Trans. Nonferrous Met. Soc. China 20(2010) s788-s793

Synthesis and characterization of 356-SiCp composites by stir casting and compocasting methods

S. AMIRKHANLOU, B. NIROUMAND

Department of Materials Engineering, Isfahan University of Technology, Isfahan 84156-83111, Iran

Received 13 May 2010; accepted 25 June 2010

Abstract:Stir casting is one of the simplest ways of producing aluminum matrix composites. However, it suffers from poor incorporation and distribution of the reinforcement particles in the matrix. These problems become especially significant as the reinforcement size decreases due to greater agglomeration tendency and reduced wettability of the particles with the melt. Development of new methods for addition of very fine particles to metallic melts which would result in more uniform distribution and effective incorporation of the reinforcement particles into the matrix alloy is therefore valuable. In this work, 356-5%SiCp (volume fraction) composites, with average SiCp sizes of about 8 and 3 ?m, were produced by injection of different forms of the reinforcement particles into fully liquid as well as semisolid slurries of 356 aluminum alloy and the effects of the injected reinforcement form and the casting method on distribution of the reinforcement particles as well as their porosity, hardness and impact strength were investigated. The results reveal that addition of SiC particles in the form of (Al-SiCp)cp composite powder and casting in semisolid state decreases the SiCp particle size, enhances the wettability between the molten matrix alloy and the reinforcements and improves the distribution of the reinforcement particles in the solidified matrix. It also increases the hardness and the impact energy of the composites and decreases their porosity.

Key words: 356-SiCp composite; compocasting; stir casting; reinforcement distribution; mechanical properties

1 Introduction

Silicon carbide particulate reinforced aluminum matrix composites (Al-SiCp) have drawn much attention over the past few decades, owing to their exceptional properties such as light weight, high specific strength, elastic modulus and wear resistance, low coefficient of thermal expansion as well as the diversity of the methods available for their fabrication[1-2]. Solid-state methods for fabrication of Al-SiCp composites include such methods as powder metallurgy, uniaxial pressing, isostatic pressing, extrusion and spray forming[2]. These methods seriously suffer from limitations in size and complexity of the components and high processing costs. Some liquid-state methods such as stir-casting and compocasting have the important advantages of simplicity, near net shaping, lower cost of processing, easier control of matrix structure and greater freedom of the component size and design[3-4]. However, uniform distribution of fine particles in metallic melts is extremely difficult by liquid-state methods due to the large specific surface area and low wettability of small size particles. As a result, agglomeration and clustering of the reinforcements are inevitable in cast metal matrix composites[5-7]. Development of new methods for addition of very fine particles to metallic melts which would result in more uniform distribution and effective incorporation of the reinforcement particles in to the matrix alloy is therefore valuable and makes the production of high performance cast metal matrix composite more promising.

In this work, 356-5%SiCp(volume fraction) composites, with average SiCp sizes of about 8 and 3 ?m, were produced by injection of different forms of the reinforcement powders into fully liquid as well as semisolid slurries of 356 aluminum alloy, and the effects of the injected reinforcement form and the casting method on distribution of the reinforcement particles as well as their porosity, hardness and impact strength were investigated.

2 Experimental

2.1 Materials

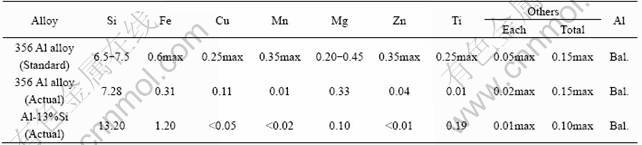

In this work, 356 cast aluminum alloy and SiCp were chosen as the matrix material and the reinforcement. The starting materials included 356 aluminum alloy, Al-13%Si (mass fraction) alloy, SiCp with average size of about 8 μm and commercially pure aluminum powder with average size of about 80 μm. The standard composition of 356 alloy[8] as well as the actual compositions of 356 and Al-13%Si alloys used in this work are shown in Table 1. If iron exceeds 0.45%, manganese content shall not be less than one-half of iron content.

Table 1 Chemical composition of 356 and Al-13%Si alloys (mass fraction, %)

The reinforcement particles were injected into the melt in two forms, i.e. as untreated SiCp powder or as particulate (Al-SiCp)cp composite powder. The latter was produced by low energy ball milling of equal volumes of aluminum and SiCp powders for 52 h to achieve a mechanically interacting composite powder. The milling was carried out in a horizontal ball mill of 145 mm inner diameter with alumina balls of different diameters (14.6-25.4 mm) at a constant rotation speed of 60 r/min.

When the reinforcement was added as (Al-SiCp)cp composite powder, 10% (volume fraction) of the composite powder was injected into the melts of proper 356 and Al-13%Si alloys mixture so that after the completion of the injection, the matrix composition reached that of 356 alloy.

2.2 Fabrication of composites

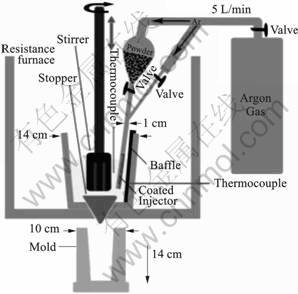

First proper quantity of 356 alloy or mixture of 356 and Al-13%Si alloys was melted in a graphite crucible of 1.5 kg capacity using a resistance furnace and the temperature of the melt was raised to 700 ?C. The melt was kept at this temperature for approximately 2 min for homogenization of the temperature while being stirred at 500 r/min[9] using a graphite stirrer and then addition of the reinforcements started. Argon was used as the carrier gas for injection of the reinforcements. After completion of the injection, the slurry was continuously cooled and stirred with an average cooling rate of 4.2 ?C/min until reaching 650 ?C (fully liquid, hence stir casting) or 607 ?C (corresponding to 0.2 solid fraction according to Scheil equation, hence compocasting) and cast into a steel die placed below the furnace. In liquid metal stir casting, both injection of the particles and pouring of the resultant composite slurry were carried out in a fully liquid state. On the other hand, in the case of compocasting process, the reinforcement addition was performed in fully liquid state but casting of the composite slurry was carried out in semi-solid state.

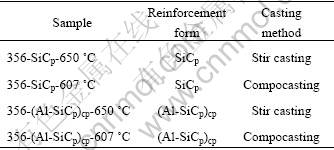

Fig.1 schematically illustrates the experimental set up used in production of the composites. Table 2 shows the experimental conditions used in different experiments.

Fig.1 Schematic of experimental set up used in this work

Table 2 Experimental conditions used in different experiments

2.3 Microstructural characterization

Microscopic examinations of the composites were carried out using an Epiphoto300 Nikon optical microscope(OM) and a Philips-XL3 scanning electron microscope(SEM) equipped with energy dispersive X-ray(EDX) facilities. Microstructures were investigated by Clemex Vision Image analyzer to determine the SiCp mean diameter and sphericity. Sphericity of individual SiC particles was measured by a dimensionless parameter ranging from zero to one where a perfect circle had the sphericity of unity and more irregular particles had lower sphericity values. Diameter of SiC particle was calculated using equivalent circle diameter (Deq) concept. Deq is defined as the diameter of a circle having the same area (A) as that of the particle (Eq.(1)).

(1)

(1)

2.4 Porosity measurement

The actual densities of the castings were measured by Archimedian principle, while the theoretical density was calculated using the mixture rule according to the mass fraction of the SiC particles. Porosities (h) of the cast composites were calculated using the following equation.

(2)

(2)

where ρmc is the actual density of the composite, ρm is the theoretical density of the matrix alloy and Vp is the volume fraction of SiCp.

2.5 Characterization of mechanical properties

Brinell hardness values were measured on several locations of each cast composite using a 2.5 mm diameter ball under 31.25 N load. Charpy impact tests were conducted on a fully instrumented Wolpert test machine using notched specimens. Standard square impact test specimens (55 mm×10 mm×10 mm) with notch depth of 2 mm and notch tip radius of 0.25 mm at angle of 45? according to ASTM E23-02a were used. Each test was repeated three times.

3 Results and discussion

3.1 Microstructure

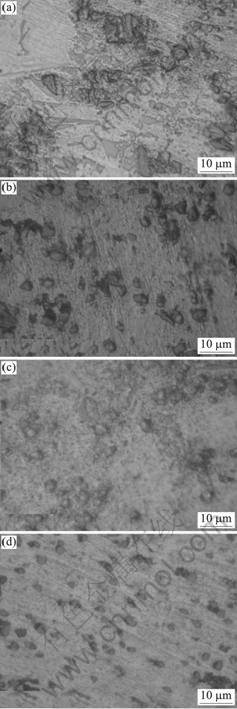

The typical microstructures of produced 356- 5% SiCp composites are presented in Fig.2. It is seen from Fig.2 that, for samples 356-SiCp-650 ?C and 356-SiCp-607 ?C, where the reinforcements were added as untreated SiCp powder, the reinforcement size is larger and the distribution of SiC particles are less uniform than samples 356-(Al-SiCp)cp-650 ?C and 356-(Al-SiCp)cp-607 ?C, where the reinforcements were added as (Al-SiCp)cp composite powder.

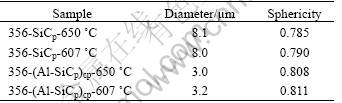

The average diameter and sphericity of SiCp particles of different samples are shown in Table 3. The table reveals that the milling operation applied on the aluminum and SiCp powders has significantly reduced the average diameter of SiC particles from about 8 to 3 ?m and has slightly increased their sphericity.

Fig.2 SiCp distribution in different samples: (a) 356-SiCp-

650 ?C; (b) 356-SiCp-607 ?C; (c) 356-(Al-SiCp)cp-650 ?C; (d) 356-(Al-SiCp)cp-607 ?C

Table 3 Average diameter and sphericity of SiCp particles of different samples

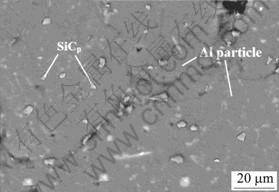

Fig.3 shows the SEM micrograph of the cross section of (Al-SiCp)cp composite powder after 52 h milling. The figure reveals that after milling operation, many of SiC particles have succeeded to enter the aluminum particles and create a relatively uniform distribution of the reinforcement in individual (Al-SiCp)cp composite particles. Also evident in the figure is the close contact between SiC particles inside the composite powders and the pure aluminum matrix. Since the surface of the majority of the reinforcement particles are entirely covered with pure aluminum, which is akin to 356 aluminum matrix, there does not seem to be any problem for wetting of SiC particles by 356 aluminum melt when (Al-SiCp)cp composite powder is injected into the melt. The pure aluminum matrix of the composite powder is expected to melt and simply mix with the surrounding molten 356 aluminum matrix. As the aluminum matrix of individual composite powders starts to melt from outside, SiC particles are progressively released into the melt resulting in a more uniform distribution of the reinforcement particles.

Fig.3 SEM micrograph of cross section of (Al-SiCp)cp composite particles

Fig.2 and Table 3 show that a much more uniform distribution of finer SiC particles is obtained when the reinforcements are added as (Al-SiCp)cp composite powder rather than untreated SiCp powder.

The milling induced mechanical bonding formed between aluminum and SiCp particles in the (Al-SiCp)cp composite powders is believed to persists after their injection into the melt, facilitating the wetting and dispersion of SiCp in the liquid matrix.

Microstructural investigations also demonstrated that distribution of SiCp particles were more uniform in compocast samples. Also fewer agglomerates and greater number of individual SiCp particles were observed in the matrix of compocast samples relative to stir cast ones. Compocasting has been shown to improve the distribution of the reinforcement particles by confining them between the growing and continuously colliding solid particles of the primary phase in the semisolid state[10].

As demonstrated in Fig.2(d) the best distribution of SiC particles were realized for sample 356-(Al-SiCp)cp-607 ?C where both benefits of compocasting and composite powder injection were utilized. Also not shown in Fig.2 is the fact that the matrix microstructures were refined by addition of the reinforcement as (Al-SiCp)cp composite powder.

3.2 Porosity

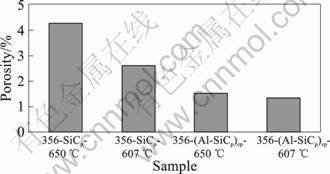

Fig.4 shows the calculated porosity content of different samples. As it is evident from the figure, the compocast samples have less porosity than the stir cast ones. Also, the composites manufactured by injection of (Al-SiCp)cp composite powder rather than untreated SiCp powder has lower porosity content.

Fig.4 Calculated porosity content of different samples

Porosity formation in cast metal matrix composites has been shown to be influenced by a number of parameters. These include gas entrapment during stirring, air bubbles entering the slurry either independently or as air envelops around the reinforcement particles, water vapor on the surface of the particles, hydrogen evolution and solidification shrinkage [11-12].

Since in compocast samples a considerable portion of solidification has taken place before pouring the slurry and the temperature of the slurry is lower than that in stir casting, the porosity arising from the solidification shrinkage and hydrogen evolution is smaller. Also, less air entrapment is expected during pouring and mold filling due to the relatively high viscosity of composite slurries.

Fig.3 shows a complete mechanical interaction between pure aluminum matrix and SiC particles in (Al-SiCp)cp composite powder with no clustering of the reinforcement particles, no gas entrapment and certainly no water vapor between the reinforcing particles. Therefore, injection of (Al-SiCp)cp composite powder rather than untreated SiC particles provides an additional advantage that large parts of the gases (air, water vapor, etc.) absorbed on the surface of the reinforcement particles or between agglomerated particles have been removed and replaced by an aluminum layer (Fig.3) which is melted and mixed with the molten matrix alloy easily.

3.3 Mechanical properties

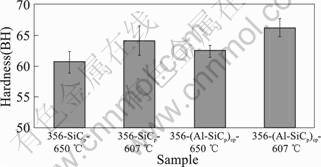

Fig.5 shows the hardness values of different composites produced. As it is seen, in either of the casting methods employed, hardness of the composite reinforced by injection of (Al-SiCp)cp composite powder is higher than that of the composite produced by injection of untreated SiCp. This can be attributed to more uniform distribution of significantly smaller (Table 3), and therefore more abundant, SiC particles in the soft matrix which resist the dislocation slip, hence increasing the hardness of the reinforced alloy. The smaller reinforcement size also increases the dislocation density due to the greater mismatch in the thermal expansion of the matrix and the reinforcement at the particles–matrix interfaces. This is in agreement with the result reported by [4-5,12]. Lower porosity content (Fig.4) and finer matrix microstructure can be other contributing factors.

Fig.5 Hardness values of different composites

Fig.5 also reveals the effect of casing method employed on the hardness of the composites. As it is evident, composites produced by compocasting method show higher hardness than their corresponding composites manufactured by stir casting method. Better distribution of SiC particles in the matrix, lower porosity content and finer and more homogeneous microstructure of the matrix in compocast composites appear to result in their higher hardness.

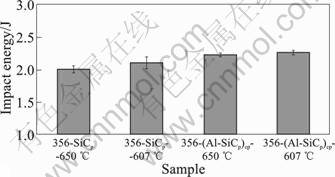

Impact energies of the produced composites are presented in Fig.6. The figure shows that the impact energy of the composites produced by injection of (Al-SiCp)cp composite powder is slightly higher than those produced by injection of untreated SiCp. However, the casting method does not influence the impact energy much. More angular shape and larger size of the brittle reinforcement particles in the composites produced by untreated SiCp appear to play a role in decreasing their impact energy.

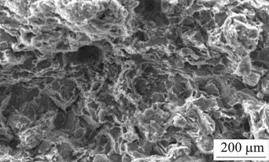

Fig.7 shows a SEM fractograph typical of all the produced composites. As it is seen, the fracture surface is rough and uneven and exhibits a predominantly brittle cleavage fracture mechanism. Limited regions of interfacial decohesion is also evident. In general, the fractured surfaces of the produced composites were not influenced much by the casting method or the form of reinforcement injection into the melt.

Fig.6 Impact energy of different composites

Fig.7 Typical SEM fractograph of produced composites

4 Conclusions

1) Injection of milled (Al-SiCp)cp composite powder instead of untreated SiC particles into the melt decreases the SiC particle size, enhances the wettability between the molten matrix alloy and the reinforcements and improves the distribution of the reinforcement particles in the solidified matrix.

2) Wettability and distribution of SiC particles are further improved by casting in semisolid state (compocasting) rather than in fully liquid state (stir casting).

3) Addition of SiC particles in the form of (Al-SiCp)cp composite powder and casting in semisolid state increases the hardness of the composites by 10% and decreases the porosity by 68%.

4) The impact energy is slightly influenced by the form of the reinforcement addition but the casting method does not influence the impact energy.

References

[1] RAY S. ZnO: Synthesis of cast metal matrix particulate composites [J]. Journal of Materials Science, 1993, 28(1): 5397-5413.

[2] HOKAED E, LAVERINYA J. Particulate reinforced metal matrix composite—A review [J]. Journal of Materials Science, 1999, 92(1): 1-7.

[3] TZAMTZIS S, BAREKAR N S, HARI N, PATEL J, DHINDAW B K, FAN Z. Processing of advanced Al/SiC particulate metal matrix composites under intensive shearing—A novel rheo-process [J]. Composites Part A, 2009, 40: 144-151.

[4] AIGBODIAN V S, HASSAN S B. Effects of silicon carbide reinforcement on microstructure and properties of cast Al-Si-Fe/SiC particulate composites [J]. Materials Science and Engineering A, 2007, 447: 335-447.

[5] PRABU S, KARUNAMOORTHY L, KATHIRESAN S, MOHANB B. Influence of stirring speed and stirring time on distribution of particles in cast metal matrix composite [J]. Journal of Materials Processing Technology, 2006, 171: 268-273.

[6] ADEL M H, ALRASHDAN A, MOHAMMED T. Wear behavior of Al-Mg-Cu-based composites containing SiC particles [J]. Tribology International, 2009, 42: 1230-1238.

[7] ZHANH Q, WU G, JIANG L. Tensile deformation behavior of a sub-micrometer Al2O3/6061Al composite [J]. Materials Science and Engineering A, 2008, 483/484: 281-284.

[8] HATCH J E. Aluminum properties and physical metallurgy [M]. 2nd ed. Metals Park, Ohio: ASM, 1984: 224-225.

[9] GHAHREMANIAN M, NIROUMAND B. Compocasting of an Al-Si-SiCp composite using powder injection method [J]. Solid state Phenomena, 2008, 21: 175-180.

[10] RLJAN T P D, PILLAI R M, PAI B C, SATYANARAYANA K G, ROHATGI P K. Fabrication and characterisation of Al-7Si- 0.35Mg/fly ash metal matrix composites processed by different stir casting routes[J]. Composites Science and Technology, 2007, 67: 3369-3377

[11] GOSH P K, RAY S. Influence of process Parameters on the porosity content in Al(Mg)-Al2O3 cast particulate composite produced by vortex Method [J]. Journal of Material Transactions A, 2003, 47: 775-782.

[12] ILEGBUSI O J, YANG J. Porosity nucleation in metal matrix composites [J]. Metallurgical and Materials Transactions A, 2000, 31: 2069-2080.

(Edited by YANG You-ping)

Corresponding author: B. NIROUMAND; Tel: +98-311-3915731; E-mail: behzn@cc.iut.ac.ir