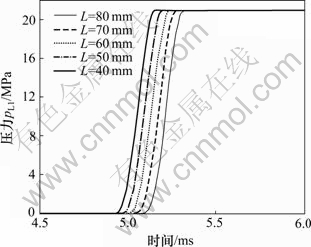

图10和图11所示分别为阀体中反馈油孔的直径dr1和长度L对主控阀换向的影响。反馈油孔的直径dr1和长度L对主控阀的换向时间的影响比较明显,随着dr1的增大主控阀换向所需时间缩短,随着L的减小主控阀换向所需时间也缩短。

图9 弹簧刚度K对主控阀换向性能的影响

Fig.9 Effects of spring stiffness K on reversing performance of main control valve

图10 孔直径dr1对主控阀换向性能的影响

Fig.10 Effects of feedback hole diameter dr1 on reversing performance of main control valve

图11 反馈孔长度L对主控阀换向性能的影响

Fig.11 Effects of feedback hole length L on reversing performance of main control valve

5 结论

(1) 结合液压打桩锤的工作特点,分析主控阀的工作原理和结构。该主控阀的应用实现了打桩过程的柔性换向和打击能,打击频率的无级调节。

(2) 根据主控阀换向性能实验的数学模型,采用Matlab和Stateflow建立的仿真模型进行仿真分析。仿真和实验结果表明,忽略电磁阀动作的影响仿真结果和实验结果是完全符合。

(3) 主控阀换向所需时间随着内腔直径D的增大而缩短,随着弹簧刚度K的减小而缩短,随着dr1的增大而缩短,随着L的减小而缩短。其中,弹簧刚度K的影响很小。

参考文献:

[1] UFC 3-220-02P, Pile driving equipment[S]. 2004-01-16.

[2] Patrick D B, Mark T, David H. Pile driving control apparatus and pile driving system: United States, US7404449B2[P]. 2008-07-29.

[3] James E A. Deep water pile driver: United States, US20100012336A1[P]. 2009-05-18.

[4] Iskander M. Behavior of pipe piles in sand[M]. Heidelberg: Springer, 2011: 127-176.

[5] 吕景忠, 隋振, 杨永海, 等. 新型液压桩锤气液驱动系统[J]. 吉林大学学报: 工学版, 2004, 34(4): 597-601.

L? Jing-zhong, SUI Zhen, YANG Yong-hai, et al. Hydro-pneumatic driving system of new type hydraulic pile hammer[J]. Journal of Jilin University: Engineering and Technology, 2004, 34(4): 597-601.

[6] 胡均平, 郭勇, 宋光伟, 等. 金属颗粒填充桩锤锤击模型的数值分析[J]. 中国公路学报, 2010, 23(2): 122-126.

HU Jun-ping, GUO Yong, SONG Guang-wei, et al. Numerical analysis for impact model of pile hammer[J]. China Journal of Highway and Transport, 2010, 23(2): 122-126.

[7] 杨永海, 王勋龙, 吕景忠, 等. 液压桩锤性能评价体系及其试验方法研究[J]. 农业机械学报, 2005, 36(4): 597-601.

YANG Yong-hai, WANG Xun-long, L? Jing-zhong, et al. Study on performance evaluation system and testing methods of hydraulic pile hammer[J]. Transactions of the Chinese Society of Agricultural Machinery, 2005, 36(4): 597-601.

[8] 李廷, 何继善, 徐振华, 等. 特大型组合式高应变动力试桩重锤[J]. 中南大学学报: 自然科学版, 2008, 39(5): 1112-1118.

LI Ting, HE Ji-shan, XU Zhen-hua. Special large-scaled and knock -down hammer in high strain dynamic pile test[J]. Journal of Central South University: Science and Technology, 2008, 39(5): 1112-1118.

[9] 胡均平, 史天亮, 张玲. 新型气液联合液压打桩锤的仿真研究[J]. 计算机仿真, 2009, 26(8): 274-277.

HU Jun-ping, SHI Tian-liang, ZHANG Ling. Simulation of a new type hydro-pneumatic hydraulic pile hammer[J]. Computer Simulation, 2009, 26(8): 274-277.

[10] 杨国平. 能独立调频调能液压冲击器的研究[J]. 湖南科技大学学报: 自然科学版, 2006, 21(1): 25-29.

YANG Guo-ping. Research of a full hydraulic pressure hydraulic impactor with strike energy and frequency adjusted independently[J]. Journal of Hunan University of Science & Technology: Natural Science Edition, 2006, 21(1): 25-29.

[11] Angadi S V, Jackson R L, Choe S Y, et al. Reliability and life study of hydraulic solenoid valve[J]. Engineering Failure Analysis, 2009, 16: 874-887.

[12] Li G, Wu M. Modeling and controlling of a flexible hydraulic manipulator[J]. Journal of Central South University of Technology, 2005, 12(5): 578-583.

[13] Aditya A, Gyula S, Gabor K. Semantic translation of Simulink/Stateflow models to hybrid automata using graph transformations[J]. Electronic Notes in Theoretical Computer Science, 2004, 109(14): 43-56.

[14] 贾秋玲, 袁冬莉, 栾云凤. 基于MATLAB7.x\Simulink\ Stateflow系仿真分析及设计[M]. 西安: 西北工业大学出版社, 2006: 176-213.

JIA Qiu-lin, YUN Dong-li, LUAN Yun-feng. System simulation and design based on MATLAB7.x\Simulink\Stateflow[M]. Xi’an: Northwest Industrial University Press, 2006: 176-213.

[15] 丁问司, 巫辉燕, 陈丽娜, 等. 单相交流液压系统设计及特性分[J]. 中南大学学报: 自然科学版, 2010, 41(4): 1348-1353.

DING Wen-si, WU Hui-yan, CHEN Li-na, et al. Design and characteristic analysis of single-phase pulsating flow hydraulic system[J]. Journal of Central South University: Science and Technology, 2010, 41(4): 1348-1353.

[16] 成大先. 机械设计手册—液压传动[M]. 北京: 化学工业出版, 2004: 497-502.

CHENG Da-xian. Handbook of mechanic design—Hydraulic transmission[M]. Beijing: Chemical Industry Press, 2004: 497-502.

(编辑 陈爱华)

收稿日期:2011-09-01;修回日期:2011-12-11

基金项目:湖南省科技厅计划项目(2008JT1014)

通信作者:郭勇(1983-),男,湖南浏阳人,博士研究生,从事液压机械与控制研究;电话:15974184466;E-mail: gy012702@126.com