文章编号:1004-0609(2015)06-1546-07

超高强Cu-6.5Ni-1Al-1Si-0.15Mg-0.15Ce合金的淬火敏感性

黎三华1,申镭诺1,李 周1, 2,董琦祎1,肖 柱1, 3,邢 岩1

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 有色金属材料科学与工程湖南省重点实验室,长沙 410083;

3. 中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:通过等温淬火方法获得Cu-6.5Ni-1Al-1Si-0.15Mg-0.15Ce合金的TTP曲线。采用硬度、电导率测试和透射电镜(TEM)观察等方法研究了等温温度和等温时间对合金性能和显微组织的影响。结果表明:合金TTP曲线的鼻尖温度约为675 ℃,淬火敏感区域为625~725 ℃;合金在650 ℃附近进行等温处理,δ-Ni2Si和共格的Ni3Al析出相的形核率和长大速率均很高;随着等温时间的延长,晶内析出的δ-Ni2Si和Ni3Al急剧粗化,同时,晶界处发生δ-Ni2Si的不连续析出,并形成无衬度析出带,导致合金经等温时效处理后硬度急剧下降,并且在鼻尖区具有很高的淬火敏感性。

关键词:CuNiAlSi合金;等温处理;淬火敏感性;显微组织

中图分类号:TG146.1 文献标志码:A

Quench sensitivity of Cu-6.5Ni-1Al-1Si -0.15Mg-0.15Ce alloy with super high strength

LI San-hua1, SHEN Lei-nuo1, LI Zhou1, 2, DONG Qi-yi1, XIAO Zhu1, 3, XING Yan1

(1. School of Material Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Metal Materials Science and Engineering of Hunan Province,

Central South University, Changsha 410083, China;

3. Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The TTP curves of Cu-6.5Ni-1Al-1Si-0.15Mg-0.15Ce alloy were established by isothermal treatment. Micro-hardness test, electrical conductivity test and transmission electron microscope observation were applied to study the influence of isothermal temperature and time on the properties and microstructure of the alloy. The results show that the nose temperature is about 675 ℃, and the quench sensitivity region is from 625 ℃ to 725 ℃. When the alloy is isothermally treated around 650 ℃, the nucleation rate and growth rate of δ-Ni2Si and Ni3Al are high; δ-Ni2Si and Ni3Al particles precipitate in the matrix coarsened rapidly, the discontinuous δ-Ni2Si particles precipitate at the grain boundary and precipitation free zone forms along the grain boundary with prolonging isothermal time. As a result, the micro-hardness decreases rapidly after isothermal treated at 650 ℃, and the alloy shows high quench sensitivity as it is treated at the temperature.

Key words: CuNiAlSi alloy; isothermal treatment; quench sensitivity; microstructure

高强铜合金由于具有较高强度、良好的导电性能和优异的弹性性能而广泛应用于制作弹簧、 膜片膜盒、谐振元件、波纹管等弹性元件[1-5]。目前为止,铍青铜是应用最广泛、综合性能最优异的弹性铜基合金之一。但是,铍青铜含有剧毒元素铍,且在高于150℃工作时,抗应力松弛性能很差,已经不能满足现代电子工业的需求[6-8]。近年来,已有大量关于Cu-Ni-Sn、Cu-Ni-Si和Cu-Ni-Al等替代合金的研究报道[9-12]。Cu-Ni-Sn合金的强度最高可达1300 MPa,但电导率小于15%(IACS)[13]。ZHAO等[14]的研究表明,Cu-3.2Ni- 0.75Si合金经固溶处理后并在450 ℃时效4 h后,抗拉强度约为750 MPa,屈服强度约为580 MPa。Cu-6.0Ni-0.5Al-1.0Si-0.15Mg-0.1Cr合金经50%冷轧变形,并在450 ℃时效1 h后,抗拉强度可达1090 MPa,屈服强度可达940 MPa[15]。铜合金的高强度和优良的导电性能难以兼得,是超高强弹性铜合金在电气工业中应用的一大瓶颈[16-19]。Cu-Ni-Al作为一种典型的沉淀强化型铜合金,在一定的温度固溶时效时,大量第二相粒子会从基体析出,获得时效强化效果的同时能够大幅度提高合金的电导率。本课题组成员通过优化合金元素配比和形变热处理工艺,获得的Cu-10Ni-3Al-0.8Si合金抗拉强度可达1180 MPa,屈服强度可达1133 MPa,电导率为18.1%(IACS),能够替代铍青铜应用于电子电器工业[20]。热处理工艺及淬火速率对析出相的体积分数、尺寸及种类有很大影响,使合金表现出淬火敏感性,并影响合金的最终性能[21-22]。为了避免合金在热处理过程中析出粗大的第二相粒子,保证合金的加工和切削性能以及优良的综合性能,亟需研究Cu-Ni-Al-Si系合金的淬火敏感性以寻求合理的热处理及淬火工艺。本文作者以Cu-6.5Ni-1Al-1Si-0.15Mg-0.15Ce合金[23]为例研究了其淬火敏感性。

1 实验

Cu-6.5Ni-1Al-1Si-0.15Mg-0.15Ce合金在中频感应炉中熔炼、铸锭。合金线切割成15 mm×15 mm×1.5 mm的方块。样品经960 ℃固溶处理4 h后,直接转移到不同温度的箱式电阻炉中的盐浴箱进行等温处理。等温处理的温度分别为550、600、650、700和750 ℃,等温处理时间分别为10 s、30 s、1 min、5 min、10 min,等温处理完成后水淬。将等温处理后的样品在盐浴炉中进行时效处理,时效温度为500 ℃,时效时间为1 h。等温和时效处理过程中,400~550 ℃时使用KNO3和NaNO3质量比为1:1的混合盐作为盐浴介质,600~750 ℃时使用BaCl、KCl和NaCl质量比为5:3:2的混合盐作为盐浴介质。

采用HV-5型维氏硬度计测定样品的显微硬度,载荷为25 N,加载时间为10 s。采用D60K型金属电导率测试仪进行测定样品的电导率。透射电镜样品经过机械减薄至0.08 mm后,采用离子减薄仪双面减薄样品至穿孔,离子减薄的束电流为1.5 mA,氩离子能量为3 keV。透射电镜观察在JEM-2100F型透射电镜上进行,操作电压为200 kV。合金经等温和时效处理后,采用硬度峰值92.5%、88.9%、85.2%、81.4%、77.8%和74.1%所对应的等温温度和等温时间绘制合金的时间-温度-性能曲线。

2 结果与讨论

2.1 等温处理对合金性能的影响

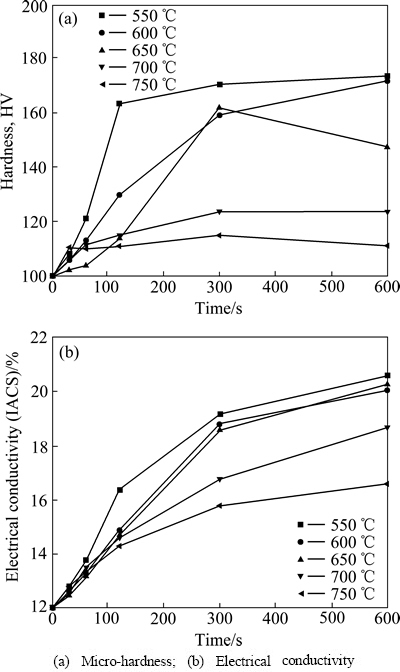

图1所示为等温温度和时间对Cu-6.5Ni-1Al-1Si- 0.15Mg-0.15Ce合金时效前硬度和电导率的影响。合金分别经过550、600、650、700和750 ℃等温处理0~600 s后的硬度曲线如图1(a)所示。由图1(a)可知,随着等温时间的延长,合金的硬度逐渐升高,并且等温温度越高,硬度值上升越缓慢。合金经650 ℃等温处理5 min后,硬度达到峰值161.9 HV,等温时间继续延长,合金的硬度迅速下降;合金高于或低于650 ℃等温处理5 min后,硬度值随等温时间的延长缓慢上升;等温处理时间相同时,等温温度越高,合金最终的硬度值越低,合金经550 ℃等温处理10 min后,硬度约为175.2 HV,而合金经750 ℃等温处理10 min后合金的硬度仅为112.7 HV。合金分别经过550、600、650、700和750 ℃等温处理0~600 s后的电导率曲线如图1(b)所示。随着等温时间延长和等温温度降低,合金的电导率升高。等温处理初期,合金的电导率上升很快,等温时间延长至5 min后,合金的电导率增加变得缓慢。以上现象表明,合金在等温处理过程中,等温温度越高,析出第二相的体积分数越小,等温处理淬火后,合金基体过饱和度越高。

图1 等温处理对合金时效前硬度和电导率的影响

Fig. 1 Influences of isothermal treatment on hardness and conductivity of alloy

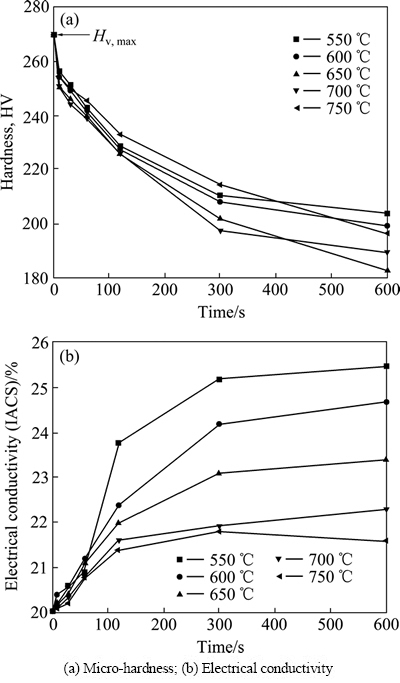

图2所示为合金经550、600、650、700和750 ℃等温处理0~600 s,并在500 ℃时效1 h后的硬度和电导率曲线。由图2(a)可知,随着等温时间的延长,合金的硬度急剧下降。合金经650 ℃等温处理后,合金时效后的硬度值下降最快。合金在650 ℃等温处理10 min后,淬火,并在500 ℃时效1 h后,合金的硬度下降至182.6 HV;等温处理温度高于700 ℃或低于650 ℃时,合金的硬度下降较为缓慢。由图2(b)可知,经过不同温度等温处理再于500 ℃时效1 h后,合金的电导率均随着等温时间的延长而升高,等温温度越高,合金电导率上升得越慢,最终获得的电导率越低。与等温处理后未经时效的合金相比,经等温和时效处理后合金的硬度值和电导率均明显升高,且等温温度越高,合金时效后硬度和电导率的增量越大。如经600 ℃等温处理10 min并时效后,合金的硬度由171.8 HV增长至199.1 HV,增量为27.3 HV;而经700 ℃等温处理10 min并时效后,合金的硬度由123.8 HV增长至189.1 HV,增量达65.3 HV。这表明等温淬火后保留的过饱和固溶体在后续的时效过程中发生了脱溶,且等温温度越高,过饱和度越大,脱溶析出的第二相体积分数越大,硬度升高越快。

图2 等温处理时间对合金时效后硬度和电导率的影响

Fig. 2 Influences of isothermal treatment time on hardness and conductivity of alloy after isothermal treatment and aging

2.2 合金微观组织的TEM观察

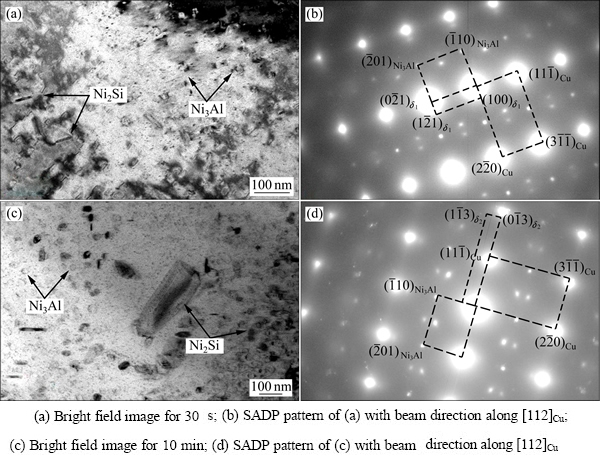

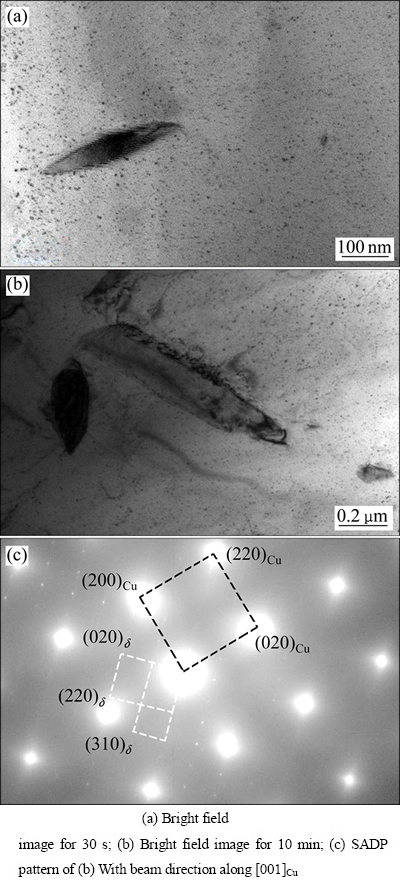

图3所示为Cu-6.5Ni-1Al-1Si-0.15Mg-0.15Ce合金在960 ℃固溶处理4 h后分别在550 ℃等温处理30 s和10 min后的明场像和相应的电子衍射花样图。由图3(a)和(b)可知,经550 ℃等温30 s后,合金基体中析出了大量的纳米级第二相。其中,具有无衬度线的第二相为Ni3Al粒子,这些粒子与基体共格,粒径约为20 nm;而较粗大的第二相为δ-Ni2Si,粒径约为50 nm,与基体为非共格或半共格关系。等温时间延长至10 min时,Ni3Al粒径仍约为20 nm,并且与基体保持共格,而δ-Ni2Si急剧长大至约300 nm,如图3(c)所示。

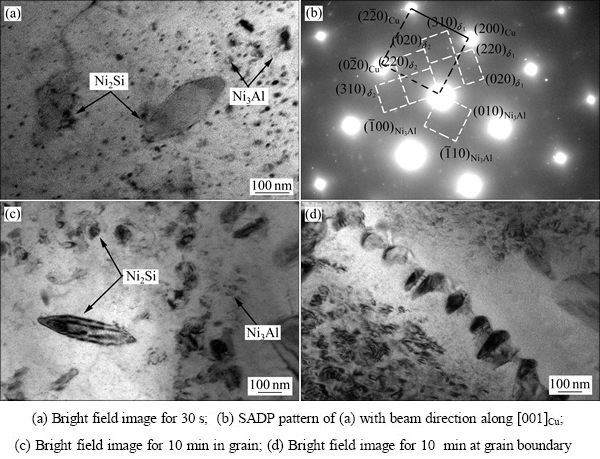

图4所示为Cu-6.5Ni-1Al-1Si-0.15Mg-0.15Ce合金在960 ℃固溶处理4 h后分别在650 ℃等温处理不同时间后的明场像。由图4(a)可知,经650 ℃等温处理30 s后,Ni3Al析出相的粒径约为30 nm,并与基体保持共格关系;而粗大δ-Ni2Si平均粒径约为150 nm。图4(b)所示的衍射花样中Ni3Al的超点阵斑点非常微弱,表明在650 ℃等温30 s时,析出的Ni3Al数量比550 ℃等温30 s时析出的Ni3Al数量明显减少。等温时间延长至10 min时,δ-Ni2Si粒径急剧长大至300 nm;而Ni3Al粒子也明显粗化,粒径约为50 nm,但仍与基体保持共格(见图4(c))。此外,晶界出析出了大量粗大的δ-Ni2Si,粒径约为200 nm,并且晶界附近出现了明显的无衬度析出区,表明合金已经发生了不连续析出(见图4(d))。

图3 合金经550 ℃等温处理不同时间后的TEM像及相应的SADP衍射花样

Fig. 3 TEM images and SADP patterns of alloy after isothermally treated at 550 ℃ for different time

图4 合金经650 ℃等温处理不同时间后的TEM像及相应的SADP衍射花样

Fig. 4 TEM images and SADP pattern of alloy after isothermally treated at 650 ℃ for different time

图5所示为Cu-6.5Ni-1Al-1Si-0.15Mg-0.15Ce合金在960 ℃固溶处理4 h后分别在750 ℃等温处理不同时间后的明场像。合金在750 ℃等温处理30 s后,基体中析出粒径约为200 nm的粗大δ-Ni2Si。等温时间延长至10 min时,粗大的δ-Ni2Si平均粒径增大至约400 nm,且对应的选区衍射花样(见图5(c))中未观察到Ni3Al的超点阵斑点,表明该合金经750 ℃等温处理10 min后,仅δ-Ni2Si从过饱和的基体中析出。

图5 合金经750 ℃等温处理不同时间后的TEM像及相应的SADP衍射花样

Fig. 5 TEM images and SADP pattern of alloy after isothermally treated at 750 ℃ for different time

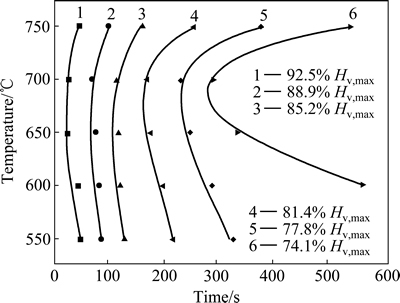

2.3 合金的时间-温度-性能曲线和淬火敏感性

Cu-6.5Ni-1Al-1Si-0.15Mg-0.15Ce合金的时间-温度-性能曲线如图6所示。由图6可知,Cu-6.5Ni-1Al- 1Si-0.15Mg-0.15Ce合金的时间-温度-性能曲线为典型的C型曲线,TTP曲线可分为3个区域,即低温区(低于675 ℃)、鼻尖区(625 ℃-725 ℃)和高温区(高于725 ℃)。合金采用不同硬度值拟合后所得6条曲线中的鼻尖温度基本一致(约为675 ℃),表明在不同温度进行等温处理时,第二相的析出方式没有明显变化,而第二相的孕育期、大小和形貌发生了变化。时间-温度-性能曲线鼻尖温度处第二相孕育期很短,硬度下降很快,表明合金在鼻尖区具有很高的淬火敏感性;而在低温区或高温区第二相的孕育期较长,硬度下降速度较慢,表明合金在低温和高温区淬火敏感性较低。

图6 Cu-6.5Ni-1Al-1Si-0.15Mg-0.15Ce合金的时间-温度-性能曲线

Fig. 6 Time-temperature-property curves of Cu-6.5Ni-1Al- 1Si-0.15Mg-0.15Ce

合金的淬火敏感性与第二相的析出密切相关。在等温淬火过程中,合金经过固溶处理后获得的过饱和固溶体发生分解,析出平衡相。第二相的形核长大是一个热激活过程。根据均匀形核理论[24],第二相的形核率可表示为

(1)

(1)

式中:I为第二相的形核率;c为常数;ΔG*为形核激活能;Q为溶质原子扩散激活能;k为玻尔兹曼常数;T为热力学温度。

由公式(1)可知,等温温度越低,温度梯度越大,第二相析出的驱动力越大,过饱和固溶体越容易发生分解,第二相将在基体中大量形核;等温温度越高,第二相的形核率越低。另一方面,等温温度较低时,溶质原子的扩散速率较慢,第二相的长大速率缓慢,合金最终的硬度较高;等温温度很高时,溶质原子的扩散速度快,第二相析出的体积分数小,但粒子急剧长大,且大量弥散细小的第二相粒子将在后续的时效过程中析出,合金最终的硬度也较高。当合金在550 ℃等温处理10 min后,合金中析出大量δ-Ni2Si和Ni3Al,其平均粒径约为20 nm;少量δ-Ni2Si发生粗化,其粒径约为400 nm;合金等温后在500 ℃时效1 h后,其硬度值较高,约为203.7 HV。合金在750 ℃等温处理10 min后,δ-Ni2Si粒径约为400 nm,但析出的体积分数小;经等温后的时效处理后,大量的纳米粒子从合金中析出,导致其硬度值升高,约为196.3 HV。因此,合金在较高或较低温度进行等温处理后,合金的硬度值较高,淬火敏感性较低。以上透射电镜的观察结果和硬度测试与TTP曲线的分析结果一致。

当合金在鼻尖温度进行等温处理时,析出相的形核率和长大速率均较大,合金析出大量粗大的第二相,这些粗大的第二相对强度的贡献很低,并且在合金的晶界处发生不连续析出,形成无沉淀析出带。由透射电镜观察和硬度测试可知,合金在650 ℃等温处理10 min后,析出大量第二相,其中δ-Ni2Si急剧长大至300 nm,Ni3Al长大至50 nm,并且晶界处析出了不连续的δ-Ni2Si相,其粒径约为200 nm,导致合金高温淬火后饱和度较低,因此,合金经过等温和后续的时效处理后,硬度值较低,约为182.6 HV,并且具有较高的淬火敏感性。

3 结论

1) 等温处理过程中,Cu-6.5Ni-1Al-1Si-0.15Mg- 0.15Ce合金的硬度和电导率均随着等温时间的延长和等温温度的下降而升高。合金经等温处理并在500 ℃时效1 h后,合金的硬度随等温时间的延长而下降,电导率随着等温时间的延长而升高。

2) 等温处理过程中δ-Ni2Si和共格的Ni3Al相从过饱和固溶体中析出,等温温度越高,析出相的体积分数越小,析出相粒径越大。

3) 合金的TTP曲线为典型的C曲线,鼻尖温度约为675 ℃,淬火敏感区间为625~725 ℃。合金在鼻尖区形核率和长大速率均很大,并且晶界处发生不连续析出,导致合金具有很高的淬火敏感性。

REFERENCES

[1] PANG Y, XIA C D, WANG M P, LI Z, XIAO Z, WEI H G, SHENG X F, JIA Y L, CHEN C. Effects of Zr and (Ni, Si) additions on properties and microstructure of Cu-Cr alloy[J]. Journal of Alloys and Compounds, 2014, 582: 786-792.

[2] ZHANG Y, LIU P, TIAN B H, LIU Y, LI R Q, XU Q Q. Hot deformation behavior and processing map of Cu-Ni-Si-P alloy[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(8): 2341-2347.

[3] 董琦祎, 汪明朴, 贾延琳, 李 周, 夏承东, 雷 前. 形变热处理对Cu-1.5Ni-0.34Si合金组织与性能的影响[J]. 粉末冶金材料科学与工程,2011, 16(4): 531-536.

DONG Qi-yi, WANG Ming-pu, JIA Yan-lin, LI Zhou, XIA Cheng-dong, LEI Qian. Effects of thermomechanical treatment on microstructure and properties of Cu-1.5Ni-0.34Si alloy[J]. Materials Science and Engineering of Powder Metallurgy, 2011, 16(4): 531-536.

[4] 张 毅, 刘 平, 田保红, 陈小红, 刘 勇. Cu-Ni-Si-P合金热变形行为及热加工图[J]. 中国有色金属学报, 2013, 23(4): 970-976.

ZHANG Yi, LIU Ping, TIAN Bao-hong, CHEN Xiao-hong, LIU Yong. Cu-Ni-Si-P-Cr alloy at elevated temperatures[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(4): 970-976.

[5] LIU N, LI Z, LI L, LIU B, XU G Y. Processing map and hot deformation mechanism of novel nickel-free white copper alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(11): 3492-3499.

[6] YAGMUR L. Effect of microstructure on internal friction and Young’s modulus of aged Cu-Be alloy[J]. Materials Science and Engineering A, 2009, 523: 65-69.

[7] XIE G L, WANG Q S, MI X J, XIONG B Q, PENG L J. The precipitation behavior and strengthening of a Cu-2.0 wt% Be alloy[J]. Materials Science and Engineering A, 2012, 558: 326-330.

[8] 谢建新, 王 宇, 黄海友. 连续柱状晶组织铜及铜合金的超延展变形行为与塑性提高机制[J]. 中国有色金属学报, 2011, 21(10): 2324-2336.

XIE Jian-xin, WANG Yu, HUANG Hai-you. Extreme plastic extensibility and ductility improvement mechanisms of continuous columnar-grained copper and copper alloys[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2324-2336.

[9] CAI W, WU Y, YANG S L, XU D, CHEN Z B, DENG Y S, LUO P. Research of Cu-15Ni-10Mn alloy as-cast[J]. Advanced Materials Research, 2012, 581/82: 479-482.

[10] LEI Q, LI Z, ZHU A Y, QIU W T, LIANG S Q. The transformation behavior of Cu-8.0Ni-1.8Si-0.6Sn-0.15Mg alloy during isothermal heat treatment[J]. Materials Characterization, 2011, 62: 904-911.

[11] LEI Q, LI Z, DAI C, WANG J, CHEN X, XIE J M, YANG W W, CHEN D L. Effect of aluminum on microstructure and property of Cu-Ni-Si alloys[J]. Materials Science and Engineering A, 2013, 572: 65-74.

[12] XIANG Z Q, LI Z, LEI Q, XIAO Z, PAN Y. High temperature mechanical behavior of alumina dispersion strengthened copper alloy with high content of alumina[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(2): 444-450.

[13] 王艳辉, 汪明朴, 洪 斌. 添加Si和Al的Cu-9Ni-2.5Sn合金的热处理工艺[J]. 金属热处理学报, 2004, 29(2): 44-47.

WANG Yan-hui, WANG Min-pu, HONG Bin. Heat treatment process of the Cu-9Ni-2.5Sn alloy added Si and Al[J]. The Heat Treatment of Metals, 2004, 29(2): 44-47.

[14] ZHAO D M, DONG Q M, LIU P, KANG B X, HUANG J L, JIN Z H. Structure and strength of the age hardened Cu-Ni-Si alloy[J]. Materials Chemistry and Physics, 2003, 79: 81-86.

[15] LEI Q, LI Z, XIAO T, PANG Y, XIANG Z Q, QIU W T, XIAO Z. A new ultrahigh strength Cu-Ni-Si alloy[J]. Intermetallics, 2013, 42: 77-84.

[16] SATOSHI S, MIKIO I, SHIGEO S, KAZUAKI W, TAKAYUKI T. Extraction of precipitates from age-hardenable Cu-Ti alloys[J]. Materials Characterization, 2013, 82: 23-31.

[17] 潘志勇, 汪明朴, 李 周, 邓楚平, 肖 柱, 陈 畅. 超高强度Cu-5.2Ni-1.2Si合金的形变热处理[J]. 中国有色金属学报, 2007, 17(11): 1821-1826.

PAN Zhi-yong, WANG Ming-pu, LI Zhou, DENG Chu-ping, XIAO Zhu, CHEN Chang. Thermomechanical treatment of super high strength Cu-5.2Ni-1.2Si alloy[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(11): 1821-1826.

[18] 李宏磊. Cu-3.2Ni-0.75Si合金的时效析出强化效应分析[J]. 中南大学学报(自然科学版), 2006, 37(3): 467-471.

LI Hong-lei. Analysis of intensified effect by aging of Cu-3.2Ni-0.75Si alloy[J]. Journal of Central South University (Science and Technology), 2006, 37(3): 467-471.

[19] CHEN L, ZHOU B W, HAN J N, XUE Y Y, JIA F, ZHANG X G. Effects of alloying and deformation on microstructures and properties of Cu-Mg-Te-Y alloys[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(12): 3697-3703.

[20] SHEN L N, LI Z, ZHANG Z M, DONG Q Y, XIAO Z, LEI Q, QIU W T. Effects of silicon and thermo-mechanical process on microstructure and properties of Cu-10Ni-3Al-0.8Si alloy[J]. Materials and Design, 2014, 62: 265-270.

[21] 刘文军, 张新民, 刘胜胆, 周新伟. 均匀化对7050铝合金板材淬火敏感性的影响[J]. 中国有色金属学报, 2010, 20(6): 1102-1109.

LIU Wen-jun, ZHANG Xin-ming, LIU Sheng-dan, ZHOU Xin-wei. Effect of homogenization on quenching sensitivity of 7050 aluminum alloy plates[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(6): 1102-1109.

[22] LIU S D, ZHONG Q M, ZHANG Y, LIU W J, ZHANG X M, DENG Y L. Investigation of quench sensitivity of high strength Al-Zn-Mg-Cu alloys by time-temperature-properties diagrams[J]. Materials and Design, 2010, 31: 3116-3120.

[23] 黎三华, 申镭诺, 李 周, 汪明朴, 肖 柱, 雷 前, 邱文婷, 刘会群. 形变热处理对Cu-6.5Ni-1Al-1Si-0.15Mg-0.15Ce合金微观组织及性能的影响[J]. 粉末冶金材料科学与工程, 2015, 20(1): 118-125.

LI San-hua, SHEN Lei-nuo, LI Zhou, WANG Ming-pu, XIAO Zhu, LEI Qian, QIU Wen-ting. The effect of thermo-mechanical treatment on microstructure and properties of Cu-6.5Ni-1Al-1Si-0.15Mg-0.15Ce alloy[J]. Materials Science and Engineering of Powder Metallurgy, 2015, 20(1): 118-125.

[24] 张新明, 刘文军, 刘胜胆, 袁玉宝, 邓运来. 7050铝合金的TTP曲线[J]. 中国有色金属学报, 2009, 19(5): 861-868.

ZHANG Xin-ming, LIU Wen-jun, LIU Sheng-dan, YUAN Yu-bao, DENG Yun-lai. TTP curve of aluminum alloy 7050[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(5): 861-868.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51271203);中南大学贵重仪器设备开放基金(CUSZC2014026);湖南有色基金资助项目(YSZN2013CL06)

收稿日期:2015-05-07;修订日期:2015-10-19

通信作者:李 周,教授,博士;电话:13187215338;E-mail: lizhou6931@163.com