李红英,宾杰,林武,魏冬冬,李阳华,曹俊

(中南大学 材料科学与工程学院,湖南 长沙,410083)

摘要:采用MTS858电液伺服万能试验机、扫描电镜及透射电镜研究回火对一种高强度微合金管线钢疲劳裂纹扩展行为的影响。研究结果表明:回火可提高微合金管线钢疲劳裂纹扩展的门槛值,降低疲劳裂纹扩展速率,但对裂纹扩展稳态区的扩展速率影响不大;回火使碳氮化物沉淀析出、晶间马氏体/奥氏体(M/A)组元由岛状转变为点状及细条状,形成马氏体薄膜结构,阻碍变形和裂纹在材料中扩展,增加裂纹的偏折程度;在控轧控冷终冷温度进行2~4 h回火热处理,可以提高微合金管线钢强韧性和抗疲劳裂纹扩展能力。

关键词:回火;微合金管线钢;针状铁素体;疲劳;裂纹扩展行为

中图分类号:TG142.1 文献标志码:A 文章编号:1672-7207(2011)09-2635-07

Effects of tempering treatment on fatigue crack propagation behavior of microalloyed pipeline steels

LI Hong-ying, BIN Jie, LIN Wu, WEI Dong-dong, LI Yang-hua, CAO Jun

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The effects of different tempering treatments on fatigue crack propagation behavior of a high strength microalloyed pipeline steel were investigated by MTS858 material testing system, scanning electron microscopy and transmission electron microscopy. The results show that tempering treatments can improve the fatigue crack propagation threshold and reduce the fatigue crack growth rate of microalloyed pipeline steels, but with little effects on the intermediate region of stable crack propagation. Tempering treatment can promote the precipitation of microalloyed carbonitrides and transform the martensite/austenite (M/A) components at the grain boundary from islands to spots and strips, and the M/A components can be further changed to thin-film martensite as tempering time increases, and all these structures can inhibit the propagation and increase the deflection of fatigue crack. The strength, toughness and fatigue crack propagation resistance of microalloyed pipeline steels can be promoted by 2-4 h tempering at the final cooling temperature of thermo-mechanical control process.

Key words: tempering; microalloyed pipeline steel; acicular ferrite; fatigue; crack propagation behavior

近年来,随着油气市场不断扩大,油气运输路线逐渐加长,必须通过提高输送压力和增加管径来提高管线的运输能力,高压、大输量和大管径输送是管线建设的主要发展趋势,一般通过提高管线钢的强度级别来实现[1-3]。世界上高强度微合金管线钢的轧制普遍采用热机械控制工艺(TMCP,Thermo-mechanical control process),充分利用钢铁材料的相变特点来改善材料的性能,所生产的管线钢产品基本能符合恶劣服役环境的性能要求[4-7]。随着管线钢强度级别的提高,大量研究工作围绕优化控轧控冷工艺展开,日本JFE钢铁公司提出了超级TMCP技术,在现有控轧控冷的工序后,增加一道在线热处理过程(HOP,Heat- treatment on-line process),充分发挥微合金钢中弥散相的强化作用,从而提高材料的综合力学性能[8-9]。疲劳断裂是油气管线服役过程中一种常见的失效形式,到目前为止,人们对管线钢疲劳性能的研究大多集中在X70以下的低钢级,而对高钢级管线钢的疲劳研究还相当缺少,对管道结构的系统疲劳分析尚未开 展[10-12]。为此,本文作者以一种采用控轧控冷工艺生产的高强度微合金管线钢为研究对象,在原有的控轧控冷基础上进行回火热处理,对不同状态试样进行疲劳裂纹扩展试验及计算研究,评价不同回火工艺对微合金管线钢微观组织及疲劳行为的影响。

1 实验材料与方法

实验材料取自工厂生产的控轧控冷态钢板,非再结晶区轧制后立即进行加速冷却,终冷温度范围为530~570 ℃,厚度约为22 mm,表1所示为检测出的化学成分。在管式电阻炉中进行热处理,将钢板重新加热至控轧控冷的终冷温度(540±10) ℃回火,回火时间分别为1,2,4和10 h,然后空冷至室温。测试回火态与控轧控冷态试样的拉伸力学性能,常规拉伸实验在CSS-44100万能电子拉伸机上进行,拉伸试样按GB/T 228—2002要求加工。

表1 实验用钢的化学成分(质量分数)

Table 1 Composition of tested steel %

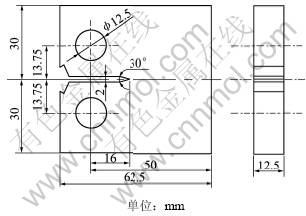

疲劳裂纹扩展实验在MTS858 Mini BionixⅡ试验机上进行,室温,大气环境,加载波形为正弦波,频率为10 Hz,最大载荷Pmax为10 kN,最小载荷Pmin为1 kN,力值比R (R=Pmin/Pmax)为0.1,最大载荷与最小载荷之差ΔP为9 kN。根据GB/T 6398—2000加工成的标准C(T)试样如图1所示。为了保证裂纹足够尖锐和在随后试验中裂纹前缘的形状不发生改变,试样加工完成后,在常温下预制长度为4 mm左右的疲劳裂纹。

根据GB/T 6398—2000,采用下式计算应力强度因子?K。

(1)

(1)

其中: ;a为裂纹的长度;W为试样宽度;B为试样厚度。

;a为裂纹的长度;W为试样宽度;B为试样厚度。

图1 测定疲劳裂纹扩展速率的C(T)试样

Fig.1 C(T) specimen for fatigue crack propagation rate test

疲劳裂纹扩展曲线一般可以分为近门槛区、中部稳态扩展区和快速扩展区3个部分,其中近门槛区和中部扩展区与含缺陷材料的启裂和扩展密切相关,可分别采用式(2)所示的Zheng-Hirt公式[13]和式(3)所示的Paris公式[14]描述其扩展行为。

(2)

(2)

(3)

(3)

式中:B,A和m为与材料性质有关的常数。

根据对断口特征、形貌和裂纹源特征的宏观分析,确定进行微观分析的区域。用线切割方法切出长为 30 mm、宽为10 mm的样品,利用QUATA200型扫描电镜观察疲劳裂纹扩展试样断口形貌,加速电压为 20 kV。利用TecnaiG2 20型透射电子显微镜对试样的析出相、微观形貌进行观察。在水磨砂纸和金相砂纸上将试样磨成厚度为60~80 μm的薄片,采用双喷法对其进行化学减薄。双喷液为体积比为1:19的高氯酸(HClO4)与无水酒精(CH3CH2OH)的混合溶液,双喷时电流为50~75 mA,用液氮对双喷液进行冷却。

2 实验结果

2.1 常规力学性能测定

图2所示为常规力学性能随回火时间变化的关系曲线,其中横坐标0对应不经回火的控轧控冷态试样。由图2(a)可知:材料的强度指标(抗压强度Rm和屈服强度Rp0.2)随回火时间的延长而增加,回火2~4 h能在控制合适屈强比的同时提高材料的强度,回火10 h后屈强比明显增加。由图2(b)可知:断后伸长率A30 mm随回火时间的延长基本保持不变,短时回火冲击功(Ak)小幅度提高,但随回火时间的延长有下降的趋势。

2.2 疲劳裂纹扩展速率测定

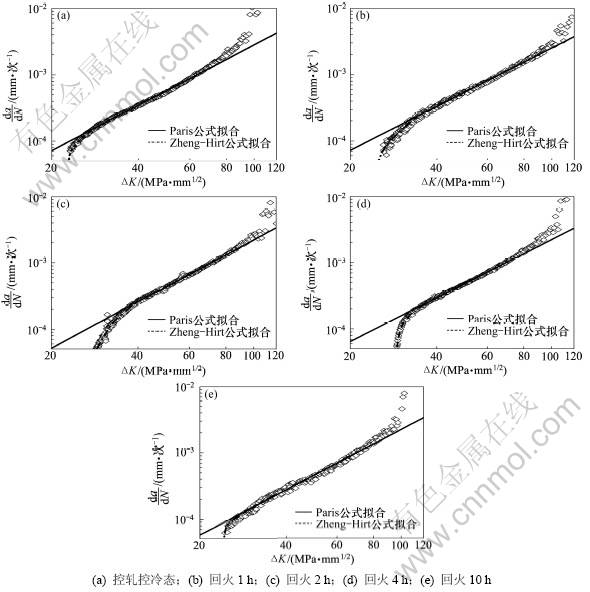

图3所示为不同回火状态试样疲劳裂纹扩展速率拟合结果,其中实线表示中部稳态扩展区按Paris公式拟合的结果,虚线表示近门槛区按Zheng-Hirt公式拟合的结果。

图2 实验钢力学性能与回火时间的关系曲线

Fig.2 Relationship between mechanical properties and tempering time of tested steel

图3 控轧控冷态和回火态试样的疲劳裂纹扩展曲线

Fig.3 Curves of fatigue crack propagation rate for rolled and tempered samples

3 分析与讨论

3.1 疲劳裂纹扩展速率分析

在疲劳裂纹萌生区,一般认为存在疲劳裂纹扩展门槛值?Kth。实测门槛值是在门槛处所能测量到的平均裂纹扩展速率,由于近门槛区裂纹扩展的基本机制是裂纹前沿的非连续扩展,因此,当?K减小到裂纹经107循环而不能扩展0.l mm时,对应的?K即定为?Kth。本实验根据Zheng-Hirt公式拟合实验结果,大致判断出?Kth,即图3中虚线段与横坐标的交点。表2所示为在不同的?K范围拟合得到的m,lg A和?Kth,由表2可见:控轧控冷态试样的?Kth为23.7 MPa·mm1/2,随着回火时间的延长,?Kth有增大的趋势,回火2~4 h达到30 MPa·mm1/2左右。

在近门槛区即疲劳裂纹扩展的第1阶段,材料的滑移特征和显微组织结构、应力水平及近顶端塑性区的尺寸对裂纹扩展的微观模式有强烈影响。中部扩展区与近门槛区不同,材料的强度、塑性以及组织结构对该阶段的影响甚小,裂纹扩展速率服从Paris公式,根据表2计算结果,可以得到控轧控冷态试样的Paris公式为da/dN=10-7.12??K2.21,回火1,2,4和10 h试样的Paris公式分别为:da/dN=10-6.99·?K2.19,da/dN=10-7.32·?K2.3,da/dN=10-7.04·?K2.19和da/dN= 10-7.21·?K2.28。假设应力强度因子?K为40 MPa·mm1/2时,根据Paris公式可以计算不同回火时间试样的疲劳裂纹扩展速率da/dN,控轧控冷态试样为2.63×10-4 mm/次,回火1,2,4和10 h试样的扩展量分别为3.30×10-4,2.32×10-4,2.94×10-4和2.14×10-4 mm/次。由此可见:回火对疲劳裂纹中部区的扩展速率的影响不大。

图4所示为疲劳裂纹稳态扩展区(?K=40 MPa·mm1/2)的形貌。由图4可以看出:试验钢的热轧态及回火态都出现了一些疲劳辉纹,呈弯曲的条纹,在局部地区成组存在,并以大致平行的方向分布。在疲劳裂纹稳态扩展初期,裂纹以条带机制扩展,每循环加载1次,裂纹向前扩展?a,并形成1个条带,因此,条纹数量与加载循环次数相等。在疲劳裂纹扩展的Paris区,如果外加循环载荷保持恒定,条纹间距?a与实验测出的裂纹扩展速率有对应关系。测量图4所示的疲劳扩展条纹宽度,其大小与拟合计算得到的结果大致相符,验证了条纹间距与扩展速率的对应关系。对比不同回火状态试样,经1~4 h回火试样条纹致密程度与控轧控冷态的相当,间距都比较小,表现出较强的抗疲劳裂纹扩展能力,而经10 h回火后,试样疲劳条纹间距较宽,表明疲劳裂纹扩展速率较高。

3.2 回火对微观组织的影响

力学性能测定的结果表明:回火2~4 h能够在不影响塑韧性的前提下提高强度。图5所示为利用透射电镜观察到的不同回火试样的微观组织,其中形状不规则、互相交错分布的针状片条结构为针状铁素体,在片条内部具有非常细微的亚结构和高密度位错。由图5(a)可以看出:在针状铁素体晶界处分布有岛状的马氏体/奥氏体(M/A)组元。M/A岛是伴随着针状铁素体形成的富碳富合金元素组元,这些岛状结构中碳化物沉淀析出量少,是富碳的残余奥氏体。图5(b)所示为回火4 h的微观组织,未能观察到具有M/A岛特征的结构,而是在晶界及晶内分布有细小的析出相,在晶界断断续续分布有细长条状的结构。图5(c)所示为该结构在更高放大倍数下的形貌,呈条状或点状分布。图5(d)所示为回火10 h试样的微观组织,晶界存在一种薄膜组织结构,即铁素体晶界上存在一层几十纳米厚的薄膜,认为这种薄膜组织为一种马氏体薄膜 相[15-17]。由以上的分析可知:回火处理过程中富碳的残余奥氏体发生了转变,图5(c)所示为转变过程中的过渡状态,M/A组元由岛状转变为点状及细条状,回火10 h后完全转化为薄膜马氏体结构。

表2 疲劳裂纹扩展速率曲线拟合结果

Table 2 Fitted parameters for curves in Fig.3

图4 控轧控冷态和回火态试样疲劳裂纹稳态扩展区(?K=40 MPa·mm1/2)的断口形貌

Fig.4 SEM images of fatigue crack propagation region for rolled and tempered samples

在控轧控冷过程中,微合金管线钢中的合金元素在铁素体中以第二相的形式沉淀析出,尤其是在终冷温度附近,能够从过饱和固溶体中析出极其细小的沉淀相。但在现有管线钢的控轧控冷工艺中,轧制后的冷却速度相对较高,微合金碳氮化物的析出强化作用未能充分发挥出来。微合金钢的回火处理及随后的冷却过程中,晶内及晶间的碳氮化物沉淀析出,M/A组元转变为点状或条状,使得回火4 h后强化效果达到最大值。回火处理有助于组织均匀性的改善,也在一定程度上弥补了沉淀相及马氏体薄膜对塑性的损害,最终使得材料的塑性指标基本保持不变。

3.3 微观组织对疲劳裂纹扩展行为的影响

回火引起材料微观组织结构的改变,对材料的疲劳裂纹扩展行为产生影响。在裂纹扩展的近门槛区,裂纹顶端的塑性变形区只局限在几个晶粒直径范围内,可以把循环载荷引起的裂纹扩展想象为在裂纹顶端近旁的滑移带内发生的局部急剧变形过程,把滑移带扩展进入相邻晶粒作为准则来确定裂纹扩展的门槛值。针状铁素体晶粒间分布有M/A组元,回火处理后出现薄膜马氏体,这些特殊结构都为高硬度相,成为裂纹扩展的阻碍。

图5 控轧控冷态和回火态试样的微观组织

Fig.5 Microstructures of rolled and tempered samples

对于针状铁素体管线钢,从奥氏体向铁素体的相变以扩散和切变的混合机制实现,针状铁素体受切变作用在基体内形成高密度位错和亚结构。经回火处理后,微合金钢析出的碳氮化物尺寸较小,不容易对裂纹的扩展产生直接的影响,但是,析出物可以通过Orowan机制阻碍和钉扎位错运动,随着裂纹的扩展,位错在运动过程中被基体中的细小析出物所钉扎,最终形成类似晶界的位错墙。

晶间的M/A组元、马氏体薄膜以及位错墙都将成为裂纹扩展的阻碍,根据Suresh[18]提出的裂纹路径周期性偏离名义扩展平面而提高疲劳裂纹扩展表观阻力的机制,裂纹扩展路径上的阻碍使得裂纹发生分叉和偏折。裂纹的偏折一方面能够增加裂纹面的面积,使裂纹扩展消耗更多的能量,降低疲劳裂纹的扩展速率。更重要的是,裂纹路径的偏折还能有效增加裂纹扩展过程中的闭合现象,降低疲劳裂纹的有效扩展驱动力,从而更有效地降低材料的疲劳裂纹扩展速率。当M/A组元转变为条状分布或者马氏体薄膜结构时,裂纹的偏折及由此带来的阻滞效应会更加明显,因此,回火能够提高裂纹扩展的门槛值。而中部扩展区受这种裂纹扩展的阻滞机制影响很小,因此,回火处理对稳态扩展区影响不大。

综上可知:针状铁素体管线钢细小的晶粒、高密度的位错以及晶间的M/A组元,使其具有很高的强韧性。在经回火处理后,微合金碳氮化物的沉淀析出,M/A组元由岛状转变为点状及条状,当回火时间延长时,进一步转变为马氏体薄膜,使其强度进一步提高,而塑性基本保持不变。条状M/A组元和马氏体薄膜通过阻碍变形和裂纹在材料中的扩展,增加裂纹的偏折程度,降低疲劳裂纹扩展速率。到目前为止,控轧控冷工艺已广泛应用于低碳微合金管线钢的生产,“低温大压下”是获取较高细晶强化效果的主要条件,但通过该途径提高管线钢性能似乎已接近极限,且性能的提高都是以高成本为代价。在现有的控轧控冷终冷温度范围进行一定时间的回火,能够使最佳力学性能与抗疲劳裂纹扩展性能匹配,为进一步改善管线钢的组织性能提供了一条有效途径。

4 结论

(1) 控轧控冷态微合金管线钢经2~4 h回火后,其疲劳裂纹扩展的门槛值ΔKth增大,但回火对稳态区的裂纹扩展速率影响不大。

(2) 回火使得微合金中的碳氮化物沉淀析出,晶间M/A组元由岛状转变为点状及细条状,回火时间延长时进一步转变为马氏体薄膜结构,阻碍变形和裂纹在材料中扩展,增加裂纹的偏折程度,降低疲劳裂纹扩展速率。

(3) 在原有的控轧控冷基础上进行回火热处理,通过2~4 h的回火可以使微合金钢获得最佳性能匹配,提高管线钢强韧性和抗疲劳裂纹扩展能力。

参考文献:

[1] 高惠临, 张骁勇, 冯耀荣, 等. 管线钢的研究进展[J]. 机械工程材料, 2009, 33(10): 1-4.

GAO Hui-lin, ZHANG Xiao-yong, FENG Yao-rong, et al. Development and current situation of pipeline steels[J]. Materials for Mechanical Engineering, 2009, 33(10): 1-4.

[2] Tabkhi F,Pibouleau L,Azzaro-Pantel C, et al. Total cost minimization of a high-pressure natural gas network[J]. Journal of Energy Resources Technology, 2009, 131(4): 1-11.

[3] 李鹤林. 油气输送钢管的发展动向与展望[J]. 焊管, 2004, 27(6): 1-11.

LI He-lin. Developing pulse and prospect of oil and gas transmission pipe[J]. Welded Pipe and Tube, 2004, 27(6): 1-11.

[4] WANG Wei, YAN Wei, ZHU Liu, et al. Relation among rolling parameters, microstructures and mechanical properties in an acicular ferrite pipeline steel[J]. Materials Design, 2009, 30(9): 3436-3443.

[5] Shanmugam S, Ramisetti N K, Misra R D K, et al. Microstructure and high strength-toughness combination of a new 700 MPa Nb-microalloyed pipeline steel[J]. Materials Science and Engineering A, 2008, 478(1/2): 26-37.

[6] Ouchi C. Development of steel plates by intensive use of TMCP and direct quenching processes[J]. ISIJ International, 2001, 41(6): 542-553.

[7] 彭艳, 李修琨, 刘宏民. 热轧带钢冷却过程奥氏体相变与温度耦合模型[J]. 中南大学学报: 自然科学版, 2009, 40(3): 699-705.

PENG Yan, LI Xiu-kun, LIU Hong-min. Model of austenite transformation and temperature coupling for hot rolled strip during cooling process[J]. Journal of Central South University: Science and Technology, 2009, 40(3): 699-705.

[8] JFE Steel Corporation. Development of HITEN “JFE- HYD1100LE” ultra high strength steel plate with high resistance to delayed fracture[EB/OL]. [2008-01-30]. http://www.jfe-steel. Co.JP/en/release/2008/080130.html.

[9] TANG Zheng-hua, Stumpf W. The role of molybdenum additions and prior deformation on acicular ferrite formation in microal1oyed Nb-Ti low-carbon line-pipe steels[J]. Materials Characterization, 2008, 59(6): 717-728.

[10] 钟勇,肖福仁,单以银, 等. 管线钢疲劳裂纹扩展速率与疲劳寿命关系的研究[J]. 金属学报, 2005, 41(5): 523-528.

ZHONG Yong, XIAO Fu-ren, SHAN Yi-yin, et al. Study of relationship between fatigue crack growth rate and fatigue life for pipeline steels[J]. Acta Metallurgica Sinica, 2005, 41(5): 523-528.

[11] Pinheiro B C, Pasqualinoa I P. Fatigue analysis of damaged steel pipelines under cyclic internal pressure[J]. International Journal of Fatigue, 2009, 31(5): 962-973.

[12] BIAN Li-chun, Taheri F. Investigation of fatigue crack propagation in line pipes containing an angled surface flaw[J]. Journal of Pressure Vessel Technology,2008, 130(1): 1-8.

[13] ZHENG Xiu-lin, Hirt M A. Fatigue crack propagation in steels[J]. Engineering Fracture Mechanics, 1983, 18(5): 965-973.

[14] Paris P C, Erdogen F. A critical analysis of crack propagation laws[J]. Journal of Basic Engineering, 1963, D85: 528-534.

[15] WANG Chun-ming, WU Xing-fang, LIU Jie, et al. Transmission electron microscopy of martensite/austenite islands in pipeline steel X70[J]. Materials Science and Engineering A, 2006, 438/439/440: 267-271.

[16] 赵明纯, 单以银, 杨柯. 时效处理对针状铁素体管线钢力学性能和抗硫化氢行为的影响[J]. 金属学报, 2004, 40(9): 948-954.

ZHAO Ming-chun, SHAN Yi-yin, YANG Ke. Effect of aging treatment on mechanical property and H2S resistant behavior of acicular ferrite pipeline steels[J]. Acta Metallurgica Sinica, 2004, 40(9): 948-954.

[17] ZHAO Ming-chun, Hanamura T, QIU Hai, et al. Lath boundary thin-film martensite in acicular ferrite ultralow carbon pipeline steels[J]. Materials Science and Engineering A, 2005, 395(1/2): 327-332.

[18] Suresh S. Fatigue of materials[M]. Cambridge: Cambridge University Press, 1998: 388-389.

(编辑 杨幼平)

收稿日期:2010-08-29;修回日期:2010-11-28

基金项目:湖南省自然科学基金资助项目(05JJ30200)

通信作者:李红英(1963-),女,湖南湘乡人,博士,教授,从事金属材料的强韧化研究;电话:0731-88836328;E-mail: lhying@csu.edu.cn