文章编号:1004-0609(2013)S1-s0585-05

TA18变径管高压气胀成形工艺及壁厚分布

刘 钢1, 2,武 永1, 2,王建珑1, 2,苑世剑1, 2,汤泽军3

(1. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001;

2. 哈尔滨工业大学 金属精密热加工国防重点实验室,哈尔滨 150001;

3. 南京航空航天大学 机电学院,南京 210000)

摘 要:在一定的温度范围,以高压气体作为传力介质,通过温度、内压和补料量匹配加载使管坯贴膜的热加工技术,称为高压气胀成形技术。在800 ℃时,以不同加载路径和不同补料量对TA18管材进行胀形实验,研究加载路径和补料量对50%膨胀率TA18钛合金变径管的成形过程和壁厚分布的影响。结果表明:在补料阶段,内压过小或者过大引起材料在变径管过渡区堆积起皱;不同轴向补料量成形的TA18变径管,壁厚分布规律不同;在合适的加载路径下,分别补料20、30、36和40 mm得到的TA18变径管的最大减薄率分别为29.07%、24.01%、18.15%和13.02%。

关键词:TA18钛合金;高压气胀成形;轴向补料;变径管;壁厚分布

中图分类号:TG306 文献标志码:A

High pressure pneumatic forming process and wall thickness distribution of TA18 titanium alloy large expansion ratio tube

LIU Gang1, 2, WU Yong1, 2, WANG Jian-long1, 2, YUAN Shi-jian1, 2, TANG Ze-jun3

(1. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

2. National Key Laboratory for Precision Hot Processing of Metals, Harbin Institute of Technology, Harbin 150001, China;

3. Mechanic and Electric Engineering, Nanjing University of Aeronautics and Astronautics, Nanjing 210000, China)

Abstract: At a certain temperature range, the tube blank is bulged out until it attaches to the inside of mould cavity by high pressure gas, matching with axial feeding. This plastic forming processing is called high pressure pneumatic forming (HPPF). At 800 ℃, the 50% expansion ratio tubes of TA18 titanium alloy were formed with different loading paths and different axial feedings. The results show that the wrinkles are formed in the transition zone of tube because the materials are accumulated when the inner pressure is too high or too low. The thickness of adjustable tubes with different axial feedings is changed. At the appropriate loading path, TA18 adjustable tubes without defects are formed with axial feeding of 20, 30, 36 and 40 mm, and their maximum thinning ratio are 29.02%, 18.73%, 13.41% and 10.49%.

Key words: TA18 titanium alloy; high pressure pneumatic forming; axial feeding; large expansion ratio tube; wall thickness distribution

钛合金具有耐高温、耐腐蚀等优良的综合性能和优异的机械加工性能,被广泛应用于国防等关键领域的零部件生产,例如发动机叶片、蒙皮、机翼、紧固件、吊架、液压管路、旋翼、驱动部件和控制系统等[1-2]。其中,TA18钛合金因良好的综合性能早在20世纪70年代就被广泛的应用于F-14、F-15和波音747等航空航天工业的液压和燃油管路系统[3]。变径管件是汽车燃油及排气系统、飞机液压控制和燃油系统、火箭等航天飞行器燃料输送系统等管路中用来作为补偿和过渡的元件。为此,研究TA18钛合金变径管等复杂截面整体结构件的成形工艺显得非常重要。

ZHANG等[4]采用超塑性成形的方法成形了钛合金波纹管件,提供钛合金复杂截面管件的生产工艺。VADILLO等[5]利用高压气胀成形工艺成形了膨胀率75%的高强钢变径管,给出了高压胀形成形在管件成形中的研究前景。HE等[6]研究TA2钛合金管材在不同条件下的成形性能,探索了钛合金管材高压气胀成形性能。LIU等[7]对TA15钛合金进行高压气胀成形 研究,改进了成形管件的壁厚和精度。

传统内高压成形利用轴向补料的方法改变了材料的应力状态,一定程度上改善成形管件的壁厚分布[8]。TIROSH等[9]求解了管材自由胀形和管材端部施加轴向力胀形时的应力状态。GEIGER等[10]和苑世剑等[11]对轻合金进行热态内压成形实验研究,表明管材轴向补料在一定的温度下仍然有效。而对于成形温度较高的钛合金,国内外一直没有开展相关研究。

为此,本文作者在传统内高压成形技术的基础上提出钛合金变径管高压气胀成形技术,在高温条件下以高压气体作为传力介质,通过温度和内压匹配加载使管坯成形为变径管。

1 实验

1.1 实验材料

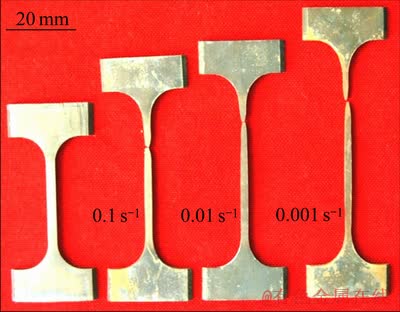

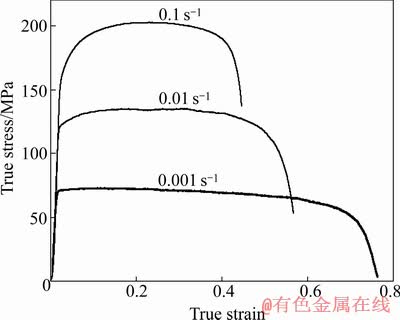

实验采用冷轧后退火的TA18钛合金管,外径和壁厚分别为40 mm和2 mm。在800 ℃下,沿管材轴向方向取样,分别以0.1、0.01和0.001 s-1的应变速率进行单向拉伸实验,得到的拉伸试样如图1所示,真实应力—应变曲线如图2所示。

1.2 管件尺寸及实验装置

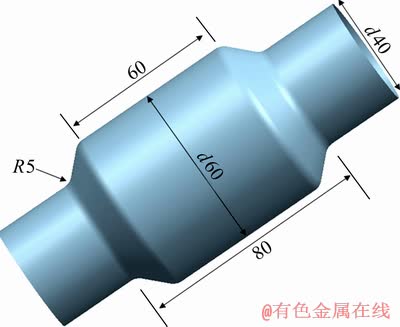

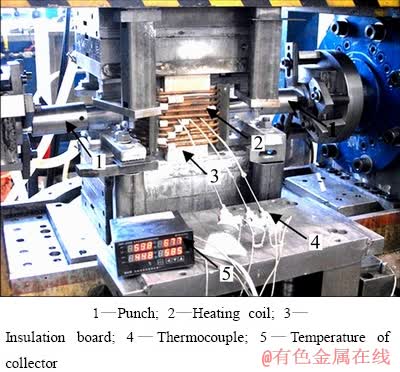

变径管外轮廓如图3所示,两端管直径40 mm,胀形区长80 mm,直径60 mm,壁厚2 mm,过渡区为45°斜面并以半径5 mm圆弧过渡。实验采用哈尔滨工业大学自主研发的高压气胀成形装置,实验中使用的高压气胀成形模具如图4所示。

图1 800 ℃时的拉伸试样

Fig. 1 Tensile test specimen at 800 ℃

图2 800 ℃时TA18钛合金的应力—应变曲线

Fig. 2 True stress—strain curves of TA18 Ti alloy at 800 ℃

图3 变径管外轮廓尺寸

Fig. 3 Designed outer contour of large expansion ratio tube (Unit: mm)

1.3 加载路径

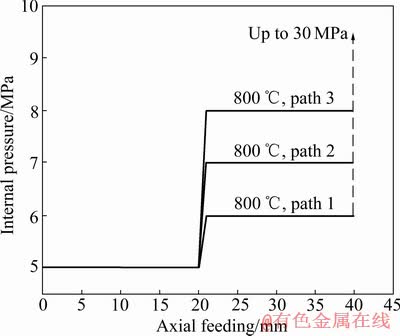

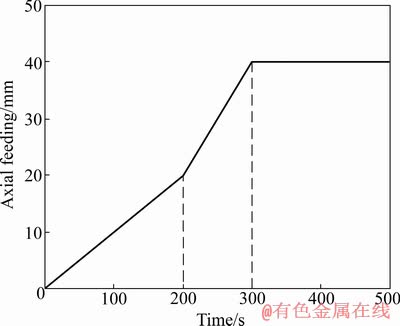

在800 ℃下,设置3个不同加载路径分别成形,如图5所示,研究加载路径对成形件质量的影响。由于TA18在为应变速率敏感性材料,为了排除应变速率对成形过程的影响,设定轴向补料量与补料时间关系如图6所示,前200 s以较低的补料速率补料,后期增大补料速度,最后增压至30 MPa整形。实验前,在TA18管材内外表面涂抹氮化硼粉末,减小管材与模具摩擦,减缓钛合金的氧化。

图4 高压气胀成形模具

Fig. 4 Mold of HPPF

图5 胀形内压随轴向补料量的变化曲线

Fig. 5 Change curves of internal pressure with axial feeding

图6 轴向补料量与补料时间关系

Fig. 6 Relationship between axial feeding and feeding time

2 结果与讨论

2.1 加载路径对表面轮廓质量的影响

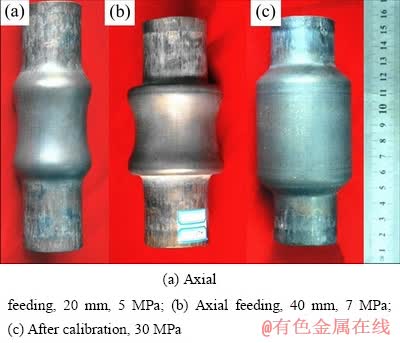

采用加载路径2进行实验,得到的成形过程件如图7所示。在5 MPa压力下,当轴向补料20 mm时,得到成形件如图7(a)所示,成形区两侧有两个波形平稳的皱纹,为后期整形积累了材料。将内压增加至7 MPa,按照加载路径2继续成形,补料至40 mm,得到成形件如图7(b)所示,皱谷的直径增大,而两个皱峰接触到模具内壁,两端波峰坡面几乎垂直于管材轴向方向。将内压增加至30 MPa整形,得到图7(c)所示变径管。成形过程中,皱纹展平,材料完全贴模,得到外表光滑无死皱、小圆角成形质量好的50%膨胀率变径管。

图7 压力加载路径2成形过程件

Fig. 7 Large expansion ratio tubes bulged by path 2

图8 压力加载路径1成形过程件

Fig. 8 Large expansion ratio tubes bulged by path 1

采用加载路径1进行实验,轴向补料40 mm无整形件和整形件如图8所示。由图8可看出,补料量从20 mm增加到40 mm阶段时,管材内压较小(6 MPa)时,皱谷变形较小,造成两端进给的管料在过渡区堆积(见图8(a));后期增压至30 MPa整形,两皱峰之间区域由于补料不足减薄较严重,两个皱峰区域由于堆积管料太多,整形时过渡区皱纹不能被完全展平形成死皱,如图8(b)所示。

采用加载路径3进行实验,轴向补料40 mm无整形件和整形件如图9所示。由图9可看出,由于补料量从20 mm增加到40 mm阶段,管材内压较大,变形区胀形过快,在补料还没有结束时,胀形区已经完全贴膜,继续轴向补料使两端材料内嵌到成形区;整形时,两端内嵌的材料不能展平,在过渡区形成死皱;胀形区由于提前贴膜,轴向进给的材料没被充分利用,减薄率增大。以上实验表明:TA18钛合金变径管成形时,需要选择合适的加载路径,当胀形压力较大或较小时,成形管件的减薄率增大并在过渡区出现死皱,采用加载路径2可以得到质量较好的管件。

图9 压力加载路径1成形过程件

Fig. 9 Large expansion ratio tubes bulged by path 3

2.2 轴向补料量对壁厚分布的影响

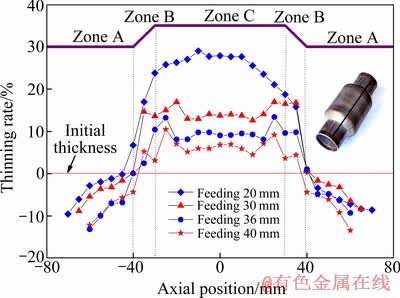

按照图5所示的路径2和图6所示的补料量和补料时间关系,分别补料20、30、36和40 mm得到图10所示零件,研究补料量对变径管成形件的影响。

补料过程中,变径管各个区域的应力应变状态不同,变形不同,轴向管壁厚度相差较大。垂直于分模面将变径管对称切开,沿切口测量成形管件的轴向壁厚,计算管件壁厚减薄率分布如图11所示(原始管材壁厚按平均厚度2.05 mm计算)。将变径管按照形状特点划分为3个区域。区域A的管材受到3向压应力,管材表面受到轴向摩擦力的作用,在区域A发生堆积导致壁厚增加,由管端向内侧增厚逐渐减小;区域B(过渡区)各处的管材膨胀率不同,壁厚分布也不同,整体呈现由端口向内侧减薄率呈增大趋势;区域C处轴向补料用于环向伸长变形,管件壁厚整体较均匀,但整体减薄率较大。

图10 不同补料量的变径管成形件

Fig. 10 Large expansion ratio tubes with different axial feedings

图11 不同补料量的变径管轴向壁厚减薄率分布

Fig. 11 Tinning rate distribution of axial thickness along tubes at different axial feedings

轴向补料20、30、36和40 mm得到的管件胀形区(区域C)的平均减薄率分别为20.47%、14.42%、8.29%和5.43%,最大减薄率分别为29.02%、18.73%、13.41%和10.49%。补料20 mm时,变径管的最大变薄位于变形区中心位置,随着补料量的增大,管件最薄处移动到靠近小圆角处。经测量发现,由于摩擦的原因,当补料量较大时,圆角处的管件壁厚大于附近两个点处壁厚。随着轴向补料量增加,变径管平均减薄率减小,最大减薄率减小,变径管的壁厚分布得到改善。

3 结论

1) 加载路径决定变径管表面轮廓质量,在补料阶段,内压过小或者过大都会出现起皱缺陷。

2) 轴向补料改善了变径管的壁厚分布,补料量越大,变径管壁厚减薄越小,壁厚越均匀;随着补料量的增加,变径管沿轴向最大减薄位置由中心处变为近圆角处。

3) 在800 ℃时,采用合适的加载路径,轴向补料40 mm时,得到膨胀率50%的变径管,最大壁厚减薄10.49%,胀形区平均减薄率5.43%。

REFERENCES

[1] MOISEYEV V N. Titanium alloys: Russian aircraft and aerospace applications [M]. London: Taylor & Francis, 2005.

[2] XU Feng, YANG Zhao. Application of the titanium alloy in civil aviation [J]. Baosteel Technical Research, 2011, 12(5): 25-35.

[3] LEYENS C,PETERS M. Titanium and titanium [M]. Weinheim: WILEY-VCH Verlag. GmbH & Co, kGaA, 2003: 329-384.

[4] ZHANG K F, WANG G, WU D Z. The superplastic capability of butt cover plate of Ti-6Al-4V titanium alloy [J]. Trans Nonferrous Met Soc China, 2002, 12(2): 251-255.

[5] VADILLO V, SANTOS M T, GUTIERREZ M A,  I,

I,  B, UTHAISANGSUK V. Simulation and experimental results of the hot metal gas forming-g technology for high strength steel and stainless steel tubes forming [C]// Proceeding of the 9th International Conference on Numerical Methods in Industrial Forming Processes. Portugal, 2007: 17- 21.

B, UTHAISANGSUK V. Simulation and experimental results of the hot metal gas forming-g technology for high strength steel and stainless steel tubes forming [C]// Proceeding of the 9th International Conference on Numerical Methods in Industrial Forming Processes. Portugal, 2007: 17- 21.

[6] HE Zhu-bin, TENG Bu-gang. Mechanical properties and formability of TA2 extruded tube for hot metal gas forming at elevated temperature [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 479-484.

[7] LIU Gang, HUAN Wang-ke, XU Yi, WANG Bin, YUAN Shi-jian. An approach to improve thickness uniformity of TA15 tubular part formed by gas bulging process [J]. Advanced Materials Research, 2013, 712/715: 651-657.

[8] 苑世剑, 何祝斌, 刘 钢, 王小松, 韩 聪. 内高压成形理论与技术的新进展[J]. 中国有色金属学报, 2011, 21(10): 2523- 2533.

YUAN Shi-jian, HE Zhu-bin, LIU Gang, WANG Xiao-song, HAN Cong. New developments in theory and processes of internal high pressure forming [J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2523-2533.

[9] TIROSH J, NEUBERGER A. On tube expansion by internal fluid pressure with additional compressive stress [J]. Int J Mech Sci, 1996, 38(8/9): 839-851.

[10] GEIGER M, MERKLEIN M, CELEGHINI M, HALDENWANGER H G, PRIER M. Sheet and tube hydroforming at elevated temperatures [J]. Hydroforming of Tubes, Extrusions and Sheet Metals, 2003, 3: 259-278.

[11] 苑世剑, 何祝斌, 刘 钢. 轻合金热态液力成形技术[J]. 锻压技术, 2005, 6: 75-80.

YUAN Shi-jian, HE Zhu-bin, LIU Gang. Warm hydroforming process of light weight alloys [J]. Forging & Stamping Technology, 2005, 6: 75-80.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51075100); 中央高校基本科研业务费专项基金资助(NS2012099)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:刘 钢,教授,博士;电话:0451-86418631;E-mail: gliu@hit.edu.cn