低碳微合金管线钢过冷奥氏体连续冷却转变

李红英,林武,宾杰,魏冬冬,曾翠婷

(中南大学 材料科学与工程学院,湖南 长沙,410083)

摘 要:利用膨胀法和差热分析法结合金相-硬度法,在Gleeble-1500热模拟机上测定一种低碳微合金管线钢以不同速度连续冷却时的膨胀曲线,结合DSC曲线和金相组织分析,确定该钢的临界温度及相变温度,获得该钢的连续冷却转变曲线(CCT图),研究该钢连续冷却时的奥氏体转变。研究结果表明:添加0.21%Mo起到抑制铁素体和珠光体作用,促进针状铁素体组织的形成,实验钢在5.0~20.0 ℃/s的较宽冷却速度范围内连续冷却都能得到需要的针状铁素体组织,表明低碳Mn-Nb-Mo微合金管线钢容易得到管线钢工程所需要的组织。

关键词:低碳微合金管线钢;连续冷却;相变;连续冷却转变曲线(CCT图)

中图分类号:TG151.2; TG151.3 文献标志码:A 文章编号:1672-7207(2010)03-0923-07

Continuous cooling transformation of undercooling austenite for low-carbon microalloyed pipeline steel

LI Hong-ying, LIN Wu, BIN Jie, WEI Dong-dong, ZENG Cui-ting

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The different dilatometric curves of continuous cooling transformation were measured on Gleeble-1500 thermal mechanical simulator with methods of dilatometric change and differential thermal analysis. Referencing microscopic test and hardness measurement, the critical points and phase transformation points were determined, and the continuous cooling transformation curves (CCT diagram) of a low-carbon microalloyed pipeline steel were obtained. Transformation of austenite in the course of continuous cooling was investigated. The results show that adding 0.21% Mo can inhibit the formation of ferrite and pearlite, and promote the formation of acicular ferrite. Acicular ferrite can be obtained within a wider cooling rate range of 5.0-20.0 ℃/s, which shows that the microstructure needed for engineering application can be obtained in the low-carbon Mn-Nb-Mo microalloyed pipeline steel.

Key words: low-carbon microalloyed pipeline steel; continuous cooling; phase transformation; continuous cooling transformation diagram

管线运输是石油、天然气的最佳运输方式。随着油气市场的不断扩大和油气运输路线的加长,必须通过提高管道的输送压力和增加管径来提高管线的运输能力,高压、大输量和大管径输送已成为管线建设的发展趋势[1-3]。管道周边环境和输送介质的日趋复杂致使油气输送管道的服役条件日益恶化,要长期承受高压、强腐蚀作用及大的温差变化,有时还要承受地震和冻土地带的大变形,对管线钢的质量和性能要求越来越高,除了高强韧要求外,还要求较高的耐腐蚀性能、一定的长程止裂性能、较好的耐热性和一定的低温韧性[4-6]。形变热处理是改善钢材组织性能的有效手段,能在提高管线钢强度、韧性的基础上,提高耐腐蚀性能、低温韧性和止裂韧性。第2代微合金管线钢是在20世纪70年代发展起来的,现在仍是油气输送管线工程的主流钢种,强度级别范围可覆盖X60~X90,其主要化学成分为C,Mn,Nb和Mo。加入Nb,V和Ti等微合金元素对钢进行控轧控冷,是有效改善钢材组织性能的主要途径之一[7-8]。利用连续冷却转变曲线(CCT图)指导生产实际,从而有效利用控轧控冷工艺改善钢材组织,对最大限度地提高材料性能具有重要意义[9-10]。为此,本文作者研究低碳微合金管线钢的相变规律,测定其连续冷却转变曲线(CCT图),并观测不同冷却速度下转变产物的显微组织和硬度,分析冷却速度对钢材组织和硬度的影响,以便为生产实际制定控轧控冷工艺提供理论基础。

1 实验

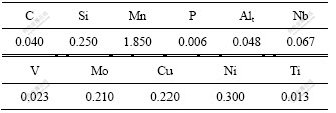

实验材料取自工厂生产的X80管线钢板,表1所示为检测的化学成分(质量分数)。

表1 X80钢的化学成分

Table 1 Chemical composition of X80 steel %

采用膨胀法并结合金相-硬度法[11]以及差热分析法(DSC),测试内容包括临界温度 和

和 (或

(或 和

和 )以及

)以及 ~

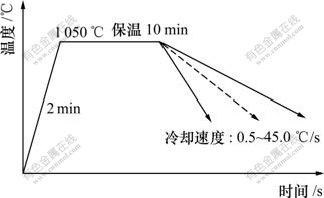

~ 之间的过冷奥氏体在不同冷却速度下连续冷却时的转变过程[12]。切割钢板取样,加工成直径×高为6 mm×10 mm的试样,在Gleeble-1500热模拟机上测定试样连续冷却时的膨胀曲线。图1所示为测定连续冷却膨胀曲线的工艺示意图。为使加热温度接近实际生产的开轧温度和保证微合金元素的充分溶解,将奥氏体化温度定为1 050 ℃,在2 min内将试样加热至奥氏体化温度,保温10 min,分别以10种不同的冷却速度(0.5~45.0 ℃/s)冷却试样,获取其膨胀曲线,再由膨胀曲线确定相变温度。以2.0 ℃/min的速度将试样升温到1 000 ℃,获得升温DSC曲线,确定其临界温度

之间的过冷奥氏体在不同冷却速度下连续冷却时的转变过程[12]。切割钢板取样,加工成直径×高为6 mm×10 mm的试样,在Gleeble-1500热模拟机上测定试样连续冷却时的膨胀曲线。图1所示为测定连续冷却膨胀曲线的工艺示意图。为使加热温度接近实际生产的开轧温度和保证微合金元素的充分溶解,将奥氏体化温度定为1 050 ℃,在2 min内将试样加热至奥氏体化温度,保温10 min,分别以10种不同的冷却速度(0.5~45.0 ℃/s)冷却试样,获取其膨胀曲线,再由膨胀曲线确定相变温度。以2.0 ℃/min的速度将试样升温到1 000 ℃,获得升温DSC曲线,确定其临界温度 和

和 。

。

当转变量较少时,膨胀曲线上的相变点不明显,致使测量的准确度受到影响,因此,要结合金相组织分析和硬度(维氏)测试来确定相变点。金相法可以直接对组织进行观察,但需要较多的试样,工作量也较大,如果转变产物的金相组织形态如下贝氏体和马氏体不易鉴别出来,就需要辅以硬度法,用硬度测试结果来确定转变产物。金相样品用常规的机械研磨及抛光方法制备,采用4%硝酸酒精浸蚀,利用Polyvar-Met金相显微镜观察金相组织和测量显微硬度(HV2)。

图1 测定连续冷却膨胀曲线的工艺示意图

Fig.1 Determination-process of dilatometric curves for continuous cooling transformation

2 结果与分析

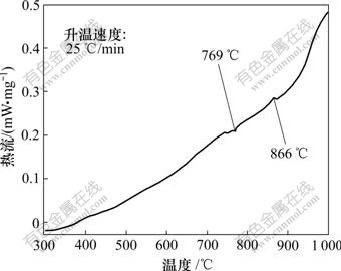

2.1 差热分析实验结果

金属材料在升温或降温过程中发生的物理和化学变化常伴有潜热的吸收或释放,在热量随时间变化的曲线上会出现吸热峰或放热峰,因此,用差热扫描(DSC)方法可以确定物相转变点。图2所示为实验钢的升温DSC曲线,采用峰值综合分析法可以得出该钢临界温度为 =769 ℃,

=769 ℃, =866 ℃。

=866 ℃。

图2 实验钢的DSC曲线

Fig.2 DSC curve of experimental steel

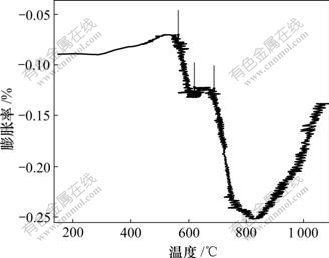

2.2 连续冷却膨胀曲线

当钢发生固态相变时,由于新、旧两相结构和比热容不同,材料的体积将发生不连续变化,因而,热膨胀曲线在相变发生的温度处形成拐点,据此可以确定相变点。从膨胀曲线上确定不同冷却速度的相变温度,通常采用极值法、切线法和平均法等方法[11]。

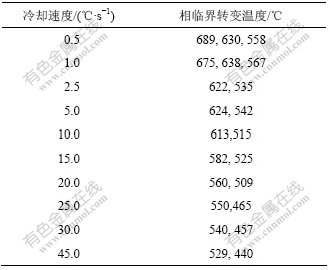

图3所示为实验钢过冷奥氏体以0.5 ℃/s冷却时的膨胀曲线。箭头标出了曲线有效的拐点位置,确定了钢在冷却过程中的相变点分别为689,630和558 ℃,依此类推,可由不同冷却速度对应的膨胀曲线确定相变点,表2所示为不同冷却速度对应的相变点。

图3 实验钢过冷奥氏体以0.5 ℃/s冷却时的膨胀曲线

Fig.3 Dilatometric curve of supercooled austenite at cooling rate of 0.5 ℃/s

2.3 CCT图的绘制及分析

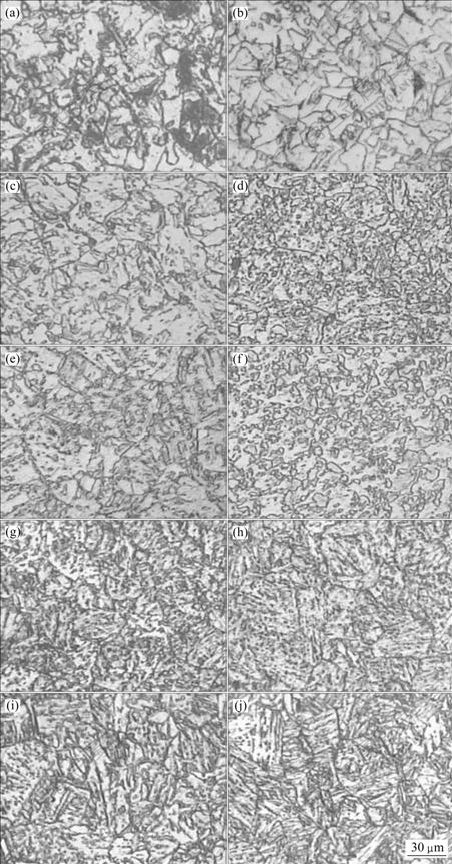

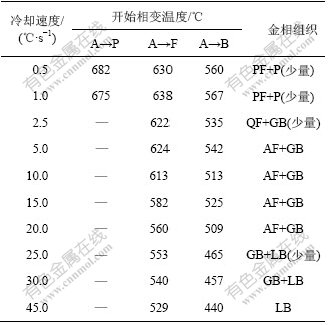

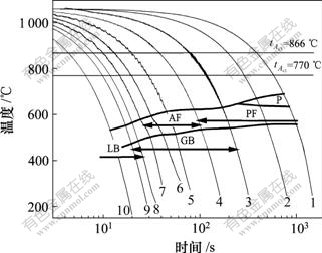

图4所示为以不同速度冷却得到的转变产物的显微组织;表3所示为以不同速度冷却到室温试样的维氏硬度HV2;表4所示为实验钢以不同速度连续冷却时发生的相变和相变温度,相变温度是根据不同冷却速度膨胀曲线上的拐点并结合金相组织确定的,以不同速度冷却得到的转变产物主要有珠光体(P)、多边形铁素体(PF)、准多边形铁素体(QF)、针状铁素体(AF)、粒状贝氏体(GB) 和下贝氏体(LB)。将表4所示的相变点绘制到温度-时间半对数坐标上,用连线法将各物理意义相同的点连接起来,同时标出 和

和 ,绘出如图5所示的CCT图。

,绘出如图5所示的CCT图。

由图4和图5可以看出:过冷奥氏体以不同速度连续冷却会得到不同的转变组织,当冷却速度为0.5~ 1.0 ℃/s时(图4(a)和(b)),转变产物主要为多边形铁素体(PF)和珠光体(P),多边形铁素体具有规则的晶粒外形,珠光体分布在多边形铁素体的晶界;当冷却速度提高到2.5 ℃/s时(图4(c)),珠光体已经消失,铁素体的形状发生变化,其晶界变得不规则、不连续、凹凸不平,为准多边形铁素体(QF)[13],同时出现了任意分布在多边形铁素体及周围的粒状贝氏体(GB);当冷却速度由5.0 ℃/s增至20.0 ℃/s,基体中的晶界更加模糊,有针状铁素体析出,粒状贝氏体的体积分数也越来越大,表现为针状铁素体和粒状贝氏体的混合组织。在更高的冷却速度下(25.0~30.0 ℃/s)(图4(h)和(i)),基体中分布的粒状贝氏体逐渐减少,同时出现了少量的下贝氏体;当冷却速度达到45.0 ℃/s时,粒状贝氏体基本消失,主要转变产物为具有明显原奥氏体晶界的下贝氏体。

表2 不同冷却速度对应的相变温度

Table 2 Transformation temperatures at

different cooling rates

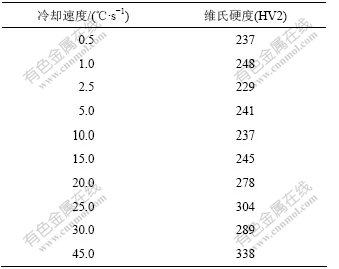

表3 不同冷却速度对应的维氏硬度(HV2)

Table 3 HV2 of experimental steel at different cooling rates

冷却速度/(℃?s-1): (a) 0.5; (b) 1.0; (c) 2.5; (d) 5.0; (e) 10.0; (f) 15.0; (g) 20.0; (h) 25.0; (i) 30.0; (j) 45.0

图4 实验钢连续冷却转变后的显微组织

Fig.4 Microstructures of experimental steel after continuous cooling transformation

表4 不同冷却速度对应的相变和相变温度

Table 4 Phase change and transformation temperature at different cooling rates

冷却速度与HV2: 1—0.5 ℃/s, 237; 2—1.0 ℃/s, 248;

3—2.5 ℃/s, 229; 4—5.0 ℃/s, 241; 5—10.0 ℃/s, 237;

6—15.0 ℃/s, 245; 7—20.0 ℃/s, 278; 8—25.0 ℃/s, 304;

9—30.0 ℃/s, 273; 10—45.0 ℃/s, 338

奥氏体化温度:1 050 ℃; 奥氏体化时间:10 min

图5 X80钢的CCT图

Fig.5 Continuous cooling transformation curves of experimental X80 steel

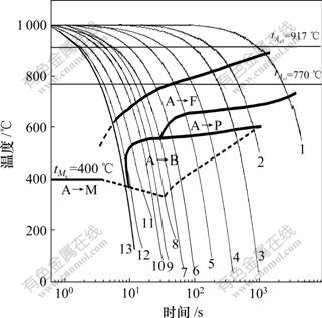

2.4 与Q345钢CCT图的比较

图6所示为Q345钢的CCT图[14]。可以看出:当Q345钢奥氏体以不同速度连续冷却时,有先共析铁素体的析出(A→F)和珠光体转变(A→P)、贝氏体转变(A→B)以及马氏体转变(A→M);当冷却速度很小(小于0.5 ℃/s)时,转变产物为铁素体和珠光体(F+P);当冷却速度为0.5 ℃/s时,开始出现贝氏体(B);当冷却速度为0.5~10.0 ℃/s时,转变产物为铁素体、珠光体和贝氏体(F+P+B);当冷却速度为15.0 ℃/s时,珠光体基本消失,转变产物为铁素体和贝氏体(F+B);当冷却速度大于20.0 ℃/s时,有马氏体转变发生,直接水冷(速度约400.0 ℃/s)时,转变产物主要为马氏体和少量游离铁素体。

冷却速度与HV2: 2—0.1 ℃/s, 121; 2—0.5 ℃/s, 127;

3—1.0 ℃/s, 134; 4—2.5 ℃/s, 142; 5—5.0 ℃/s, 158;

6—10.0 ℃/s,176; 7—15.0 ℃/s, 180; 8—20.0 ℃/s, 215;

9—25.0 ℃/s, 252; 10—30.0 ℃/s, 286; 11—45.0 ℃/s, 301;

12—60.0 ℃/s, 305; 13—75.0 ℃/s, 351

图6 Q345钢的CCT图

Fig.6 Continuous cooling transformation curves of Q345 steel

根据相应的组织分析,Q345钢几乎在每种冷却速度下都有铁素体析出,只是铁素体形态随冷却速度变化而变化。当冷却速度较慢时,其形态以块状为主,随着冷却速度的增大,铁素体组织细化并且出现针状形态,当冷却速度非常大(60.0 ℃/s和75.0 ℃/s)时,有游离铁素体存在。珠光体转变大约在冷却速度低于15.0 ℃/s时发生,随着冷却速度的增加,较粗形态珠光体过渡为较细的索氏体和屈氏体,数量逐渐减少。贝氏体转变的冷却速度范围非常宽,在冷却速度为0.5 ℃/s时,就出现少量贝氏体,其形态似针状铁素体,冷却速度加大,其针状组织变细。快速冷却对应的显微组织以马氏体为主,也有少量贝氏体存在。当冷却速度大于20.0 ℃/s时,发生马氏体转变,主要转变产物为板条状马氏体。

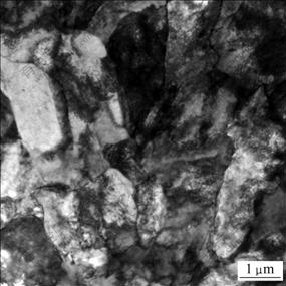

Q345钢是我国产量最大、应用最广的低碳微合金钢,早期也用作管线钢。对比X80实验钢和Q345钢的化学成分可知:X80钢的C含量比Q345的碳含量低,P和S含量也更低,此外,X80实验钢以Mn-Nb低碳微合金钢为基础,加入了0.21% Mo。添加微合金元素Mo起到抑制铁素体和珠光体相变作用,形成非等轴状显微组织。图7所示为实验钢的透射电镜像。可见:获得的是一种类贝氏体组织,在透射电镜下呈板条或针片状。Coldren和Smith提出的针状铁素体的特征为不规则非等轴状、晶粒界限模糊、没有完整的连续晶界、粒度不一致[15-16]。对于低碳微合金管线钢,将连续冷却过程中形成的准多边形铁素体、无明显原奥氏体晶界的贝氏体铁素体、粒状贝氏体及M/A组元归类到工程用管线钢针状铁素体(AF)组织的范畴。

图7 实验钢微观结构的TEM像

Fig.7 TEM image of Microstructure of experimental steel

针状铁素体的形成温度略高于上贝氏体的形成温度,以扩散和切变的混合机制实现相变,因而在非等轴铁素体基体中具有高的亚结构和位错密度。典型的针状铁素体是以1~5 ?m的准多边形铁素体与针状片条或板条结构为基础的上贝氏体的混合组织,原奥氏体晶界没有保存。对于X80实验钢,当冷却速度为5.0 ℃/s时,开始出现大量粒状贝氏体;当冷却速度为20.0 ℃/s时,组织以粒状贝氏体和针状铁素体为主。因此,实验钢在5.0~20.0 ℃/s的冷速范围内均能获得大量针状铁素体组织,细小弥散的针状铁素体使实验用钢具有较大的强度和韧性匹配,这正是管线钢生产中所期望达到的目标。

3 结论

(1) 利用差热分析法、膨胀法结合金相-硬度法,测得1种低碳微合金管线钢的CCT图。CCT图表明:随着冷却速度增加,相转变温度下降,且下降幅度较大。

(2) 根据CCT图和不同冷却速度对应的显微组织可知:当冷却速度为0.5~1.0 ℃/s时,转变产物为多边形铁素体和少量珠光体;当冷却速度为2.5 ℃/s时,转变产物为准多边形铁素体和少量粒状贝氏体;在5.0~20.0 ℃/s的冷速范围内,转变产物主要为针状铁素体和粒状贝氏体,且粒状贝氏体的数量随冷速的增加逐渐增多;当冷却速度大于25.0 ℃/s时,转变产物中开始出现少量下贝氏体;当冷却速度大于45.0 ℃/s时,主要转变产物为有明显原奥氏体晶界的下贝氏体。

(3) 添加0.21%Mo起到抑制铁素体和珠光体相变作用,促进针状铁素体组织形成,实验钢在5.0~20.0 ℃/s的较宽冷却速度范围内连续冷却都能得到需要的针状铁素体组织,说明采用低碳Mn-Nb-Mo微合金管线钢容易得到管线钢工程需要的组织。在实际工业生产中,采用较大冷却速度,可使奥氏体组织能够充分转变为针状铁素体组织。

参考文献:

[1] LI He-lin, JI Ling-kang, XIE Li-hua. Current situation analysis of oil steel pipe in China[J]. Journal of Hebei University of Science and Technology, 2006, 27(1): 1-5.

[2] 刘智慧. 国内外原油管道技术发展综述[J]. 石油规划设计, 2006, 17(3): 42-44.

LIU Zhi-hui. Development status of technologies for oil transmission pipeline at home and abroad[J]. Petroleum Planning and Engineering, 2006, 17(3): 42-44.

[3] 冯耀荣, 李鹤林. 管道钢及管道钢管的研究进展与发展方向[J]. 石油规划设计, 2005, 16(5): 1-7.

FENG Yao-rong, LI He-lin. Trend of research on pipeline steel and tube[J]. Petroleum Planning and Engineering, 2005, 16(5): 1-7.

[4] XIAO Fu-ren, LIAO Bo, SHAN Yi-yin, et al. Challenge of mechanical properties of an acicular ferrite pipeline steel[J]. Materials Science and Engineering A, 2006, 431: 126-136.

[5] Tabkhi F, Pibouleau L, Azzaro-Pantel C, et al. Microstructure and high strength-toughness combination of a new 700 MPa Nb-microalloyed pipeline steel[J]. Materials Science and Engineering A, 2008, 478(1/2): 26-37.

[6] 竹内泉, 牧野宽之. 高压输气管线用高强度级管线钢管[J]. 焊管, 2007, 30(6): 19-23.

Takeuchi I, Makino H. High strength pipeline steel pipe used for high pressure gas transmission[J]. Welded Pipe, 2007, 30(6): 19-23.

[7] ZHAO Ming-chun, YANG Ke, XIAO Fu-ren, et al. Continuous cooling transformation of undeformed and deformed low carbon pipeline steels[J]. Materials Science and Engineering A, 2003, 355: 126-136.

[8] XUE Xiao-huai, SHAN Yi-yin, ZHENG Lei, et al. Microstructural characteristic of low carbon microalloyed steels produced by thermo-mechanical controlled process[J]. Materials Science and Engineering A, 2006, 438/440: 285-287.

[9] FAN Yue-hua, FAN Xin-min, WEI Wei, et al. Study oncontinuouscoolingtransformationof high strengthpipeline steel[J]. Transactions of Materials and Heat Treatment, 2008, 29(3): 62-65.

[10] 刘守显, 罗海文, 王瑞珍, 等. 低碳微合金管线钢的连续冷却相变及组织研究[J]. 中国冶金, 2007, 17(8): 36-39.

LIU Shou-xian, LUO Hai-wen, WANG Rui-zhen, et al. Study on microstructures and continuous cooling transformation behavior of low-carbon microalloyed pipeline steel[J].China Metallurgy, 2007, 17(8): 36-39.

[11] 崔忠圻. 金属学与热处理[M]. 北京: 机械工业出版社, 2001: 172-190.

CUI Zhong-qi. Metallurgy and heat treatment[M]. Beijing: China Machine Press, 2001: 172-190.

[12] YB/T 5129—93, 钢的连续冷却转变曲线图的测定方法(膨胀法)[S].

YB/T 5129—93, Mesuring method of curves of continuous cooling transformation[S].

[13] 李鹤林. 高强度微合金管线钢显微组织分析与鉴别图谱[M]. 北京: 石油工业出版社, 2001: 102-123.

LI He-lin. Fingerprint of microstructure analysis and identify of high strength pipelines[M]. Beijing: Petroleum Industry Press, 2001: 102-123.

[14] 林武, 张希旺, 赵延阔, 等. Q345钢奥氏体连续冷却转变曲线(CCT图)[J]. 材料科学与工艺, 2009, 17(2): 247-250.

LIN Wu, ZHANG Xi-wang, ZHAO Yan-kuo, et al. Continuous cooling transformation curve of undercooling austenite about Q345[J]. Materials Science and Technology, 2009, 17(2): 247-250.

[15] LIAO Bo, XIAO Fu-ren. Research on microstructure and strength-toughening mechanism ofacicularferritepipeline steel[J]. Transactions of Materials and Heat Treatment, 2009, 30(2): 57-62.

[16] Kima Y M, Lee H, Kimb N J. Transformation behavior and microstructural characteristics ofacicular ferrite in linepipe steels[J]. Materials Science and Engineering A, 2008, 478(1/2): 361-370.

收稿日期:2009-10-23;修回日期:2010-02-05

基金项目:湖南省自然科学基金资助项目(05JJ30200)

通信作者:李红英(1963-),女,湖南湘乡人,博士,教授,从事金属材料的强韧化研究;电话:0731-88836328;E-mail: lhying@mail.csu.edu.cn

(编辑 陈爱华)