DOI: 10.11817/j.issn.1672-7207.2017.12.004

连铸板坯全冶金长度凝固形貌

王鑫,孟祥宁,黄烁,朱苗勇

(东北大学 冶金学院,辽宁 沈阳,110819)

摘要:采用移动边界法计算低碳钢连铸板坯全冶金长度温度场,利用CAFE耦合模型模拟其凝固行为,考察过热度和拉坯速度对板坯宽面中心温度、横断面微观组织形貌及二次枝晶臂间距等影响,并计算二次枝晶臂间距与冷却速度关系及碳元素中心偏析。研究结果表明:过热度和拉坯速度降低均能使宽面中心温度和中心二次枝晶臂间距下降,而拉坯速度的影响更为显著;拉坯速度越高中心等轴晶率越高,晶粒半径越小,利于提高连铸板坯质量,过热度对中心等轴晶率及晶粒半径影响较小;二次枝晶臂间距在固液两相区生成并增大,二次枝晶臂间距与冷却速度之间呈指数关系;连铸板坯中心偏析区域呈岛状分布在中心线上,最大偏析指数为1.14,中心部位负压抽吸临近枝晶间富积溶质钢液导致中心线附近形成负偏析。

关键词:连铸板坯;宽面中心温度;微观组织形貌;二次枝晶臂间距;碳偏析

中图分类号:TF777 文献标志码:A 文章编号:1672-7207(2017)12-3160-10

Solidification morphology for full metallurgical length of continuous casting slab

WANG Xin, MENG Xiangning, HUANG Shuo, ZHU Miaoyong

(School of Metallurgy, Northeastern University, Shenyang 110819, China)

Abstract: Steel solidification for continuously cast low carbon slab was calculated using a coupled model of CAFE in combination with the temperature distribution in the full metallurgical length, which was predicted by the moving boundary method. Further, the influences of steel superheat and casting speed on the central temperature of slab wide-surface, morphology of slab section and secondary dendritic arm spacing were investigated, and the relationship between arm spacing and cooling rate of steel as well as the central carbon segregation of slab were analyzed. The results show that the decreases of superheat and casting speed lead to the reductions of central temperature and arm spacing, and the impact from casting speed is more significant. Ratio of equiaxed zone increases with casting speed and the grain radius decreases, and it is conducive to improve the continuous casting slab quality, while the superheat does not have significant effect on casting speed and grain radius. Secondary dendritic arm spacing is formed and increased in mushy zone, and it presents an exponential trend with cooling rate. Central carbon segregation distributes in the central line of slab in the form of islands, and the maximum segregation index reaches 1.14. Enriched solute elements around the dendrites are pumped into the steel by negative pressure and then generate the negative segregation.

Key words: continuous casting slab; center temperature of wide surface; morphology; secondary dendritic arm spacing; carbon segregation

钢液在结晶器中初步冷却凝固成具有一定外形尺寸的连铸坯壳,其凝固前沿微观组织粗化易导致偏析,使其易沿柱状晶开裂而形成内裂纹、皮下气孔和夹杂等质量缺陷[1]。连铸板坯出结晶器进入二冷区,当二冷冷却制度不理想时,在结晶器中形成的表面缺陷会继续扩展;温升和温降速度过大,易形成皮下裂纹[2-3]:因此,研究板坯凝固过程和微观组织形成规律,对于冶金生产中合理制定连铸工艺,改善连铸坯质量具有重要指导作用[4]。国内外学者对连铸坯凝固行为进行了大量研究,HUANG等[5]系统研究了钢液流动和传热对连铸坯凝固过程的影响,分析了拉坯速度、过热度和结晶器散热对流场的影响,促进了连铸坯流场方面研究。LOUHENKILPI等[6]忽略连铸坯宽度方向导热,建立了瞬态连铸坯纵断面上二维连铸坯导热方程,从而瞬态导热方程在连铸过程中得到发展。SEDIAKO等[7]忽略小方坯拉坯方向散热,建立各个时刻连铸坯横断面二维非稳态凝固导热模型,进一步完善了二维连铸坯凝固导热模型。蔡开科[8]建立一维非稳态连铸坯凝固传热模型,计算出连铸坯结晶器凝固过程传热行为。PAPPAZ等[9-10]预测了从柱状晶到等轴晶的转变并得到试验验证,把有限元方法(finite element,FE)与元胞自动机模型(cellular automaton,CA)耦合起来,建立了(宏观-微观)元胞自动机模型(CAFE耦合模型),即CAFE。WANG等[11-13]应用CAFE模型耦合钢液浇注、温度场、流场、缩孔、疏松,实现对易切削钢9SMn28铸件组织的模拟。冯军等[14-15]研究出过热度、二冷强度和电磁搅拌技术对一次枝晶间距、二次枝晶间距及一次枝晶间距和二次枝晶间距比值的影响。程明涛等[16]研究了冷却速率对45钢二次枝晶间距的影响。PIEXER等[17]研究了C含量对二次枝晶间距的影响。结晶压力、熔体超温处理及磷偏析与二次枝晶间距的关系也有相应研究[18-20]。这些研究仅对连铸过程中某一段展开深入分析。本文作者针对连铸板坯全冶金长度凝固行为,计算低碳钢宽面中心温度、横断面微观组织形貌、二次枝晶臂间距和碳元素中心偏析。通过设置不同的工艺参数,考察过热度和拉坯速度对板坯宽面中心温度、微观组织形貌和二次枝晶臂间距的影响,并分析结果以优化工艺参数。

1 模型建立

1.1 形核模型

利用连续而非离散的分布函数来描述晶粒密度变化,分布函数由式(1)高斯分布[21]确定:

(1)

(1)

过冷度为△T时,积分求得晶粒密度为

(2)

(2)

式中:△T为枝晶尖端总过冷度,K;△Tmax为平均形核过冷度,K;△Tδ为形核过冷度标准方差,K;nmax为正态分布积分所得到的最大形核密度;n为晶粒密度。

枝晶尖端过冷度是晶粒形核和长大的前提条件[22-23],其总过冷度△T为

(3)

(3)

式中:△Tc为成分过冷度,K;△Tt为热力学过冷度,K;△Tr为固液界面曲率过冷度,K;△Tk为生长动力学过冷度,K。

合金的△Tt,△Tr和△Tk都较小,可以忽略不计,柱状晶和等轴晶的生长速度用KGT模型计算,得到枝晶尖端生长速度多项式:

(4)

(4)

式中:a2和a3为多项式系数,此系数可由CAFE模块计算得出。

1.2 工艺模型

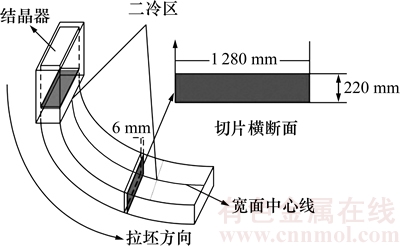

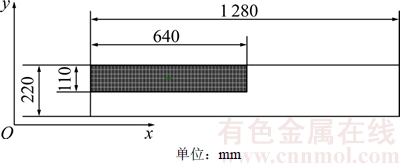

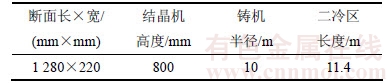

考虑到连铸过程的连续重复性,模拟时选取厚度为6 mm的切片为研究对象,如图1所示,采用移动边界法计算该切片。本文的凝固过程是从结晶器入口到矫直区完全凝固处,考虑到结构对称性,取切片断面的1/4进行研究,利用Procast中mesh-2D模块对切片划分二维网格,如图2所示。本文所用连铸机参数见表1。

图1 模型示意图

Fig. 1 Schematic of model

图2 网格划分示意图

Fig. 2 Schematic of grid division

表1 连铸机参数

Table 1 Parameters of casting machine

1.3 边界条件

1.3.1 结晶器传热

根据结晶器冷却水流量及进出口处温差,可以求出结晶器平均热流密度:

(5)

(5)

(6)

(6)

式中:t为时间,s;z为距结晶器入口距离,m;vc为拉坯速度,m/min;A和B为热平衡系数。

1.3.2 二冷区换热

将连铸板坯从二冷区入口至二冷区出口依次分为7个区域,各区域采用不同的水冷强度[24]。

1区换热系数为

(7)

(7)

2~7区换热系数为

(8)

(8)

式中:h为换热系数,W/(m-2·k);η为喷射水流密度,L/(m2·s)。

1.3.3 辐射换热

空冷区域连铸坯与周围环境的辐射换热可由下式表示:

(9)

(9)

式中:qr为辐射换热热流密度,W·m2;σ为玻尔兹曼常数;k为表面辐射系数;θb为板坯表面温度,℃;θa为环境温度,℃。

1.4 工艺参数

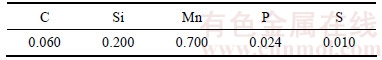

以低碳钢成分见表2。

表2 低碳钢成分(质量分数)

Table 2 Compositions of low-carbon steel %

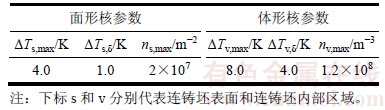

WANG等[11-13]对钢坯各项形核参数进行对比模拟,阐述高斯形核分布参数对微观结构的影响。对比其结果得出低碳钢在本连铸条件下形核参数,设计形核参数见表3。

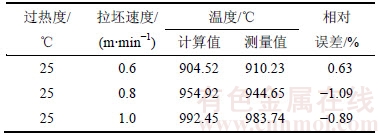

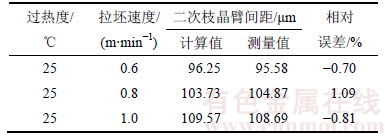

基于上述模型,计算求得连铸坯出二冷区时宽面中心温度和二次枝晶臂间距与实测结果对比,分别如表4和表5所示。由表4和表5可知,其相对误差在允许范围之内,故此模型具备应用性。

表3 形核参数

Table 3 Nucleation parameters

表4 温度的计算值与测量值对比

Table 4 Comparison between calculated and measured temperatures

表5 枝晶间距的计算值与测量值对比

Table 5 Comparison between calculated and measured dendritic arm spacing

2 结果与分析

2.1 宽面中心温度

2.1.1 温度变化规律

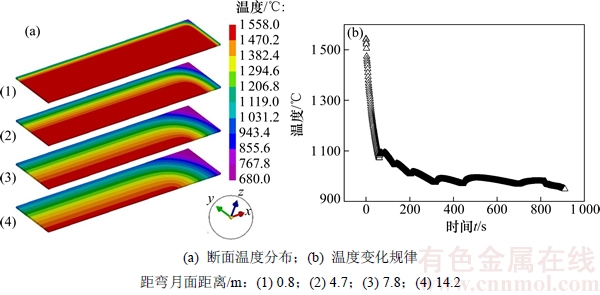

在过热度为25 ℃,拉坯速度为0.8 m/min前提下,连铸板坯断面温度分布云图如图3(a)所示,其中图(1)~(4)分别为距弯月面0.8,4.7,7.8和14.2 m的断面温度分布图。由图3(a)可知:随着凝固进行,板坯断面温度逐渐下降。其中,角部温度下降较快,这是由于角部区域受到宽面和窄面冷却水的双重冷却,冷却强度大。板坯从结晶器入口到二冷区出口的宽面中心温度变化情况如图3(b)所示。由图3(b)可知:在60 s之前(即结晶器内)宽面中心温降速率较快,60 s后板坯进入二冷区,温降速率变慢。宽面中心温度在二冷区各段交界处出现回升现象,这是由于钢水凝固过程中发生了明显物相变化,在此过程中释放大量的凝固潜热,板坯从前一冷却区到下一冷却区的过程中,冷却水量减少,冷却强度变小,所以,传递到坯壳的凝固潜热不能及时散失,导致宽面中心温度回升。

图3 温度分布及变化规律

Fig. 3 Temperature distribution and change regulation

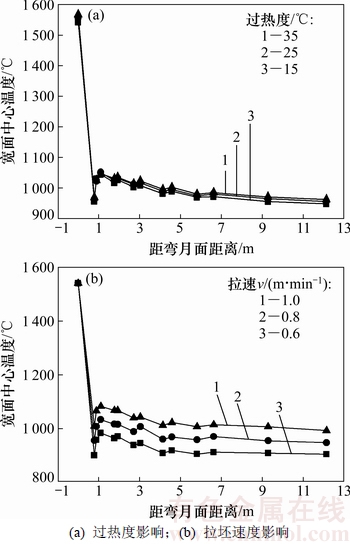

2.1.2 工艺参数影响

在连铸板坯拉坯速度为0.8 m/min,冷却条件不变前提下,浇注钢液过热度对宽面中心温度的影响如图4(a)所示。由图4(a)可知:在凝固时间相同的情况下,过热度由35 ℃降至15 ℃,宽面中心温度相应降低约13 ℃;过热度平均每降低10 ℃,宽面中心温度降低约6.5 ℃。具体原因为:当拉坯速度和冷却条件不变时,过热度越高,连铸坯冷却速率越慢,凝固得越少,连铸坯宽面中心温度越高。

当钢液过热度为25 ℃时,拉坯速度对连铸坯宽面中心温度的影响如图4(b)所示。由图4(b)可以看出:拉坯速度由1.0 m/min减至0.6 m/min,连铸坯宽面中心温度降低约100 ℃;拉坯速度每降低0.1 m/min,宽面中心温度平均降低约25 ℃。这是由于随着拉坯速度降低,连铸板坯在冷却区停留时间变长,从而相对冷却强度变大,通过相同距离时,温降增大,故随着拉坯速度降低,板坯宽面中心温度降低。

2.2 微观组织形貌

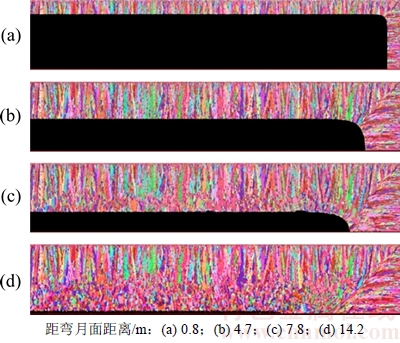

2.2.1 断面分布

当过热度为25 ℃,拉坯速度为0.8 m/min时,连铸板坯断面微观组织形貌如图5所示。钢液倒入结晶器后,由于结晶器壁处散热速率快且有大量非均匀形核基底,故在表层形成细晶区。此后,结晶器壁被液态金属及凝固释放的结晶潜热加热,温度升高,已凝固的细晶区与结晶器壁之间产生缝隙,使钢液散热较困难,导致钢液冷却变慢,固液界面温度梯度变小,晶粒生长方向沿着热流方向,柱状晶生成。随着柱状晶的生长,板坯中心部位液态金属温度降到液相线以下,满足形核对过冷度的要求,加上液态金属中杂质为非均匀形核提供条件,于是,在整个液态金属中形成晶核,此时钢液向不同方向散热,晶核在不同方向上的生长速度均匀,等轴晶出现并长大。

图4 工艺参数对宽面中心温度的影响

Fig. 4 Effects of process parameters on wide surface center temperature

图5 断面微观形貌分布

Fig. 5 Morphology distributions of sections

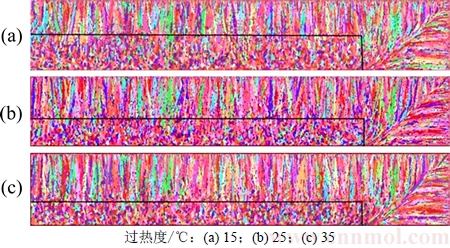

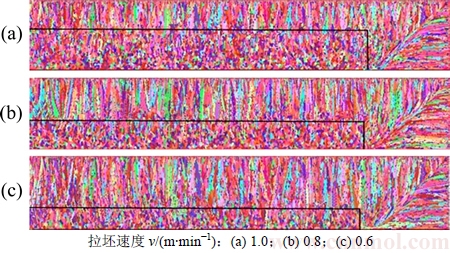

2.2.2 工艺参数影响

钢水过热度和连铸坯拉坯速度是保证连铸产量和连铸坯质量的关键工艺参数。鉴于此,以过热度15,25和35 ℃,拉坯速度0.8 m/min为条件进行模拟,结果如图6所示;以过热度25 ℃,拉坯速度0.6,0.8和1.0 m/min为条件进行模拟,结果如图7所示。具体表现为:过热度增大和拉坯速度减小,都会使中心等轴晶率减小。对比图6和图7可得:拉坯速度变化对中心等轴晶率的影响较过热度大。在工业生产中,为了获得较高的等轴晶率,根据过热度和拉坯速度对等轴晶率的影响,应采取低过热度以及高拉坯速度,但是,若过热度过低,则连铸坯杂质较多,连铸坯质量下降;拉坯速度过高会使连铸坯温度升高,坯壳厚度变薄,出现拉漏。

2.2.3 工艺参数对等轴晶率影响

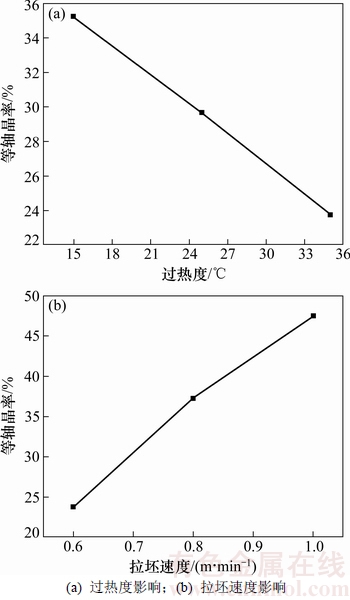

中心等轴晶率随过热度和拉坯速度变化分别见图8。可见:1) 过热度由15 ℃升至35 ℃,中心等轴晶率减小约11.5%。2) 拉坯速度由0.6 m/min增至1.0 m/min,中心等轴晶率增长约23.8%。其原因是:1) 过热度增大,连铸坯中杂质被大量溶解,非均匀形核基底减少,使形核参数发生变化,最大形核密度减小,导致等轴晶率降低。2) 当钢液过热度增大时,结晶前沿形成的成分过冷区会变小,这样就更利于柱状晶的生长,抑制中心等轴晶生长。3) 拉坯速度增大,连铸坯在冷却区停留时间变短,相对冷却强度变小,柱状晶前沿固液混合区温度梯度减少,促进晶体的形核和长大,从而中心等轴晶率提高。

图6 过热度对微观形貌的影响

Fig. 6 Effect of superheating temperatrue on morphology

图7 拉坯速度对微观形貌的影响

Fig. 7 Effect of tensile speed on morphology

图8 工艺参数对等轴晶率的影响

Fig. 8 Effect of process parameters on equiaxed crystal rate

2.2.4 工艺参数对晶粒半径影响

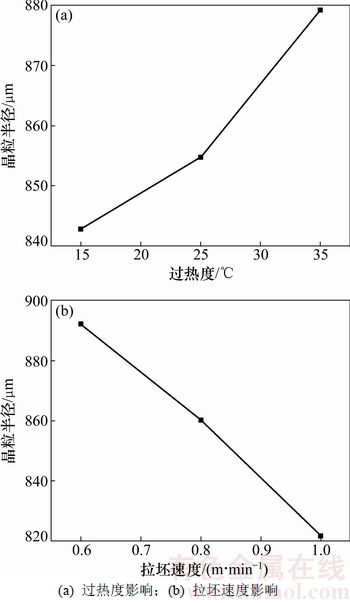

图9所示为过热度和拉坯速度对晶粒半径影响。由图9可知:1) 过热度升高,晶粒半径逐渐增大,由过热度为15 ℃时842.7 μm增至过热度为35 ℃时879.2 μm。2) 拉坯速度增大,晶粒半径减小,由0.6 m/min时892.2 μm减至1.0 m/min时的821.7 μm。具体原因为:1) 过热度越高,非均匀形核数目越少,单位体积晶核数目越少,每个晶粒相对生长空间变大,因而最终晶粒平均半径越大。2) 拉坯速度越高,连铸坯相对冷却强度变低,柱状晶前沿固液混合区温度梯度越小,过冷区范围变宽,形核率增大,单位体积中晶核数目越多,每个晶粒相对生长空间变小,因而,晶粒长大后,平均半径越小。

图9 工艺参数对晶粒半径的影响

Fig. 9 Effect of process parameters on grain radius

2.3 二次枝晶臂间距

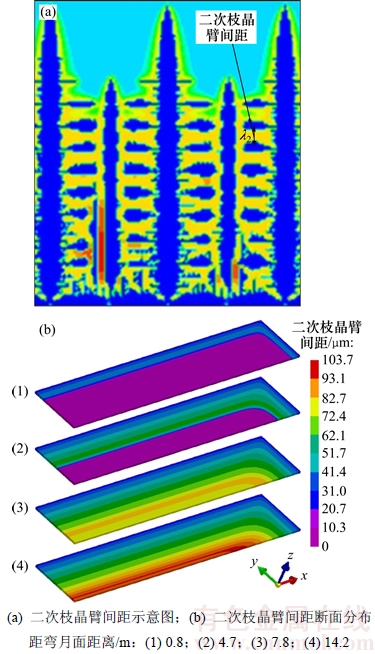

2.3.1 断面分布

二次枝晶臂间距是相邻2个二次枝晶臂轴线之间的距离,其依赖连铸板坯局部凝固时间,具体示意图如图10(a)所示。当过热度为25 ℃,拉坯速度为0.8 m/min时,计算出连铸板坯断面二次枝晶臂间距分布见图10(b),(1)~(4)分别为距弯月面0.8,4.7,7.8和14.2 m的二次枝晶臂间距断面分布图。由图10可知,二次枝晶臂间距在液相区时为0,在固相中,随着凝固的进行,间距不变,只在固液两相区生长,二次枝晶臂间距从板坯表面到中心逐渐增大,由表面的20.7 μm增至板坯中心的103.7 μm。具体原因为:连铸板坯靠近表面部分冷却强度较大,冷却速度较快,固液两相区持续时间较短,凝固时间较短;当连铸坯凝固前沿向中心部位移动时,由于潜热的释放使冷却强度变小,从而完全凝固所用时间变长。

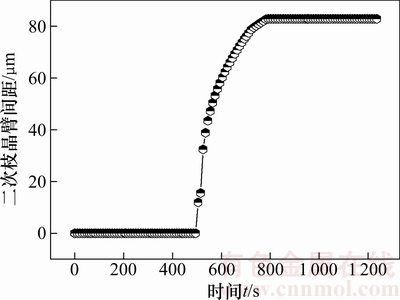

2.3.2 变化规律

为研究板坯某点二次枝晶臂间距变化规律,取距连铸坯表面85 mm处某点并以过热度25 ℃,拉坯速度0.8 m/min为条件进行模拟,结果如图11所示。二次枝晶臂间距的变化具体表现为:1) 二次枝晶臂间距在0~500 s时间段内为0 m,这是由于过热度存在,连铸坯未凝固,没有二次枝晶生成,故间距为0 m。2) 从500 s开始,凝固前沿到达85 mm处,二次枝晶开始生长并粗化,二次枝晶臂间距逐渐增大,其增长速度逐渐变慢。其原因可归结为:溶质浓度梯度的存在将促使溶质扩散,其结果将造成细枝晶臂溶解和粗枝晶臂增厚粗化。起初液相前沿有较大过冷度,冷却速率较快,液相流动性也好,故枝晶间距增长较快。随着凝固的进行,结晶潜热释放使凝固前沿温度梯度变小,过冷度变小,枝晶生长缓慢,粗化效果也变缓慢,其次温度降低也使糊状区流动性变差,溶质流动减缓,细小枝晶不易被溶解,粗大枝晶也不易继续增粗。3) 从780 s后,连铸板坯全部凝固,二次枝晶臂间距也停止增大。

图10 二次枝晶臂间距示意图及断面分布

Fig. 10 Schematic of secondary dendritic arm spacing and distribution of sections

图11 二次枝晶臂间距变化规律

Fig. 11 The variation law of secondary dendritic arm spacing

2.3.3 工艺参数影响

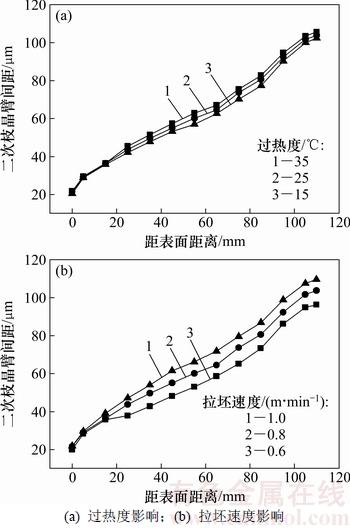

在连铸坯拉坯速度0.8 m/min,冷却条件不变前提下,改变浇注钢液过热度,对连铸坯二次枝晶臂间距影响如图12(a)所示。在18 mm之前,随着过热度降低枝晶臂间距变化不大;18 mm之后,过热度由35 ℃降至15 ℃,变化量不超过6 μm,过热度由35 ℃降至25 ℃,变化量不超过3 μm。其原因是:1) 连铸坯表面部位冷却强度较大,过热度升高对其凝固时间影响较小,故二次枝晶臂间距变化较小。2) 过热度提高,连铸坯凝固时需要散出更多热量,在冷却条件一定的情况下,凝固时间随之延长,故二次枝晶臂间距增大。

在过热度为25 ℃,拉坯速度为0.6,0.8,1.0 m/min条件下模拟出二次枝晶臂间距变化情况如图12(b)所示。从图12(b)可见:在18 mm之前,随着拉坯速度增加,枝晶臂间距变化不大;18 mm之后,拉坯速度由1.0 m/min减至0.6 m/min,枝晶臂间距减小约13 μm,过热度由1.0 m/min减至0.8 m/min,枝晶臂间距减小约6 μm。原因可归结为:拉坯速度增大,连铸坯在冷却区停留时间变短,相对冷却强度变小,从而连铸坯凝固过程中需要更长时间,有利于枝晶粗化,故随着拉坯速度增大,二次枝晶臂间距也随之增大。二次枝晶臂间距增大易使连铸坯偏析变得严重,为了减小偏析,连铸坯的工艺参数应采取低过热度、低拉坯速度。

图12 工艺参数对二次枝晶臂间距的影响

Fig. 12 Effect of process parameters on secondary dendrite arm spacing

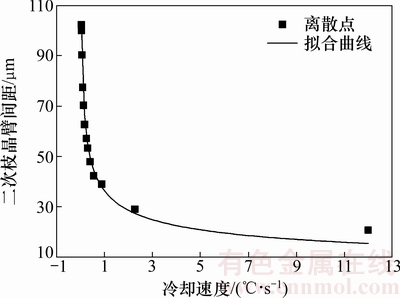

2.3.4 二次枝晶臂间距与冷却速度的关系

连铸板坯二次枝晶臂间距依赖固液两相区冷却速度和非平衡凝固时间,EI-BEALY等[25-26]依据碳含量的取值范围分别采用冷却速度ε和局部凝固时间tf来计算二次枝晶臂间距。YOUNG-MOK等[27]根据不同研究者在不同冷却速率和钢种碳含量条件下的实测数据,通过拟合回归得到二次枝晶臂间距计算式,综合以上研究二次枝晶臂间距与冷却速度的函数关系可归结为:

(10)

(10)

(11)

(11)

式中:a和b为常数;ε为冷却速度,℃·s-1;tf为非平衡凝固温度区间,℃;△ts为合金局部凝固时间,s。

计算出二次枝晶臂间距与冷却速度的对应关系并采用Origin软件进行数据拟合回归处理如图13所示。

图13 二次枝晶臂间距与冷却速度的关系

Fig. 13 Relationship between secondary dendritic arm spacing and cooling rate

由图13可得低碳钢连铸板坯二次枝晶臂间距与冷却速度之间的拟合函数关系为

y = 36.31 x-0.35 (12)

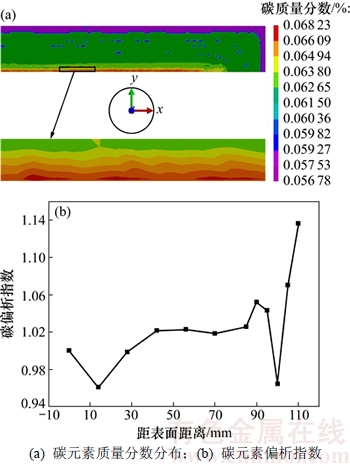

2.4 碳元素中心偏析

当过热度为25 ℃,拉坯速度为0.8 m/min时,计算出连铸板坯凝固末端横断面上碳元素分布情况,如图14所示。由图14可知:1) 碳元素分布由表层紫色逐渐过渡到中心红色,碳元素在中心处呈现较明显正偏析带,中心处碳偏析指数可达1.14。2) 板坯大部分区域偏析指数约为1.02,在距板坯中心19 mm处,偏析指数突然上升。3) 碳元素在中心线附近形成负偏析带。具体原因为:1) 板坯凝固界面附近选分结晶及凝固末期枝晶间富含溶质钢液流动和积累而形成中心偏析。2) 凝固末期板坯中心部位凝固收缩成孔洞,产生负压,中心部位附近枝晶间富集合金元素的钢液向中心补缩,从而在中心线附近出现负偏析带。3) 柱状晶凝固前沿由于选分结晶缘故,元素富积在柱状晶前沿,当柱状晶与等轴晶相遇时,由于等轴晶粒生长方向无序性会影响溶质传输,造成溶质元素聚集在两种组织的交界处形成正偏析。

由图14(a)还可知:碳元素中心偏析区域分布在连铸板坯中心线上,但偏析区域并不连续,而是呈分散的岛状分布。模拟结果与许志刚等[28]对管线钢半宏观偏析的实验结果吻合。

图14 碳元素分布及偏析指数

Fig. 14 Distribution and segregation index of carbon element

3 结论

1) 二冷区各段交界处出现温度回升现象。角部区域温度下降较快。拉坯速度和过热度降低均能使连铸板坯宽面中心温度降低,过热度从35 ℃降至15 ℃,板坯宽面中心温度降低约13 ℃,拉坯速度从1.0 m/min减至0.6 m/min,板坯宽面中心温度降低约100 ℃,对比得出拉坯速度影响较过热度大。

2) 过热度由35 ℃降至15 ℃,中心等轴晶率从23.7%升至35.2%,晶粒半径减小36.5 μm。拉坯速度由1.0 m/min减至0.6 m/min,中心等轴晶比率从47.5%降至23.7%,晶粒半径增大70.5 μm。为得到较高比率的等轴晶和较小的晶粒半径,应采用低过热度、高拉坯速度。

3) 液相区二次枝晶臂间距为零,随着凝固进行,枝晶臂间距逐渐增大,直到局部区域凝固完全,枝晶臂间距停止增大。连铸板坯断面上从表面到中心,凝固时间变长,二次枝晶臂间距逐渐增大。过热度降低和拉坯速度减小,均能使二次枝晶臂间距变小。

4) 由于钢液凝固过程的选分结晶,钢液中碳元素含量逐渐升高,后凝固的钢液中碳元素含量较高,形成偏析。碳元素在板坯中心处偏析最严重,在中心线附近形成负偏析。碳元素中心偏析区域并不连续,而是成岛状分布在板坯中心线上。

参考文献:

[1] 窦坤, 卿家胜, 王雷, 等. 基于微观偏析模型的连铸方坯内裂纹敏感性研究[J]. 金属学报, 2014, 50(12): 1505-1512.

DOU Kun, QING Jiasheng, WANG Lei, et al. Research on internal crack susceptibility of continuous-casting bloom based on micro-segregation model[J]. Acta Metallurgica Sinica, 2014, 50(12): 1505-1512.

[2] 付建勋, 李京社, 张慧, 等. 连铸二冷区铸坯展宽现象的黏弹塑性分析[J]. 金属学报, 2010, 46(1): 91-96.

FU Jianxun, LI Jingshe, ZHANG Hui, et al. Visco elastic plastic analysis of the spreading phenomenon in secondary colling zone of continuous casting slab[J]. Acta Metallurgica Sinica, 2010, 46(1): 91-96.

[3] OSORIO W R, SPINELLI J, CHEUNG N, et al. Secondary dendritic arm spacing and solute redistribution effects on the corrosion resistance of Al-10 wt% Sn and Al-20 wt% Zn alloys[J]. Materials Science and Engineering A, 2006, 420(2): 179-186.

[4] 仲红刚. 连铸坯凝固过程热模拟研究[D]. 上海: 上海大学材料科学与工程学院, 2013: 2-10.

ZHONG Honggang. Thermal simulation of solidification process of continuous casting slab[D]. Shanghai: Shanghai University. School of Materials Science and Engineering, 2013: 2-10.

[5] HUANG X, THOMAS B G, NAJJAR F M, et al. Modeling superheat removal during continuous casting of steel slab[J]. Metall Mater Trans B, 1992, 23(3): 339-356.

[6] LOUHENKILPI S, LAITINEN E, NIEMINEN R, et al. Real-Time simulation of heat transfer in continuous casting[J]. Metall Mater Trans B, 1993, 24(4): 685-693.

[7] SEDIAKO D, SEDIAKO O, KUAN Julin, et al. Some aspects of thermal analysis and technology upgrading in steel continuous casting[J]. Canadian Metallurgical, 1999, 38(5): 377-385.

[8] 蔡开科, 吴元增. 连续铸锭板坯凝固传热数学模型[J]. 金属学报, 1983, 19(1): 115-122.

CAI Kaike, WU Yuanzeng. Heat transfer mathematical model of continuous slab ingot solidification[J]. Acta Metallurgica Sinica, 1983, 19(1): 115-122.

[9] RAPPAZ M, GANDIN A C. Probabilistic modeling of microstructure formation in solidification processes[J]. Acta Mactallurgical ct Macterialia, 1993, 41(2): 345-351.

[10] ZHU M F, HONG C P. A modified cellular auto-maton model for the simulation of dendritic growth in solidification of alloy[J]. ISIJ International, 2001, 41(5): 436-445.

[11] WANG Jinlong, WANG Fuming, LI Chongrong, et al. Simulation of 3D-microstructure in free-cutting steel 9SMn28 under cooling condition with convection and porosity[J]. ISIJ International, 2010, 50(2): 222-227.

[12] WANG Jinlong, WANG Fuming, LI Chongrong, et al. Simulation of solidification microstructure and columnar to equiaxed transition in free-cutting steel 9SMn28 based on a CAFE method[J]. Steel Research International, 2010, 81(2): 150-157.

[13] WANG Jinlong, WANG Fuming, ZHAO Yanyu, et al. Numerical simulation of 3D-microstructure in solidification processes based on a CAFE method[J]. Metallurgy and Materials, 2009, 16(6): 640-647.

[14] 冯军, 陈伟庆. 高碳钢小方坯的一次枝晶臂间距的影响因素[J]. 北京科技大学学报, 2007, 29(1): 25-29.

FENG Jun, CHEN Weiqing. Influence factors of primary dendritic arm spacing in high carbon steel billets[J]. Journal of University of Science and Technology Beijing, 2007, 29(1): 25-29.

[15] 冯军, 陈伟庆, 韩静, 等. 连铸参数对高碳钢小方坯二次枝晶臂间距的影响[J]. 钢铁, 2006, 41(9): 37-39.

FENG Jun, CHEN Weiqing, HAN Jing, et al. Effect of casting parameters on high carbon steel billet secondary dendritic arm spacing[J]. Iron & Steel, 2006, 41(9): 37-39.

[16] 程鸣涛, 唐仲和, 倪满森, 等. 45号钢二次枝晶臂间距与冷却速度的关系[J]. 钢铁研究学报, 1993, 51(4): 1-4.

CHENG Mingtao, TANG Zhonghe, NI Mansen, et al. The relationship between the secondary dendritic arm spacing and the cooling rate of 45 steel[J]. Journal of iron and Steel Research, 1993, 51(4): 1-4.

[17] PIEXER R, BEMHAND C. On the influence of carbon on secondary dendrite arm spacing in steel[J]. Journal of Material Science, 2008, 43(21): 6938-6943.

[18] 严青松, 余欢, 芦刚, 等. 结晶压力对真空差压铸造铝合金二次枝晶间距的影响[J]. 中国有色金属学报, 2014, 24(5): 1194-1199.

[19] YAN Qingsong, YU Huan, LU Gang, et al. Effect of crystallization pressure on the secondary dendrite arm spacing of vacuum differential pressure casting aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(5): 1194-1199.

[20] 邹敏明, 张军, 刘林, 等. 熔体超温处理对DD3单晶高温合金二次枝晶间距的影响[J]. 金属学报, 2008, 44(2): 155-158.

ZOU Minming, ZHANG Jun, LIU Lin, et al. Effect of melt super temperature treatment on the secondary dendrite arm spacing of DD3 single crystal superalloy[J]. Acta Metallurgica Sinica, 2008, 44(2): 155-158.

[21] 左晓静, 林仁敢, 汪宁, 等. 低碳钢与中碳钢连铸方坯初始凝固的对比研究[J]. 工程科学学报, 2016, 38(5): 650-657.

ZUO Xiaojing, LIN Rengan, WANG Ning, et al. Comparative study on the initial solidification behavior of continuous casting billets between low-carbon steel and medium-carbon steel[J]. Chinese Journal of Engineering, 2016, 38(5): 650-657.

[22] 左晓静, 孟祥宁, 黄烁, 等. 连铸低碳钢一次枝晶演变数值模拟及其受力分析[J]. 物理学报, 2016, 65(16): 166101.

ZUO Xiaojing, MENG Xiangning, HUANG Shuo, et al. Morphology simulation and mechanical analysis of primary dendrites for continuously cast low carbon steel[J]. Acta Phys Sin, 2016, 65(16): 166101.

[23] 张冬晓, 常庆明, 方健, 等. 大断面立式半连铸坯凝固微观组织的数值模拟[J]. 铸造技术, 2015, 36(9): 2271-2275.

ZHANG Dongxiao, CHANG Qingming, FANG Jian, et al. Numerical simulation of solidification microstructure of large section vertical semi continuous casting slab[J]. Foundry Engineering, 2015, 36(9): 2271-2275.

[24] 周景龙, 齐力军. 高碳钢小方坯二次枝晶间距与P偏析的关系[J]. 重型机械, 2013(4): 30-33.

ZHOU Jinglong, QI Lijun. The relation between the secondary dendrite arm spacing in high carbon steel and segregation phosphorus[J]. Heavy Machinery, 2013(4): 30-33.

[25] EI-BEALY M, THOMAS B G. Prediction of dendrite arm spacing for low alloy steel casting processes [J]. Metallurgical and Materials Transactions B, 1996, 27(4): 689-692.

[26] 郭薇. 板坯连铸凝固过程微观组织的模拟研究[D]. 沈阳: 东北大学材料与冶金学院, 2010: 19-20.

GUO Wei. Simulation of microstructure for steel solidification during slab continuous casting process[D]. Shenyang: Northeastern University. School of Materials and metallurgy, 2010: 19-20.

[27] YOUNG-MOK W, THOMAS B G. Simple model of microsegregation during solidification of steels[J]. Metallurgical and Materials Transactions A, 2001, 32(7): 1755-1767.

[28] 许志刚, 王新华, 黄福祥, 等. 管线钢连铸板坯的半宏观偏析和凝固组织[J]. 北京科技大学学报, 2014, 36(6): 751-756.

XU Zhigang, WANG Xinhua, HUANG Fuxiang, et al. Semi macrosegregation and solidification structure of pipeline steel continuous casting slab[J]. Journal of University of Science and Technology Beijing, 2014, 36(6): 751-756.

(编辑 赵俊)

收稿日期:2016-12-10;修回日期:2017-03-26

基金项目(Foundation item):国家自然科学基金资助项目(51004031);中央高校基本科研业务费资助项目(N140205002)(Project(51004031) supported by the National Natural Science Foundation of China; Project(N140205002) supported by the Fundamental Research Funds for the Central Universities)

通信作者:孟祥宁,博士,副教授,从事高品质钢连铸研究;E-mail:mengxn@smm.neu.edu.cn