DOI: 10.11817/j.issn.1672-7207.2020.11.018

银基复合材料真空电接触特性

周元子1, 2,李利1,朱林林1,张可墨1,张强1, 2

(1. 北京控制工程研究所,北京,100094;

2. 精密转动和传动机构长寿命技术北京市重点实验室,北京,100094)

摘要:为获得卫星太阳电池阵功率滑环的载流摩擦学性能,通过模拟真实工况试验测试采用粉末冶金工艺制备的Ag-Cu-MoS2复合材料的真空磨损率和载流电接触特性。在真空下开展Ag-Cu-MoS2电刷/银铜合金滑环的滑动电接触性能试验,获得电刷-滑环对偶材料在不同行程阶段的磨损率,并对真空磨损率随工作行程的变化规律以及磨损机理进行分析。在真空、高低温环境下开展电刷-滑环传输模拟太阳电池阵功率试验,对温度、工作行程对电接触性能的影响进行分析。研究结果表明:Ag-Cu-MoS2电刷的真空磨损率稳定在10-14 m3/(N·m)量级,真空高低温下在轨最大工作转速下的电噪声小于1.5 mV/A,完全满足目前中高轨道长寿命卫星的使用需求。

关键词:太阳电池阵功率滑环;Ag-Cu-MoS2电刷;真空磨损率;电接触噪声

中图分类号:TH117.1 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2020)11-3152-07

Sliding electrical contact behavior of silver-based composite in vacuum

ZHOU Yuanzi1, 2, LI Li1, ZHU Linlin1, ZHANG Kemo1, ZHANG Qiang1, 2

(1. Beijing Institute of Control Engineering, Beijing 100094, China;

2. Beijing Key Laboratory of Long-life Technology of Precise Rotation and Transmission Mechanisms,

Beijing 100094, China)

Abstract: In order to obtain the friction and wear behavior of the satellite solar array power slip-ring with current, the running experiment in which Ag-Cu-MoS2 brushes sliding on a stack of silver-copper rings was performed in vacuum environment. The vacuum wear rate and electrical noise of silver-based composite brush in different stages were tested by actually measuring the brush pressure and the amount of wear. The wear mechanism and the amount of wear with working distance were studied. The effects of temperature and work distance on electrical contact performance of power slip-ring undergoing thermal vacuum cycling testing were analyzed. The results show that The vacuum wear rate of Ag-Cu-MoS2 brush is stable at the magnitude of 10-14 m3/(N·m), and the electrical noise at high and low vacuum temperature at the maximum working speed in orbit is less than 1.5 mV/A, which fully meets the current usage requirements of long-life satellites in medium and high orbit.

Key words: solar array slip-ring; Ag-Cu-MoS2 brush; wear rate under vacuum; electrical noise

长寿命三轴稳定卫星多采用帆板式太阳电池阵进行能源供应,并使用太阳电池阵驱动装置(solar array drive assembly, SADA)使电池阵对日定向,以获得高的电能转换效率。该类驱动装置中的功率滑环将连续旋转的太阳电池阵的电功率传输至星内,是影响整星能源安全、寿命和可靠性的重要机构[1-2]。卫星太阳电池阵功率滑环的性能指标主要体现在磨损率、摩擦因数、接触电阻、电噪声以及储存稳定性等方面,其中电刷-滑环对偶材料的磨损率和电接触噪声是判定功率滑环寿命和工作可靠性的关键性能指标[3-5]。银基固体自润滑材料和金合金材料是最重要的卫星导电环用电刷材料,与金合金材料相比,银基固体自润滑具有摩擦因数低、接触稳定性好、成本低等优点,但也存在磨损率高、电噪声高等问题[5-8]。Ag-MoS2体系是应用最广的卫星导电环用银基自润滑材料体系,材料的摩擦因数通常在0.1~0.3之间,磨损量在10-14~10-13m3/(N·m)之间[9-11]。材料的磨损率随固体润滑剂的增加而降低,但电噪声随固体润滑剂的增加而升高[7],固体润滑剂(MoS2)的质量分数为6%~12%时,材料可以获得较好的滑动电接触性能[10-11]。Cu的加入可以提高材料基体的力学性能,降低磨损量,材料中Cu的添加量(质量分数)为2%~8%[11-12]。银基固体自润滑材料的载流摩擦性能受其使用环境的影响显著,电流密度的提高和环境温度的提升都会导致电刷的磨损率和电噪声升高[13-14]。材料的磨损量和电噪声在对偶件形成稳定的摩擦状态之前一般较高,且存在一定的扰动,当稳定的摩擦偶形成后,材料的磨损量和电噪声明显降低并稳定在一定的区间内[15]。

为了研究卫星太阳电池阵功率滑环的载流摩擦学性能,为粉末冶金复合材料的稳定空间应用提供基础测试数据,推动其可靠空间应用,本文作者在真空环境下进行复合材料电刷对偶银铜合金滑环的跑合试验,通过实测真空磨损量考察不同行程下的磨损率,并对磨损率随工作行程的变化规律以及磨损机理进行分析,在此基础上,在真空、高低温环境下进行传输模拟太阳电池阵功率试验,对温度、工作行程对电接触性能的影响进行分析。

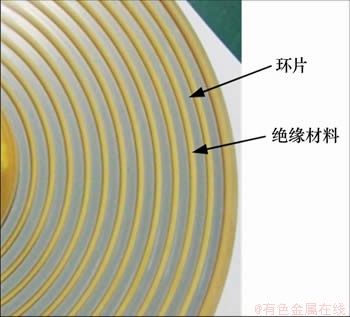

图1 太阳电池阵功率滑环的环体

Fig. 1 Rings of solar array power transfer assembly

1 试验方案

1.1 功率滑环介绍

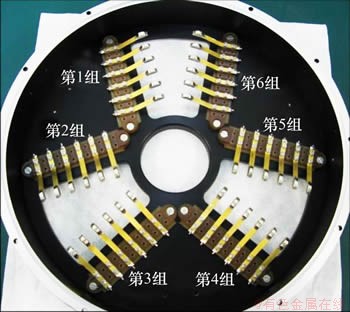

太阳电池阵功率滑环常设计为盘式结构以实现较小的轴向尺寸,如图1和图2所示。环体采用银铜合金材料,以环状排布在绝缘材料上,各环间通过绝缘介质隔离,每环在周向上布置多个电刷。电刷结构主体为片状弹性合金,通过其弹性实现与对应环片的可靠接触,电刷末端与环片接触部分为块状Ag-Cu-MoS2粉末冶金材料,通过电刷与环片的滑动接触,实现电功率从旋转太阳电池阵到星内的传输。

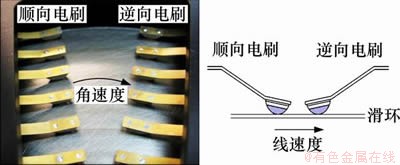

图2 Ag-Cu-MoS2电刷的排布方式

Fig. 2 Arrangement of Ag-Cu-MoS2 brushes.

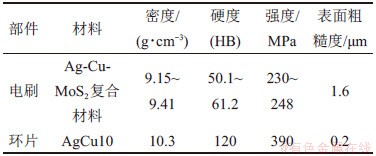

试验电刷与环片的材料特性见表1。

表1 试验电刷及环片材料特性

Table 1 Material properties of brushes and rings

1.2 真空磨损率试验方法及磨损面形貌表征

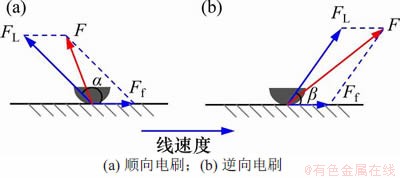

在优于1 mPa真空环境下,按转速0.5 r/min进行电刷对偶环片的跑合。为尽可能多地获得不同工作行程的电刷磨损率数据,设置了6组电刷,每组安装的6个电刷与不同半径的环片对偶跑合。由于试验中只进行单方向跑合,因此,电刷经历的摩擦磨损历程有2种状态。如图3所示,滑动速度和电刷折弯角度同向的为顺向跑合电刷,反向的为逆向跑合电刷,则图2中的第1,3和5组电刷为逆向跑合电刷,第2,4和6组电刷为顺向跑合电刷。

在跑合1万转、2万转、10万转后分别拆卸第1~2组、第3~4组、第5~6组电刷,采用分辨率0.1 mg的电子天平对跑合前后的电刷称质量,可获得18个跑合行程点上顺向、逆向电刷的磨损率数据。磨损率计算方法为

(1)

(1)

图3 单方向跑合中的顺向电刷和逆向电刷

Fig. 3 Brushes in forward and backward directions

式中: m为电刷磨损量;L为跑合行程,由r(环片半径)和n(跑合转数)计算获得;F为电刷与环片的接触压力;ρ为电刷材料密度。

m为电刷磨损量;L为跑合行程,由r(环片半径)和n(跑合转数)计算获得;F为电刷与环片的接触压力;ρ为电刷材料密度。

为研究Ag-Cu-MoS2电刷材料真空跑合过程中的磨损机制,采用FEI公司的Nova NanoSEM 230型场发射扫描电子显微镜(field scanning electron microscope, SEM)对磨损后的电刷进行显微观察,并采用其附带的能谱仪(EDS)对磨损面的特征区域元素进行测定。

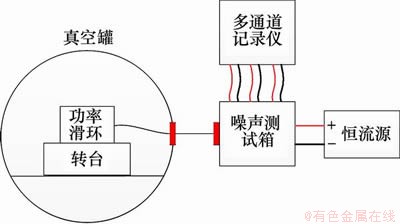

1.3 电噪声试验方法

为模拟太阳电池阵功率滑环的真实在轨工作环境,在优于1 mPa真空环境下开展高温+75°C、低温-40°C的交变循环试验。功率滑环真空高低温交变电摩擦试验示意图如图4所示。在功率滑环的12个环路上加载等效太阳电池阵额定功率的高压恒流。试验共进行了22 000转,超过目前GEO,IGSO和MEO等中高轨道卫星在轨全寿命转动圈数。在8 000转、16 000转、22 000转时分别进行功率滑环摩擦电接触性能的测试。在测试过程中,滑环按在轨最大工作转速(0.04 r/min)运转,重点采集环刷接触电噪声,该值为滑环连续转动过程中的电压波动量,可直观反映电刷和环片之间的滑动电接触性能的可靠性。为避免整周连续转动过程中电缆缠绕问题,将两环串联起来构成1个测量通路,利用多通道记录仪完成6个测量通道的电噪声信号采集。

图4 功率滑环真空高低温交变电摩擦试验示意图

Fig. 4 Electrical contact noise test of power slip-ring under vacuum and high & low temperature alternating

2 真空滑动磨损状态分析

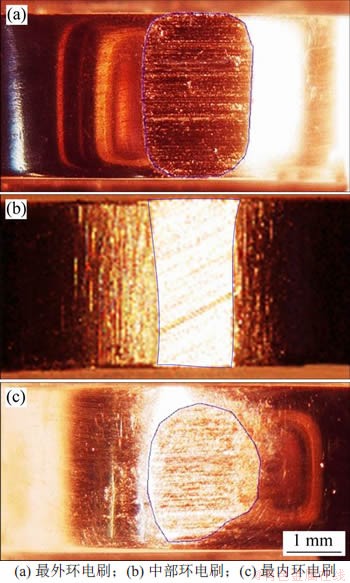

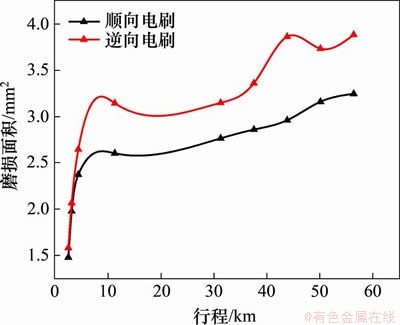

完成真空环境10万转跑合试验后,在电子显微镜观察材料磨损形貌,如图5所示,并测量磨损表面的面积,如图6所示。通过研究发现,电刷的磨损面呈现为椭圆形或矩形,在同一跑合转数下,外环电刷磨损面积明显大于内环电刷的磨损面积。随着跑合行程增大,电刷磨损面积不断增大。在真空跑合的初期阶段,磨损面积增长较快,跑合至10 km时的顺向、逆向电刷磨损面积较试验开始时分别增加了65%和67%;跑合行程超过10 km后,磨损面积的增幅变缓;跑合至56 km时,顺向、逆向电刷的磨损面积较10 km时分别增大了33%和44%;另外,相同跑合行程下逆向跑合电刷的磨损面积均高于正向跑合电刷的情况,且跑合行程越长这一现象越明显,跑合行程在40~56 km范围内逆向电刷的磨损面积是正向电刷的1.2倍,这说明跑合方向会严重影响电刷材料磨损行为。

图5 真空跑合的电刷磨损形貌

Fig. 5 Wear morphology of brushes

图6 真空跑合电刷的磨损面积

Fig. 6 Wear aera of brushes

跑合方向对电刷材料磨损行为影响与顺向电刷和逆向电刷的受力状态相关。图7所示为跑合过程中顺向电刷和逆向电刷受力分析示意图,顺向电刷和逆向电刷由于摩擦力的方向不同,2组电刷的受力状态显著不同。电刷在跑合过程中主要受到2个力的作用:通过弹片加载电刷上的载荷,电刷会受到对偶环体给出的大小一致、方向相反的作用力FL,另一个是与环体转动方向相同的摩擦力Ff;FL和Ff共同作用于电刷形成合力F。顺向电刷中FL与Ff夹角为α(90°<α<180°),从图7可见:顺向电刷所受到的合力FL;逆向电刷FL与Ff的夹角为β(0°<β<90°),逆向电刷受到的合力F>FL;由于弹片给电刷加载的力相同,即FL为一固定值,因此,在摩擦过程顺向电刷中所受的合力小于逆向电刷。顺向电刷实际受到的力小于逆向电刷受到的力,导致顺向电刷的磨损率要小于逆向电刷的磨损率。

图7 单方向跑合中的顺向电刷和逆向电刷受力分析

Fig. 7 Stress analysis of brushes in forward and backward directions

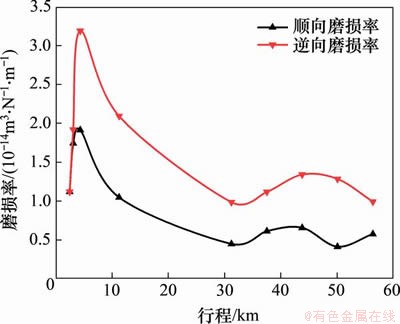

在摩擦磨损过程中,金属基自润滑材料的中的润滑相会不断向磨损表面富集,形成润滑膜,从而降低材料的摩擦因数和磨损率,因此,金属基自润滑材料的摩擦磨损行为会受到跑合里程的影响[12]。图8所示为Ag-Cu-MoS2电刷材料磨损率与跑合行程的关系。从图8可见:在小于10 km的初期跑合阶段,磨损率变化剧烈,顺向电刷的磨损率分布在(1.1~2.3)×10-14m3/(N·m)范围内;逆向电刷的磨损率分布在(0.9~3.2)×10-14m3/(N·m)范围内。而在10~56 km的长期跑合阶段,磨损率保持在较低的水平且基本稳定,顺向电刷的磨损率分布在(0.5~1.0)×10-14m3/(N·m)范围内,逆向电刷的磨损率分布在(1.0~2.1)×10-14m3/(N·m)范围内,且相同跑合行程下逆向电刷的磨损率都是顺向电刷的2倍左右。因此,采用复合材料电刷的太阳电池阵功率滑环在发射前可先进行10 km预跑合,使环刷对偶副进入稳定磨合阶段,以保证入轨工作后具有较好的摩擦磨损性能。

图8 真空跑合磨损率

Fig. 8 Wear rate of brushes

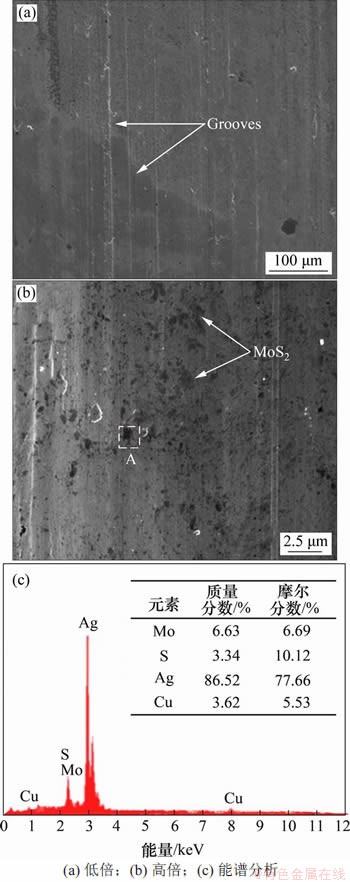

Ag-Cu-MoS2电刷的磨损表面形貌如图9所示。从图9可见:电刷磨损表面沿滑动摩擦方向形成了大量深度浅且均匀的犁沟,大量黑色小块均匀分布于电刷的磨损表面。对图中黑色小块区域进行能谱分析,发现黑色小块区域含有大量的Mo元素和S元素,这说明在Ag-Cu-MoS2电刷经真空跑合后,电刷材料内部的MoS2不断在电刷表面黏着富集,在电刷表面形成了稳定MoS2润滑膜;磨损率随着行程的增加不断降低且最后趋于稳定也和MoS2润滑膜的形成有关;当滑动行程较短时(0~5 km),Ag-Cu-MoS2电刷材料中的MoS2未能有效释放,润滑缺少,也造成该阶段材料的磨损较为严重;随着行程增加(5~30 km),MoS2不断从Ag-Cu-MoS2电刷材料中释放出来,并转移至银铜合金环的表面形成润滑膜,起到润滑效果,磨损率随着行程的增加不断降低;随着行程继续增加(30~60 km),MoS2润滑膜的增长与消耗达到基本平衡的稳定摩擦阶段,环表面的润滑膜逐渐发展成均匀铺展状态,润滑效果充分,材料的磨损率也就达到一个低且稳定的水平,同时,磨损面能谱中并未检测到氧元素。这是由于实验在真空下进行,材料不易发生氧化,材料并未发生氧化磨损。通过Ag-Cu-MoS2电刷表面的微观形貌和能谱分析可以得出犁削磨损及磨粒磨损成为电刷-环片稳定磨合阶段的主导磨损机制[16-17]。

图9 真空跑合后的电刷工作面显微分析

Fig. 9 Microscopic analysis of brush working face after vacuum running

3 真空电接触性能分析

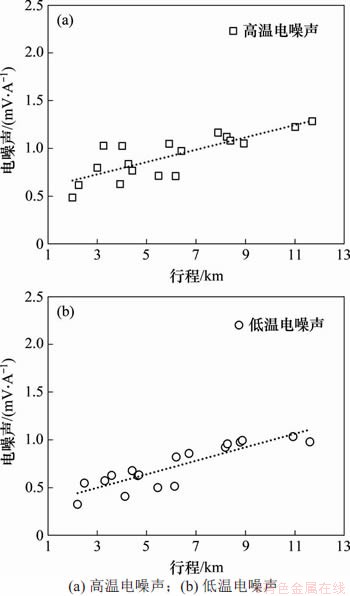

图10所示为高温环境、低温环境下不同跑合行程的电接触噪声测试值。在真空高低温交变环境下,基于复合材料电刷和银铜合金环片对偶副的太阳电池阵功率滑环在试验全程内的电噪声处于较低水平,在轨最大工作转速下的电噪声始终低于1.5 mV/A。

图10 功率滑环电噪声

Fig. 10 Electrical contact noise of power slip-ring

滑环的真空电噪声和跑合行程间呈近似线性增大的关系,跑合2 km时,高温、低温电噪声分别为0.49 mV/A和0.33 mV/A;跑合至6 km时,分别增大至0.82 mV/A和0.67 mV/A;跑合至12 km时,分别增大至1.28 mV/A和1.04 mV/A。随着跑合行程不断增大,电刷与滑环逐渐磨损,形成了较大的稳定接触面积。这导致电刷磨屑排出摩擦界面的距离和时间也随之增加,磨屑黏附在滑环或者电刷表面,使得接触表面变得更为粗糙,电接触噪声逐步增大。另外,在相同的跑合行程下,+75°C高温环境下的电噪声较-40°C低温环境下的约高20%。

真空高低温环境下电接触性能测试结果表明,在轨最大工作转速下的Ag-Cu-MoS2电刷和银铜合金环对偶副电噪声满足小于5 mV/A的性能指标要求,电刷载流工作寿命大于12 km,能够满足目前GEO,IGSO和MEO等中高轨道卫星在轨全寿命转动圈数应用需求。

4 结论

1) Ag-Cu-MoS2电刷及银铜合金环体材料电刷材料的真空磨损率稳定在10-14m3/(N·m)量级,且滑动方向对Ag-Cu-MoS2电刷真空滑动点磨损性能有显著影响。

2) 真空高低温交变环境的环刷材料滑动电接触性能测试结果显示,Ag-Cu-MoS2电刷全寿命阶段在轨最大工作转速下的电噪声均小于1.5 mV/A,可以满足目前中高轨道长寿命卫星的使用需求。

参考文献:

[1] WINGERT P C, ALLEN S E, BEVINGTON R C. The effects of graphite particle size and processing on the performance of silver-graphite contacts[J]. IEEE Transactions on Components, Hybrids, and Manufacturing Technology, 1992, 15(2): 154-159.

[2] MICHAL R, SAEGAR K E. Metallurgical aspects of silver-based contact materials for air-break switching devices for power engineering[J]. IEEE Transactions on Components, Hybrids, and Manufacturing Technology, 1989, 12(1): 71-81.

[3] BAKER J C, BAKER G A Sr . Impact of the space environment on spacecraft lifetimes[J]. Journal of Spacecraft and Rockets, 1980, 17(5): 479-480.

[4] CROWTHER R, STOKES H, WALKER R, et al. Characterization of the potential impact of space systems on the orbital debris environment: satellite constellations[C]// SPIE's 1995 Symposium on OE/Aerospace Sensing and Dual Use Photonics. Orlando, FL, USA, 1995: 88-99.

[5] KOONS H C, MAZUR J E, SELESNICK R S, et al. The impact of the space environment on space systems[C]// 6th Spacecraft Charging Technology Conference. M A, USA, 2000: 1-15.

[6] Roberts E W. Space tribology handbook 3rd edition[M]. Warrington UK: AEA Technology, 2002: 72-76.

[7] FRITSCH C, MONDIER J B. Sliver-based brush electric contacts performances[C]// Proceedings of the 8th European Symposium. Toulouse, France: European Space Agency, 1999: 37-42.

[8] SOHOLM M, MAUSLI P A, BONNER F, et al. Development and qualification of the international space station centrifuge slip ring assembly[C]// 11th European Space Mechanisms and Tribology Symposium. 2005: 133-140.

[9] 王新平, 肖金坤, 张雷, 等. 银合金粉末粒度对Ag-MoS2复合材料摩擦磨损性能的影响[J]. 中国有色金属学报, 2012, 22(10): 2811-2817.

WANG Xinping, XIAO Jinkun, ZHANG Lei, et al. Effect of silver alloy particle size on friction and wear properties of Ag-MoS2 composites[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(10): 2811-2817.

[10] LI Shu, FENG Yi, YANG Xiting, et al. Structure and formation mechanism of surface film of Ag-MoS2 composite during electrical sliding wear[J]. Rare Metal Materials and Engineering, 2009, 38(11): 1881-1885.

[11] 张雷, 周科朝, 刘文胜, 等. 梯度结构Ag-Cu-MoS2电刷材料的制备及性能[J]. 中国有色金属学报, 2005, 15(11): 1766-1769.

ZHANG Lei, ZHOU Kechao, LIU Wensheng, et al. Preparation and properties of Ag-Cu-MoS2 brush materials[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(11): 1766-1769.

[12] CHEN Wu, WANG Yan, FENG Chunfang, et al. Effect of hot extrusion on electrical tribological behavior of Ag-Cu/MoS2 composite under air and vacuum conditions[J]. Tribology Transactions, 2017, 60(4): 653-662.

[13] WU Jisi, LI Jingfu, ZHANG Lei, et al. Effects of environment on dry sliding wear behavior of silver-copper based composites containing tungsten disulfide[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(10): 2202-2213.

[14] CHEN Fanyan, FENG Yi, SHAO Hao, et al. Friction and wear behaviors of Ag/MoS2/G composite in different atmospheres and at different temperatures[J]. Tribology Letters, 2012, 47(1): 139-148.

[15] LI Shu, FENG Yi, YANG Xiting. Influence of adding carbon nanotubes and graphite to Ag-MoS2 composites on the electrical sliding wear properties[J]. Acta Metallurgica Sinica, 2010, 23(1): 27-34.

[16] CHENG Jun, LI Fei, ZHU Shengyu, et al. High temperature tribological properties of a nickel-alloy-based solid-lubricating composite: Effect of surface tribo-chemistry, counterpart and mechanical properties[J]. Wear, 2017, 386/387: 39-48.

[17] ZHANG Lei, XIAO Jinkun, ZHOU Kechao. Sliding wear behavior of silver-molybdenum disulfide composite[J]. Tribology Transactions, 2012, 55(4): 473-480.

(编辑 赵俊)

收稿日期: 2020 -07 -18; 修回日期: 2020 -11 -04

基金项目(Foundation item):“十三五”装备预研专用技术项目(30508050301);国防科技重点实验室稳定支持科研项目(KGJZDSYS-2018-16) (Project(30508050301) supported by Special Technical Project of Equipment Pre-research during the 13th Five-Year Plan; Project(KGJZDSYS-2018-16) supported by The Key Laboratory of National Defense Science and Technology)

通信作者:周元子,博士,高级工程师,从事空间精密机构及电传输技术研究;E-mail:zyz626@163.com