反应熔渗法制备耐烧蚀陶瓷改性C/C复合材料的研究进展

来源期刊:中南大学学报(自然科学版)2020年第11期

论文作者:郝振华 侯旭初 舒永春 何季麟

文章页码:3032 - 3044

关键词:C/C-陶瓷复合材料;反应熔渗法;基体改性;耐烧蚀性能

Key words:C/C-ceramic composite; reactive melt infiltration; matrix modification; ablation resistance

摘 要:根据熔渗体系组成分类介绍RMI改性C/C复合材料的研究进展,探讨影响RMI改性C/C复合材料的因素和过程强化手段,最后提出RMI改性C/C复合材料亟待解决的主要问题和相应的解决思路,并对RMI改性C/C复合材料未来的发展趋势进行展望。研究结果表明:基体改性技术中反应熔渗是提升C/C复合材料耐烧蚀性能的有效手段,多元素熔渗体系如Si-Mo-Zr和Zr-Si-Al等改性C/C复合材料具有耐烧蚀性能优良、陶瓷相分布均匀、致密度高等特点。应通过不断调节多元素熔渗体系及熔渗元素比例对RMI工艺进行优化,用低成本高性能的C/C复合材料改性技术来突破RMI工艺产业化的限制。

Abstract: The recent development of the RMI process was introduced according to composition of infiltrant system. The main process parameters affecting RMI were discussed as well as process enhancement of RMI. The summary of unsettled issues was put forward, and the potential future directions in RMI was suggested. The results show that in the matrix modification technology, reactive infiltration is an effective means to improve the ablation resistance of C/C composites. The multi-element infiltration systems such as Si-Mo-Zr, Zr-Si-Al and other modified C/C composite materials have the characteristics of excellent ablation resistance, uniform ceramic phase distribution, and high density. RMI process should be optimized by continuously adjusting the multi-element infiltration system and the proportion of infiltration elements, so as to break through the industrialization limit of RMI process with low-cost and high-performance C/C composite modification technology.

DOI: 10.11817/j.issn.1672-7207.2020.11.004

侯旭初1, 2,郝振华1, 2,舒永春1, 2,何季麟1, 2

(1. 郑州大学 河南省资源与材料工业技术研究院,河南 郑州,450001;

2. 郑州大学 材料科学与工程学院,河南 郑州,450001)

摘要:根据熔渗体系组成分类介绍RMI改性C/C复合材料的研究进展,探讨影响RMI改性C/C复合材料的因素和过程强化手段,最后提出RMI改性C/C复合材料亟待解决的主要问题和相应的解决思路,并对RMI改性C/C复合材料未来的发展趋势进行展望。研究结果表明:基体改性技术中反应熔渗是提升C/C复合材料耐烧蚀性能的有效手段,多元素熔渗体系如Si-Mo-Zr和Zr-Si-Al等改性C/C复合材料具有耐烧蚀性能优良、陶瓷相分布均匀、致密度高等特点。应通过不断调节多元素熔渗体系及熔渗元素比例对RMI工艺进行优化,用低成本高性能的C/C复合材料改性技术来突破RMI工艺产业化的限制。

关键词:C/C-陶瓷复合材料;反应熔渗法;基体改性;耐烧蚀性能

中图分类号:TB332 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2020)11-3032-12

HOU Xuchu1, 2, HAO Zhenhua1, 2, SHU Yongchun1, 2, HE Jilin1, 2

(1. Henan Province Industrial Technology Research Institute of Resources and Materials, Zhengzhou University, Zhengzhou 450001, China;

2. School of Materials Science and Engineering, Zhengzhou University, Zhengzhou 450001, China)

Abstract: The recent development of the RMI process was introduced according to composition of infiltrant system. The main process parameters affecting RMI were discussed as well as process enhancement of RMI. The summary of unsettled issues was put forward, and the potential future directions in RMI was suggested. The results show that in the matrix modification technology, reactive infiltration is an effective means to improve the ablation resistance of C/C composites. The multi-element infiltration systems such as Si-Mo-Zr, Zr-Si-Al and other modified C/C composite materials have the characteristics of excellent ablation resistance, uniform ceramic phase distribution, and high density. RMI process should be optimized by continuously adjusting the multi-element infiltration system and the proportion of infiltration elements, so as to break through the industrialization limit of RMI process with low-cost and high-performance C/C composite modification technology.

Key words: C/C-ceramic composite; reactive melt infiltration; matrix modification; ablation resistance

C/C复合材料因具有低密度、高热导率、低热膨胀系数以及良好的高温力学性能等优点而广泛应用于飞机刹车片、高铁刹车片、火箭发动机喷管、高速飞行器的鼻锥端和翼前缘部分以及再入弹头等部件[1-4]。然而,C/C复合材料在温度达到773 K以上时急剧氧化,难以承受苛刻服役条件下的剧烈烧蚀,严重制约了其进一步广泛使用[5]。为了解决这一难题,通常采用引入高温性能优良的碳化物、硼化物以及硅化物等陶瓷相的办法提高C/C复合材料的高温耐烧蚀性能。根据陶瓷相在C/C材料中引入位置的不同,可以将C/C复合材料的改性方法分为表面涂层技术和基体改性2种。由于C/C复合材料热膨胀系数较小,表面涂层技术所制备涂层与基体之间的热膨胀系数差异较大,因此,C/C复合材料在高温段受热时,陶瓷涂层容易发生开裂、剥落,产生氧扩散通道,难以有效地保护基体材料[6]。与表面涂层技术相比,基体改性使复合材料自身具备较好的抗氧化性能,是一种更为彻底的改性方法[7]。

目前,C/C复合材料基体改性的方法主要包括反应熔渗法(reactive melt infiltration,RMI)[8]、液相浸渍法(liquid-phase impregnation,LPI)[9]、前驱体浸渍—裂解法(polymer infiltration and pyrolysis,PIP)[10]及化学气相渗透法(chemical vapor infiltration,CVI)[11]等。其中,RMI利用毛细管力将熔融的金属或合金渗入多孔C/C预制体内并通过反应生成陶瓷改性C/C复合材料,具有工艺周期短、效率高、成本低、可实现近净成形等优点,此外,RMI制备的改性材料密度高、孔隙率低[12],因而被认为是最具前景的高温耐烧蚀陶瓷改性C/C复合材料工业化制备技术。本文根据近年来RMI改性C/C复合材料的国内外相关报道,对RMI改性C/C复合材料的研究进展进行了综述,并探讨RMI改性C/C复合材料的影响因素、过程强化和亟待解决的主要问题,此外,还对RMI改性C/C复合材料未来的发展趋势进行展望。

1 RMI改性C/C复合材料的进展

RMI起源于反应烧结SiC材料,20世纪80年代,德国材料科学家FIRZER采用此方法将熔融Si渗入C/C预制体中,制备了C/C-SiC复合材料,并发展成为RMI工艺[13]。此后,越来越多的科研工作者不断深入研究C/C复合材料的RMI改性,从最初的单元素熔渗剂熔渗,发展到Si-Mo,Zr-Si和Zr-Cu等二元熔渗体系熔渗,再从二元熔渗体系基础上开发出的多元熔渗体系熔渗。通过采用不同的熔渗剂对C/C复合材料进行基体改性,可以使其满足不同服役条件下的使用要求。

1.1 单元素熔渗剂RMI改性C/C复合材料

C/C复合材料在高温氧化气氛中,烧蚀性能差,严重影响材料的正常使用,采用RMI工艺对C/C复合材料改性,可以有效提高C/C复合材料的耐烧蚀性能。单元素熔渗剂RMI改性由于其熔渗剂成分单一,改性后材料的化学稳定性好而被广泛应用。单元素熔渗剂RMI改性C/C复合材料中的陶瓷相均为单一碳化物陶瓷,其中熔渗剂使用最多的是Si和Zr,所对应的陶瓷相分别为SiC和ZrC。国内研究锆、硅熔渗改性C/C复合材料的机构主要有中南大学[14]、西北工业大学[15]、北京化工大学[16]等。Si是最早使用的RMI改性C/C复合材料熔渗剂,其制备所得SiC改性的C/C复合材料具有良好的抗氧化能力。SiC改性C/C复合材料中的SiC高温下和氧气反应形成的致密SiO2层在1 700 ℃以下时具有较强的氧扩散阻挡能力,可以有效提高C/C复合材料的抗氧化性能,因此,采用单一硅元素熔渗改性得到的C/C复合材料广泛应用于航空航天器的高温结构件[17-19]。在国内,中南大学研发的C/C-SiC在制动摩擦领域处于领先地位并且已经在战略装备上投入使用,然而,SiC改性的C/C复合材料的高温耐烧蚀性能较差,当烧蚀温度过高时,容易发生剪切断裂,引起基体失效、界面脱粘[20]。

由于SiC在高温条件下对材料保护能力有限,众多学者开始利用RMI工艺将高温性能更加优异的过渡金属碳化物(如ZrC,HfC,TaC和NbC等)引入C/C复合材料之中以提高其高温耐烧蚀性能。其中,ZrC因其高熔点、耐烧蚀性能优良而成为研究的焦点[21-23]。如ZHAO等[24]采用Zr作为熔渗剂对C/C复合材料进行RMI改性,改性后基体外表面形成的多孔ZrC层在高温烧蚀过程中形成的致密ZrO2层对基体具有较好的保护作用。

根据Zr-C相图可知,当C原子数分数为38.5%时,Zr和C即可反应生成ZrC,WANG等[25]研究了RMI改性C/C-ZrC复合材料,发现由于Zr改性C/C复合材料所需温度较高,加速C的扩散,促进C与Zr发生反应,检测发现C/C-ZrC复合材料中不存在残余Zr,烧蚀结果表明,C/C-ZrC烧蚀速率较低、耐烧蚀性能优异。然而,C/C-ZrC外部的ZrC层存在大量孔洞及裂缝,当烧蚀温度较低时,ZrO2熔点高难以熔化填补缺陷,这些缺陷便作为氧扩散通道,基体在烧蚀过程中难以受到有效保护[26-31]。此外,Zr的熔点为1 870 ℃,采用单一Zr元素熔渗所需熔渗温度较高,而熔渗温度过高会对基体中的碳纤维造成严重损害,导致材料机械性能降低。

综上所述,采用单元素熔渗改性C/C复合材料往往存在一定的缺陷。其中单一Si元素RMI改性材料中存在残余Si并且在高温环境中耐烧蚀性较差,而单一Zr元素熔渗改性材料的表面孔隙率高,在低温环境中耐烧蚀性较差。

1.2 二元熔渗体系RMI改性C/C复合材料

为了解决单一熔渗体系改性C/C复合材料中存在的不足,国内外学者进行了大量的探索,研究发现,向单元素熔渗剂中有针对性的加入其他特定元素能够有效解决单元素熔渗过程中所存在的相应问题,如二元熔渗体系中研究较多的Si-Mo[32],Zr-Si[33-36]和Zr-Cu[37]体系,旨在解决单一硅RMI改性过程中存在的残余Si及单一锆RMI改性致密度差及所需温度过高等问题。二元熔渗体系改性C/C复合材料中陶瓷相大多是二元相,密度为2.0~2.4 g/cm3,与单元素RMI改性C/C复合材料相比,密度较高,材料更加致密,耐烧蚀性能更好。此外,Si-Ti[38],Si-Hf[39],Zr-Ti[40]和Si-Fe[41]等其他二元熔渗体系也具有一定的优势。

1) Si-Mo体系。Si-Mo体系不仅解决了单一Si熔渗过程中存在残余硅的问题,同时,Si-Mo反应所生成的MoSi2也具有优异的高温性能。侯党社等[42]研究了Si-Mo相对含量对RMI改性C/C复合材料SiC-MoSi2耐烧蚀性能的影响,发现SiC-MoSi2具有比单一SiC或MoSi2更优良的耐烧蚀性能,并且当熔渗剂中硅钼质量比为6:1时,改性材料的耐烧蚀性能最佳。虽然采用Si-Mo体系熔渗解决了熔渗过程中存在残余Si的问题,但Si-Mo体系熔渗所需温度过高,熔渗过程中会损伤基体,造成材料力学性能下降。

2) Zr-Si体系。Zr-Si二元熔渗体系同时解决了单一Si元素熔渗改性材料高温烧蚀性能不佳和单一Zr元素熔渗改性材料烧蚀过程中ZrO2层不够致密的问题。ZHOU等[43-44]利用Zr-Si-C混合粉末作为熔渗剂改性C/C复合材料得到C/C-SiC-ZrC,在烧蚀过程中,SiO2层部分蒸发,带走大量热,同时,由于SiO2具有良好的流动性,熔融SiO2填补材料表面孔洞、裂纹等缺陷,而高熔点的ZrO2层则增强材料的高温耐烧蚀性能,Zr-Si二元熔渗体系熔渗与基体反应所生成的ZrC、SiC相在烧蚀过程中具有一定的协同效应。

3) Zr-Cu体系。Zr-Cu合金熔点显著低于纯Zr,最低为886 ℃,可以解决单一Zr元素熔渗温度过高这一难题。HAO等[37]利用Zr2Cu锭作为熔渗剂改性C/C复合材料,Zr-Cu体系改性C/C复合材料与单一Zr元素改性C/C复合材料类似,改性材料的耐烧蚀性能均依赖于表面的ZrO2层,但Zr-Cu体系改性材料中存在残余的Cu相,在烧蚀过程中,Cu相挥发对材料具有冷却的作用,从而使Zr-Cu改性C/C复合材料的耐烧蚀性能更优异。

虽然二元熔渗体系改性C/C复合材料的性能比单元素RMI改性C/C复合材料有一定提升,但仍然存在如Si-Mo体系熔渗所需温度较高等难以解决的问题[41]。

1.3 多元熔渗体系RMI改性C/C复合材料

为了解决二元熔渗体系中存在的难题,国内外研究者们尝试在二元熔渗体系的基础上加入第3种或是更多元素构成多元熔渗体系对C/C复合材料进行RMI改性,如解决了单一硅熔渗中存在残余硅问题的Si-Mo二元熔渗体系,由于Mo的熔点约2 000 ℃,Si-Mo体系熔渗所需高温会导致改性后材料力学性能下降,研究发现,在Si-Mo体系的基础上加入Ti,Zr和Al可以使C/C复合材料RMI改性在较低温度下进行。多元熔渗体系解决了二元熔渗体系改性C/C复合材料过程中存在的问题,并且改性后C/C复合材料耐烧蚀性能更好。

1.3.1 Si-Mo-X(X=Ti, Zr, Al)体系

Si-Mo-X体系主要是为了解决Si-Mo体系熔渗温度较高以及生成的MoSi2相存“pesting”效应的问题。HAO等[45-47]采用Si-Mo-Ti混合粉熔渗到多孔C/C复合材料中制备了梯度C/C-XSi2-SiC(X=Mo, Ti)复合材料。梯度C/C-XSi2-SiC(X=Mo,Ti)中含Ti陶瓷相分布在远离碳纤维束的位置,含Ti陶瓷相可以有效降低烧蚀速率,增强基体的耐烧蚀性能。在此基础上,进一步采用Mo-Si-Ti-Al混合粉熔渗多孔C/C复合材料得到了C/MoSi2-SiC-C基复合材料,经分析发现,含Al陶瓷相通常分布在碳纤维束附近,在Si-Mo-Ti体系中加入Al后,复合材料致密度提高,耐烧蚀性能增强。不难看出,Si-Mo体系中加入Al和Ti不仅可以降低Si-Mo体系改性C/C复合材料的熔渗温度[48-49],减缓碳纤维高温受损,同时,还可以有效提高基体的致密度和耐烧蚀性能。

1.3.2 Zr-Si-X(X=Al、Cr)体系

Zr-Si-X体系可以进一步提高Zr-Si改性复合材料的密度,以提升其烧蚀性能。如CHANG等[50-51]将Al8Cr5渗入梯度C/C-ZrC-SiC复合材料,得到高度致密的Al/Cr-C/C-ZrC-SiC复合材料,其中无明显的孔洞及裂纹,解决了Zr-Si体系改性后,材料致密度低的问题。此外,对Al/Cr-C/C-ZrC-SiC进行烧蚀测试发现其烧蚀速率极低,表明熔渗体系中加入Al/Cr可以有效提高改性后C/C复合材料的耐烧蚀性能。杜善义院士团队制备的Zr-Si-B改性C/C复合材料已通过全温域验证及大量的风洞试验,在保持结构完整的前提下,实现零烧蚀,在抗氧化及耐温性能方面超过国外公开报道的最好水平,支撑国内高端战略装备的发展。

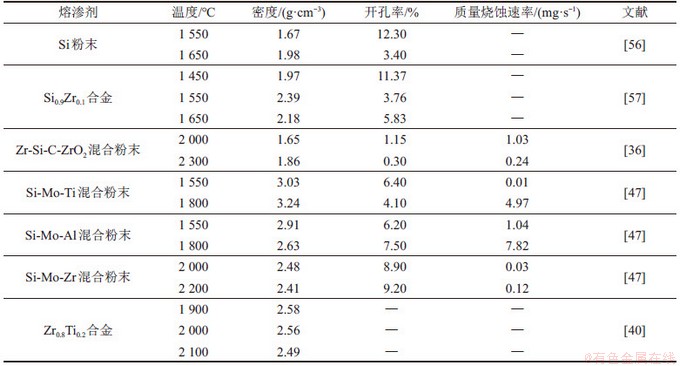

表1所示为部分多元熔渗体系RMI改性C/C复合材料的氧乙炔焰烧蚀性能情况[47-49, 52]。从表1可以看出,多元熔渗改性C/C复合材料与二元熔渗改性C/C复合材料相比,密度明显提高、生成的陶瓷相更复杂。图1所示为部分单元素熔渗剂、二元熔渗体系和多元熔渗体系改性C/C复合材料的耐烧蚀性能。从图1可以看出,单元素熔渗剂RMI改性C/C复合材料烧蚀速率较高,而采用Zr-Si和Si-Mo等双元素体系熔渗改性C/C复合材料质量烧蚀速率明显降低。采用多元熔渗体系改性其耐烧蚀性能进一步提高,尤其是Al/Cr-C/C-ZrC-SiC在2 500 ℃使用氧乙炔焰烧蚀仪烧蚀200 s后,其质量烧蚀速率仅为0.02 mg/s,线烧蚀速率为0.25 μm/s。显然,随着熔渗体系组分的增多,改性C/C复合材料中的陶瓷相也更为复杂,其耐烧蚀性能也更为优异,这主要得益于其烧蚀过程中存在的多重化学反应和熔化挥发行为可以有效降低烧蚀面温度和缓解热应力。

表1 各类多元熔渗体系RMI改性C/C复合材料的氧乙炔焰烧蚀性能

Table 1 Oxyacetylene flame properties of RMI modified C/C composites of various multi-element infiltration systems

图1 C/C-陶瓷复合材料的烧蚀性能

Fig. 1 Ablation properties of C/C-ceramic composites

2 RMI改性C/C复合材料的影响因素

RMI改性C/C复合材料的整个过程包括熔渗剂熔化、熔渗剂渗入基体和熔渗剂与基体反应生成陶瓷相等过程,影响这3个过程的因素都是RMI改性C/C复合材料整体过程的影响因素,主要包括熔渗温度、熔渗时间、基体碳种类、碳纤维编织方式、预制体密度和熔渗剂状态等。

2.1 熔渗温度

熔渗温度是影响RMI过程最重要因素,熔渗温度必须保证熔渗剂可以充分熔化,同时熔渗温度还直接影响熔体的流动性和表面张力等,进而影响熔体的渗入过程,熔体渗入基体孔径中的深度可用式(1)表示[53-55]:

其中:h为熔渗深度;C为常数;

表2 不同熔渗温度对各类RMI改性C/C复合材料氧乙炔焰烧蚀性能的影响

Table 2 Effect of different infiltration temperatures on the ablation performance of various RMI modified C/C composites by oxyacetylene flame

2.2 熔渗时间

从式(1)还可以看出,当熔渗温度和初始毛细半径不变时,熔渗深度随熔渗时间的增加而增加。此外,熔渗剂渗入多孔C/C复合材料的深度可以表示为:

其中:

由式(2)和式(3)可以看出,熔渗速率随着时间的增加而逐渐减缓,孔英杰等[57]对不同的熔渗时间所得Zr-Si合金RMI改性C/C复合材料性能的对比研究也证实了这一点,研究结果表明:随着熔渗时间延长,C/C-SiC-ZrC的密度随之越大,开孔率也随之越低,同时密度增大的趋势逐渐放缓。由此可见,RMI过程需要一定的熔渗时间保证熔渗剂完全渗入基体并且完成反应过程,适当延长熔渗时间能够使改性后的材料更加致密,然而,当时间过长时其对致密度的提升作用并不明显,但会造成基体碳纤维受损,引起材料力学性能下降。

2.3 碳纤维编织方式

不同编织方式的碳纤维预制体中基体碳含量、分布以及孔隙结构不同,因而经过RMI改性后得到的C/C复合材料中陶瓷相的分布存在差异。ZENG等[40, 58]探究了具有相同密度、不同碳纤维编织结构的细编穿刺(fine-weave pierced preform,FWPP)、整体针刺(Needle-integratedPreform,NIP)、短纤维层针刺(chopped web needled preform, CWNP)结构Zr-Ti-C改性C/C复合材料耐烧蚀性能的差别,结果表明:FWPP和NIP结构的改性C/C复合材料烧蚀性能较差,而具有CWNP结构的C/C复合材料改性后耐烧蚀性能优异。ZENG等[58]同时还给出了抗烧蚀性能和多孔C/C结构之间的关系式:

其中:

由式(4)和式(5)可以看出,

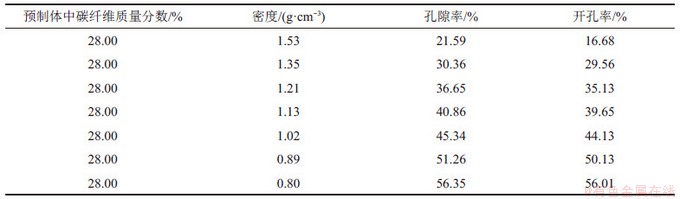

2.4 多孔C/C复合材料密度

多孔C/C复合材料的密度反映其孔隙率,进而引起改性C/C复合材料中的陶瓷相含量不同,对具有相同碳纤维含量而密度不同的C/C预制体进行RMI改性的C/C复合材料的致密度如表3所示。由表3可见:发现具有相同碳纤维含量的预制体的密度越小,则闭孔越少,开孔率越高[59],而开孔率高有利于熔渗剂浸入,改性后材料的致密度越高,耐烧蚀性能更好。

表3 预制体密度对RMI改性C/C复合材料致密度的影响

Table 3 Influence of preform density on densityofRMI modified C/C composite

2.5 熔渗剂状态

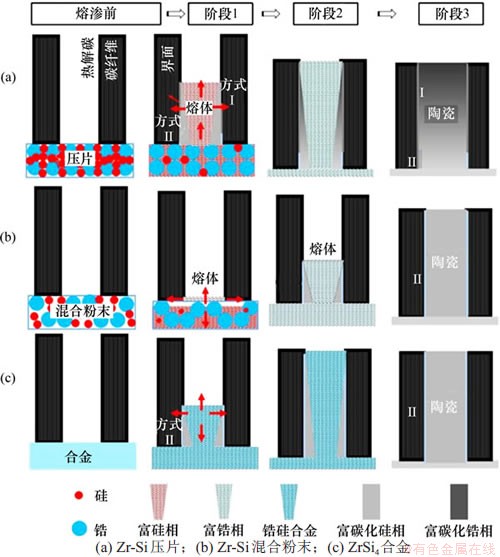

不同物理状态的熔渗剂在RMI过程中,其熔化及渗入基体的行为截然不同。CHANG等[50]研究了Zr-Si混合粉末、Zr-Si合金和Zr-Si压块3种不同状态熔渗剂改性C/C复合材料的结构和性能差异,图2所示为3种熔渗剂的熔渗模型,当使用Zr-Si混合粉末及Zr-Si合金作为熔渗剂时,改性C/C复合材料具有均匀的微观结构,由于Zr-Si压块改性C/C复合材料是由低熔点Si先熔渗并与基体反应生成SiC,随后高熔点Zr在熔池中向SiC含量的方向不断渗入,最终形成致密的梯度微观结构。由以上研究可以看出,熔渗剂状态影响C/C复合材料的熔渗过程,使用不同状态的熔渗剂其改性材料中陶瓷相分布不同,导致改性C/C复合材料的耐烧蚀性能存在差异。

图2 3种熔渗途径的渗入模型示意图[50]

Fig. 2 Schematic diagrams of infiltration model for three infiltration pathways[50]

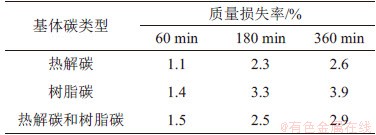

2.6 基体碳种类

C/C复合材料基体碳主要采用树脂碳和热解碳,其中树脂碳基体存在很多微小的孔隙,易于熔体渗入进行反应,而热解炭基体则较为致密。JIANG等[56]通过实验分析发现熔融硅和树脂碳基体、热解碳基体反应行为差异较大:熔融Si可以与树脂碳基体反应生成厚度为2~7 μm的SiC层,然而,熔融Si仅能热解碳的最外层反应,所得SiC层较薄并且维持热解碳的原始形态。冉丽萍等[60-62]研究了不同类型基体碳的多孔C/C复合材料经SiC熔渗改性后在1 200 ℃氧化时的质量损失率,结果如表4所示,由表4可以看出:热解碳基体的C/C复合材料经SiC改性耐烧蚀性能更优。

综合以上研究可知,虽然树脂碳更容易和熔体反应,但是热解碳与熔体反应更充分,所形成的碳化物陶瓷包覆基体较为完整,因而热解碳基体的改性C/C复合材料耐烧蚀性能往往更好。

表4 1 200°C不同碳基体制备SiC改性C/C复合材料的氧乙炔焰烧蚀性能

Table 4 Oxyacetylene ablation properties of SiC modified C/C composites prepared with different carbon substrates at 1 200°C overtime

3 熔盐/微波辅助RMI制备C/C复合材料

RMI改性C/C复合材料往往需要较高的反应温度,在制备过程中容易损伤基体中的碳纤维,造成复合材料的力学性能下降。此外,尽管RMI在C/C复合材料基体改性中的工艺时间最短,但是,RMI过程使用电炉加热至熔渗温度仍需要较长时间,而采用特殊手段对RMI过程进行强化可以有效促进反应进行,其中主要包括熔盐辅助和微波辅助2种。

3.1 熔盐辅助

氯化盐的熔点通常比RMI所用熔渗剂的低,因此能够在较低温度形成连续的液相,提高熔渗剂的迁移速率,从而促进反应的进行。例如,XU等[63]研究了4种不同的氯化物熔盐添加对Si-Zr合金RMI改性C/C复合材料过程的影响,结果表明,在RMI过程中氯化物熔盐可以作为熔渗剂载体,促进反应进行,尤其是CaCl2还提可以高熔渗剂流动性,进一步提高改性C/C复合材料致密度。

3.2 微波辅助

微波辅助作为一种非接触式加热手段,在提高熔渗体系升温速率,缩短烧结时间,降低成本的同时,能够在基体内部产生由基体中心到表面的反向温度梯度,反向温度梯度的存在促进熔渗剂渗入基体,此外,微波辅助对反应具有一定的催化作用。BIANCHI等[64]在微波辅助条件下进行RMI渗硅,有效缩短了反应时间,降低了反应能耗,并且所得改性复合材料的性能和常规RMI改性材料基本相当。

传统RMI改性C/C复合材料熔渗过程,熔渗剂主要通过基体表面的开孔渗入基体,而微波辅助RMI改性C/C复合材料过程中,微波场增加了熔渗反应的有效活性点,从而使得改性材料更加致密,耐烧蚀性能更好。

4 RMI改性C/C复合材料技术发展趋势

RMI法制备陶瓷改性C/C复合材料具有成本低、周期短、可实现近净成形等优点,已经证实RMI是一种有效提高C/C复合材料抗烧蚀性能的基体改性工艺。然而,随着航天航空技术的不断发展,其对热防护结构材料的要求也不断提升,RMI法改性C/C复合材料不断面临新的挑战,目前存在的问题以及解决思路主要如下。

1) RMI工艺需要金属以熔体形式渗入多孔C/C复合材料内部,通常需要在高温下进行。在高温熔渗条件下,熔体在与碳基体反应的同时也会和碳纤维反应,对碳纤维造成一定损伤,导致材料力学性能下降。此外,高温熔渗对设备要求也较高,导致工业化生产受限。因此,通过控制熔渗体系组分和熔渗过程强化等手段实现低温反应熔渗,是RMI工艺亟待解决的重点问题。

2) 多孔C/C复合材料基体碳和碳纤维都有可能与熔渗剂反应,并且多元熔渗体系在熔渗过程中会形成副产物等原因,目前还难以通过调控熔渗剂添加量实现陶瓷相含量的精确控制。因此,通过对C/C复合材料孔隙率、反应温度和反应时间等参数的调控,实现陶瓷改性C/C复合材料中陶瓷相含量的精准控制,是RMI工艺需要解决的难点问题之一。

3) 多孔C/C复合材料中孔隙结构呈复杂化特征,熔体在基体不同部位的渗入必然存在一定差异。尤其是多组元熔渗体系的RMI过程,各组元之间的熔化、扩散和反应行为之间更是存在一定差异,陶瓷改性C/C复合材料的中陶瓷相分布难以控制,服役过程易产生局部缺陷。因此,通过多孔C/C复合材料孔隙结构的设计等实现陶瓷相的分布的精确控制,也是RMI工艺未来需要解决的难点问题。

5 结论

1) 热防护材料是世界各国军工领域研究的重点及难点,其中多元熔渗体系RMI改性C/C复合材料能够在材料表面形成连续致密的氧化层并降低反应温度,能够满足材料在超高温环境中短时间耐烧蚀的要求,但随着高端战略装备对热防护系统的要求越来越高,仍需要对超高温耐烧蚀C/C复合材料进行更多的研究才能实现C/C复合材料长时间全温域耐烧蚀的目标。

2) 从单元素熔渗体系到多元熔渗体系,RMI工艺历经四十余年的发展,显现出大量的研究成果,然而,目前的研究仍集中在熔渗体系的扩展和单一因素对熔渗效果的影响,尚未形成完整的理论体系。未来应通过系统性研究建立完整的理论体系,实现RMI过程的低温化和改性C/C复合材料中陶瓷相含量和分布控制的精确化,为RMI工艺的推广和应用提供理论基础。

3) RMI工艺的产业化仍存在相当大的局限性,主要原因是熔渗所需温度较高、陶瓷相含量和分布难以精确控制与产业化工艺成本之间的矛盾,低成本的单元素及双元素体系熔渗改性C/C复合材料所需熔渗温度高,导致改性后材料综合性能下降,而实现碳基体中陶瓷相分散均匀的RMI工艺成本过高。故未来应不断探索更好的多元素熔渗体系及熔渗元素比例,并对RMI工艺进行优化,用低成本高性能的C/C复合材料改性技术来突破RMI工艺产业化的限制。

参考文献:

[1] WINDHORST T, BLOUNT G. Carbon-carbon composites: a summary of recent developments and applications[J]. Materials & Design, 1997, 18(1): 11-15.

[2] FITZER E. The future of carbon-carbon composites[J]. Carbon, 1987, 25(2): 163-190.

[3] 姚栋嘉, 李贺军, 张守阳, 等. C/C复合材料SiC涂层强冲蚀环境的烧蚀性能研究[J]. 中国材料进展, 2015, 34(7): 610-614.

YAO Dongjia, LI Hejun, ZHANG Shouyang, et al. Anti-ablation property of Si C coating on C/C composites at high speed[J]. Materials China, 2015, 34(7): 610-614.

[4] CHRISTIN F. Design, fabrication, and application of thermostructural composites (TSC) like C/C, C/SiC, and SiC/SiC composites[J]. Advanced Engineering Materials, 2002, 4(12): 903-912.

[5] DONG Zhijun, YUAN Guanming, LI Xuanke, et al. Influence of infiltration temperature on the microstructure and oxidation behavior of SiC-ZrC ceramic coating on C/C composites prepared by reactive melt infiltration[J]. Ceramics International, 2015, 41(1): 797-811.

[6] 弭群, 曹丽云, 黄剑锋, 等. 碳/碳复合材料基体抗氧化改性研究进展[J]. 兵器材料科学与工程, 2010, 33(2): 98-103.

MI Qun, CAO Liyun, HUANG Jianfeng, et al. Research progress in matrix oxidation-resistance modification of carbon/carbon composites[J]. Ordnance Material Science and Engineering, 2010, 33(2): 98-103.

[7] 付前刚, 李贺军, 沈学涛, 等. 国内C/C复合材料基体改性研究进展[J]. 中国材料进展, 2011, 30(11): 6-12, 39.

FU Qiangang, LI Hejun, SHEN Xuetao, et al. Domestic research process of matrix modification for carbon/carbon composites[J]. Materials China, 2011, 30(11): 6-12, 39.

[8] LIU Lei, ZHANG Leilei, FENG Wei, et al. Microstructure and properties of C/C-SiC composites prepared by reactive melt infiltration at low temperature in vacuum[J]. Ceramics International, 2020, 46(6): 8469-8472.

[9] RODRIGUEZ-MIRASOL J, THROWER P A, RADOVIC L R. On the oxidation resistance of C/C composites obtained by liquid-phase impregnation/ carbonization of different carbon cloths[J]. Carbon, 1993, 31(5): 789-799.

[10] HUANG Dong, ZHANG Mingyu, HUANG Qizhong, et al. Mechanical property, oxidation and ablation resistance of C/C-ZrB2-ZrC-SiC composite fabricated by polymer infiltration and pyrolysis with preform of Cf/ZrB2[J]. Journal of Materials Science & Technology, 2017, 33(5): 481-486.

[11] NASLAIN R R. Processing of non-oxide ceramic matrix composites: an overview[J]. Advances in Science and Technology, 2006, 50: 64-74.

[12] 王林山, 熊翔, 肖鹏, 等. 反应熔渗法制备C/C-SiC复合材料及其影响因素的研究进展[J]. 粉末冶金技术, 2003, 21(1): 37-41.

WANG Linshan, XIONG Xiang, XIAO Peng, et al. Factors affecting properties of C/C-SiC composites prepared by reactive melt infiltration[J]. Powder Metallurgy Technology, 2003, 21(1): 37-41.

[13] HILLIG W B. Making ceramic composites by melt infiltration[J]. American Ceramic Society Bulletin, 1994, 73(4): 56-62.

[14] 但奇善, 孙威, 熊翔, 等. 反应熔渗法制备C/C-ZrC复合材料的微观结构及烧蚀性能[J]. 粉末冶金材料科学与工程, 2013, 18(3): 403-408.

DAN Qishan, SUN Wei, XIONG Xiang, et al. Microstructure and ablation property of C/C-ZrC composites manufactured by reactive melt infiltration[J]. Materials Science and Engineering of Powder Metallurgy, 2013, 18(3): 403-408.

[15] 黄沛宇, 徐永东, 范尚武, 等. 浸渗时间对C/C-SiC复合材料显微结构和力学性能的影响[J]. 固体火箭技术, 2009, 32(1): 103-108.

HUANG Peiyu, XU Yongdong, FAN Shangwu, et al. Effect of infiltration time on microstructure and mechanical properties of C/C-SiC composites[J]. Journal of Solid Rocket Technology, 2009, 32(1): 103-108.

[16] 尹立, 赵东林, 沈曾民. RMI法制备三维针刺c/c-SiC复合材料的组织结构演变研究[C]// 第七届中国功能材料及其应用学术会议论文集. 长沙, 2010: 32-35.

YIN Li, ZHAO Donglin, SHEN Zengmin. Research on the evolution of microstructure of three-dimensional needle punched C/C-SiCcomposites prepared by RMI method[C]// Proceedings of the Seventh Chinese Conference on Functional Materials and Applications. Changsha, 2010: 32-35.

[17] PADTURE N P. Advanced structural ceramics in aerospace propulsion[J]. Nature Materials, 2016, 15(8): 804-809.

[18] LIU Lei, LI Hejun, FENG Wei, et al. Ablation in different heat fluxes of C/C composites modified by ZrB2-ZrC and ZrB2-ZrC-SiC particles[J]. Corrosion Science, 2013, 74: 159-167.

[19] CHEN H M, XIANG Y, WANG S, et al. Thermodynamic assessment of the C-Si-Zr system[J]. Journal of Alloys and Compounds, 2009, 474(1/2): 76-80.

[20] 曹晓雨, 张程煜, 殷小玮, 等. C/C-SiC复合材料的制备及其层间剪切强度分析[J]. 热加工工艺, 2012, 41(12): 87-90.

CAO Xiaoyu, ZHANG Chengyu, YIN Xiaowei, et al. Preparation and analysis of interlaminar shear strength of C/C-SiC composite[J]. Hot Working Technology, 2012, 41(12): 87-90.

[21] SRIKANTH I, PADMAVATHI N, KUMAR S, et al. Mechanical, thermal and ablative properties of zirconia, CNT modified carbon/phenolic composites[J]. Composites Science and Technology, 2013, 80: 1-7.

[22] 高晓晴, 郭全贵, 史景利, 等. 短切炭纤维-炭复合材料的制备及传导性能和微观结构的研究[J]. 新型炭材料, 2005, 20(1): 18-22.

GAO Xiaoqing, GUO Quangui, SHI Jingli, et al. The fabrication of chopped carbon fiber-carbon composites and their thermal/electrical conductivity and microstructure[J]. New Carbon Materials, 2005, 20(1): 18-22.

[23] GUO Weiming, ZHOU Xiaojun, ZHANG Guojun, et al. Effect of Si addition on hot-pressed ZrB2-SiC composite with polycarbosilane as a precursor[J]. Materials Letters, 2008, 62(21/22): 3724-3726.

[24] ZHAO Liyou, JIA Dechang, DUAN Xiaoming, et al. Oxidation of ZrC-30 vol% SiC composite in air from low to ultrahigh temperature[J]. Journal of the European Ceramic Society, 2012, 32(4): 947-954.

[25] WANG Yiguang, ZHU Xiaojuan, ZHANG Litong, et al. Reaction kinetics and ablation properties of C/C-ZrC composites fabricated by reactive melt infiltration[J]. Ceramics International, 2011, 37(4): 1277-1283.

[26] VOITOVICH R F, PUGACH E A. High-temperature oxidation of ZrC and HfC[J]. Soviet Powder Metallurgy and Metal Ceramics, 1973, 12(2): 145-148.

[27] SHIMADA S, NISHISAKO M, INAGAKI M, et al. Formation and microstructure of carbon-containing oxide scales by oxidation of single crystals of zirconium carbide[J]. Journal of the American Ceramic Society, 1995, 78(1): 41-48.

[28] SHIMADA S, YOSHIMATSU M, INAGAKI M, et al. Formation and characterization of carbon at the ZrCZrO2 interface by oxidation of ZrC single crystals[J]. Carbon, 1998, 36(7/8): 1125-1131.

[29] SHIMADA S, INAGAKI M, SUZUKI M. Microstructural observation of the ZrC/ZrO2 interface formed by oxidation of ZrC[J]. Journal of Materials Research, 1996, 11(10): 2594-2597.

[30] SHIMADA S. Interfacial reaction on oxidation of carbides with formation of carbon[J]. Solid State Ionics, 2001, 141/142: 99-104.

[31] SHIMADA S. Microstructural observation of ZrO2 scales formed by oxidation of ZrC single crystals with formation of carbon[J]. Solid State Ionics, 1997, 101/102/103: 749-753.

[32] SINGH M, BEHRENDT D R. Reactive melt infiltration of silicon-molybdenum alloys into microporous carbon preforms[J]. Materials Science and Engineering: A, 1995, 194(2): 193-200.

[33] 房啸, 苏哲安, 黄启忠, 等. 2种C/C材料高温熔渗制备 C/C-SiC-ZrC复合材料的力学性能[J]. 粉末冶金材料科学与工程, 2013, 18(6): 899-905.

FANG Xiao, SU Zhe'an, HUANG Qizhong, et al. Mechanical properties of C/C-SiC-ZrC composites prepared by reactive melt infiltration using two kinds of C/C materials[J]. Materials Science and Engineering of Powder Metallurgy, 2013, 18(6): 899-905.

[34] WANG Yiguang, ZHU Xiaojuan, ZHANG Litong, et al. C/C-SiC-ZrC composites fabricated by reactive melt infiltration with Si0.87Zr0.13 alloy[J]. Ceramics International, 2012, 38(5): 4337-4343.

[35] TONG Yonggang, BAI Shuxin, ZHANG Hong, et al. C/C-SiC composite prepared by Si-10Zr alloyed melt infiltration[J]. Ceramics International, 2012, 38(4): 3301-3307.

[36] LI Zhaoqian, LI Hejun, ZHANG Shouyang, et al. Effect of reaction melt infiltration temperature on the ablation properties of 2D C/C-SiC-ZrC composites[J]. Corrosion Science, 2012, 58: 12-19.

[37] HAO Zhenhua, SUN Wei, XIONG Xiang. Comparison of ablative behaviour for ZrC and ZrC-Cu doped carbon/carbon composites in oxyacetylene torch environment[J]. Materials Research Innovations, 2014, 18(Supp4): S4-711-S4-714.

[38] YIN Xiaowei, HE Shanshan, ZHANG Litong, et al. Fabrication and characterization of a carbon fibre reinforced carbon-silicon carbide-titanium silicon carbide hybrid matrix composite[J]. Materials Science and Engineering: A, 2010, 527(3): 835-841.

[39] ZHANG Peng. C/C-SiC-HfC composite prepared by alloyed reactive melt infiltration[J]. 材料科学与工程学报, 2015, 33(2): 173-177.

ZHANG Peng. C/C-SiC-HfC composite prepared by alloyed reactive melt infiltration[J]. Journal of Materials Science and Engineering, 2015, 33(2): 173-177.

[40] ZENG Yi, XIONG Xiang, WANG Dini, et al. Infiltration mechanism and factors influencing carbon/carbon-Zr-Ti-C composites prepared by liquid metal infiltration[J]. Journal of Materials Processing Technology, 2014, 214(12): 3150-3157.

[41] FAN Shangwu, NING Yifan, MA Xu, et al. Microstructure and mechanical properties of Fe-Si alloy modified C/C-SiC composites[J]. Ceramics International, 2019, 45(17): 21579-21589.

[42] 侯党社, 李克智, 李贺军, 等. 硅钼含量对C/C复合材料SiC-MoSi2涂层结构和高温抗氧化性能的影响[J]. 固体火箭技术, 2008, 31(3): 283-287.

HOU Dangshe, LI Kezhi, LI Hejun, et al. Effect of Si/Mo ratio on microstructure and high-temperature antioxidation property of SiC-MoSi2 coating for carbon/carbon composites[J]. Journal of Solid Rocket Technology, 2008, 31(3): 283-287.

[43] ZHOU Zhe, SUN Zexu, GE Yicheng, et al. Microstructure and ablation performance of SiC-ZrC coated C/C composites prepared by reactive melt infiltration[J]. Ceramics International, 2018, 44(7): 8314-8321.

[44] CHEN Si'an, DE LI Guan, HU Haifeng, et al. Microstructure and properties of ablative C/ZrC-SiC composites prepared by reactive melt infiltration of zirconium and vapour silicon infiltration[J]. Ceramics International, 2017, 43(3): 3439-3442.

[45] HAO Zhenhua, SUN Wei, XIONG Xiang, et al. Microstructure and ablation properties of a gradient Cf/C-XSi2-SiC(X=Mo, Ti) composite fabricated by reactive melt infiltration[J]. Journal of the European Ceramic Society, 2016, 36(15): 3775-3782.

[46] HAO Zhenhua, SUN Wei, XIONG Xiang, et al. Effects of Ti/Al addition on the microstructures and ablation properties of Cf/C-MoSi2-SiC composites[J]. Journal of the European Ceramic Society, 2016, 36(3): 457-464.

[47] HAO Zhenhua, SUN Wei, XIONG Xiang, et al. Comparison of microstructure and ablation behavior of Si-Mo-Ti/Al/Zr infiltrated C/C composites prepared at different infiltration temperature[J]. Ceramics International, 2017, 43(2): 2765-2773.

[48] ESFEHANIAN M, GUNSTER J, MOZTARZADEH F, et al. Development of a high temperature Cf/XSi2-SiC(X=Mo, Ti) composite via reactive melt infiltration[J]. Journal of the European Ceramic Society, 2007, 27(2/3): 1229-1235.

[49] ESFEHANIAN M, GUENSTER J, HEINRICH J G, et al. High-temperature mechanical behavior of carbon-silicide-carbide composites developed by alloyed melt infiltration[J]. Journal of the European Ceramic Society, 2008, 28(6): 1267-1274.

[50] CHANG Yabin, SUN Wei, XIONG Xiang, et al. Microstructure and ablation behaviors of a novel gradient C/C-ZrC-SiC composite fabricated by an improved reactive melt infiltration[J]. Ceramics International, 2016, 42(15): 16906-16915.

[51] CHANG Yabin, SUN Wei, XIONG Xiang, et al. A novel design of Al-Cr alloy surface sealing for ablation resistant C/C-ZrC-SiC composite[J]. Journal of the European Ceramic Society, 2017, 37(2): 859-864.

[52] CHEN Yuntian, SUN Wei, XIONG Xiang, et al. Microstructure, thermophysical properties, and ablation resistance of C/HfC-ZrC-SiC composites[J]. Ceramics International, 2019, 45(4): 4685-4691.

[53] YANG J, ILEGBUSI O J. Kinetics of silicon-metal alloy infiltration into porous carbon[J]. Composites Part A: Applied Science and Manufacturing, 2000, 31(6): 617-625.

[54] WASHBURN E W. The dynamics of capillary flow[J]. Physical Review, 1921, 17(3): 273-283.

[55] RHIM W K, OHSAKA K. Thermophysical properties measurement of molten silicon by high-temperature electrostatic levitator: density, volume expansion, specific heat capacity, emissivity, surface tension and viscosity[J]. Journal of Crystal Growth, 2000, 208(1/2/3/4): 313-321.

[56] JIANG Sizhou, XIONG Xiang, CHEN Zhaoke, et al. Influence factors of C/C-SiC dual matrix composites prepared by reactive melt infiltration[J]. Materials & Design, 2009, 30(9): 3738-3742.

[57] 孔英杰, 于新民, 裴雨辰. 熔渗温度和时间对C/C-SiC-ZrC复合材料性能的影响研究[J]. 装备环境工程, 2016, 13(3): 88-92.

KONG Yingjie, YU Xinmin, PEI Yuchen. Effects of infiltration temperature and time on the properties of C/C-SiC-ZrC composites fabricated by RMI[J]. Equipment Environmental Engineering, 2016, 13(3): 88-92.

[58] ZENG Yi, XIONG Xiang, LI Guodong, et al. Effect of fiber architecture and density on the ablation behavior of carbon/carbon composites modified by Zr-Ti-C[J]. Carbon, 2013, 63: 92-100.

[59] TONG Y G, BAI S X, ZHANG H, et al. Effect of C/C preform density on microstructure and mechanical properties of C/C-SiC composites prepared by alloyed reactive melt infiltration[J]. Materials Science and Technology, 2012, 28(12): 1505-1512.

[60] 冉丽萍, 刘亦奇, 杨琳, 等. 基体炭对反应熔渗法制备的 C/C-SiC复合材料性能的影响[J]. 粉末冶金材料科学与工程, 2011, 16(3): 374-378.

RAN Liping, LIU Yiqi, YANG Lin, et al. Effect of matrix carbon on properties of C/C-SiC composites fabricated by RMI[J]. Materials Science and Engineering of Powder Metallurgy, 2011, 16(3): 374-378.

[61] 冉丽萍, 易茂中, 陈斌. C/C坯体对RMI C/C-SiC复合材料组织的影响[J]. 中国有色金属学报, 2005, 15(8): 1208-1213.

RAN Liping, YI Maozhong, CHEN Bin. Influence of different C/C performs on microstructure of C/C-SiC composites fabricated by RMI[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(8): 1208-1213.

[62] 冉丽萍, 易茂中, 王朝胜, 等. 添加Al对MSI制备C/C-SiC复合材料组织和力学性能的影响[J]. 复合材料学报, 2006, 23(5): 34-38.

RAN Liping, YI Maozhong, WANG Chaosheng, et al. Influence of adding Al on the microstructure and mechanical properties of C/C-SiC composites fabricated by MSI[J]. Acta Materiae Compositae Sinica, 2006, 23(5): 34-38.

[63] XU Yonglong, SUN Wei, XIONG Xiang, et al. Chloride salt assisted reactive molten infiltration method for Cf-UHTCs and their unique microstructure[J]. Ceramics International, 2020, 46(5): 6424-6435.

[64] BIANCHI G, VAVASSORI P, VILA B, et al. Reactive silicon infiltration of carbon bonded preforms embedded in powder field modifiers heated by microwaves[J]. Ceramics International, 2015, 41(9): 12439-12446.

(编辑 赵俊)

收稿日期: 2020 -06 -20; 修回日期: 2020 -09 -14

基金项目(Foundation item):中国博士后基金面上资助项目(2020M672270);国家自然科学基金资助项目(51804277);中国工程科技发展战略河南研究院重大咨询项目(201903ZDA01);郑州市协同创新重大专项(XKZDJC201903) (Project(2020M672270) supported by Postdoctoral Research Foundation of China; Project(51804277) supported by the National Natural Science Foundation of China; Project(201903ZDA01) supported by Henan Research Institute of China Engineering Science and Technology Development Strategy; Project(XKZDJC201903) supported by Zhengzhou Collaborative Innovation Major Project)

通信作者:郝振华,博士,副教授,硕士生导师,从事陶瓷材料和陶瓷基复合材料研究;E-mail: zh_hao@zzu.edu.cn