三级均匀化对7N01铝合金显微组织和性能的影响

来源期刊:中国有色金属学报(英文版)2018年第5期

论文作者:林化强 叶凌英 孙琳 肖涛 刘胜胆 邓运来 张新明

文章页码:829 - 838

关键词:7N01铝合金;三级均匀化;显微组织;力学性能;应力腐蚀开裂

Key words:7N01 aluminum alloy; three-step homogenization; microstructure; mechanical properties; stress corrosion cracking

摘 要:采用硬度、电导率、拉伸、慢速率拉伸、电子探针显微镜(EPMA)、金相显微镜(OM)、扫描电镜(SEM)和透射电镜(TEM)研究不同均匀化制度对7N01铝合金显微组织和性能的影响。研究结果表明,三级均匀化制度在有效消除主合金元素成分偏析的前提下,较大程度提高Zr元素在晶内和晶界分布的均匀性;此外,在350 °C保温10 h进行第二级均匀化处理后形成的粗大长条状平衡η相具有较大的界面能和尺寸,这有利于Al3Zr粒子的异质形核,减小晶界附近Al3Zr粒子无沉淀析出带的宽度。经过200 °C, 2 h + 350 °C, 10 h + 470 °C, 12 h均匀化处理能较大程度抑制粗大再结晶的发生,这有利于获得更高综合性能的7N01铝合金。

Abstract: The effect of different homogenization treatments on the microstructure and properties of the 7N01 aluminum alloy was investigated using hardness measurements, electrical conductivity measurements, tensile and slow strain rate tests, electron probe microanalysis, optical microscopy, scanning electron microscopy, and transmission electron microscopy. The results revealed that three-step homogenization improved the uniformity of Zr distribution by eliminating segregation of the main alloying elements. During the second homogenization step at 350 °C for 10 h, coarse and strip-like equilibrium η phases formed which assisted the nucleation of Al3Zr dispersoids and reduced the width of the precipitate-free zone of A13Zr dispersoids. As a result, coarse recrystallization was greatly reduced after homogenization at 200 °C, 2 h + 350 °C, 10 h + 470 °C, 12 h, which contributed to improving the overall properties of the 7N01 aluminum alloys.

Trans. Nonferrous Met. Soc. China 28(2018) 829-838

Hua-qiang LIN1,2, Ling-ying YE2, Lin SUN1, Tao XIAO3, Sheng-dan LIU2, Yun-lai DENG2,3, Xin-ming ZHANG2,3

1. National Engineering Research Center for High-Speed EMU, CRRC Qingdao Sifang Co., Ltd., Qingdao 266000, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

3. Light Alloy Research Institute, Central South University, Changsha 410083, China

Received 2 March 2017; accepted 10 November 2017

Abstract: The effect of different homogenization treatments on the microstructure and properties of the 7N01 aluminum alloy was investigated using hardness measurements, electrical conductivity measurements, tensile and slow strain rate tests, electron probe microanalysis, optical microscopy, scanning electron microscopy, and transmission electron microscopy. The results revealed that three-step homogenization improved the uniformity of Zr distribution by eliminating segregation of the main alloying elements. During the second homogenization step at 350 °C for 10 h, coarse and strip-like equilibrium η phases formed which assisted the nucleation of Al3Zr dispersoids and reduced the width of the precipitate-free zone of A13Zr dispersoids. As a result, coarse recrystallization was greatly reduced after homogenization at 200 °C, 2 h + 350 °C, 10 h + 470 °C, 12 h, which contributed to improving the overall properties of the 7N01 aluminum alloys.

Key words: 7N01 aluminum alloy; three-step homogenization; microstructure; mechanical properties; stress corrosion cracking

1 Introduction

7N01 aluminum alloys have been widely used in components for high-speed trains due to their excellent extrusion properties, high strength, high fracture toughness, satisfactory welding properties, and resistance to fatigue [1-3]; these excellent properties are dependent on the microstructure of the material. Degradation in the overall properties occurs due to micro-segregation, non- equilibrium phases, and coarse crystalline intermetallic particles; such undesirable microstructures can be eliminated by homogenization treatments [4,5]. Zr tends to be enriched in dendritic networks leading to segregation of solute atoms as the solute distribution coefficient K>1 for Zr. Therefore, homogenization can also optimize the distribution of Al3Zr dispersoids for the material containing Zr, which inhibits recrystallization during subsequent heat treatment, and therefore, the overall properties of the material can be significantly enhanced [6,7].

The fraction of fine Al3Zr dispersoids increases during the two-step homogenization which can effec- tively restrain the migration of grain boundaries [8,9]. It is worth noting that small Al3Zr dispersoids can be seen near grain boundaries, and as a result the inhibition of recrystallization in subsequent treatments is limited.

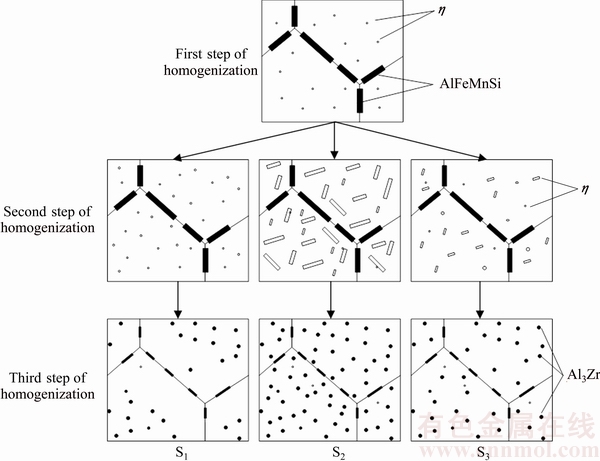

Further research on homogenization processes is still needed to achieve uniform distribution of Al3Zr particles which can precipitate both at the center of the grains and near the grain boundaries. In this work, a three-step homogenization process was designed to obtain a large amount of Al3Zr dispersoids near the grain boundaries. In the first homogenization step, a period for incubating the η phases which act as nucleation sites was provided to ensure the growth of a sufficiently large number and size of induced phases in the next steps. The second homogenization step regulated the number and size of Al3Zr dispersoids near the grain boundaries, while part of the micro-segregation of the material was eliminated. During heating in the third step, large amounts of Al3Zr dispersoids precipitated in the region with higher Zr concentration; simultaneously, η phases which were formed during the second step provided many favorable nucleation sites for Al3Zr dispersoids near grain boundaries which had low Zr concentration. Theoretically, three-step homogenization provides favorable conditions for Al3Zr dispersoids to uniformly precipitate both at the center of grains and near the grain boundaries. Meanwhile, three-step homogenization could both eliminate segregation and some detrimental secondary phases, therefore achieving traditional homogenization as well. A previous study confirmed that three-step homogenization can contribute to increasing the density and uniformity of Al3Zr dispersoids [3]; however, optimized three-step homogenization treatment for the 7N01 aluminum alloy was not discussed. In this work, the nucleation mechanism of Al3Zr dispersoids under different three-step homogenization treatments is described, and the results contributed to further improvement of the overall properties of the 7N01 aluminum alloy compared with the two-step process, making the material suitable for use in high-speed train applications.

2 Experimental

2.1 Material and treatment

The material used in this work was 7N01 aluminum alloy with a composition of 4.33Zn, 1.29Mg, 0.13Cu, 0.20Zr, 0.07Fe, 0.05Si and balance Al (mass fraction, %). Various processes, including casting, homogenization, extrusion, annealing at 500 °C for 10 min, and an aging treatment, were applied to the 7N01 aluminum alloy samples. Different homogenization treatments are given in Table 1. In order to achieve reproducible samples, the casting, extrusion, and aging treatments were the same for all samples. Characterization of the mechanical properties was carried out after the aging treatment.

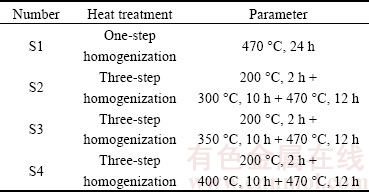

Table 1 Details of one-step and three-step homogenization treatments applied to 7N01 aluminum alloy

2.2 Microstructural observation

Microstructural observations were undertaken using optical microscopy (OM, OLYMPUS GX71) to quantify the fraction of recrystallized structures. The microscopy samples were sectioned parallel to the extrusion direction and etched with Graff reagent (16 mL HNO3, 1 mL HF, 3 g CrO3, and 83 mL H2O) for 15 min. The secondary phases near the grain boundaries were analyzed using scanning electron microscopy (SEM, FEI-Quanta). Thin slices for transmission electron microscopy (TEM, TECNAI G220) observations were cut from the 7N01 aluminum alloy samples, polished to a thickness of 80 μm, and then thinned using twin-jet electro-polishing in a solution of 30% nitric acid and 70% methanol (volume fraction) from -35 to -25 °C with an applied current of 60 mA and an applied voltage of 20 V.

2.3 Mechanical and conductivity properties

The Vickers hardness of the alloy samples was measured using a HV3 hardness tester with a load of 30 N and a dwell time of 15 s. Electrical conductivity of the samples was measured using a D60K digital test instrument. The Vickers hardness and the electrical conductivity values were the average of at least five measurements. Tensile testing was undertaken using a CSS-44100 testing machine at a stretching rate of 2 mm/min, where the long axis of the samples was parallel to the extrusion direction. The stress corrosion cracking (SCC) resistance of the 7N01 aluminum alloy was measured using the slow strain rate test (SSRT) method according to ASTM G 129. Specimens were tested using RSW50, and the tests were carried out at a strain rate of 1×10-6 s-1, where the long axes of the specimens were parallel to the extrusion direction. The SSRT samples were tested either in air and 25 °C, 3.5% (mass fraction) NaCl solution with a strain rate of 1×10-6 s-1 in order to characterize the SCC susceptibility of the 7N01 aluminum alloy, ISSRT, as defined below:

(1)

(1)

where δ is the elongation and Rm is the strength. The SCC susceptibility increases when the parameter ISSRT varies from 0 to 1.

3 Results

3.1 Microstructure

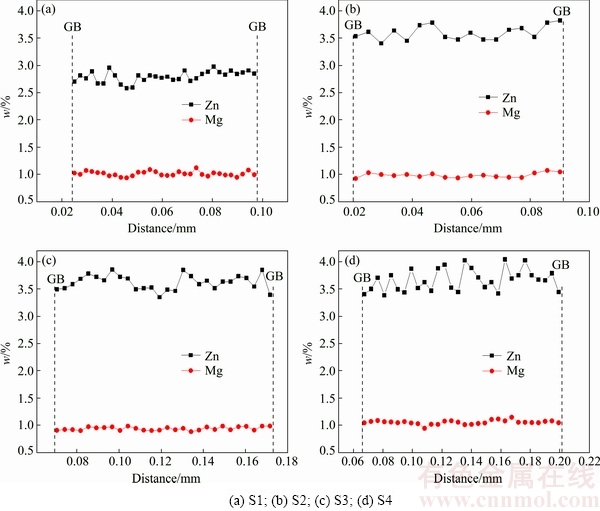

Zn and Mg were enriched near the grain boundaries to varying degrees as K>1, while Zr tended to be enriched in the center of the grains [10]. Figure 1 shows EPMA line scanning results of the elemental distributions of Zn and Mg in the grains. It is clear that there were no significant differences after different homogenization treatments. Therefore, both the one-step and three-step homogenization treatments effectively eliminated the segregation of the main elements in the ingot.

Fig. 1 EPMA line scanning results of elemental distributions of Zn and Mg in grains after different homogenization treatments

Fig. 2 EPMA line scanning results of elemental distribution of Zr in grains after different homogenization treatments

Figure 2 shows EPMA line scanning results for Zr in the grains after different homogenization treatments, which shows that the Zr content was enhanced at the grain centers. In addition, the distribution of Zr in the grains was quite different after different homogenization treatments. It is worth noting that a more uniform distribution was observed after the three-step homogenization treatments than after the one-step treatment. Among different three-step homogenization treatments, the most uniform distribution of Zr was achieved when the second-step temperature was 350 °C (S3), where segregation of Zr was mostly eliminated. In addition, the homogenization treatment with the second-step temperature of 300 °C (S2) showed the least effect on the segregation of Zr.

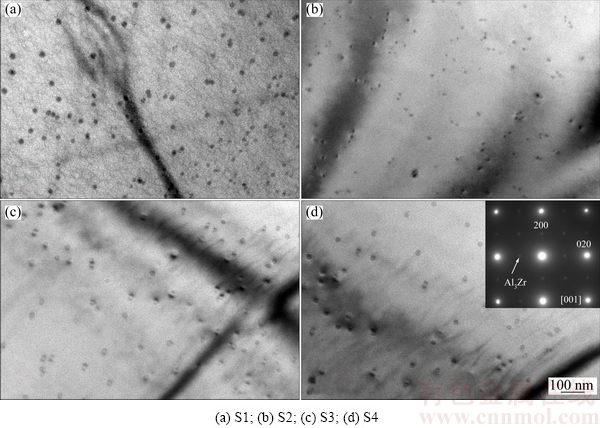

Figure 3 shows TEM images of the alloys after different homogenization treatments. According to the SAED patterns of the material in the [001] projection shown in Fig. 3(d), the spherical secondary particles after different homogenization treatments represented Al3Zr dispersoids. According to the Zener pinning equation, the average pinning force of Al3Zr dispersoids on the grain boundaries can be expressed as [11]

(2)

(2)

where Z is the pinning force, k is a constant, φ is the volume fraction of Al3Zr dispersoids, γ is the interfacial energy of the grain boundaries, and r is the radius of Al3Zr dispersoids. This means that fine and dense Al3Zr dispersoids have a greater pinning force on the grain boundaries and a favorable effect on inhibiting the recrystallization.

Table 2 gives the geometrical parameters of grains calculated from at least ten TEM images of the matrix after each homogenization treatment, as analyzed by Image-J software. Compared with the one-step homogenization treatment, different three-step homogenization treatments, especially the S3 treatment, resulted in relatively uniform, fine, and dense distribution of Al3Zr dispersoids in the material. Compared with the S1 treatment, many differences in the geometrical parameters of the dispersoids were observed after the S3 treatment. The average radius decreased by 22.6%, the average density increased by 50.3%, and the ratio of the average area fraction to the average radius increased from 278.1 to 385.0 μm-1. Based on the statistical results of the geometrical parameters, we can conclude that the three-step homogenization treatments, especially the S3 treatment, increased the number of fine and dispersed Al3Zr dispersoids.

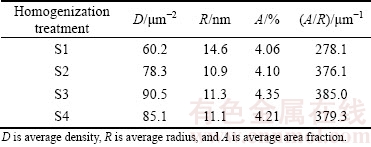

TEM images of the region near the grain boundaries of the specimens after different homogenization treatments are shown in Fig. 4. The number and distribution of Al3Zr dispersoids near the grain boundaries in the 7N01 aluminum alloys were significantly different after various homogenization treatments. Except for extremely few coarse particles after one-step homogenization, no other Al3Zr dispersoids were observed in the material. The number of small Al3Zr dispersoids near the grain boundaries increased significantly after the three-step homogenization processes. The densities of the Al3Zr dispersoids near the grain boundaries after the S1, S2, S3 and S4 treatments, as analyzed using Image-J software, were 1.7, 3.5, 81.7 and 41.8 μm-2, respectively. Therefore, the S3 treatment had the largest effect on optimizing the distribution of Al3Zr dispersoids near the grain boundaries.

Fig. 3 TEM images of specimens after different homogenization treatments

Table 2 Statistical data for geometric parameters of Al3Zr dispersoids after different homogenization treatments

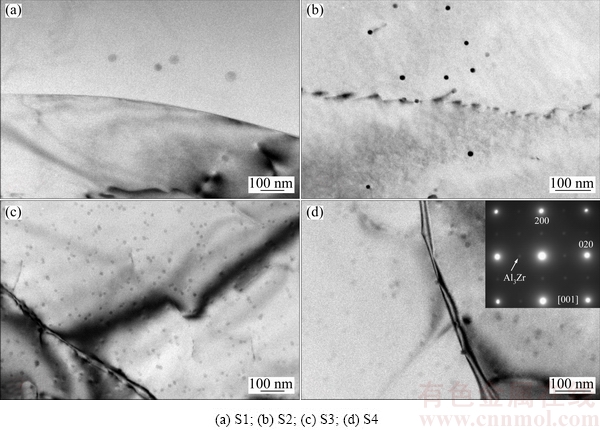

It is well known that coarse recrystallized grains greatly deteriorate the mechanical properties of alloys. Optical microscopy images of specimens after aging are shown in Fig. 5 in order to analyze the pinning effect of Al3Zr dispersoids on the coarse recrystallization behavior of the material. The grain boundaries and sub-grain boundaries were sensitive to corrosion and showed a black color after treatment in the Graff reagent due to their high energy. In addition, the small recrystallized grains and sub-grains showed similar behavior after prolonging soaking in Graff reagent. The central region of coarse recrystallization grain was white in color as it was not easily eroded by the Graff reagent. The fraction of these white areas of the alloys after S1, S2, S3 and S4 treatments were 31.5%, 18.9%, 1.9% and 5.7%, respectively. A large and small area fraction of the coarse white region for the material after one-step homogenization and three-step homogenization, respectively, indicates that the three-step homogenization more effectively inhibited coarse recrystallization during the heat treatment process.

Fig. 4 TEM images of regions near grain boundaries of specimens after different homogenization treatments

Fig. 5 Optical microscopy images of specimens after same extrusion, annealing at 500 °C for 10 min and aging treatment, but different homogenization processes

3.2 Electrical conductivity and mechanical properties

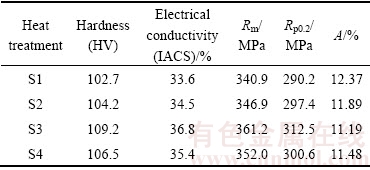

The results of the electrical conductivity and mechanical properties of the materials after different homogenization treatments are present in Table 3. The hardness and electrical conductivity of the material were improved after three-step homogenization compared with those after one-step homogenization due to the reduced recrystallization. The values of hardness and electrical conductivity of the specimens after the S3 treatment were the highest of all three-step homogenization treatments, while the values for the S1 treatment were the lowest.

Table 3 Electrical conductivity and mechanical properties of alloys after artificial aging treatments

The strength of aluminum is closely related to the microstructure, which can also be indicated by the hardness [12,13]. HUANG et al [5] suggested that the coarse recrystallization reduces the hardness of the material; lower Vickers hardness values were observed for higher levels of recrystallization. We observed that the recrystallization fraction of the material was greatly reduced after the S3 treatment, resulting in high hardness and strength. Moreover, the S3 treatment promoted the generation of more uniform, finer, and more densely distributed Al3Zr dispersoids, which can improve the strength of the material due to the dispersion- strengthening effect [14] in the material. The electrical conductivity of a material can give a measure of the corrosion resistance, where higher electrical conductivity values indicate better corrosion resistance [15,16]. The electrical conductivity is affected by the solid solubility of solute atoms, the strain energy of coherent phases, and high-energy grain boundaries [17-19]. Regions with high distortion energy have a greater reflectivity of electrons; hence, materials with more large-grain boundaries have more reflected power of electrons resulting in reduced electrical conductivity of the Al-Zn-Mg alloys. The fine and abundant Al3Zr dispersoids near grain boundaries inhibit recrystallization; hence, the materials after three-step homogenization with low recrystallization fraction showed higher electrical conductivity. The slight decrease in the elongation of the material after S3 treatment was due to the equiaxed recrystallized grains showing better deformation than the fibrous grains.

3.3 SCC resistance

Table 4 gives the SSRT results of the materials in different conditions. It can be seen that the strength of the material soaked in the 3.5% NaCl solution was lower than that of the sample treated in air, indicating that the material suffered damage from stress corrosion. The tensile strength loss and SCC susceptibility of the material after three-step homogenization were less than those after one-step homogenization; in particular, the material after S3 treatment possessed the best stress corrosion resistance with almost no loss of strength after exposure to the corrosive environment. The second best homogenization treatment was S4, while S2 showed relatively poor stress corrosion resistance (but better performance than the sample treated with one-step homogenization).

Table 4 SSRT results of specimens after different homogenization treatments and exposure to corrosive environments (air or 3.5% NaCl solution)

The occurrence of stress corrosion cracking in the Al-Zn-Mg alloys is due to anodic dissolution and hydrogen-induced fracture [20-22]. High-energy recrystallization grain boundaries will deteriorate the corrosion resistance of the material. Considering the effect of Al3Zr dispersoids on recrystallization, hardness, electrical conductivity, mechanical properties and stress corrosion resistance, it is concluded that the finely dispersed Al3Zr dispersoids can improve both the mechanical properties and stress corrosion resistance of the material by effectively restraining the occurrence of recrystallization.

4 Discussion

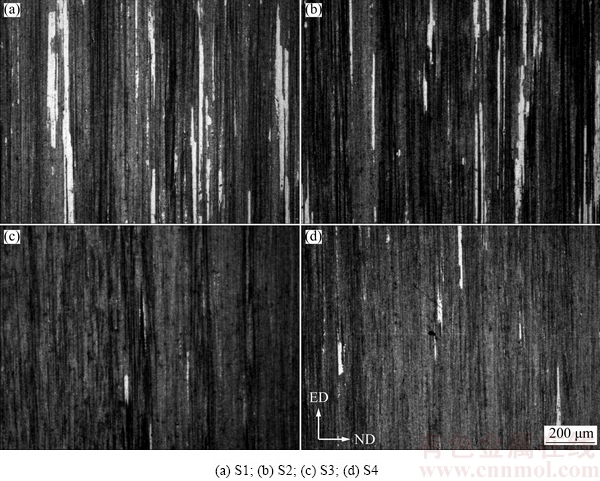

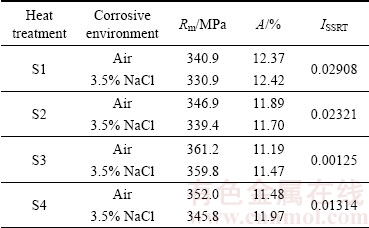

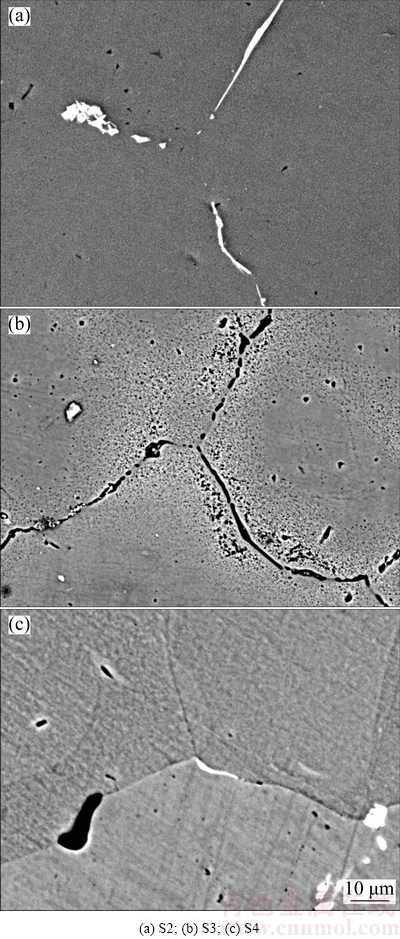

The nucleation energy of the equilibrium η phase, which is incoherent with the matrix with relatively high interfacial energy, can be reduced by the presence of the Al3Zr dispersoids [23-25]. Figure 6 shows SEM images of the phases at the grain boundaries of the specimens after the second homogenization step. There were a large number of long, thin precipitates near the grain boundaries after the second homogenization step of the S3 treatment; however, such precipitates were not observed in the S2 and S4 samples. Figure 7 shows TEM images of the microstructure near the grain boundaries after the second homogenization step, where very small spherical particles were observed when the temperature was 300 °C. The secondary phases near the grain boundary were transformed into coarse strip-like particles when the temperature of the second homogenization step was 350 °C. Most of the secondary phases near the grain boundary dissolved back into the matrix when the temperature of the second homogenization step was increased to 400 °C, leaving a few spherical particles and strip-like secondary phases. The coarse strip-like particles near the grain boundary were identified as equilibrium η phases by the SAED pattern of the material in the [112] projection. Thus, the state of the precipitates had a significant influence on the Al3Zr dispersoids. Consequently, Al3Zr dispersoids precipitated on equilibrium η phases during the second homogenization step; therefore, the density and uniformity of the Al3Zr particles increased greatly, both at the center and grain boundary regions. These results agree well with the elemental distribution of Zr from the EPMA line scanning results.

Fig. 6 SEM images of grain boundary regions of specimens after second homogenization step

Fig. 7 TEM images of grain boundary regions of specimens after second homogenization step

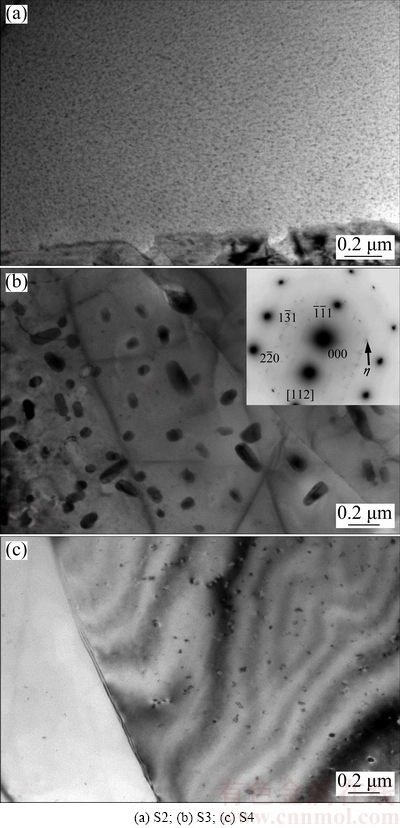

The nucleation mechanisms of the Al3Zr dispersoids under different three-step homogenization treatments are shown in Fig. 8. The first homogenization step at the low temperature of 200 °C provided an incubation period for the η phases that act as nucleation sites to ensure a sufficiently large number and size of induced phases in the following homogenization process. Dendrite segregation in the aluminum alloy cannot be eliminated as the elements spread slowly at low temperature. The temperature of the second homogenization step was relatively high; therefore, the number and size of η phases could be optimized, which provided hetero- geneous nucleation sites for the A13Zr dispersoids [3]. Reduction of the segregation of the material occurred at the same time with the spreading of some alloying elements. The large number of η phases after the second homogenization step had a significant influence on the formation of the Al3Zr dispersoids. Spherical particles which formed at 300 °C can provide less interfacial energy for nucleation of Al3Zr dispersoids. Compared with the tiny spherical phases, the strip-like equilibrium η phases provided greater interfacial energy for Al3Zr dispersoids, which provided favorable heterogeneous nucleation of the Al3Zr dispersoids. The size and number of coarse η phases decreased as they dissolved into the matrix; therefore, the interfacial energy provided by the η phases formed at 400 °C was at an intermediate level. The Al3Zr dispersoids precipitated in the region with high concentration of Zr and simultaneously nucleated on the equilibrium η phase near the grain boundary with a relatively low concentration of Zr during heating in the third homogenization step. Segregation and formation of detrimental secondary phases in the material were further eliminated by the high-temperature homogenization process; crystalline phases with a high melting point could not be completely eliminated, but gradually became smaller and intermittent. Therefore, three-step homogenization promoted the precipitation of Al3Zr dispersoids both at the central region of the grain and near the grain boundary, and also effectively reduced micro-segregation and detrimental secondary phases.

Fig. 8 Nucleation mechanisms of Al3Zr dispersoids under different three-step homogenization processes

5 Conclusions

Three-step homogenization effectively improved the uniform distribution of Zr both at the central region of the grain and near the grain boundary by eliminating compositional segregation of the main elements. As a result, the density and uniformity of the Al3Zr dispersoids were improved. The temperature of the second step of the three-step homogenization had a large impact on the number and size of η phases near the grain boundary. At 350 °C, a large amount of η phase was observed which provided favorable heterogeneous nucleation sites for Al3Zr dispersoids to effectively inhibit recrystallization. The three-step homogenization had a positive influence on the microstructure and properties of the 7N01 aluminum alloy. The recrystallization fraction of the material after the treatment at 200 °C, 2 h + 350 °C, 10 h + 470 °C, 12 h decreased from 31.5% to 1.9% compared with that after a single-step treatment at 470 °C for 24 h. Excellent mechanical properties and stress corrosion resistance of the material were observed.

References

[1] WANG Ming-liang, JIN Pei-peng, WANG Jin-hui, LI Han. Hot deformation behavior of as-quenched 7005 aluminum alloy [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(9): 2796-2804.

[2] RAMIREZ-LEDESMA A L,  R A, CHAVEZ- CARVAYAR J, ALVAREZ-FREGOSO O, JUAREZ-ISLAS J A. Effect of growth rate on microstructure and solute distribution of Al-Zn-Mg alloy [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(5): 1391-1398.

R A, CHAVEZ- CARVAYAR J, ALVAREZ-FREGOSO O, JUAREZ-ISLAS J A. Effect of growth rate on microstructure and solute distribution of Al-Zn-Mg alloy [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(5): 1391-1398.

[3] XIAO Tao, DENG Yun-lai, YE Ling-ying, LIN Hua-qiang, SHAN Chao-jun, QIAN Peng-wei. Effect of three-stage homogenization on mechanical properties and stress corrosion cracking of Al-Zn-Mg-Zr alloys [J]. Materials Science and Engineering A, 2016, 675: 280-288.

[4] HE Li-zi, JIA Pin-feng, ZHANG Lin, CUI Jian-zhong. Evolution of secondary phases and properties of 7B04 aluminum alloy during DC homogenization [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(2): 319-327.

[5] HUANG Xing, PAN Qing-lin, LI Bo, LIU Zhi-ming, HUANG Zhi-qi, YIN Zhi-min. Microstructure, mechanical properties and stress corrosion cracking of Al-Zn-Mg-Zr alloy sheet with trace amount of Sc [J]. Journal of Alloys and Compounds, 2015, 650: 805-820.

[6] LIU Jing, YAO Pei, ZHAO Nai-qin, SHI Chun-sheng, LI Hui-jun, LI Xuan, XI De-sheng, YANG Shuo. Effect of minor Sc and Zr on recrystallization behavior and mechanical properties of novel Al-Zn-Mg-Cu alloys [J]. Journal of Alloys and Compounds, 2016, 657: 717-725.

[7] WANG Tao, YIN Zhi-min, SUN Qiang. Effect of homogenization treatment on microstructure and hot workability of high strength 7B04 aluminium alloy [J]. Transactions of Nonferrous Metals Society of China, 2007, 17(2): 335-339.

[8] GUO Zhan-ying, ZHAO Gang, CHEN X G. Effects of two-step homogenization on precipitation behavior of Al3Zr dispersoids and recrystallization resistance in 7150 aluminum alloy [J]. Materials Characterization, 2015, 102: 122-130.

[9] LU Xin-yu, GUO Er-jun, ROMETSCH P, WANG Li-juan. Effect of one-step and two-step homogenization treatments on distribution of Al3Zr dispersoids in commercial AA7150 aluminium alloy [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(11): 2645-2651.

[10] SCHAFFER G B, HUO S H, DRENNAN J, AUCHTERLONIE G J. The effect of trace elements on the sintering of an Al-Zn-Mg-Cu alloy [J]. Acta Materialia, 2001, 49: 2671-2678.

[11] DOHERTY R D. Role of interfaces in kinetics of internal shape changes [J]. Metal Science, 1982, 16(1): 1-14.

[12] CURLE U A, CORNISH L A, GOVENDER G. Predicting yield strengths of Al-Zn-Mg-Cu-(Zr) aluminium alloys based on alloy composition or hardness [J]. Materials and Design, 2016, 99: 211-218.

[13]  M. On the relationship between vickers hardness and yield stress in Al-Zn-Mg-Cu alloys [J]. Materials Science and Engineering A, 2015, 633: 17-19.

M. On the relationship between vickers hardness and yield stress in Al-Zn-Mg-Cu alloys [J]. Materials Science and Engineering A, 2015, 633: 17-19.

[14] DENG Yun-lai, ZHANG Yun-ya, WAN Li, ZHU Alf-a, ZHANG Xin-ming. Three-stage homogenization of Al-Zn-Mg-Cu alloys containing trace Zr [J]. Metallurgical and Materials Transactions A, 2013,44(6): 2470-2477.

[15] SHE Huan, CHU Wei, SHU Da, WANG Jun, SUN Bao-de. Effects of silicon content on microstructure and stress corrosion cracking resistance of 7050 aluminum alloy [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 2307-2313.

[16] JIANG J T, XIAO W Q, YANG L, SHAO W Z, YUAN S J, ZHEN L. Ageing behavior and stress corrosion cracking resistance of a non-isothermally aged Al-Zn-Mg-Cu alloy [J]. Materials Science and Engineering A, 2014, 605: 167-175.

[17] SUN Yi-shan, JIANG Fu-lin, ZHANG Hui, JIAN Su, YUAN Wu-hua. Residual stress relief in Al-Zn-Mg-Cu alloy by a new multistage interrupted artificial aging treatment [J]. Materials and Design, 2016, 92: 281-287.

[18] ROUT P K, GHOSH M M, GHOSH K S. Microstructural, mechanical and electrochemical behaviour of a 7017 Al-Zn-Mg alloy of different tempers [J]. Materials Characterization, 2015, 104: 49-60.

[19] XU D K, BIRBILIS N, ROMETSH P A. The effect of pre-ageing temperature and retrogression heating rate on the strength and corrosion behaviour of AA7150 [J]. Corrosion Science, 2012, 54: 17-25.

[20] RAO A C U, VASU V, GOVINDARAJU M, SAI SRINADH K V. Stress corrosion cracking behaviour of 7xxx aluminum alloys: A literature review [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(6): 1447-1471.

[21] LI Hui-zhong, YAO San-cheng, LIANG Xiao-peng, CHEN Yong-hui, LIU Chao, HUANG Lan. Grain boundary pre- precipitation and its contribution to enhancement of corrosion resistance of Al-Zn-Mg alloy [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(10): 2523-2531.

[22] KANNAN M B, RAJA V S. Enhancing stress corrosion cracking resistance in Al-Zn-Mg-Cu-Zr alloy through inhibiting recrystallization [J]. Engineering Fracture Mechanics, 2010, 77(2): 249-256.

[23] FENG Chun, SHOU Wen-bin, LIU Hui-qun, YI Dan-qing, FENG Yao-rong. Microstructure and mechanical properties of high strength Al-Zn-Mg-Cu alloys used for oil drill pipes [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(11): 3515-3522.

[24] GUO Wei, GUO Ji-yan, WANG Jin-duo, YANG Meng, LI Hui, WEN Xi-yu, ZHANG Jin-wu. Evolution of precipitate microstructure during stress aging of an Al-Zn-Mg-Cu alloy [J]. Materials Science and Engineering A, 2015, 634: 167-175.

[25] YANG Rong-xian, LIU Zhi-yi, YING Pu-you, LI Jun-lin, LIN Liang-hua, ZENG Su-min. Multistage-aging process effect on formation of GP zones and mechanical properties in Al-Zn-Mg-Cu alloy [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(5): 1183-1190.

林化强1,2,叶凌英2,孙 琳1,肖 涛3,刘胜胆2,邓运来2,3,张新明2,3

1. 中车青岛四方机车车辆股份有限公司 国家高速动车组总成工程技术研究中心,青岛 266000;

2. 中南大学 材料科学与工程学院,长沙 410083;

3. 中南大学 轻合金研究院,长沙 410083

摘 要:采用硬度、电导率、拉伸、慢速率拉伸、电子探针显微镜(EPMA)、金相显微镜(OM)、扫描电镜(SEM)和透射电镜(TEM)研究不同均匀化制度对7N01铝合金显微组织和性能的影响。研究结果表明,三级均匀化制度在有效消除主合金元素成分偏析的前提下,较大程度提高Zr元素在晶内和晶界分布的均匀性;此外,在350 °C保温10 h进行第二级均匀化处理后形成的粗大长条状平衡η相具有较大的界面能和尺寸,这有利于Al3Zr粒子的异质形核,减小晶界附近Al3Zr粒子无沉淀析出带的宽度。经过200 °C, 2 h + 350 °C, 10 h + 470 °C, 12 h均匀化处理能较大程度抑制粗大再结晶的发生,这有利于获得更高综合性能的7N01铝合金。

关键词:7N01铝合金;三级均匀化;显微组织;力学性能;应力腐蚀开裂

(Edited by Bing YANG)

Foundation item: Projects (2016YFB0300901, 2016YFB0300902) supported by the National Key Research and Development Program of China; Project (51375503) supported by the National Natural Science Foundation of China; Project (2013A017) supported by Guangxi Zhuangzu Autonomous Region of China

Corresponding author: Ling-ying YE; Tel: +86-13607435545; E-mail: 30575421@qq.com

DOI: 10.1016/S1003-6326(18)64716-8