文章编号:1004-0609(2016)-06-1272-09

炭/炭复合材料耐烧蚀W涂层

周 哲,葛毅成,汪 沅,龚洁明,易茂中

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:采用等离子喷涂技术成功在坯体密度为1.8 g/cm3 炭/炭复合材料上面制备厚度为1.2 mm与基体结合良好的较致密的W涂层的试样。利用氧乙炔焰分别测试其在30 s、60 s、90 s和120 s下的烧蚀性能。结果表明:试样的质量烧蚀率和线烧蚀率均随时间的增加而增加。其中,最大质量烧蚀率和线烧蚀率分别为7.8 μg/s和3.5 μm/s。XRD、SEM分析表明:在烧蚀中心区,涂层试样的烧蚀以升华分解为主,同时,还伴有氧化烧蚀和微区机械剥蚀;在烧蚀过渡区,涂层的烧蚀机制以热氧化和燃气冲刷为主;而在烧蚀边缘区,涂层的烧蚀则主要表现为弱氧化烧蚀。

关键词:大气等离子喷涂;耐烧蚀;W涂层;炭/炭复合材料

中图分类号:TB331 文献标志码:A

冲压发动机的性能直接决定对应飞行器的性能。其中,喉衬是发动机中烧蚀最严重的部位,需在无冷却条件下承受高温(>3000 ℃)、高速(>1000 m/s)固体粒子和气流的冲刷及剧烈温升(>2000 ℃/s)的恶劣环境[1-3]。因此,喉衬需要选择比热大、导热系数低、烧蚀速度小、密度低、在高温下保持稳定的物理和化学性能的材料[4-5]。目前,炭/炭复合材料以其低密度、高比强度、耐烧蚀和耐热冲击等性能优异已成为冲压发动机喷管喉衬的首选材料之一[6],但炭/炭复合材料在空气中400 ℃以上开始氧化[7],材料的结构稳定性被破坏,低抗氧化性限了炭/炭复合材料在高温下的应用[8]。因此,纯炭/炭复合材料难以长时间在非真空环境中承受高温、高速粒子流的冲刷。钨是早期的喉衬材料,目前采用类似钨渗Cu的工艺对炭/炭复合材料渗Cu制成含Cu炭/炭耐烧蚀涂层喉衬材料烧蚀率较纯炭/炭材料的成倍降低[9-10]。实验表明,SiC、ZrC、ZrB2、TaC和HfC等超高温陶瓷掺杂改性炭/炭复合材料可在保持其原有优异的高温力学性能前提下,显著提高炭/炭复合材料的高温抗氧化性和耐烧蚀性[11-14]。但其工艺相对复杂,周期长,且部分涂层氧化后的氧化物熔点低而不耐烧蚀。

W在所有金属中熔点最高(3410 ℃)、蒸汽压最低(1.3×10-7 Pa @ Tmelt)并且具有良好的热导率、高温强度和耐烧蚀性能[15-16]。另外,由于其原子量较大,W具有较高的物理溅射阈值、低溅射产额[17],曾是导弹发动机喉衬使用的主要材料,其耐烧蚀性高于纯炭/炭复合材料[18-19]。在目前的技术下,钨的成形制备是国际上公认的难题,传统的方法包括熔盐电镀法[20-21],爆炸喷涂法[22],化学气相沉积法(CVD)[23-24],自蔓延高温合成(SHS)[25-26]、粉末冶金(PM)[27-28],等离子喷涂法等。然而,熔盐电镀法中的所用的卤化物体系中都要加入毒性物质(KF),而且该体系一般要求进行严格的物质净化,过程复杂且较难控制,爆炸喷涂法设备噪音大(高达180 dB)和喷涂粉末污染等问题,在一定程度上限制了此方法的应用,CVD和SHS方法生产周期长、成形效率低。此外,钨加工脆性大、熔点高,对粉末冶金烧结设备要求高,生产成本昂贵,不宜大规模生产。因此,W涂层的制备迫切需要新的成形与加工手段。等离子喷涂技术因其喷射温度高达10000 ℃,喷射速度达300~400 m/s[29],集高温熔化、快速凝固和近净成形等优势于一体,已在钨及钨基难熔金属的成形方面得到应用。

吴子健等[30]、WANG等[31-32]和闵小兵等[33-34]采用等离子喷涂成形制备出了大尺寸难熔金属薄壁和复杂形状构件。因此,采用等离子喷涂技术在炭/炭材料表面制备合适厚度钨涂层可以保证材料整体质量增量小高温抗氧化性高,是提高冲压发动机喷管喉衬部耐烧蚀性能突破点[35-36]。本文作者采用等离子喷涂成形在炭/炭复合材料表层制备纯钨涂层并深入分析涂层烧蚀产物、烧蚀形貌及烧蚀机理。

1 实验

1.1 试样制备

以聚丙烯腈基炭纤维无纬布/炭毡混合叠层针刺毡为增强坯体,通过化学气相渗透(CVI)增密到1.8 g/cm3炭/炭复合坯体。实验等离子喷涂所用的钨粉为不规则的多角形颗粒,粒度为150~75 μm,纯度为99.95%(质量分数)。为防止喷涂过程中粉末堵塞送粉软管,需先将其置于干燥箱中100℃下干燥1 h。采用DH-1080型等离子喷涂设备(最大功率80 kW)进行等离子喷涂成形,喷涂系统参数如表1所列。

表1 W涂层等离子喷涂参数

1.2 耐烧蚀性能测试

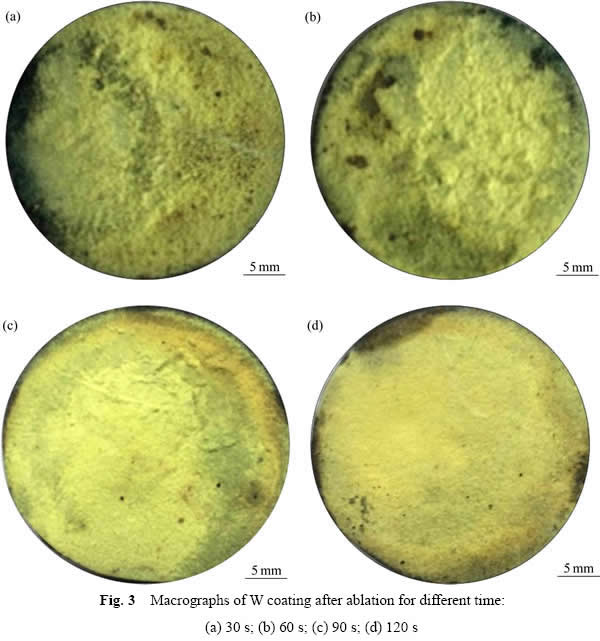

采用DR6130型氧乙炔焰烧蚀仪进行涂层的烧蚀性能测试。以氧乙炔焰为热源(火焰温度最高3500 ℃左右),样品放置于装有冷却系统的载物台上,烧蚀枪喷嘴直径为2 mm,试样初始表面距火焰喷嘴的距离为(10±0.2) mm,火焰烧蚀角度为90°。氧乙炔焰烧烛的实验条件见表2。

表2 氧乙炔烧性实验条件

采用比色高温计测量烧烛过程中氧乙块焰的最高温度。将涂层样品分别进行30~120 s烧蚀实验,烧蚀时间由控制系统精确控制。釆用精度为0.1 mg的AdventureTM电子天平称量试样烧蚀前后的重量;采用精度为0.01 mm的测厚仪测量样品烧蚀前后烧蚀中心的厚度变化。涂层试样的质量烧烛率(Rm)和线烧蚀率(Rd)可由式(1)和(2)分别计算。

(1)

(1)

(2)

(2)

其中:m1和m2分别为复合材料烧蚀前、后的质量,g;d1和d2分别为复合材料烧蚀前、后的厚度,mm;t是烧蚀时间,s。

采用JEOL JSM-6360LV型扫描电子显微镜观察等离子喷涂成形试样的显微形貌;采用D/ruax2550型X射线衍射仪(XRD)及能谱仪(EDS)分析试样的烧蚀产物,并分析等离子喷涂成形试样的烧蚀机理。

2 结果与讨论

2.1 涂层的组织形貌

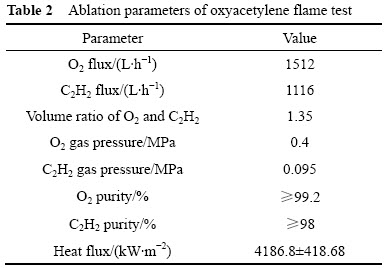

图1(a)所示为等离子喷涂成形炭/炭基W涂层的显微形貌,等离子喷涂沉积层为典型的层片组织结构,W颗粒的熔化铺展程度较好,相对平整,层片间结合处可见细小孔隙及纳米级尺寸缝隙。当高速熔融粒子碰撞到已形成的涂层表面时,由于基材表面粗糙及熔融粒子间结合不完全,涂层中不可避免存在孔隙。分析表明,涂层中产生孔隙的主要原因是:1)由于熔融液滴在基体或已形成的涂层表面的不完全填充、铺排;2)未完全熔化粒子不充分扁平化形成的边界处孔隙。产生小的孔隙和裂纹的原因是:1)冷却凝固过程扁平钨颗粒产生收缩;2)撞击过程有气体的卷入。另外,等离子喷涂成形时,位于等离子焰流外围的钨颗粒未能充分吸收热量,导致其仅表面熔化,碰撞到基体前几乎完全凝固,造成沉积层中出现细小且表面光滑的球形颗粒。

图1(b)所示为炭/炭基钨涂层横截面形貌。由图1(b)可见,涂层厚度为1.2 mm,较致密。涂层表面有孔隙,涂层内层孔隙较少,较致密。与基体结合面较平直。

图1(c)所示为涂层表面XRD谱。由图1(c)可见,该涂层中没有钨的氧化物。这说明等离子喷涂过程钨粉几乎完全没有发生氧化,对于所制备的涂层是有利的。当采用等离子喷涂金属时,由于空气的卷入,产生金属粒子的氧化,这些氧化物夹杂在所制备的金属涂层中,由于氧化物呈脆性且与母体金属的线膨胀系数差别较大,易造成涂层的脱离,影响涂层的力学性能。本实验采用等离子喷涂,涂层中几乎没有氧化物的存在,这是由于:1)粗颗粒钨粉,不易被氧化;2)喷涂采用的工作气体是氩气和氢气,氩气具有保护作用,而氢气则能防止钨粉氧化和将氧化物还原;3)喷涂过程基体保持较低的温度,沉积的粒子不易被氧化;4)氧化物含量少,难以检测。

图1 W涂层表面的SEM像、W涂层和基体截面SEM像以及W涂层表面的XRD谱

2.2 炭/炭基体及W涂层烧蚀后的结构与形貌

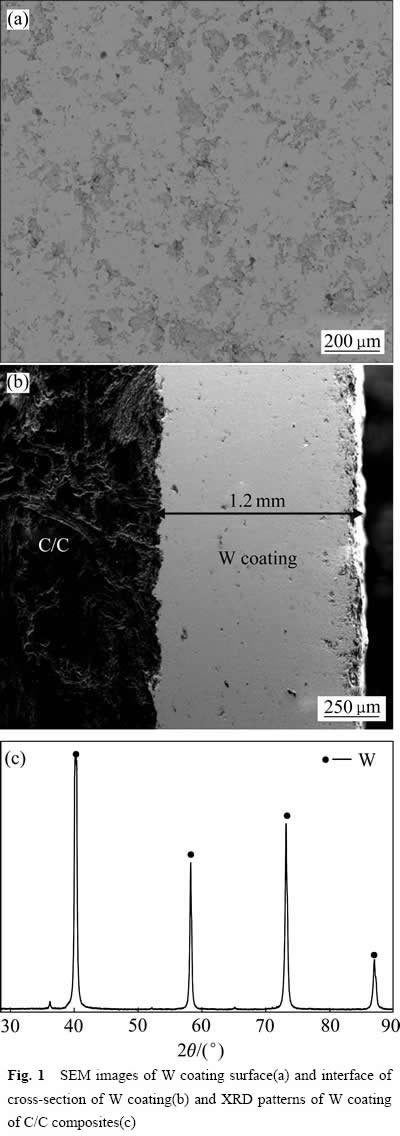

图2所示为相同测试条件下炭/炭复合材料烧烛30 s后的宏观照片。样品中心烧烛中心不明显,大多数为垂直于烧蚀火焰的纤维束,而平行于烧烛火焰的纤维束大量几乎被完全烧烛,炭/炭复合材料质量烧蚀率和线烧蚀率分别为4.6 μg/s和6.0 μm/s。

图2 炭/炭复合材料基体氧乙块焰烧独30 s后宏观形貌

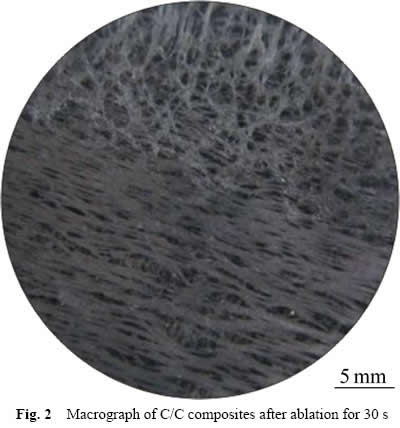

图3所示为不同时间炭/炭基W涂层烧蚀形貌宏观图片。由图3可见,烧蚀后表面较粗糙,4种不同烧蚀时间的样品表面都出现黄色疏松多孔的组织和剥蚀凹坑。通过SEM-EDS和XRD分析得知黄色疏松物质为WO3,该物质在1472 ℃时熔化,加热变橙黄色,1100℃升华,故而造成W涂层表面呈疏松多孔以及部分沟壑状的烧蚀形貌。炭/炭基钨涂层烧蚀时,钨、碳等发生氧化。疏松多孔的WO3不能有效隔离W与氧气的接触[37-38]。造成烧蚀时的质量损失主要是由于氧化产物CO、CO2的挥发,而WO3粉末被烧蚀气流冲刷走、熔化、升华。

由SEM-EDS分析可知产物中并没有发现WO2、WO2.72和WO2.90生成,证明燃气的氧化性气氛较强。由图3可见,随着烧蚀时间的增加,烧蚀时间从30 s到60 s时,涂层表面黄色疏松多孔WO3增加;烧蚀时间为90 s和120 s时,烧蚀涂层表面相对60 s减少,这可能是由于长时间烧蚀焰的冲击导致黄色疏松多孔WO3剥落,而且在烧蚀台上有少量黄色WO3。涂层表面还可以观察到WO3由烧蚀中心向边缘呈现先增加后减少的趋势,这一规律在图3(b)较为明显。

图3 W涂层烧蚀不同时间后的宏观图片

2.3 炭/炭基体W涂层烧蚀氧化过程热力学分析

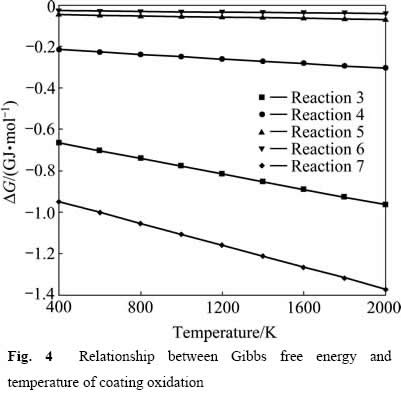

钨的氧化物中比较稳定的有4种:黄色WO3、蓝色WO2.90、紫色WO2.72和褐色WO2。氧乙炔烧蚀过程中W氧化过程中的相关反应及对应的吉布斯自由能变化分别为:

W(s)+O2(g)=WO2(s) (3)

WO2(s)+0.36O2(g)=WO2.72(s) (4)

WO2.72(s)+0.1O2(g)=WO2.90(s) (5)

WO2.90(s)+0.05O2(g)=WO3(s) (6)

W(s)+1.5O2(g)=WO3(s) (7)

为了进一步了解W涂层在氧乙炔焰烧蚀过程中氧化行为,根据文献[39]提供的热力学数据,对以上的反应进行热力学计算并作图。便得到氧化过程中各反应的吉布斯自由能随温度关系如图4所示。由图4可知,当温度在400~2000 K时,氧化过程中各反应发生趋势由大到小依次为式(7)、式(3)、式(4)、式(5)、式(6)。以上氧化过程中吉布斯自由能变化ΔG均小于0,表明反映均能自发进行。比较各组元的热力学计算结果可知,在相同的温度下,W和O2直接生成WO3具有最低的吉布斯自由能,也说明WO3更能够稳定存在。

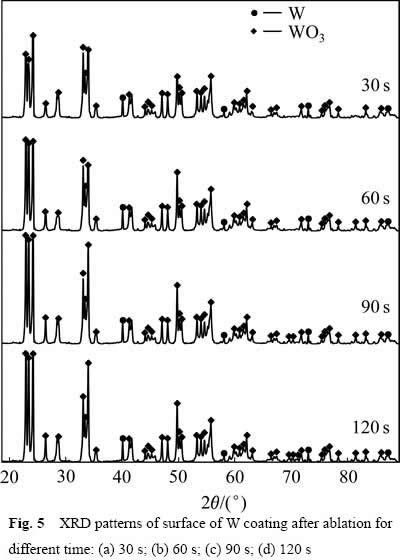

图5所示为炭/炭基W涂层烧蚀不同时间后表面的XTD谱。由图5可以看出,炭/炭基W涂层在不同时间烧蚀后都有WO3生成。XRD和SEM-ESD结果都表明:烧蚀后涂层表面都没有WO2、WO2.72和WO2.90。而涂层表面W并未完全氧化成WO3。

炭/炭基W涂层烧蚀不同时间的烧蚀结果如表3所列。结果表明:随着时间的延长,炭/炭基W涂层的质量烧蚀率和线烧蚀率均有增加。

图4 涂层氧化过程中相关反应自由能变化与温度的关系

图5 烧蚀不同时间后W涂层烧蚀表面XRD谱

当烧蚀时间从30 s延长到60 s时,材料的质量烧蚀率增加15.4%,线烧蚀率增加11.1%;当烧蚀时间由60 s增加到90 s时,质量烧蚀率增加16.1%,线烧蚀率增加10%;当烧蚀时间由90 s增加到120 s时,质量烧蚀率增加8.3%,线烧蚀率增加6.1%。结果表明,在120 s氧乙炔烧蚀过程中,涂层表面质量较好,未被破坏。烧蚀增率呈现先增加后减小,逐步趋于平稳的趋势,而线烧蚀增率呈现稳步减少趋势,总的来说,随着烧蚀时间的延长,炭/炭基W涂层的烧蚀率增大。

表3 炭/炭基W涂层烧蚀不同时间的烧蚀性能

图6所示为炭/炭基W涂层烧蚀不同时间的显微形貌。由图6(a)可见,烧蚀后表面存在大量粒径为2 μm左右的块状颗粒,颗粒之间有大的孔隙,也有球状物质。通过SEM-EDS和XRD分析得知,块状颗粒和球状物质都是WO3。从图6(b)看出,表面粗糙、杂乱,存在大量粒径为5 um左右颗粒,呈现山川起伏状的烧蚀形貌,并有数量较多、尺寸较大的孔洞存在。由图6(c)可见,颗粒尺寸进一步增大,并且在大颗粒上面有细小颗粒生成,这应是在晶粒形核的过程中又发生了再结晶。从图6(d)可见,部分WO3为不规则颗粒,再结晶颗粒尺寸增大。由此可知,随着烧蚀时间的增加,WO3颗粒发生形核和长大和再结晶,颗粒形貌都呈不规则形状生长。

2.4 炭/炭基W涂层复合材料烧蚀机理

图7所示为炭/炭基复合材料在氧乙炔焰下烧蚀示意图。烧蚀后的炭/炭基W涂层表面可以分为3个区域:烧蚀中心区、烧蚀中心与边缘过渡区、边缘区(分别对应图7的区域C、T、R),不同区域的烧蚀情况存在很大差异。

炭/炭复合材料距离火焰最近的烧蚀中心区烧蚀一般最为严重,此区域的火焰温度及流速最高,因此,涂层的烧蚀主要由W的氧化和WO3的升华(分解)为主,同时还伴有微区机械剥蚀,相对其他区域而言,此区域内涂层的烧蚀损耗最大,因此,涂层的烧蚀率也最大,涂层表面形成了烧蚀凹坑。从3(d)图中可以看到烧蚀坑,其SEM-EDS分析可知这些颗粒为WO3,该物质在高温发生氧化和升华现象,对应为图7所示C区为烧蚀中心。在烧蚀中心区,炭/炭基W涂层的烧蚀机制主要为升华、氧化和机械冲刷。

图7中T区为炭/炭基W涂层烧蚀中心与边缘的过渡区微观烧蚀形貌。与烧蚀中心区域相比,烧蚀过渡区的火焰温度和流速有所降低,涂层的烧蚀相对减弱。在烧蚀中心与边缘的过渡区,炭/炭基W涂层的烧蚀机制为氧化和以对疏松孔状WO3和基体炭的机械冲刷为主。

图6 炭/炭基W涂层烧蚀不同时间的SEM像

图7 W涂层烧蚀过程示意图

图7中R区域为炭/炭基W涂层烧蚀边缘区的微观烧蚀形貌。SEM-EDS分析可知,涂层表面相为WO3颗粒,其形貌较为规则,颗粒之间有细小的裂纹,但没有明显的冲击和剥蚀现象,这主要是此区远离火焰中心,受温度及压力梯度影响,此区域内火焰温度及流速明显降低,气流的冲刷最小,这些颗粒才大量地保存下来。在烧蚀边缘区,炭/炭基W涂层的烧蚀机制主要是W涂层的氧化烧蚀。

3 结论

1) 采用大气等离子喷涂技术在炭/炭复合材料表面制备出厚度为1.2 mm较致密的W涂层,对基体起到了较好的防护作用,氧乙炔烧蚀涂层120 s后,涂层稳定性仍然较好,烧蚀坑不明显。

2) 烧蚀120 s内,时间对炭/炭基W涂层的烧蚀性能影响不大,随烧蚀时间的延长,其质量烧蚀率和线烧蚀率平稳缓慢增加。

3) 在氧乙炔火焰烧蚀下,炭/炭基W涂层的烧蚀机制是氧化烧蚀、热物理烧蚀和微区机械剥蚀的综合作用,且炭/炭基W涂层不同区域的烧蚀机制有明显不同。

REFERENCES

[1] 宋桂明. 固体火箭发动机喉衬材料[J]. 固体火箭技术, 1998, 21(2): 51-55.

SONG Gui-ming. Throat materials for solid rocket motors[J]. Journal of Solid Rocket Technology, 1998, 21(2): 51-55.

[2] 陈 博, 张立同, 成来飞, 栾新刚. 3D C/SiC复合材料喷管在小型固体火箭发动机中的烧蚀规律研究[J]. 无机材料学报, 2008, 23(5): 938-944.

CHEN Bo, ZHANG Li-tong, CHENG Lai-fei, LUAN Xin-gang. Ablation characteristic of 3D C/SiC composite nozzle in a small solid rocket motor[J]. Journal of Inorganic Materials, 2008, 23(5): 938-944.

[3] 陈 剑, 魏祥庚, 李 江, 何国强. 固体火箭发动机长尾喷管烧蚀实验研究[J]. 固体火箭技术, 2010(1): 34-35.

CHEN Jian, WEI Xiang-geng, LI Jiang, HE Guo-qiang. Ablation test for tailpipe nozzle of solid rocket motor[J]. Journal of Solid Rocket Technology, 2010(1): 34-35.

[4] LI Ke-zhi, SHEN Xue-tao, LI He-jun, ZHANG Shou-yang, FENG Tao, ZHANG Lei-lei. Ablation of the carbon/carbon composite nozzle-throats in a small solid rocket motor[J]. Carbon, 2011, 49(4): 1208-1215.

[5] JACKSON T A, EKLUND D R, FINK A J. High speed propulsion: Performance advantage of advanced materials[J]. Journal of Materials Science, 2004, 39(19): 5905-5913.

[6] 于 澍,刘根山,李溪滨, 熊 翔. 炭/炭复合材料导热系数影响因素的研究[J]. 稀有金属材料与工程, 2003, 32(3): 213-215.

YU Shu, LIU Gen-shan, LI Xi-bin, XIONG Xiang. The main factors on heat conductivity for carbon-carbon composites[J]. Rare Metal Materials and Engineering, 2003, 32(3): 213-215.

[7] WARREN A, NYLUND A, OLEFJORD I. Oxidation of tungsten and tungsten carbide in dry and humid atmospheres[J]. International Journal of Refractory Metals and Hard Materials, 1996, 14(5): 345-353.

[8] JACOBSON N S, CURRY D M. Oxidation microstructure studies of reinforced carbon/carbon[J]. Carbon, 2006, 44: 1142-1150

[9] 易振华, 易茂中, 冉丽萍, 杨 琳. 添加钛对炭/炭复合材料渗铜的影响[J]. 中国有色金属学报, 2006, 16(7): 1214-1218.

YI Zhen-hua, YI Mao-zhong, RAN Li-ping, YANG Lin. Influence of adding Ti on molten copper infiltration into C/C composites[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(7): 1214-1218.

[10] 冉丽萍, 李文军, 杨 琳, 易茂中. C/C-Cu复合材料的烧蚀性能及烧蚀机理[J]. 中国有色金属学报, 2010, 20(3): 510-515.

RAN Li-ping, LI Wen-jun, YANG Lin, YI Mao-zhong. Ablation properties and ablation mechanism of C/C-Cu composites[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3): 510-515.

[11] MA J Q, XU Y D, ZHANG L T, CHENG L F, NIE J J, DONG N. Microstructure characterization and tensile behavior of 2.5 DC/SiC composites fabricated by chemical vapor infiltration[J]. Scripta Materialia, 2006, 54(11): 1967-1971.

[12] ZHAO D, ZHANG C R, HU H F, ZHANG Y D. Ablation behavior and mechanism of 3D C/ZrC composite in oxyacetylene torch environment[J]. Composites Science and Technology, 2011, 71(11): 1392-1396.

[13] WANG D N, ZENG Y, XIONG X, LI G D, CHEN Z K, SUN W, WANG Y L. Ablation behavior of ZrB2-SiC protective coating for carbon/carbon composites[J]. Ceramics International, 2015, 41(6): 7677-7686.

[14] PIENTI L, SCITI D, SILVESTRONI L, CECERE A, SAVINO R. Ablation tests on HfC-and TaC-based ceramics for aero propulsive applications[J]. Journal of the European Ceramic Society, 2015, 35(5): 1401-1411.

[15] DAVIS J W, BARABASH V R, MAKHANKOV A, PL?CHL L, SLATTERY K T. Assessment of tungsten for use in the ITER plasma facing components[J]. Journal of Nuclear Materials, 1998, 258: 308-312.

[16] PHILIPPS V. Tungsten as material for plasma-facing components in fusion devices[J]. Journal of Nuclear Materials, 2011, 415: S2-S9.

[17] CONN R W, DOERNER R P, WON J. Beryllium as the plasma-facing material in fusion energy systems-experiments, evaluation, and comparison with alternative materials[J]. Fusion Engineering and Design, 1997, 37(4): 481-513.

[18] TOKUNAGA K, YOSHIDA N, NODA N, SOGABE T, KATO T. High heat load properties of tungsten coated carbon materials[J]. Journal of Nuclear Materials, 1998, 258: 998-1004.

[19] SONG G M, WANG Y J, ZHOU Y. Elevated temperature ablation resistance and thermophysical properties of tungsten matrix composites reinforced with ZrC particles[J]. Journal of Materials Science, 2001, 36(19): 4625-4631.

[20] KOJI N, SHINJI I, KAZUNORI O, HIRONORI N, TOSHIYUKI N, RIKA H. Analysis of tungsten film electrodeposited from a ZnCl2-NaCl-KCl melt[J]. Electrochimica Acta, 2007, 53: 20-23.

[21] HIRONORI N, TOSHIYUKI N, RIKA H, KOJI N, SHINJI I, KAZUNORI O. Electrodeposition of metallic tungsten films in ZnCl2-NaCl-KCl-KF-WO3 melt at 250 ℃[J]. Electrochimica Acta, 2007, 53(1): 24-27.

[22] 卢国辉, 潘振鹏. 美国与乌克兰爆炸喷涂装置的结构与特点[J]. 新技术新工艺, 2000(5): 35-36.

LU Guo-hui, PAN Zhen-peng. The structure and characteristic of detonation gun spraying device in America and Ukraine[J]. New Technology & New Process, 2000(5): 35-36.

[23] MARIANO E, GERARDO H R, MORENO M S, SILVIA G, ROBERTO C. Influence of tungsten on the carbon nanotubes growth by CVD process[J]. Journal of Alloys and Compounds, 2009, 479(1/2): 440-444.

[24] 马 捷, 毕安国, 王从曾, 周美玲. 化学气相沉积制备钼钨合金[J]. 真空科学与技术学报, 2005, 25(3): 229-232.

MA Jie, BI An-guo, WANG Cong-zeng, ZHOU Mei-ling. Preparation of Mo-W alloy by chemical vapor deposition[J]. Journal of Vacuum Science and Technology, 2005, 25(3): 229-232.

[25] 许剑光, 张厚安, 张光业, 颜建辉. 自蔓延高温合成制备二硅化钼基材料的研究进展[J]. 材料导报, 2007, 21(4): 69-72.

XU Jian-guang, ZHANG Hou-an, ZHANG Guang-ye, YAN Jian-hui. Progress in the self-propagating high temperature synthesis of MoSi2-based materials[J]. Materials Review, 2007, 21(4): 69-72.

[26] KUMAR S, KRUTH J P. Composites by rapid prototyping technology[J]. Materials and Design, 2010, 31(2): 850-856.

[27] VOLKER P, BERTHOLD Z, PRACHAI N, ROBERT R, AXEL V W, JUERGEN H. Development of a powder metallurgy process for tungsten components[J]. Fusion Engineering and Design, 2008, 83(10/12): 1517-1520.

[28] LUO T G, QU X H, QIN M L, OUYANG M L. Dimension precision of metal injection molded pure tungsten[J]. International Journal of Refractory Metals and Hard Materials, 2009, 27(3): 615-620.

[29] KAZUYUKI I, MAKOTO K, TOYONOBU Y. Growth of tin oxide thick films by plasma spray physical vapor deposition[J]. Sensors and Actuators B: Chemical, 2011, 2(3): 156-163.

[30] 吴子健, 张虎寅, 堵新心, 吕艳红. 大直径钨管发热体等离子体喷涂成形制造技术[J]. 粉末冶金工业, 2005, 15(5): 1-4.

WU Zi-jian, ZHANG Hu-yin, DU Xin-xin, L? Yan-hong. Plasma sparying manufacturing technique for heating objection of tungsten tubular[J]. Powder Metallurgy Industry, 2005, 15(5): 1-4.

[31] WANG Yue-ming, XIONG Xiang, MIN Xiao-bing, XIE Lu, ZHENG Feng. Nearnetshape 95W3.5Ni1.5Fe thinwalled products produced by plasma spray forming[J]. Materials Science and Engineering A, 2010, 527(21/22): 5782-5789.

[32] WANG Yue-ming, XIONG Xiang, MIN Xiao-bing, YAO Ping-ping. Near-net-shape refractory metal products produced by plasma spray forming[C]// PM2010 Powder Metallurgy World Congress Proceedings. Florence, Italy: European Powder Metallurgy Association, 2010: 617-625.

[33] 闵小兵, 王跃明, 夏光明, 严淑群, 卢 静. 一种新型难熔金属异型件的制备技术及其应用[J]. 粉末冶金技术, 2010, 28(4): 297-301.

MIN Xiao-bing, WANG Yue-ming, XIA Guang-min, YAN Shu-qun, LU Jing. Preparation and applications of a new heterotypical refractory metal part[J]. Powder Metallurgy Technology, 2010, 28(4): 297-301.

[34] 徐 玄, 王跃明, 熊翔, 解 路, 闵小兵. 等离子喷涂成形钨喉衬的烧蚀性能[J]. 中国有色金属学报, 2011, 21(6): 1435-1443.

XU Xuan, WANG Yue-ming, XIONG Xiang, XIE Lu, MIN Xiao-bing. Ablation property of tungsten nozzle produced by plasma spray forming[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(6): 1435-1443.

[35] 葛毅成, 彭 可, 杨 琳, 冉丽萍, 易茂中, 李文军, 彭 芬. C/C-Cu复合材料表面等离子喷涂钨涂层[J]. 粉末冶金材料科学与工程, 2010, 15(2): 136-140.

GE Yi-cheng, PENG Ke, YANG Lin, RAN Li-ping, YI Mao-zhong, LI Wen-jun, PENG Fen. Coating tungsten on C/C-Cu composites surface by plasma spraying[J]. Materials Science and Engineering of Powder Metallurgy, 2010, 15(2): 136-140.

[36] 葛毅成, 刘艾平, 杨 琳, 雷宝灵, 易茂中. 热处理对 C/C-Cu复合材料钨涂层结构和烧蚀性能的影响[J]. 粉末冶金材料科学与工程, 2011, 16(2): 309-314.

GE Yi-cheng, LIU Ai-ping, YANG Lin, LEI Bao-ling, YI Mao-zhong. Effect of heat-treatment on structure of tungsten coating and ablation properties of C/C-Cu composites[J]. Materials Science and Engineering of Powder Metallurgy, 2011, 16(2): 309-314

[37] 宋桂明, 孟庆昌. TiC和ZrC颗粒增强钨基合材料的烧蚀研究[J]. 固体火箭技术, 2001, 24(2): 48-53.

SONG Gui-ming, MENG Qing-chang. Ablation of tungsten matrix composites reinforced by TiC and ZrC particles[J]. Journal of Solid Rocket Technology, 2001, 24(2): 48-53.

[38] 宋桂明, 王玉金. ZrCp/W 复合材料的烧蚀性能[J]. 稀有金属材料与工程, 2001, 30(2): 101-104.

SONG Gui-ming, WANG Yu-jin. Ablation properties of ZrCp/W composites[J]. Rare Metal Materials and Engineering, 2001, 30(2): 101-104.

[39] 叶大伦, 胡建华. 实用无机热力学数据手册[M]. 北京: 冶金工业出版社, 2002.

YE Da-lun, HU Jian-hua. Handle of applied inorganic thermodynamic data[M]. Beijing: Metallurgical Industry Press, 2002.

Ablation performances of carbon/carbon composites with W coatings

ZHOU Zhe, GE Yi-cheng, WANG Yuan, GONG Jie-ming, YI Mao-zhong

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: Compact tungsten coatings with thickness of 1.2 mm were successfully deposited by the atmosphere plasma spraying technique on carbon/carbon composites with the density of about 1.8 g/cm3. W coating ablation resistances were studied by using oxyacetylene flame for 30 s, 60 s, 90 s and 120 s. The results show that both the mass ablation rate and linear ablation rate increase with the ablation time prolonging. The maximum mass ablation rate and linear ablation rate are 7.8 μg/s and 3.5 μm/s, respectively. The phase compositions and microstructures of the composites before and after ablation were examined by XRD and SEM. In the ablation center, the ablation mechanism of the coated sample is sublimation and decomposition, combined with thermo-oxidation and mechanical denudation. In the transitional field, the ablation mechanism of the coating is controlled by thermo-oxidation and scouring. And in the ablation rim, the coating exhibits slight oxidation behavior.

Key words: air plasma spray; ablation resistance; W coating; carbon/carbon composite

Foundation item: Project(GFZX0101040101-2012C20X) supported by Major National Construction Project

Received date: 2015-09-07; Accepted date: 2016-01-15

Corresponding author: YI Mao-zhong; Tel: +86-731-88830894; E-mail: yimaozhong@126.com

(编辑 王 超)

基金项目:国家重大工程项目(GFZX0101040101-2012C20X)

收稿日期:2015-09-07;修订日期:2016-01-15

通信作者:易茂中,教授,博士;电话:0731-88830894;E-mail: yimaozhong@126.com