DOI:10.19476/j.ysxb.1004.0609.2018.11.11

C/C-ZrC-Cu复合材料等离子喷涂W组织结构

周 哲,葛毅成,汪 沅,龚洁明,易茂中

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:在金属反应熔渗法(RMI)制备的C/C-ZrC-Cu复合材料上采用大气等离子喷涂法(APS)得到厚度为1.3 mm的W涂层。运用扫描电镜-能谱(SEM-EDS),X射线衍射(XRD)测试技术分析研究了等离子喷涂W与C/C-CuZr复合材料界面相组成。结果表明:C/C复合材料反应熔渗法采用Cu-48.9%Zr(摩尔分数)粉末制备出均匀的熔渗组织,这是因为Zr提高了Cu 在1300 ℃的C/C复合材料中的润湿性,在熔渗过程中生成了正交晶系相Cu10Zr7。W涂层与C/C-ZrC-Cu复合材料的结合类型以扩散结合为主,其界面区内主要是W和C通过包晶反应生成WC扩散层,反应扩散层厚度约为10 um。

关键词:C/C-ZrC-Cu复合材料;金属反应熔渗;大气等离子喷涂;W涂层

文章编号:1004-0609(2018)-11-2257-09 中图分类号:TB333 文献标志码:A

喉衬是冲压发动机喷管中烧蚀最为严重的部位,需要在承受高温热载、高速粒子热冲击和热化学腐蚀等恶劣环境下保证其使用性能。因此,喉衬需要选择比热容大、导热系数低、烧蚀速率小、密度低且能够在高温下保持稳定的物理和化学性能的材料[1-3]。C/C复合材料以其低密度、高比强度、耐烧蚀、耐热冲击、低热膨胀、抗热震以及抗高温蠕变性能成为冲压发动机喷管喉衬的首选材料之一,但C/C复合材料在空气中400 ℃以上开始氧化,其结构稳定性被破坏,限制了材料在高温下的应用[4]。因此一般采用基体改性或表面涂层的方法来提高C/C复合材料高温抗氧化和耐烧蚀性能。实验表明,SiC[5]、ZrC[6]、ZrB2[7]、Mo2C[8-9]等高温陶瓷改性可显著提高C/C复合材料的高温抗氧化性。与基体改性技术相比,涂层技术同样能有效地隔离材料和外部有氧氛围的扩散接触,可长时间更高温度段的氧化防护,从而提高材料耐烧蚀性能[10]。陈照峰等[11]采用双辉离子技术在C/C复合材料上制备了Ir涂层,在2000 ℃具有稳定抗氧化性;MUMTAZ等[12]采用溅射的方法在C/C复合材料制备Ir涂层。研究制备方法包括化学气相沉积[13-15]、涂覆反应烧结(或包埋)[16]、反应浸渗[17]和热喷涂[18-20]等,涂层体系包含TiC[21-22]、ZrC[23]、ZrC-SiC[24-25]、TaC[26]、HfC[27]等。涂层和基体相结合的方法能够对C/C复合材料起到双层保护的作用,本实验选取Cu-48.9%Zr合金粉末采用RMI法预先制备出C/C-ZrC-Cu复合材料,然后采用APS技术在所得复合材料制备W涂层。运用SEM-EDS、XRD测试技术并结合平衡合金法分析研究W涂层与C/C-ZrC-Cu复合材料界面相组成。熔渗剂中Zr含量(质量分数)为60%时C/C复合材料耐烧蚀性的陶瓷相ZrC含量达到最高[28],有利于提高材料整体的耐烧蚀性能,C/C复合材料中的热解炭为ZrC的生成提供C源。

1 实验

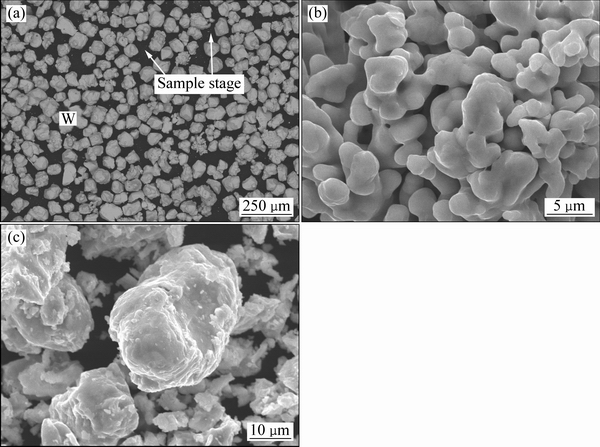

以聚丙烯腈基(PAN)炭纤维(Cf)针刺无纬布为预制体,然后通过化学气相沉积(CVD)得到密度为1.6 g/cm3的C/C复合材料坯体。其中坯体密度采用表观密度即坯体质量除以坯体体积。采用纯度≥99.9%(质量分数)的Zr金属粉末和Cu金属粉末按照Cu-48.9%Zr(摩尔分数)比例配料后通过高能球磨机混合均匀,Zr和Cu粉末的颗粒大小如图1所示。样品熔渗过程及涂层界面相关金属和化合物晶体结构如表1所列,相关金属和化合物的物理性能如表2所列。

图1 W、Cu和Zr粉末的SEM像

Fig. 1 SEM images of W (a), Cu (b) and Zr (c) powders

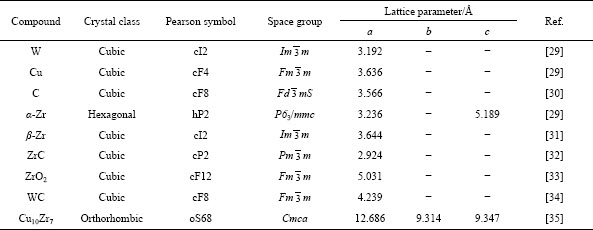

表1 样品中的金属及其化合物晶体结构参数

Table 1 Crystallographic parameters of metal and compounds found in samples

表2 样品中相关金属和化合物的物理性能

Table 2 Physical properties of related metal and compounds in samples

将所得混合均匀金属合金粉作为高温熔渗渗剂,采用石墨发热体的高温真空电阻炉(最高温度2200 ℃)进行RMI高温处理。工艺流程为:将C/C复合材料坯体竖直放置于石墨纸盒中央后加入球磨后的Cu-48.9%Zr合金粉末,轻轻震动密实直到金属粉末加至刚好盖住表面C/C坯体为准。为防止高温处理后石墨纸破裂污染炉体,将石墨纸盒放于石墨罐内后一同放置在高温炉中进行熔渗处理,熔渗温度为1300 ℃,真空度为1×10-3 Pa,室温到800 ℃采用速度为10 ℃/min升温,800 ℃到1300 ℃采用5 ℃/min升温,在1300 ℃保温1~2 h,最后得到坯体密度为3.5 g/cm3的C/C-ZrC-Cu复合材料。实验等离子喷涂所用的钨粉为不规则的多角形颗粒,粒度为44~75 um,纯度为99.95%。为防止喷涂过程中粉末堵塞送粉软管,需先将其置于干燥箱中100 ℃下干燥1 h。采用DH-1080等离子喷涂设备(最大功率80 kW)进行等离子喷涂成形,喷涂工艺参数为:电压70 V,电流650 A,主气(Ar)60 L/min,次气(H2)15 L/min,送粉速率10 g/min,喷涂距离120 mm,厚度1 mm。工艺流程为:丙酮净化样品表面→表面喷砂粗化→工件200 ℃预热→喷涂。

2 结果与讨论

2.1 C/C熔渗Cu-48.9%Zr形貌与组织

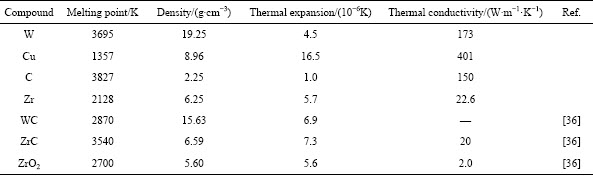

图2(a)和(b)所示为C/C复合材料熔渗Cu-48.9%Zr前后表面的宏观照片,可看出图2(b)中熔渗后的C/C-ZrC-Cu复合材料相对图2(a)中C/C复合材料明显致密,呈现金属光泽。样品表观密度增加到3.74 g/cm3。熔体渗入到相邻炭纤维束熔体间隙中完全铺满了C/C多孔预制体的孔隙。表明该C/C复合材料与Cu-48.9%Zr粉末在1300 ℃下有良好的润湿性。除此之外,材料表面呈现条纹状沟壑为C/C复合材料无纬布层间间隙和少量孔洞。这是因为:1) 通过CVD处理后的PAN基Cf预制体不可避免存在闭孔,熔融后的Cu-48.9%Zr粉末很难渗入,最后形成封闭小气孔;2) Cf预制体中存在不同形状大小和方向的孔隙,熔融固体的前沿随孔隙通道方向的变化而变换向,熔渗过程中需要克服黏滞力、摩擦力和拐弯阻力。随着熔渗深度的增加,当液体受到的外界压力和自身重力小于临界阻力时,熔体的渗入被中止,就会在溶体流动毛细管内形成封闭孔洞。

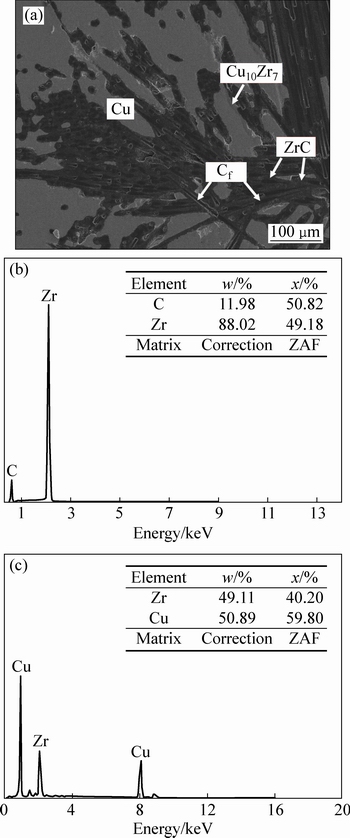

图3(a)所示为C/C复合材料熔渗Cu-48.9%Zr粉末后微观形貌的SEM像,图3(b)和(c)所示分别为图3(a)中所对应位置ZrC和Cu10Zr7的EDS结果。由图3(a)可知,熔渗所得C/C-ZrC-Cu复合材料致密度高,未见明显的孔隙,结合图3(b)中EDS分析结果可知,炭纤维附近包裹浅灰色相为含有49.18%Zr的体心立方结构ZrC,呈海绵状分布在纤维束间,且有微裂纹。

图2 C/C复合材料表面坯体宏观图片和C/C-ZrC-Cu复合材料宏观图片

Fig. 2 Macro morphology of C/C composite (a) and Macro morphology of C/C-ZrC-Cu composite (b)

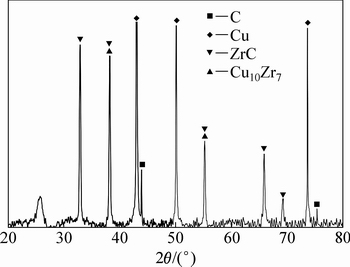

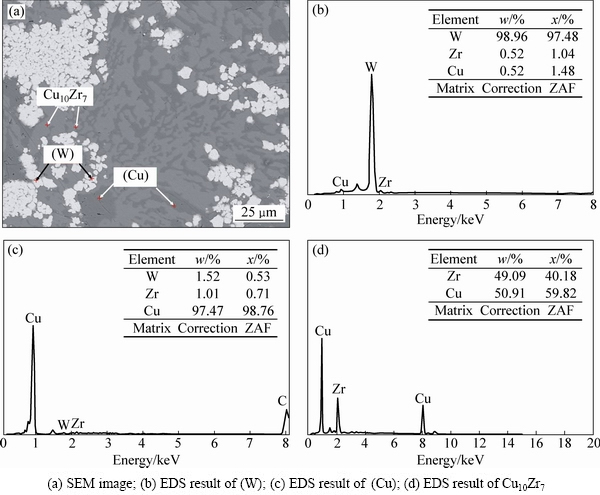

大块状灰色相为面心立方结构Cu,熔融Cu和C/C坯体不润湿,而Zr的加入提高了Cu在1300 ℃时在C/C复合材料中润湿性。这是由于:C/C复合材料中炭纤维周围的热解炭提供C源和Zr反应生成ZrC,而ZrC和Cu的润湿角比Cu和C和润湿性要小,因此提高了Cu在C/C复合材料中的润湿性。结合图3(c)中EDS结果可知,在Cu相边缘的暗灰色相为含有40.2%Zr的正交晶系相Cu10Zr7,表明CuZr合金粉末在熔渗过程中生成化合物Cu10Zr7。C/C-ZrC-Cu复合材料中没有出现氧化物以及与设计元素不一致的元素出现,表明熔渗过程中未造成样品的污染。图4所示为熔渗Cu-48.9%Zr粉末后C/C-ZrC-Cu复合材料的XRD谱,其结果和SEM-EDS结果一致,进一步证实了样品中Cu10Zr7相的存在,原料粉末中的Zr粉和炭纤维束周围的热解炭反应生成ZrC。

图3 C/C-ZrC-Cu材料SEM像和ZrC及Cu10Zr7能谱结果

Fig. 3 SEM image of C/C-ZrC-Cu(a), EDS results of ZrC (b) and Cu10Zr7 (c) in C/C-ZrC-Cu

2.2 C/C-CuZr等离子喷涂W形貌与组织

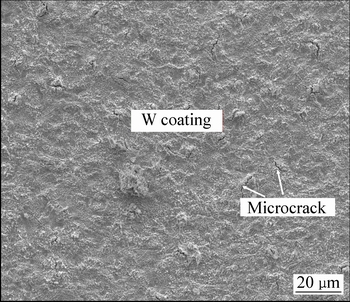

图5所示为等离子喷涂后W涂层表面SEM像。由图5可见,等离子喷涂沉积层表面呈现凹凸起伏状形貌,其中还有大块状W颗粒,涂层结合处可见细小孔隙及纳米级尺寸缝隙。这是因为当高速熔融粒子碰撞到已形成的涂层表面时,由于基材表面粗糙及熔融粒子间结合不完全,涂层中不可避免存在孔隙。产生孔隙主要原因是由于熔融液滴在基体或已形成的涂层表面的不完全填充、铺排,未完全熔化粒子不充分扁平化形成的边界处孔隙;其次冷却凝固过程中钨颗粒产生收缩,撞击过程有气体的卷入。另外,等离子喷涂成形时,位于等离子焰流外围的钨颗粒未能充分吸收热量,导致其仅表面熔化,碰撞到基体前几乎完全凝固,造成沉积层中出现较为明显大块的W颗粒。

图4 C/C-ZrC-Cu复合材料X射线结果分析

Fig. 4 XRD pattern of C/C-ZrC-Cu campsite

图5 等离子喷涂W涂层表面SEM像

Fig. 5 SEM image of W coating surface

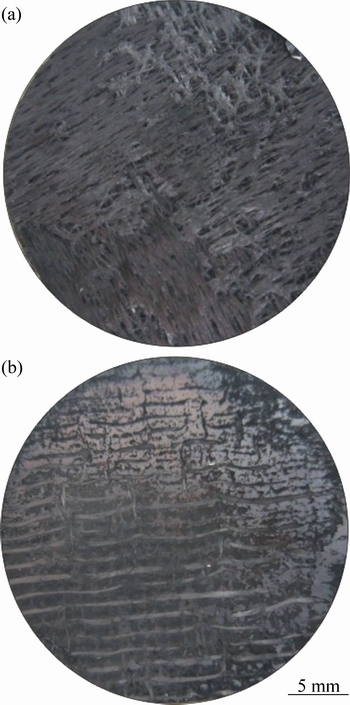

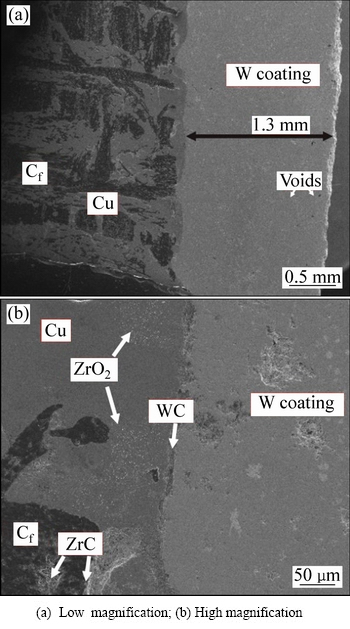

图6(a)所示为C/C-ZrC-Cu复合材料等离子喷涂W横截面形貌。由图6(a)可见,涂层厚度约为1.3 mm,涂层表面有孔隙,涂层和基体结合处在低倍SEM观察下并没有看到扩散层,有少量的Cu向涂层内渗透以及部分涂层嵌入C/C-ZrC-Cu复合材料表面孔洞内,界面呈现凹凸起伏状。图6(b)所示为涂层和基体界面高倍SEM像。通过SEM-EDS分析可知,界面区内发生了反应扩散,反应扩散层厚度约为10 μm,生成物质主要是WC,其中WC中C含量(摩尔分数)约为49.5%,且没有发现其他扩散产物,可知W涂层与Cu和ZrC并未相互扩散。在W涂层处可以发现其中也有不少孔洞以及块状白色相,EDS证明白色相是W。这是因为等离子喷涂过程中,W颗粒的大小不一致,而且喷射过程出来的位置也不同,导致熔融W颗粒凝固的速率和位置不同,从而在W涂层中出现了不同于大块涂层的白色相W。在C/C-ZrC-Cu基体中还发现了白色颗粒状ZrO2,这是由于大气等离子喷涂过程是在含有氧气的环境中进行的,熔融态W颗粒从喷枪口喷射达到基体表面时,虽然W颗粒本身温度已大幅度降低, 但W颗粒沉积在复合材料表面时仍然含有较多热量,从而导致C/C-ZrC-Cu复合材料中ZrC和残余Zr与O2反应生成颗粒状ZrO2。

图6 样品横截面SEM像

Fig. 6 SEM images of cross-section of sample

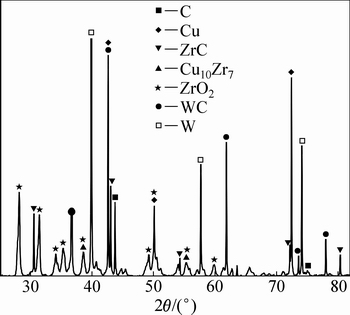

图7所示为C/C-ZrC-Cu复合材料等离子喷涂W截面XRD谱。结果再次证实ZrO2和WC的存在,另外还发现了Cu10Zr7的峰值,但是在SEM-EDS分析结果中并没有发现,可以推测出在高温熔融W颗粒的影响下导致Cu10Zr7减少。而且也没有W的氧化物,其主要原因是选择的W粉颗粒粗大,不易被氧化;喷涂采用的工作气体是氩气和氢气,氩气具有保护作用,而氢气则能防止W粉氧化和将氧化物还原,这与本来孔隙中就有空气的C/C-ZrC-Cu基体中ZrC能够氧化生成ZrO2不同。

图7 样品横截面XRD谱

Fig. 7 XRD pattern of cross-section of sample

2.3 C/C-ZrC-Cu复合材料W涂层制备过程中反应机理分析

在制备C/C-ZrC-Cu复合材料过程中,由图2(a)可知,C/C复合材料坯体内部纤维束之间有很多孔隙,熔融Cu-48.9%Zr粉末通过纤维束之间相当于毛细管的孔隙渗入到C/C复合材料坯体中。在不考虑相互反应能、重力和黏性流动阻力情况下,熔渗的驱动力主要是熔体在C/C坯体孔隙中受到的毛细管力,只有当熔融体与C/C坯体润湿的情况时,即熔体与C/C坯体之间的润湿角小于90°时,熔体才能在毛细管力的作用下渗入到C/C坯体的孔隙中。根据实验所得结果可知,熔渗效果较好,熔体渗透C/C坯体内部(见图2(b)),这是因为Zr的加入改善了熔体和C/C坯体的润湿性。在熔体润湿C/C坯体的情况下,熔体内部以及熔体和C/C复合材料在高温下发生相互反应。其中相关反应如下:

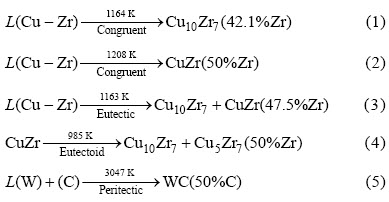

由图8中Cu-Zr二元相图[37]和图3(a)以及式(1)可知,熔体内部在1164 K时42.1%Zr成分下由液相L生成中间化合物Cu10Zr7;在1208 K时50%Zr成分下由液相L生成中间化合物CuZr;在1163 K时47.5%Zr成分下液相L通过共晶反应生成CuZr和Cu10Zr7。随着温度降低,在985 K时50%Zr成分下式(2)和(3)生成的CuZr相共析反应生成Cu10Zr7和Cu5Zr7。实验过程中并没有检测到CuZr和Cu5Zr7,而只发现了Cu10Zr7,这是因为:1) 整体粉末虽然采用Cu-48.9%Zr比例混合,但是熔渗过程中局部成分和设计设计成分上存在偏差,从而导致生成了更多的Cu10Zr7,且CuZr相共析反应完全生成Cu10Zr7和Cu5Zr7。但是相对Cu10Zr7的量来说,Cu5Zr7可以忽略不计从而导致结果中并没有检测到Cu5Zr7。

图8 Cu-Zr二元相图

Fig. 8 Phase diagram of Cu-Zr binary system

图9 W5Cu55Zr40合金在800 ℃相平衡关系的SEM像和EDS结果

Fig. 9 Phase equilibrium of W5Cu55Zr40 alloy at 800 ℃ and EDS results

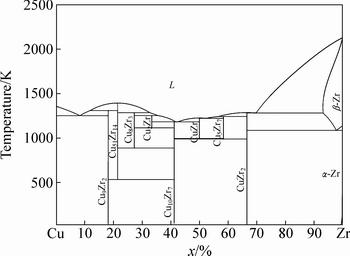

为了研究熔渗后Cu-Zr合金相和W涂层之间相关系,采用平衡合金法制备了W5Cu55Zr40(摩尔分数,%)三元合金,其中Cu和Zr粉比例和熔渗所配比例接近。样品在800 ℃退火60天所得W-Cu-Zr三元相关系如图9(a)所示。由图9(a)可知,样品达到(Cu10Zr7+(W)+(Cu))三相平衡时,其中白色颗粒相为(W),由图9(b)中EDS结果可知其能够分别固溶1.48%Cu和1.04%Zr。结合图9(c)中EDS结果可知,暗灰色相(Cu)能够分别固溶0.53%W和0.71%Zr。介于(W)和(Cu)相之间灰色相为Cu10Zr7,EDS结果(见图9(d))表明其中Zr含量为40.18%。根据图9(a)中W-Cu-Zr三元系相关系,结合SEM-EDS分析结果同样再次证明Cu10Zr7的存在。由图6(b)可知,等离子喷涂W和C/C-ZrC-Cu复合材料基体之间发生扩散,生成10 μm左右的WC扩散层。由W-C二元相图[38]中的反应式(5)可知在3047 K时50%C成分下C与W通过包晶反应生成WC扩散层。这是因为喷涂过程中,虽然熔融体没有刚出来时的温度高,但是喷射到基体时仍具有较高温度,另外,由于C/C复合材料中熔渗了Cu和Zr元素,它们能够降低扩散温度。

3 结论

1) C/C复合材料反应熔渗法采用Cu-48.9%Zr粉末制备出组织均匀的复合材料,Zr的加入提高了Cu在1300 ℃时在C/C复合材料中润湿性,样品密度由1.60 g/cm3增加到3.74 g/cm3,熔渗过程中生成了包围在Cu附近的低熔点正交晶系相Cu10Zr7,原料粉末中的Zr粉和炭纤维束周围的热解炭反应生成ZrC。

2) 在RMI制备的C/C-CuZr复合材料上采用APS方法成功得到厚度为1.3 mm的W涂层,喷涂后截面基体部分出现白色颗粒状ZrO2,界面结合处发现WC层。

3) W涂层与C/C-ZrC-Cu复合材料的结合类型以扩散结合为主还包括机械结合,其界面区内主要是液相L通过包晶反应生成WC扩散层,反应扩散层厚度约为10 μm。W-Cu-Zr平衡合金法进一步证实Cu10Zr7与W和Cu以及基体ZrC共存。

REFERENCES

[1] LI K Z, SHEN X T, LI H J, ZHANG S Y, FENG T, ZHANG L L. Ablation of the carbon/carbon composite nozzle-throats in a small solid rocket motor[J]. Carbon, 2011, 49(4): 1208-1215.

[2] YIN J, XIONG X, ZHANG H B, HUANG B Y. Microstructure and ablation performances of dual-matrix carbon/carbon composites[J]. Carbon, 2006, 44(9): 1690-1694.

[3] 成会朝, 范景莲, 李鹏飞, 田家敏. 难熔钼合金的高温抗氧化和烧蚀行为[J]. 中国有色金属学报, 2011, 21(3): 570-576.

CHENG Hui-zhao, FAN Jing-lian, LI Peng-fei, TIAN Jia-min. Oxidation resistance and ablation behavior of refractory alloy at high temperature[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(3): 570-576.

[4] JACOBSON N S, CURRY D M. Oxidation microstructure studies of reinforced carbon/carbon[J]. Carbon, 2006, 44(7): 1142-1150.

[5] 李 军, 杨 鑫, 刘红卫, 黄启忠, 苏哲安. 耐烧蚀超高温陶瓷改性C/C复合材料的研究进展[J]. 中国有色金属学报, 2015, 25(7): 1731-1743.

LI Jun, YANG Xing, LIU Hong-wei, HUANG Qi-zhong, SU Zhe-an. Research process of ultra high temperature ceramics modified carbon/carbon composites for ablation resistance[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(7): 1731-1743.

[6] ZHAO D, ZHANG C R, HU H F, ZHANG Y D. Ablation behavior and mechanism of 3D C/ZrC composite in oxyacetylene torch environment[J]. Composites Science and Technology, 2011, 71(11): 1392-1396.

[7] WANG D N, ZENG Y, XIONG X, LI G D, CHEN Z K, SUN W, WANG Y L. Ablation behavior of ZrB2-SiC protective coating for carbon/carbon composites[J]. Ceramics International, 2015, 41(6): 7677-7686.

[8] ZHOU W Y, YI M Y, PENG K, RAN L P, GE Y C. Preparation of a C/C-Cu composite with Mo2C coatings as a modification interlayer[J]. Materials Letters, 2015, 145: 264-268.

[9] ZHOU W Y, RAN L P, PENG K, GE Y C, WU H, YI M Z. Effect of Carbon/Carbon Preform density on the microstructure and properties of Mo2C interlayer-modified carbon/carbon-copper composites for sliding contact materials[J]. Advanced Engineering Materials, 2016, 18(2): 277-283.

[10] YANG X, SU Z A, HUANG Q Z, CHAI L Y. Preparation and oxidation resistance of mullite/SiC coating for carbon materials at 1150 ℃[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(12): 2997-3002.

[11] CHEN Z F, WU W P, CHENG H, LIU Y, WANG S M, XUE R J. Microstructure and evolution of iridium coating on the C/C composites ablated by oxyacetylene torch[J]. Acta Astronautica, 2010, 66(5/6): 682-687.

[12] MUMTAZ K, ECHIGOYA J, HIRAI T, SHINDO Y. Iridium coatings on carbon-carbon composites produced by two different sputtering methods: a comparative study[J]. Journal of Materials Science Letters, 1993, 12(12): 1411-1412.

[13] WANG Y G, LIU Q M, LIU J L, ZHANG L T, CHENG L F. Deposition mechanism for chemical vapor deposition of zirconium carbide coatings[J]. Journal of the American Ceramic Society, 2008, 91(4): 1249-1252.

[14] WANG Y J, LI H J, FU Q G, WU H, YAO D J, LI H L. SiC/HfC/SiC ablation resistant coating for carbon/carbon composites[J]. Surface and Coatings Technology, 2012, 206(19/20): 3883-3887.

[15] WANG Y L, XIONG X, LI G D, ZHANG H B, CHEN Z K, SUN W, ZHAO X J. Microstructure and ablation behavior of hafnium carbide coating for carbon/carbon composites[J]. Surface and Coatings Technology, 2012, 206(11/12): 2825-2832.

[16] YAO X Y, LI H J, ZHANG Y L, REN J J, YAO D J, TAO J. A SiC/ZrB2-SiC/SiC oxidation resistance multilayer coating for carbon/carbon composites[J]. Corrosion Science, 2012, 57: 148-153.

[17] ZHOU H J, GAO L, WANG Z, DONG S M. ZrB2-SiC oxidation protective coating on C/C composites prepared by vapor silicon infiltration process[J]. Journal of the American Ceramic Society, 2010, 93(4): 915-919.

[18] BARTULIA C, VALENTEA T, TULUIB M. Plasma spray deposition and high temperature characterization of ZrB2-SiC protective coatings[J]. Surface and Coatings Technology, 2002, 155(2/3): 260-273.

[19] 徐 玄, 王跃明, 熊 翔, 解 路, 闵小兵. 等离子喷涂成形钨喉衬的烧蚀性能[J]. 中国有色金属学报, 2011, 21(6): 1435-1443.

XU Xuan, WANG Yue-ming, XIONG Xiang, JIE Lu, MIN Xiao-bing. Ablation property of tungsten nozzle produced by plasma spray forming[J]. 2011, 21(6): 1435-1443.

[20] 周 哲, 葛毅成, 汪 沅, 龚洁明, 易茂中. 炭/炭复合材料耐烧蚀W涂层[J]. 中国有色金属学报, 2016, 26(6): 1272-1280.

ZHOU Zhe, GE Yi-cheng, WANG Yuan, GONG Jie-ming, YI Mao-zhong. Ablation performances of carbon/carbon composites with W coatings[J]. 2016, 26(6): 1272-1280.

[21] 舒武炳, 郭海明, 乔生儒, 孟国文, 田长生. 化学气相沉积法制备TiC涂层的相组成和表面形貌[J]. 西北工业大学学报, 2000, 18(2): 229-232.

WU Bing-shu, GUO Hai-ming, QIAO Sheng-ru, MENG Guo-wen, TIAN Chang-sheng. Phase composition and surface morphology of TiC coating by chemical vapor deposition[J]. Journal of North western Polytechnical University, 2000, 18(2): 229-232.

[22] 王坤杰, 郭全贵, 史景利, 刘 朗. 在位反应制备TiC涂层的动力学研究[J]. 材料工程, 2007(s1): 169-171.

WANG Kun-jie, GUO Quan-gui, SHI Jing-li, LIU Lang. Study on kinetic properties of TiC coatings prepared by in-situ reaction[J]. Journal of Materials Engineering, 2007(s1): 169-171.

[23] SUN W, XIONG X, HUANG B Y, LI G D, ZHANG H B, CHEN Z K, ZHENG X L. ZrC ablation protective coating for carbon/carbon composites[J]. Carbon, 2009, 47(14): 3368-3371.

[24] LIU Q M, ZHANG L T, CHENG L F, WANG Y G. Chemical vapour deposition of zirconium carbide and silicon carbide hybrid whiskers[J]. Materials Letters, 2010, 64(4): 552-554.

[25] LIU Q M, ZHANG L T, JIANG F R, LIU J, CHENG L F, LI H, WANG Y G. Laser ablation behaviors of SiC-ZrC coated carbon/carbon composites[J]. Surface and Coatings Technology, 2011, 205(17/18): 4299-4303.

[26] WANG Y J, LI H J, FU Q G, WU H, LIU L, SUN C. Ablation behaviour of a TaC coating on SiC coated C/C composites at different temperatures[J]. Ceramics International, 2013, 39(1): 359-365.

[27] WANG Y L, XIONG X, ZHAO X J, LI G D, CHEN Z K, SUN W. Structural evolution and ablation mechanism of a hafnium carbide coating on a C/C composite in an oxyacetylene torch environment[J]. Corrosion Science, 2012, 61: 156-161.

[28] 张仲灵, 易茂中, 周文艳, 吴 皇, 庞伟林, 葛毅成,冉丽萍. 粉末熔渗制备C/C-ZrC-Cu复合材料的组织结构[J]. 粉末冶金材料科学与工程, 2016, 21(2): 311-316.

ZHANG Zhong-ling, YI Mao-zhong, ZHOU Wen-yan, WU Huang, PANG Wei-lin, GE Yi-cheng, RAN Li-ping. Microstructure of C/C-ZrC-Cu composite fabricated by reactive melt infiltration[J]. Materials Science and Engineering of Powder Metallurgy, 2016, 21(2): 311-316.

[29] LEJAEGHERE K, VAN S V, VAN O G, COTTENIER S. Error estimates for solid-state density-functional theory predictions: an overview by means of the ground-state elemental crystals[J]. Critical Reviews in Solid State and Materials Sciences, 2014, 39(1): 1-24.

[30] BINDZUS N, STRAASO T, WAHLBERG N, BECKER J, BJERG L, LOCK N, DIPPEL A C, IVERSEN B B. Experimental determination of core electron deformation in diamond[J]. Acta Crystallographica, 2014, 70(Pt 1): 39-48.

[31] YANG Xiao, TAKEICHI N, SHIDA K, TANAKA H, KURIYAMA N, SAKAI T. Novel Mg-Zr-A-H (A=Li, Na) hydrides synthesized by a high pressure technique and their hydrogen storage properties[J]. Journal of Alloys and Compounds, 2011, 509(4): 1211-1216.

[32] LV Z T, HU H Q, WU C, CUI S X, ZHANG G Q, FENG W X. First-principles study of structural stability, electronic and elastic properties of ZrC compounds[J]. Physica B: Condensed Matter, 2011, 406(14): 2750-2754.

[33] DING H P, VIRKAR A V, LIU F. Defect configuration and phase stability of cubic versus tetragonal yttria-stabilized zirconia[J]. Solid State Ionics, 2012, 215: 16-23.

[34] ABDULLAEVA Z, OMURZAK E, IWAMOTO C, OKUDERA H, KOINUMA M, TAKEBE S. High temperature stable WC1-x@C and TiC@C core–shell nanoparticles by pulsed plasma in liquid[J]. Rsc Advances, 2012, 3(2): 513-519.

[35] ALBISETTI A F, BIFFI C A, TUISSI A. Synthesis and structural analysis of Cu10Zr7[J]. Journal of Alloys and Compounds, 2012, 544(24): 42-45.

[36] HYDE A R. Ceramic matrix composites[J]. Elsevier Applied Science, 1990, 11(1): 30-36.

[37] WANG N, LI C R, DU Z M, WANG F M, ZHANG W J. The thermodynamic re-assessment of the Cu-Zr system[J]. Calphad, 2006, 30(4): 461-469.

[38] GUSTAFSON P. Thermodynamic evaluation of C-W system[J]. Materials Science & Technology, 2013, 2(7): 653-658.

Microstructure of W coating by atmosphere plasma spraying on C/C-ZrC-Cu composite

ZHOU Zhe, GE Yi-cheng, WANG Yuan, GONG Jie-ming, YI Mao-zhong

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: W coating with thickness of 1.3 mm was successfully deposited by the atmosphere plasma spray (APS) technology on C/C-ZrC-Cu composite which was fabricated by reactive metal infiltration (RMI). Phase composition of interface between W coating and C/C-ZrC-Cu composite was investigated using a combination of X-ray diffraction (XRD) and scanning electron microscopy with energy-dispersive X-ray analysis (SEM-EDS). The results show that good performances of C/C-ZrC-Cu composite are obtained by reactive infiltration method with using powders of Cu-48.9% Zr, and Zr element can increase the wettability of Cu in C/C composite at 1300 ℃, the orthorhombic phase Cu10Zr7 is found in the composite. The type of bonding between W coating and C/C-ZrC-Cu composite is diffusion bonding on the main area of the interface. The diffusion bonding of WC layer is produced by peritectic reaction of phase W and C, and the thickness of reaction-diffusion layer is about 10 μm.

Key words: C/C-ZrC-Cu composite; RMI; APS; W coating

Foundation item: Project(GFZX0101040101-2012C20X) supported by National Basic Construction Program, China

Received date: 2016-07-26; Accepted date: 2017-01-16

Corresponding author: YI Mao-zhong; Tel: +86-731-88830894; E-mail: yimaozhong@126.com

(编辑 何学锋)

基金项目:国家重大工程项目(GFZX0101040101-2012C20X)

收稿日期:2016-07-26;修订日期:2017-01-16

通信作者:易茂中,教授,博士;电话:0731-88830894;E-mail:yimaozhong@126.com