DOI: 10.11817/j.issn.1672-7207.2015.03.004

3D-CAFE法对温度场影响430铁素体不锈钢凝固组织的分析

庞瑞朋1, 2, 3,李长荣2,王福明1, 3,张国庆1, 3

(1. 北京科技大学 钢铁冶金新技术国家重点实验室,北京,100083;

2. 北京科技大学 材料科学与工程学院,北京,100083;

3. 北京科技大学 冶金与生态工程学院,北京,100083)

摘要:在缓冷条件下,430铁素体不锈钢铸件的等轴晶比例只有30%(体积分数)左右,等轴晶的直径为0.5~2.0 mm,柱状晶的长度为1.5~2.5 mm,宽度为0.5~1.5 mm;当传热系数h为30 W/(m2·K)时,模拟计算得到的铸件凝固组织和冷却曲线与实验基本一致。采用Procast软件的3D-CAFE模块对缓冷条件下430铁素体不锈钢凝固过程的温度场进行分析,铸件凝固过程是从四周向中心推进,热流密度从表面到中心逐渐减小;离侧壁23 mm后和离底部27 mm后液相线前沿为均匀的温度场,离侧壁20 mm和离底部27 mm后凝固前沿温度场变得均匀;底部到75 mm处,凝固速率逐渐减小,靠近侧壁的凝固速率最大为1.88 mm/s,在75 mm处达到了最小值0.22 mm/s。固两相区的宽度逐渐增加且在75 mm处达到最大值为52 mm。

关键词:等轴晶;柱状晶;温度场

中图分类号:TF771.1 文献标志码:A 文章编号:1672-7207(2015)03-0786-08

Effect of temperature field on solidification structure of 430 ferritic stainless steel based on 3D-CAFE method

PANG Ruipeng1, 2, 3, LI Changrong2, WANG Fuming1, 3, ZHANG Guoqing1, 3

(1. State Key Laboratory of Advanced Metallurgy, University of Science and Technology Beijing, Beijing 100083, China;

2. School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China;

3. School of Metallurgical and Ecological Engineering, University of Science and Technology Beijing,

Beijing 100083, China)

Abstract: The equiaxed grains ratio of 430 ferritic stainless steel is only about 30% under slow cooling conditions, and the equiaxed grains diameter is between 0.5-2.0 mm. The columnar grain length is between 1.5-2.5 mm, and the width is between 0.5-1.5 mm. When the heat transfer coefficient h is 30 W/(m2·K), the solidification structure and cooling curve of the simulation computation are basically the same as the experimental results. The temperature field of 430 ferrite stainless steel during solidification process under slow cooling conditions was analyzed based on 3D-CAFE method provided by Procast software. The simulation results show that the solidification process of casting is propelled from the periphery to the center, and heat flux from the surface to the center gradually decreases. The liquidus front temperature field is uniform at 23 mm from the side and 27 mm from the bottom, and from the bottom to 75 mm, the solidification rate gradually decreases. It reaches the maximum value of 1.88 mm/s near the side wall, and achieves the minimum value of 0.22 mm/s at 75 mm; solid-liquid two-phase region width gradually increases and reaches the maximum value of 52 mm at 75 mm.

Key words: equiaxed grains; columnar grains; temperature field

温度场决定凝固组织,晶粒的形核和长大释放潜热又影响温度场和凝固组织[1]。在铸件凝固过程中,通过有效地控制温度场,能够获得需要的凝固组织;铸件凝固组织的晶粒形态分为柱状晶和等轴晶,当铸件成分确定,晶粒形态控制是凝固组织控制的关键,可以通过凝固过程控制温度场来实现[2],且温度场直接影响铸件凝固组织中形成的等轴晶比率[3]。430铁素体不锈钢凝固过程中形成发达的柱状晶将影响其成形性,减少甚至避免柱状晶的形成,促进等轴晶的形成,对430铁素体不锈钢来说尤为重要[4],因此,研究430铁素体不锈钢凝固过程的温度场具有重要的意义。对铸件凝固过的温度场进行分析需要多点测温,而多点测温在实验室是很难实现的,且分析过程既费时又费力,数值模拟能有效克服多点测温的困难且准确的获得温度数据[5-6]。本文作者采用实验与Procast的3D-CAFE[7-9]模块(元胞自动机模型CA与有限元FE耦合起来而建立宏观-微观的模型)相结合的方法,对缓冷条件下430铁素体不锈钢凝固过程的温度场进行分析,主要研究铸件凝固过程的热流密度、凝固前沿和液相线前沿的温度梯度、固液两相区宽度、凝固速率及凝固组织。3D-CAFE模块对凝固过程宏观模拟的方法是采用有限元(FE)方法对铸件凝固过程中发生的传热、溶质扩散及动量传输等宏观传输过程进行模拟。该方法可以计算出铸件凝固时的温度场、溶质场、速度场[10-11];同时,可以再现晶粒的形核与生长和预测铸件在不同凝固条件下的凝固组织[12-14]。

1 实验与模型建立

1.1 实验结果分析

采用ZG-0.01型真空感应炉冶炼430铁素体不锈钢,真空度为10 Pa,冶炼铸坯质量为5 kg,其主要成分如表1所示。由Procast软件算得固相线和液相线温度分别为1 733 K和1 771 K,浇注方式为炉内浇注,浇注温度为1 821 K,钢液瞬间充满高纯氧化铝坩埚(顶部加高纯氧化铝盖),并整体放入石英砂中,冷却条件为缓冷。

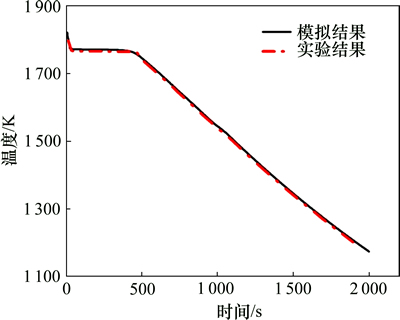

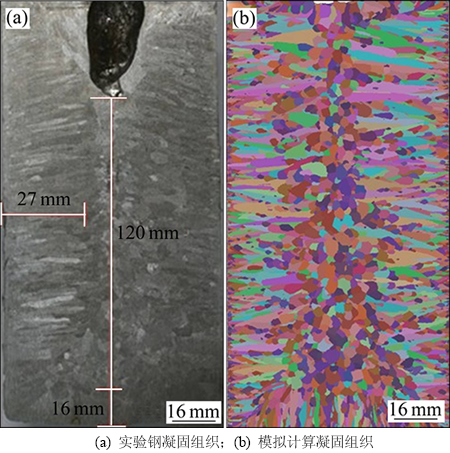

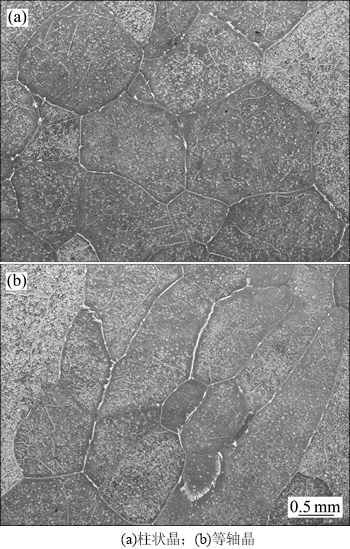

采用PtRh30-PtRh60型热电偶进行测温,热电偶垂直放入铸件中,得到的冷却曲线如图1所示,得到直径×高度为76 mm×150 mm的铸件,将其沿直径纵向抛开,用砂纸打磨后,采用HCl,HNO3与H2O三者之间体积比为1:1:1的试剂对其侵蚀,得到的铸件凝固组织见图2(a)。由图2(a)可以看出:铸件中等轴晶比例(体积分数)只有30%左右。图3(a)和(b)所示分别为柱状晶照片和等轴晶照片,等轴晶的直径在0.5~2.0 mm之间,柱状晶的长度为1.5~2.5 mm之间,宽度为0.5~1.5 mm之间。

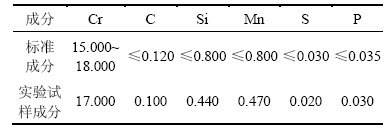

表1 430铁素体不锈钢的标准成分及实验试样成分(质量分数)

Table 1 Standard and experimental sample composition of 430 ferritic stainless steels %

图1 实验与模拟计算的冷却曲线

Fig.1 Cooling curves of experimental and simulative calculation

图2 铸件的凝固组织

Fig. 2 Solidification structures of casting

图3 铸件的宏观组织

Fig. 3 Macrostructure of casting

1.2 模型建立与参数确定

为了对缓冷条件下430铁素体不锈钢凝固过程的温度场进行分析,采用Procast软件的3D-CAFE模块对相同尺寸的铸件进行模拟计算。为了使模拟条件与实验条件相同,模拟计算的铸件四周均设为传热且采用相同的传热系数h,由于瞬间充满高纯氧化铝坩埚,可以忽略充型过程的温度损失和流体流动。模拟计算采用的方程如下。

1.2.1 控制方程

1) 质量守恒方程:

(1)

(1)

2) 动量守恒方程(x方向,y和z方向与其类似):

(2)

(2)

3) 能量守恒方程:

(3)

(3)

其中:

(4)

(4)

式中:u,v和w分别为x,y和z方向速度分量,m/s;fl为液相体积分数;fs为固相体积分数;p为压力,Pa;gx为x方向重力分量,m/s2;ρ为密度,kg/m3;u为绝对黏度,Pa·s,kT为热传导率,W/(m·K);K为渗透率,m2;cp为比热容,J/(kg·K);t为时间,s;L为凝固潜热,J/kg;T为节点温度,K;H为热焓,J/mol。

1.2.2 异质形核模型

3D-CAFE采用连续形核模型来处理形核,假设不均匀形核时,形核发生在一系列不同的形核位置上,而这些形核位置可以由连续的分布函数dn/d( )即高斯分布来描述:

)即高斯分布来描述:

(5)

(5)

式中: 为平均形核过冷度,K;

为平均形核过冷度,K; 为形核过冷度标准方差,K;nmax为正态分布从0到∞积分得到的最大形核密度,面形核的单位是m-2,体形核的单位是m-3。其中dn是由过冷度

为形核过冷度标准方差,K;nmax为正态分布从0到∞积分得到的最大形核密度,面形核的单位是m-2,体形核的单位是m-3。其中dn是由过冷度 的增加引起晶粒密度增加量,因此,在某一过冷度下晶粒密度可以由下式计算:

的增加引起晶粒密度增加量,因此,在某一过冷度下晶粒密度可以由下式计算:

(6)

(6)

式中:n为晶粒密度。

1.2.3 动力学模型

固液界面前沿总的过冷度为

(7)

(7)

式中: ,

, ,

, 和

和 分别为成分过冷度、热过冷度、动力学过冷度和曲率过冷度,通常后3项相对于

分别为成分过冷度、热过冷度、动力学过冷度和曲率过冷度,通常后3项相对于 来说很小,所以计算中常常忽略。

来说很小,所以计算中常常忽略。

为了加速计算的进程,对KGT模型进行拟合,即用三次多项式拟合枝晶生长速度v和过冷度 之间的关系,得到枝晶尖端生长速度的多项式:

之间的关系,得到枝晶尖端生长速度的多项式:

(8)

(8)

其中:a2和a3为生长动力学系数,m/(s·K3)。

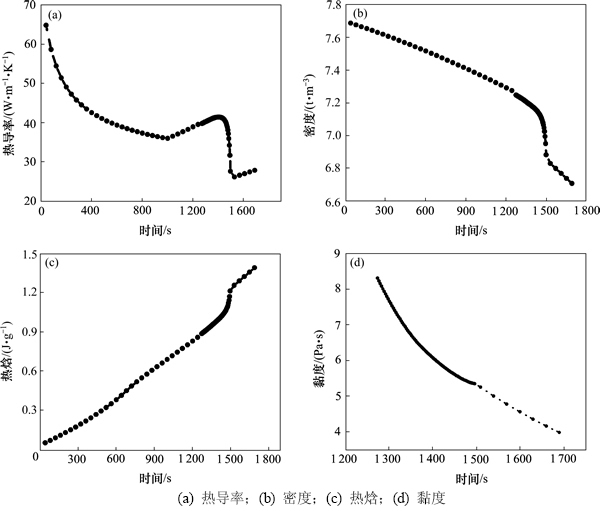

由图3和ASTM标准算得体形核密度nv,max=8×108,面形核密度ns,max=4×106;动力学系数为:a2=0,a3=2.3×10-6 ,模拟计算采用的其他高斯分布参数为:体形核过冷度 =2 K,体标准方差+--+过冷度

=2 K,体标准方差+--+过冷度 =0.5 K,面形核过冷度

=0.5 K,面形核过冷度 =1 K,面标准方差过冷度

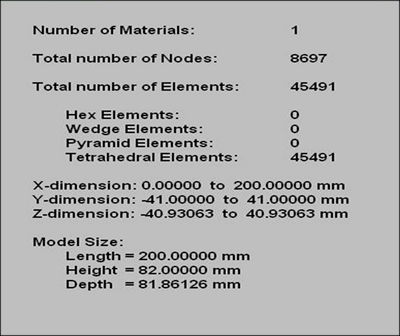

=1 K,面标准方差过冷度 =0.1 K。截取铸件纵截面沿半径方向厚度为10 mm的区域进行凝固组织计算。模拟计算使用的热物性参数如图4(a)~(d)所示,铸件尺寸和网格参数如图5所示。采用不同h进行反复计算,当h=30 W/(m2·K) 时,与实验相同位置的测温点得到的冷却曲线如图1所示,得到的430铁素体不锈钢铸件的凝固组织如图2(b)。由图1和图2可知:模拟计算得到的温度数据和铸件的凝固组织与实验得到的基本一致,说明用Procast的3D-CAFE模块分析缓冷条件下430铁素体不锈钢凝固过程的温度场是可行的。

=0.1 K。截取铸件纵截面沿半径方向厚度为10 mm的区域进行凝固组织计算。模拟计算使用的热物性参数如图4(a)~(d)所示,铸件尺寸和网格参数如图5所示。采用不同h进行反复计算,当h=30 W/(m2·K) 时,与实验相同位置的测温点得到的冷却曲线如图1所示,得到的430铁素体不锈钢铸件的凝固组织如图2(b)。由图1和图2可知:模拟计算得到的温度数据和铸件的凝固组织与实验得到的基本一致,说明用Procast的3D-CAFE模块分析缓冷条件下430铁素体不锈钢凝固过程的温度场是可行的。

图 4 热物性参数

Fig. 4 Thermo-physical property parameters

2 温度场结果分析

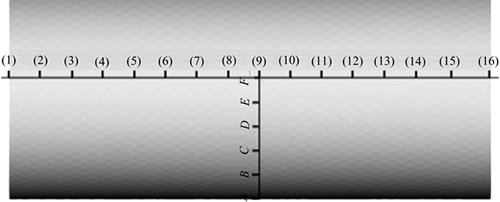

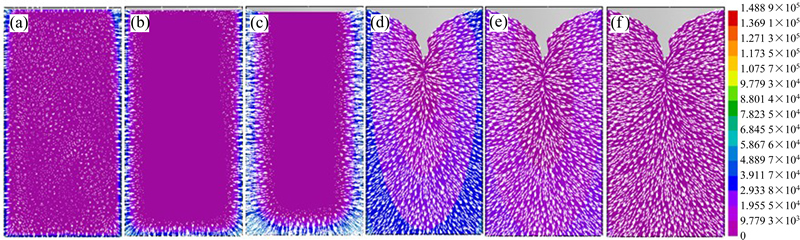

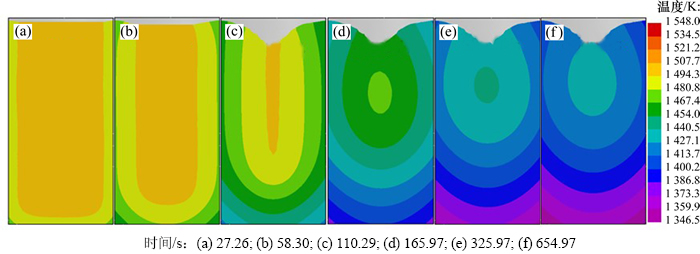

图6所示为测温点位置分布,图7所示为铸件凝固过程中不同时刻的热流密度变化,图中白色箭头代表热流方向。由图7可以看出:由于铸件四周冷却条件一样,铸件凝固过程热量是从四周散出,且四周的热流密度相同;同时,热流密度从表面到中心逐渐减小,铸件的凝固过程是从四周向中心推进,随着凝固的进行,由于顶部液体的补缩导致顶部产生凝固收缩。

图5 网格参数和铸件尺寸

Fig. 5 Grid parameters and size of casting

图6 测温点位置分布

Fig. 6 Location distribution of temperature measuring points

图7 铸件凝固过程的热流密度变化(由左到右依次是凝固开始到结束的热流变化)

Fig. 7 Variationa of heat flux density in solidification process of casting (from left to right shows in sequence change of heat flux from beginning to end of solidification)

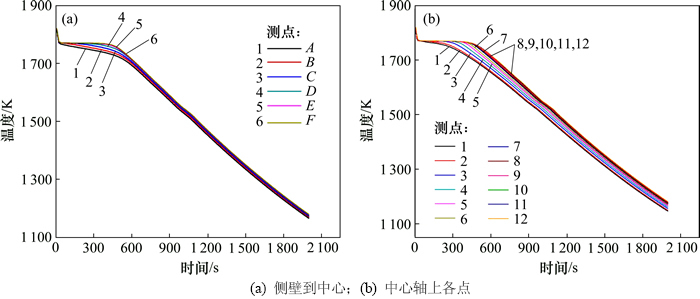

图8(Ⅰ)和(Ⅱ)所示分别为离铸件底部75 mm(各点之间的间隔为7.6 mm)处沿半径从侧壁到中心各点的冷却曲线和沿铸件纵向中心轴从底部到顶部各点的冷却曲线(各点之间的间隔为10 mm),由于铸件顶部凝固收缩,所以温度取值只到110 mm处。由图8可以看出:钢液开始冷却时,由于周围环境与熔体温差大和液相中的对流和导热散热,导致冷却初期温度迅速下降;随着凝固冷却的进行,由于潜热释放量与热量散失量相等,冷却曲线的液相线温度附近出现了温度平台,且越靠近铸件中心区域的温度平台越大,说明越靠近中心区域热量散失越困难,通过热流密度越靠近中心越小也可以说明这一点;铸件凝固结束后,是连续降温过程。

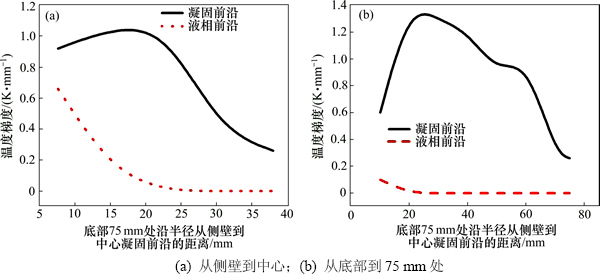

图9所示为铸件凝固过程中温度场。由图9可见:由于铸件是四周均传热且传热系数相同,铸件凝固过程中形成了对称的温度场,所以只分析了从铸件底部沿纵向轴到纵向高度一半和铸件中间位置从侧壁沿半径到中心的凝固前沿和液相线前沿温度梯度及凝固速率,结果如图10和图11所示。当测温点i达到液相线温度TL的时刻ti,对应的下一点测温点i+1的温度为Ti+1,则G=(Ti+1-TL)/(xi+1-xi)为液相线前沿温度梯度,其中xi和xi+1分别为测温点i和i+1离侧壁或底部的距离;将固相线推进速率定义为凝固速率,测温点i和i+1达到固相线温度的时刻分别为ti和ti+1,则凝固速率为R=(xi+1-xi)/(ti+1-ti)。

图10所示分别为离铸件底部75 mm处沿半径从侧壁到中心凝固前沿和液相线前沿的温度梯度随离侧壁距离变化曲线和从铸件底部到75 mm处凝固前沿和液相线前沿的温度梯度随离底部距离变化曲线。由图10可知:在离侧壁23 mm到铸件中心和在离底部27 mm到75 mm处的液相线前沿温度梯度均为0 K/mm,而分别在离侧壁8 mm处和离底部10 mm处达到了最大值0.92 K/mm和0.1 K/mm,说明缓冷条件下液相线前沿温度场比较均匀,且离侧壁23 mm后和离底部27 mm后液相线前沿为均匀的温度场。

图8 冷却曲线

Fig. 8 Cooling curves

图9 铸件的温度分布

Fig. 9 Temperature distribution of casting

图10 温度梯度随距离的变化

Fig. 10 Temperature gradient change with distance

从侧壁到中心和从底部到75 mm处,凝固前沿温的度梯度总的趋势是降低的,如图10(a)所示;从铸件的侧壁到中心凝固前沿的温度梯度在离侧壁20 mm达到最大值1.05 K/mm后呈线性降低,在中心处达到最小值0.26 K/mm。由图10(b)可以看出:从铸件底部到75 mm处凝固前沿温度梯度先逐渐增加,在离底部27 mm处达到最大值1.36 K/mm后逐渐降低,在中心位置达到最小值0.26 K/mm;说明离侧壁20 mm和离底部27 mm后凝固前沿温度场变得均匀。

温度场决定凝固组织,温度梯度越小,温度场越均匀越有利于形成等轴晶,由上述分析可知,从侧壁到中心和从底部到中心温度场逐渐变得均匀,且从离侧壁23 mm后和离底部27 mm后温度场变均匀;如图2所示:从离底部16 mm后和离侧壁27 mm后铸件的凝固组织转变为等轴晶。

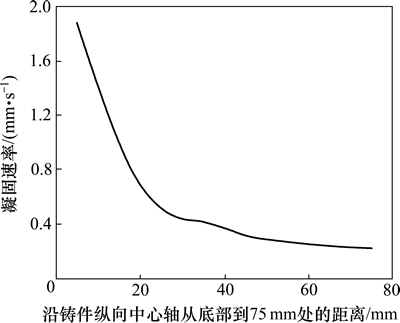

图11所示为沿铸件纵向中心轴从底部到75 mm处的凝固速率。由图11可以看出:在缓冷条件下,从底部到75 mm处,凝固速率逐渐减小,靠近侧壁的凝固速率最大为1.88 mm/s,在75 mm处达到最小值0.22 mm/s,说明缓冷条件下,随着凝固壳厚度的增加,热量散失困难;从侧壁到中心,凝固速率逐渐降低,说明晶粒生长速度逐渐降低,而晶粒生长速度越小,释放的潜热越少,有利于凝固前沿过冷区的产生和过冷度的增加,被激发等轴晶的形核核心数目增加,从而阻止了柱状晶的生长,凝固组织由柱状晶转变为等轴晶(如图2所示),在离底部16 mm后为铸件的凝固组织为等轴晶。

图11 凝固速率

Fig. 11 Solidification rate

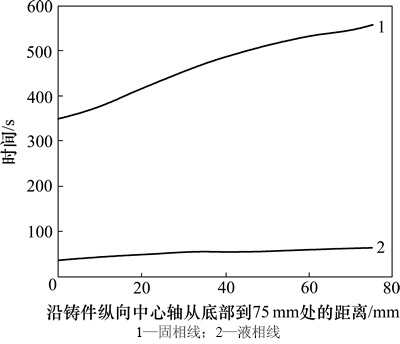

在铸件凝固过程中,很难测量固液两相区的宽度,可以用固相线和液相线的位置来估计固液两相区的宽度[15],图12所示为固相线和液相线离铸件底部距离随时间变化曲线。从铸件底部到110 mm处固两相区的宽度逐渐增加,在75 mm处达到了最大值,宽度大约为52 mm。由式(9)可知:温度梯度和凝固速率越小,固液两相区宽度越大。从图10和11可见:铸件凝固过程中温度梯度和凝固速率逐渐降低,所以,在凝固过程中,固液两相区的宽度逐渐增加。固液两相区越宽,越有利于细瘦纤维枝晶的发展,有利于枝晶碎片的产生;当碎片传送到柱状晶前沿可以作为等轴晶的形核核心,从而利于等轴晶的形成。

(9)

(9)

式中:DL为扩散系数,m2/s;R为凝固速率,mm/s;ko为分配系数;GL为温度梯度,K/mm;mL为液相线斜率;co为原始合金成分(质量分数),%。

图12 固相线和液相线离底部距离随时间变化曲线

Fig. 12 Change curve of solidus and liquidus distance from bottom with time

3 结论

1) 在缓冷条件下,430铁素体不锈钢铸件中等轴晶比例只有30 %左右,等轴晶的直径在0.5~2.0 mm之间,柱状晶的长度为1.5~2.5 mm之间,宽度为0.5~1.5 mm之间;当传热系数h=30 W/(m2·K)时,模拟计算得到的铸件凝固组织和冷却曲线与实验基本一致。

2) 在缓冷条件下,越靠近铸件中心区域冷却曲线的温度平台越大;铸件的凝固过程是从四周向中心推进,热流密度从表面到中心逐渐减小,说明随着凝固壳厚度的增加,热量散失困难。

3) 在缓冷条件下,液相线前沿温度场比较均匀,且离侧壁23 mm后和离底部27 mm后液相线前沿为均匀的温度场;从侧壁到中心和从底部到75 mm处,凝固前沿的温度梯度总的趋势降低,且离侧壁20 mm和离底部27 mm后凝固前沿温度场变得均匀。

4) 在缓冷条件下,底部到75 mm处,凝固速率逐渐减小,靠近侧壁的凝固速率最大为1.88 mm/s,在75 mm处达到最小值0.22 mm/s;从铸件底部到110 mm处固两相区的宽度逐渐增加,在75 mm处达到了最大值,宽度大约为52 mm。

参考文献:

[1] David R J, Haruyuki I, Shinji M, et al. Microstructural development during directional solidification of a-seeded TiAl alloys[J]. Acta Materialia, 2006, 54(4): 1077-1085.

[2] 马幼平. 金属凝固理论与技术[M]. 北京: 冶金工业出版社, 2008: 71-73.

MA Youping. Fundamentals of metal solidification[M]. Beijing: Metallurgical Industry Press, 2008: 71-73.

[3] Chung S I, Yoon J K. Numerical analysis of effect of electromagnetic stirring on solidification phenomena in continuous casting[J]. Ironmaking and Steelmaking, 1996, 23(5): 425-432.

[4] Huh M Y, Engler O. Effect of intermediate annealing on texture, formability and ridging of 17%Cr ferritic stainless steel sheet[J]. Material Science and Engineering: A, 2001, 308(1/2): 74-87.

[5] Yoshihiro Y, Yoshihiro O, Kato Y, et al. Development of ferritic stainless steel sheets with excellent deep drawability by {111} recrystallization texture control[J]. JSAE Review, 2003, 24(4): 483-488.

[6] Dong H B, Lee P D. Simulation of the columnar-to-equiaxed transition indirectionally solidified Al-Cu alloys[J]. Acta Materialia, 2005, 53(3): 659-668.

[7] Banaszek J, Mcfadden S, Browne D J, et al. Natural convection and columnar-to-equiaxed transition prediction in a front- tracking model of alloy solidification[J]. Metallurgical and Materials Transactions A, 2007, 38(A): 1476-1484.

[8] Lan C W, Lee M H, Chuang M H, Shih C J. Phase field modeling of convective and morphological instability during directional solidification of an alloy[J]. Journal of Crystal Growth, 2006, 295(2): 202-208.

[9] Li D M, Li R, Zhang P W A. cellular automaton technique for modeling of a binary dendritic growth with convection[J]. Applied Mathematical Modelling, 2007, 31 (6): 971-982.

[10] Gandin C A, Desbiolles J L, Rappaz M, et al. A three- dimensional cellular automation-finite element model for the prediction of solidification grain structures[J]. Metallurgical and Materials Transaction A, 1999, 30(12): 3153-3165.

[11] Martorano M A, Biscuola V B. Predicting the columnar-to- equiaxed transition for a distribution of nucleation under coolings[J]. Acta Materialia, 2009, 57(2): 607-615.

[12] 张红伟, Keiji N, 王恩刚, 等. Al-Si合金宏观偏析、凝固组织演变的元胞自动机-控制容积法耦合模拟[J]. 中国有色金属学报, 2012, 22(7): 1904-1913.

ZHANG Hongwei, Keiji N, WANG Engang, et al. Research and development progress of high temperature deformation of titanium alloy with discontinuous yielding[J]. The Chinese Journal of Nonferrous Metals, 2013, 22(7): 1904-1913.

[13] Chang S R, Kim J M, Hong C P. Numerical simulation of microstructure evolution of Al alloys in centrifugal casting[J]. ISIJ International, 2001, 41(7): 738-747.

[14] Dong H B, Lee P D. Simulation of the columnar-to-equiaxed transition in directionally solidified Al-Cu alloys[J]. Acta Materialia, 2005, 53(3): 659-668.

[15] Singh A K,Muraleedharan K, Banerjee D.Solidification structure in a cast γ alloy[J].Scripta Materialia, 2003, 48(6): 767-772.

(编辑 陈爱华)

收稿日期:2014-05-22;修回日期:2014-07-13

基金项目(Foundation item):国家高技术研究发展计划(863计划)项目( 2013AA031601);中央高校基本科研业务费专项资金资助(FRF-SD-12-010A) (Project(2013AA031601) supported by the National High Research Development Program of China (863 Program); Project(FRF-SD-12-010A) supported by the Fundamental Research Funds for the Central Universities)

通信作者:王福明,教授,博士生导师,从事合金化、相变与组织控制研究;E-mail: wangfuming@metall.ustb.edu.cn