文章编号:1004-0609(2009)05-0861-08

7050铝合金的TTP曲线

张新明,刘文军,刘胜胆,袁玉宝,邓运来

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:通过分级淬火方法获得7050铝合金的时间—温度—性能(TTP)曲线。结果表明:合金TTP曲线的鼻尖温度为330 ℃,淬火敏感温度区间为240~420 ℃;等温保温时,过饱和固溶体分解析出第二相粒子,在330 ℃附近,第二相(主要为η平衡相)的析出速率达到最高;随着时间的延长,晶内η相数量增加、尺寸变大,时效后粒子周围出现无沉淀析出区,导致强化效果显著降低;晶界处η相粒子粗化,由不连续分布形貌转变为连续分布形貌,无沉淀析出带宽化;鼻尖温度的高相变驱动力和较快的扩散速率是η相析出和长大的主要原因,建议在淬火敏感区间应加快淬火冷却速率避免平衡相的析出,而高于淬火敏感区间温度时可适当降低冷却速率减小热应力的影响。

关键词:7050铝合金;TTP曲线;淬火敏感性

中图分类号:TG 146 文献标识码:A

TTP curve of aluminum alloy 7050

ZHANG Xin-ming, LIU Wen-jun, LIU Sheng-dan, YUAN Yu-bao, DENG Yun-lai

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The time—temperature—property (TTP) curve of aluminum alloy 7050 was determined by an interrupted quench method. The results show that the quench sensitive temperature range of TTP curve of alloy is 240-420℃ with the nose temperature of 330 ℃. Microstructure observation indicates that the supersaturated solid solution decomposites and particles precipitate during quench process, the precipitation rate is the highest at about 330 ℃. A number of coarse equilibrium η particles precipitate at grain boundaries and in the grains during isothermal-holding at 330 ℃. Prolonging holding time leads to more and coarser η particles in the matrix, which results in loss of solutes and decrease of subsequent aging hardening effect, and more spaced η particles at the grain boundary that widen precipitation free zone. In the quench sensitive sector, primary precipitating reasons of η particles are severe phase transformation driving force and high diffusion rate of solute atoms. According the results, speeding up the cooling rate in the quench sensitive sector to reduce the precipitation of equilibrium phase is meaningful, and at higher temperature, decreasing the cooling rate is helpful to relieve the effect of thermal load.

Key words: 7050 aluminum alloy; TTP curve; quench sensitivity

7050铝合金厚板被广泛用作航天航空领域大型结构件[1-4],怎样使该合金沿厚度方向获得较均匀的高强度、良好的韧性和耐腐蚀性能,一直是材料科学工作者研究的重要课题。对于合金化程度高的7×××系铝合金,在相变温度区间具有较高的驱动力,尤其对厚截面板材淬火时,中心冷却速率通常较慢,相变范围内粗大的平衡相有足够的时间在含Cr或Zr元素粒子上析出并长大至一定尺寸,降低了合金的时效强化效果,导致该系合金多表现出一定的淬火敏感性,关于这方面的研究已有报道[5-7]。而对于7050铝合金的淬火敏感性能,国外虽早在20世纪70年代就有研究,ROBINSON等[8]研究了7050铝合金T7651TTP曲线的相关参数,但因时间较久,并没有详细的文献资料可查,尤其是该合金相应热处理状态的鼻尖温度、敏感区间等并无可靠资料报道。

7×××系合金的实际生产中,国内外常采用固溶后快速淬火的方法,抑制对性能有害的粗大第二相的形成,再经过后续时效热处理来赋予合金优异的综合性能[5, 9-10],但由于该系大多数合金厚板快速淬火时表层和中心冷却速度不均匀,将导致热应力增大,这些残留的内应力将极大地影响到材料的最终性能。因此,本文作者通过测定7050铝合金的TTP曲线,研究其淬火敏感性,为控制和改善合金的淬火制度提供依据,同时为后续改善该系合金淬火敏感性能的研究提供实验数据。而且借助TTP曲线,可对该合金的力学性能和腐蚀性能进行预测[8, 11],具有实际意义和理论价值。

1 实验

将7050铝合金热轧板切割成尺寸3 mm×15 mm×15 mm大小的试样。试样于473 ℃固溶60 min后,立刻淬入温度210~450 ℃(共取9个点,相邻温度间隔30 ℃)的盐浴炉并进行等温保温,转移时间小于2 s,盐浴炉温波动为±3 ℃,保温时间从2 s至1 h。试样经过等温保温后立刻取出并淬入室温水中,分为两组分别进行121 ℃,24 h单级和(121 ℃,4 h)+ (166 ℃,12 h)双级时效。

采用Model HV-10B型硬度计测定时效后试样的硬度值。金相试样经机械抛光、侵蚀剂(1%HF+ 16%HNO3+83%H2O+3 g CrO3)腐蚀后,在XJP-6A型光学显微镜下进行。

透射样品采用双喷减薄,电解液为20%HNO3+ 80%CH3OH,温度控制在-20 ℃以下,样品的组织观察在TecnaiG2 20型透射电镜上进行,加速电压为 200 kV。

DSC测试则在德国NETZSCH DSC200F差式量热扫描仪上完成,试样切取成直径为6 mm、质量约 3 g的圆片,测试时先以快速升温至472 ℃并保温 60 min,接着以10 K/s左右速率降温直至室温,数据的采集密度约为每分钟2次。

2 实验结果

2.1 等温保温对样品时效后硬度的影响

首先就没有经过中间保温样品的硬度值进行测定:(473 ℃,1 h)+室温淬火+(121 ℃,24 h)热处理后样品的维氏硬度为HV 197,经(473 ℃,1 h)+室温淬火+(121 ℃,4 h)+(166 ℃,12 h)热处理后样品的维氏硬度为HV 192。

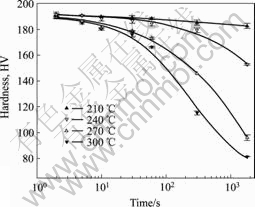

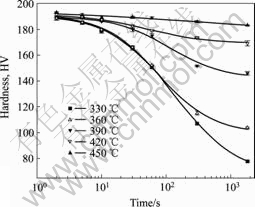

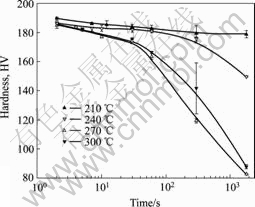

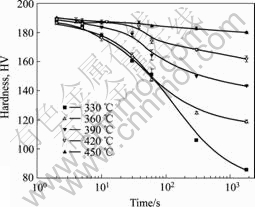

图1~4所示为等温保温温度、时间对合金时效后硬度的影响。结果显示,无论是单级亦或是双级时效,试样的硬度值随等温保温时间的延长总体呈下降趋势,区别是两种时效制度下降的幅度略有差异。

对于单级时效后的样品,在210 ℃至300 ℃范围,随着等温保温时间的延长,时效后7050铝合金硬度值下降的速率随温度的升高快速增加;300 ℃等温保温5 min时,材料的硬度下降了近39%;而在210 ℃等温保温30 min时,其硬度值下降只有5%左右。当淬火温度由330 ℃提高至450 ℃时,随着保温时间的延长,硬度值下降的速率又随着温度的升高有减小趋势,如图2所示。330 ℃等温保温时,样品的硬度值将随着保温时间的延长而急剧降低,保温1 min时,其硬度下降了约19%,延长保温时间至5 min后,其硬度值接近HV 100,下降了约44%。

图1 210~300 ℃保温时间对单级时效合金硬度的影响

Fig.1 Influence of holding time at 210-300 ℃ on hardness of one-step aged alloy

图2 330~450 ℃保温时间对单级时效合金硬度的影响

Fig.2 Influence of holding time at 330-450 ℃ on hardness of one-step aged alloy

图3 210~300 ℃保温时间对双级时效合金硬度的影响

Fig.3 Influence of holding time at 210-300 ℃ on hardness of two-stage aged alloy

而双级时效后的样品硬度值下降趋势与单级时效相似,稍有不同的是在保温时间小于30 s时,下降较缓慢,超过30 s后,硬度值快速下降,这在高温和低温阶段尤为明显。

据以上结果可知,在240~420 ℃等温保温时,合金硬度的下降速率对保温时间比较敏感,下降很快。但不在此温度区间淬火,保温时间超过30 min后,硬度下降的幅度仍小于10%。

图4 330~450 ℃保温时间对双级时效合金硬度的影响

Fig.4 Influence of holding time at 330-450 ℃ on hardness of two-stage aged alloy

2.2 TEM观察

经过对7050铝合金等温保温时间与合金时效后硬度关系曲线分析,分别选取330 ℃等温保温2 s、5 s、10 s、30 s、1 min和5 min的样品制备试样进行TEM观察,对合金于该温度下等温保温不同时间后两种时效态的组织演变进行深入分析。

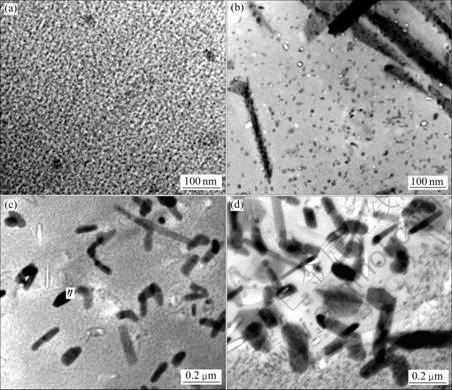

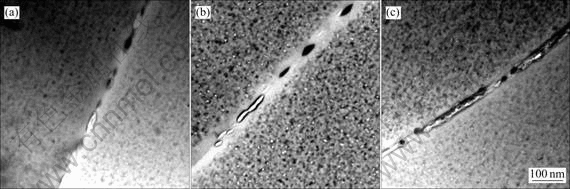

图5所示为在330 ℃等温保温2 s、10 s、1 min和5 min单级时效试样晶内析出的TEM像。经过2 s等温保温的试样基体分布着细小弥散的沉淀强化相η′,没有观察到大粒子的存在;延长保温时间至10 s,观察到尺寸较小的第二相粒子,文献显示该相为平衡相η(即MgZn2)[12-13],这些粒子将随着保温时间的延长进一步长大并相互吞并,如图5(c)中所示,保温1 min后尺寸已长大至0.2 μm左右,伴随着时效沉淀强化相无析出区出现;保温时间延长至5 min时,晶内观察到了大量第二相粒子(尺寸在0.5 μm左右,因位向关系形貌有所区别),析出密集区域基本找不到弥散的时效沉淀强化相存在。

图5 330 ℃等温保温不同时间单级时效合金的晶内析出形貌

Fig.5 Morphologies of precipitates in matrix of one-step aged alloy after holding different times at 330 ℃: (a) 2 s; (b) 10 s; (c) 1 min; (d) 5 min

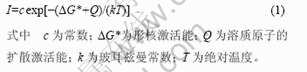

另对晶界处的TEM像(见图6)分析发现,经过2 s等温保温的试样晶界分布着尺寸较小的第二相,且粒子间保持一定距离;随保温时间增加,这些粒子开始聚集长大,相互交错趋于连续;直至保温5 min,η粒子进一步富集长大(见图6(d),其尺寸接近0.5 μm)连续至整个晶界,并伴随PFZ的宽化。这种平衡第二相粒子在晶界大量连续富集的形貌将严重降低合金的抗应力腐蚀性能[14]。

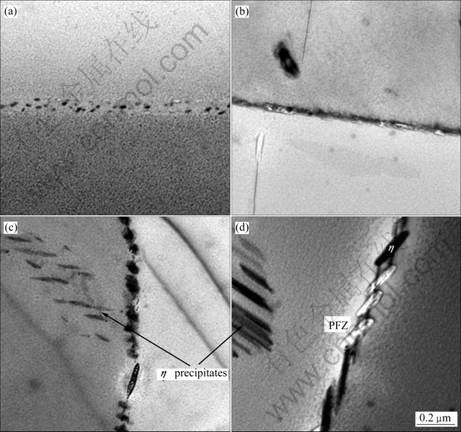

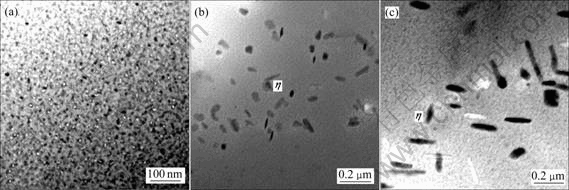

图7~8所示为330 ℃等温保温2、5、10和30 s淬火后双级时效试样的TEM像。与单级时效的组织比较,等温保温2 s后晶内除细小弥散的η′相外(见 图7),还存在大量粒径10 nm左右的粒子,相关文献报导为第二级时效过程中形成的平衡相η[5]。同样随保温时间延长,观察到了的较大η(即MgZn2)粒子,保温30 s后,这些粒子长大到了0.2 μm左右。此外,相比于单级时效制度,等温保温10 s后,晶界处(见图8)析出仍为不连续分布,这是因为高温时效将促使第二相粒子聚集并趋于球化,并促使PFZ的宽化;继续延长等温保温时间至30 s,第二相粒子在晶界处转变为连续分布(见图8(c)),即引入二级时效已经不能改善晶界的析出形貌。

3 分析及讨论

3.1 淬火后等温保温过程中的形核长大

在中间等温保温过程中的平衡相析出,是一个热激活过程。根据经典形核理论公式[15],形核速率I可表示为

一般来说,η平衡相的形核激活能不很高,查文献可知铝自扩散的激活能为142. 8kJ/mol[16],Mg在铝中的扩散激活能135.1 kJ/mol,Zn在铝中的扩散激活能106.1 kJ/mol,因此,判断溶质原子尤其是Zn原子在体系中扩散较为容易。依据式⑴可推断当温度降低至一定范围时,足够的过冷度将致使合金中大量形核。同时温度所影响的扩散过程将对平衡相的进一步长大有重要意义,所以温度对平衡相析出的影响极其重要。

图6 经330 ℃等温保温不同时间单级时效合金的晶界析出相形貌

Fig.6 Morphologies of precipitates at grain boundaries of one-step alloy after holding different times at 330 ℃: (a) 2 s; (b) 10 s; (c) 1 min; (d) 5 min

图7 经330 ℃等温保温不同时间双级时效合金的晶内析出相形貌

Fig.7 Morphologies of precipitates in matrix of two-stage aged alloy after holding different times at 330 ℃ (η is precipitation phase during holding treatment): (a) 2 s; (b) 10 s; (c) 30 s

图8 经330 ℃等温保温不同时间双级时效合金的晶界析出相形貌

Fig.8 Morphologies of precipitates at grain boundaries of two-stage aged alloy after holding different times at 330 ℃: (a) 2 s; (b) 10 s; (c) 30 s

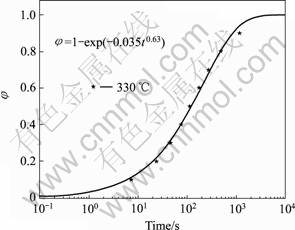

图9所示为由所测的330 ℃等温保温时间与单级时效后硬度关系曲线所绘制的该温度下相变体积分数与时间关系图,图中实心五角星点为由硬度曲线计算得到的值,这里采用了基于唯象理论建立的Johnson- Mehl-Avrami相变动力学方程方程 进行拟合[17],其中

进行拟合[17],其中 为相转变体积分数;t表示反应时间;k为与时间、形核等无关的常数,和n值共同表征不同的相变反应过程。通过拟合k和n值所得的曲线如图所示,得到n=0.63,介于0.5与1之间。依据动力学定律,对于长程扩散控制的相变过程,该值表示合金中相变以棒状、层片状沉淀相的增大、增厚并相互吞并为主[17],且这些沉淀相间的间距较小,这与透射电镜照片中观察到的组织形貌相符。

为相转变体积分数;t表示反应时间;k为与时间、形核等无关的常数,和n值共同表征不同的相变反应过程。通过拟合k和n值所得的曲线如图所示,得到n=0.63,介于0.5与1之间。依据动力学定律,对于长程扩散控制的相变过程,该值表示合金中相变以棒状、层片状沉淀相的增大、增厚并相互吞并为主[17],且这些沉淀相间的间距较小,这与透射电镜照片中观察到的组织形貌相符。

因此,7050铝合金在实际固溶淬火过程中,由于合金的过饱和度较高,在相转变温度范围极易发生脱溶沉淀析出第二相。而在不同温度范围内的相变过程有所差异,低温时形核率高但溶质原子扩散慢,高温时溶质原子扩散快但形核率低,因此在高温和低温范围,第二相的生长速率依然较小,合金的性能下降缓 慢[17];而当温度降低至中间温度范围时(300~390 ℃),此时合金处于敏感区间,具有一定的过冷度能和较大相变驱动力,形核更为容易,合金中将在大范围内高密度形核,同时此温度区间溶质原子仍具有一定的扩散速率,使得由扩散控制的第二相生长较快。最终平衡相将长大至0.5 μm,甚至更大,这些大粒子无强化效果,还将导致合金中相应区域主要溶质元素(Zn和Mg等)浓度的明显降低,这些时效强化相组成元素的大量脱溶,将导致合金的性能降低,这与实验硬度测定结果及组织观察结果相符合。

图9 330 ℃等温保温η相体积分数与等温保温时间的关系

Fig.9 Relationship between holding time and volume fraction of η phase

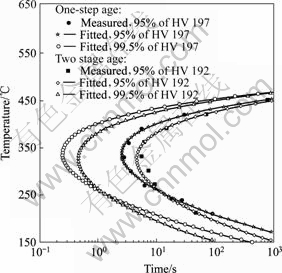

3.2 TTP曲线的绘制

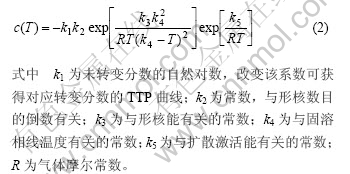

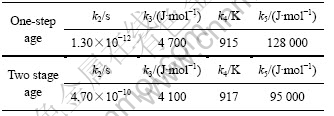

实际淬火过程中,并不是淬火越快,淬火速率越好,还需考虑淬火过快所引起的热应力问题。因此获得合金的TTP曲线对制定淬火工艺就显得尤为重要了。由合金经两种不同时效制度后维氏硬度值与等温保温时间关系曲线,取峰值硬度的95%所对应保温温度和时间则采用方程(2)来进行拟合得到TTP曲线[8],具体方法见文献[6, 8]。根据拟合后的曲线,确定其系数如表1所列。

比较两种不同时效制度的TTP和相关常数,对不同时效制度对合金淬火敏感的影响进行分析。结合前面的硬度曲线,可发现淬火后时效工艺对于合金TTP曲线的鼻尖温度以及敏感温度区间影响不大,但拟合得到的k2、k3和k5相比于单级时效有一定差别,这是因为过时效阶段也会析出相当比例的η相,虽然这些η粒子尺寸较小(大多在10 nm左右),但一定程度上亦降低了合金性能[5],这就使得双级时效的试样固溶后等温保温过程平衡相析出的影响相对减弱。另过时效阶段η相的形核长大与等温保温的析出方式有很大差异(过饱和度低、形核率高、扩散缓慢、时间长等),因而与形核长大及扩散相关的常数亦会不同。总的说来,虽然双级时效有助于改善合金的淬火性能,但同时应注意此时晶界的析出形貌,TEM组织显示等温保温10 s的试样晶界处析出相已经呈连续分布(见图8),因此可以预见即使采用双级时效甚至RRA处理,因合金淬火敏感性的影响,当淬火速率较慢时合金的腐蚀性能不会得到有效改善,具体需进一步的实验验证分析。

图10 7050铝合金TTP曲线

Fig.10 TTP curves of aluminum alloy 7050

表1 拟合得到的7050铝合金TTP曲线系数

Table 1 Coefficients of TTP curve for aluminum alloy 7050 by fitting

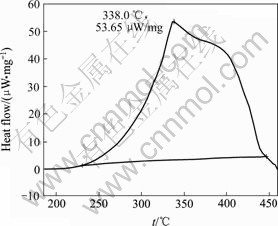

图11所示为实验用合金热轧板的DSC曲线。试样经过472 ℃保温1 h后,再以10 K/min的速率降温至室温。由图11可知,合金在整个降温过程中持续析出η相,且当温度降至337 ℃时,放热达到峰值。由此判断在338 ℃时第二相析出最快,结合拟合的99.5%曲线(见图10),确定7050铝合金TTP曲线的鼻尖温度约为330 ℃;同时根据TTP曲线可以判断,转变时间为10 s时,合金的淬火敏感区间为240~ 420 ℃。确定了7050铝合金TTP的鼻尖温度和淬火敏感区间后,即可据此设计合金的淬火制度:为保证合金性能,建议合金固溶后淬火应在敏感区间内(240~420 ℃)加快冷却速率快速通过,而当温度大于420 ℃时(该温度区域对淬火速率不敏感),可适当降低淬火速率以减小热应力,在不显著降低材料性能的同时,减小因冷却不均匀造成的残余应力,实验过程中可通过调整冷却环境(冷却介质,喷淋的流量及压强)来控制。

图11 7050铝合金的DSC曲线

Fig.11 DSC curves of 7050 plate at cooling rate of 10 K/min after solution treatment

4 结论

1) 7050作为高合金化铝合金,固溶后淬火速率较慢时极易发生脱溶沉淀,尤其在获得一定过冷度时将出现大范围的形核,若此时在相变温度范围持续停留一定时间,溶质原子的进一步扩散将促使这些第二相快速长大,合金表现出一定的淬火敏感性。

2) 为研究7050铝合金的淬火敏感性,合理制定淬火制度,采用了分级淬火的方法测得该合金TTP曲线的鼻尖温度在330 ℃左右,淬火敏感区间为240~420 ℃,在此区间以外合金的性能对淬火较不敏感。

3) 合金等温保温过程中主要析出相为η平衡相,于330 ℃附近时析出速率最快,且随着保温时间的延长,这些析出相快速形核长大,晶内出现大量密集析出相,在晶界上趋向于连续分布。

4) 时效制度对TTP的鼻尖温度和敏感区间影响不大,过时效在一定程度上减小等温保温过程对力学性能的影响。

5) 合金固溶后,淬火可在(>420 ℃)以上采用较小冷却速率,而在淬火敏感区间加快冷却速率,不仅获得较高的力学性能,还可减小残余应力。

REFERENCES

[1] 王祝堂, 田荣璋. 铝合金及其加工手册[M]. 长沙: 中南工业大学出版社, 1989.

WANG Zhu-tang, TIAN Rong-zhang. Aluminum alloy and processing handbook[M]. Changsha: Central South University of Technology Press, 1989

[2] 钟 利. 铝合金厚板市场与生产技术发展[J]. 稀有金属, 2006, 30(S1): 186-191.

ZHONG Li. Developments of markets and production technology for aluminum alloys plates[J]. Chinese Journal of Rare Metals, 2006, 30(S1): 186-191.

[3] 李成功, 巫世杰, 戴圣龙. 先进铝合金在航空航天工业中的应用与发展[J]. 中国有色金属学报, 2002, 12(3): 14-21.

LI Cheng-gong, WU Shi-jie, DAI Sheng-long. Application and development of advanced aluminum alloy in aerospace industry[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(3): 14-21.

[4] 肖亚庆. 铝加工技术实用手册[M]. 北京: 冶金工业出版社, 2005.

XIAO Ya-qing. Aluminum process technology practical guide[M]. Beijing: Metallurgical Industry Press, 2005.

[5] DUMONT D, DESCHAMPS A, BRECHET C. Characterization of precipitation microstructures in aluminium alloys 7040 and 7050 and their relationship to mechanical behavior[J]. Materials Science and Technology, 2004, 20(5): 567-576.

[6] 刘胜胆, 张新明, 黄振宝. 7055铝合金的淬火敏感性研究[J]. 中南大学学报: 自然科学版, 2006, 37(5): 846-849.

LIU Sheng-dan, ZHANG Xin-ming, HUANG Zhen-bao. Quench sensitivity of 7055 aluminum alloy[J]. Journal of Central South University: Science and Technology, 2006, 37(5): 846-849.

[7] DESCHAMPS A, BRECHET Y. Nature and distribution of quench-induced precipitation in an Al-Zn-Mg-Cu alloy[J]. Scripta Materialia, 1998, 39(11): 1517-1522.

[8] ROBINSON J S, CUDD R L, TANNER D A. Quench sensitivity and tensile property inhomogeneity in 7010 forgings[J]. Journal of Materials Processing Technology, 2001, 119: 261-267.

[9] IQBAL M, SHAIKH M A, AHMAD M. Ageing effect on hardness and microstructure of Al-Zn-Mg alloys[J]. Journal of Materials Science and Technology, 2000, 16(3): 319-322.

[10] WILLIAMS J C, STARKE E A Jr. Progress in structural materials for aerospace systems[J]. Acta Materialia, 2003, 51(19): 5775-5799.

[11] STALEY J T. Quench factor analysis of aluminium alloys[J]. Materials Science and Technology, 1987, 3(11): 923-935.

[12] CONSERVA M, DI RUSSO E, CALONI O. Comparison of the influence of chromium and zirconium on the quench sensitivity of Al-Zn-Mg-Cu alloys[J]. Metallurgical and Materials Transactions B, 1971, 2(4): 1227-1232.

[13] DUMONT M, LEFEBVRE W, DOISNEAU-COTTIGNIES B. Characterisation of the composition and volume fraction of η′ and η precipitates in an Al-Zn-Mg alloy by a combination of atom probe, small-angle X-ray scattering and transmission electron microscopy[J]. Acta Materialia, 2005, 53(10): 2881-2892.

[14] PUIGGALI M, ZIELINSKI A, OLIVE J M. Effect of microstructure on stress corrosion cracking of an Al-Zn-Mg-Cu alloy[J]. Corrosion Science, 1998, 40: 805-819.

[15] BURKE J. The kinetics of phase transformation in metal[M]. London: Pergamon Press, 1965.

[16] NAGAHAMA K, MIKI I. Precipitation during recrystallization in Al-Mn and Al-Cr alloys[J]. Trans Jap Inst Met, 1974, 15(3): 185-192.

[17] 肖纪美. 合金相与相变[M]. 北京: 冶金工艺出版社, 2004: 310-312.

XIAO Ji-mei. The alloy phrase and phrase transformation[M]. Beijing: Metallurgical Technology Press, 2004: 310-312.

基金项目:国家重点基础研究发展计划资助项目(2005CB623700)

收稿日期:2008-06-18;修订日期:2009-01-15

通讯作者:张新明,教授,博士;电话/传真:0731-8830265;E-mail: xmzhang@mail.csu.edu.cn

(编辑 龙怀中)