J. Cent. South Univ. (2020) 27: 469-477

DOI: https://doi.org/10.1007/s11771-020-4309-y

Process control technology of low NOx sintering based on coke pretreatment

WANG Zhao-cai(王兆才)1, 2, ZHOU Zhi-an(周志安)1, 2, GAN Min(甘敏)2,FAN Xiao-hui(范晓慧)2, HE Guo-qiang(何国强)1

1. Zhongye Changtian International Engineering Co., Ltd., Changsha 410125, China;

2. School of Minerals Processing and Bioengineering, Central South University, Changsha 410083, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2020

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2020

Abstract: Process control is an effective approach to reduce the NOx emission from sintering flue gas. The effects of different materials adhered on coke breeze on NOx emission characteristics and sintering performance were studied. Results showed that the coke breeze adhered with the mixture of CaO and Fe2O3 or calcium ferrite significantly lowers the NOx emission concentration and conversion ratio of fuel-N to NOx. Pretreating the coke with the mixture of lime slurry and iron ore fines helped to improve the granulation effect, and optimize the carbon distribution in granules. When the mass ratio of coke breeze, quick lime, water and iron ore fines was 2:1:1:1, the average NOx emission concentration was decreased from 220 mg/m3 to 166 mg/m3, and the conversion ratio of fuel-N was reduced from 54.2% to 40.9%.

Key words: iron ore sintering; nitrogen oxide; process control; coke breeze pretreatment

Cite this article as: WANG Zhao-cai, ZHOU Zhi-an, GAN Min, FAN Xiao-hui, HE Guo-qiang. Process control technology of low NOx sintering based on coke pretreatment [J]. Journal of Central South University, 2020, 27(2): 469-477. DOI: https://doi.org/10.1007/s11771-020-4309-y.

1 Introduction

Nitrogen oxides, a typical gas pollutant, which is harmful to the environment and human health, should be reduced. In China, 6% of NOx emission is generated from iron and steel industry [1]. Meanwhile, the NOx emitted from sintering process accounted for 48%, which is the main emission source in iron and steel industry [2]. In 2019,the “Emission Standard of Air Pollutants for Sintering and Pelletizing of Iron and Steel Industry” [3] was issued by the government of China, which indicated that the limit of NOx emission was reduced to 50 mg/m3. Therefore, realizing the reduction of NOx emission is significant for the sustainable development of Chinese iron and steel industry.

The present work on reducing the NOx emission mainly focuses on the raw material control, process control and terminal treatment. It is a functional way of choosing coal or coke with low nitrogen content [4]. Biomass energy can also be used to replace the traditional solid fuels for reducing NOx generation [5, 6]. However, optimizing fuel to reduce NOx emission can not be widely used due to the limitation of resource region and cost. Currently, only two kinds of de-nitration technologies have been popularized in the sintering industry, which are selective catalytic reduction (SCR) [2] and synergistic purification of multi pollutants with activated carbon [7]. Only relying on terminal treatment to reduce the NOx emission will increase the investment and operation cost. Therefore, process control should be introduced to help to decrease the load of terminal treatment on reducing NOx emission. Studies made by YU et al [8], GAN et al [9] and PEI et al [10] all showed that adding Ca-Fe oxides into sintering raw materials can reduce the emission of NOx. It was also found that adding hydrocarbon such as sawdust and flour in the sintering raw materials can reduce NOx emission as well [11]. The effects of sinter basicity and grain size of limestone on NOx generation were also investigated [12-14]. Although the sintering flue gas circulation method is also a function way to help to reduce the emission of pollutants [15-17], there are still some problems when it was carried out, including insufficient recirculation ratio, the deterioration of sintering indexes, etc.

The emission of NOx generated from solid fuels is closely related to the combustion atmosphere of the fuel [18]. NOx can be formed from fuel-N under the condition of oxygen atmosphere. It should be noticed that NOx can also be reduced to N2 through reduction reaction. Therefore, how to reduce the formation of NOx through controlling the combustion atmosphere of the solid fuel during the combustion process is a promising method. Then the effects of different adhesion layer materials on the NOx generated during coke breeze combustion were studied, and the feasible materials inhibiting and degrading NOx were analyzed. Through the experiment of sintering pot, the effects of fuel pretreatment on granulation, fuel distribution and NOx generation of sintering flue gas were studied as well. Finally, the method of low NOx sintering based on coke pretreatment was proposed.

2 Experimental

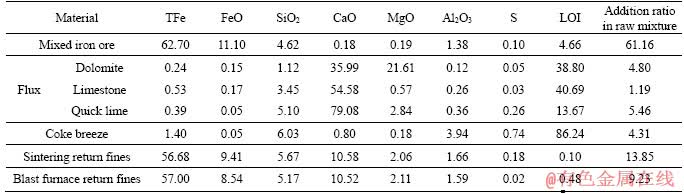

The chemical compositions of sintering raw materials are shown in Table 1. The flux includes dolomite, limestone and quick lime. The basicity of sinter was 1.95. Quick lime was used to pretreat coke surface, of which the CaO content was higher than 80%, and the activity was higher than 250 mL of 4 mol/L HCl. The proportion of coke breeze was 4.31% with its industrial analysis shown in Table 2. The N content in the coke breeze is 0.55%.

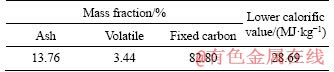

Fe2O3, CaO and xCaO·yFe2O3 were ground to <0.5 mm. To improve the adhesion of Fe2O3 and xCaO·yFe2O3, 0.06 wt.% sodium carboxymethyl cellulose (CMC), a typical binder, was added with reasonable amount of water. The coke breeze was screened to 1-2 mm. Then 2.0 g coke breeze was attached with different mass of Fe2O3, CaO and xCaO·yFe2O3, respectively. And then the pretreated coke breeze was dried in the drying box. As shown in Figure 1, the coke combustion test was carried out in a vertical heating furnace, of which the temperature would be set as 1100 °C. And a quartz tube of f38 mm×70 mm was used as the reactor. 25 g sample (pretreated coke breeze) was loaded into the quartz tube and placed on the gasket with uniform holes, which would allow the gas passed through the pellet layer uniformly. During the combustion process, a flue gas analyzer (Vario Plus enhanced, York Co., Austria) was used to detect the flue gas composition, especially the NOx.

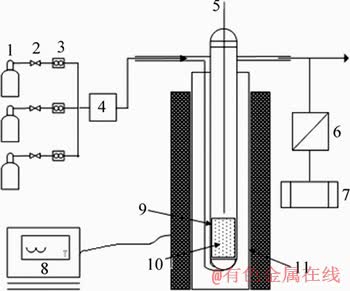

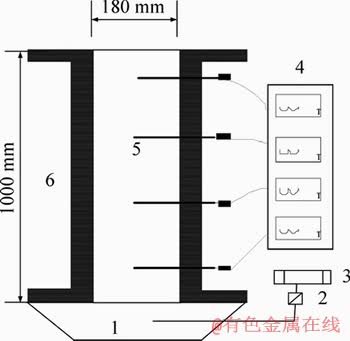

By using a mixer (JJ-5 type, Shanghai Yanggong Co., China), quick lime with moderate water was mixed firstly. Then the coke breeze was added in to be covered with the lime slurry. The pretreated coke breeze was used for further sintering cup trials, as shown in Figure 2. The sintering pot test includes proportioning, mixing, granulating, feeding, igniting, sintering, cooling and quality testing, etc. The total consumption of water and quick lime in the whole sintering process remained unchanged, and only part of them was transferred for coke pretreatment. An analyzer (HW2000 CS, Shanghai Dongruan Zaiweibo Co., China) was used to analyze the content of carbon in granulated pellets with different grain size levels. During the sintering process, the concentration of NOx was also measured.

Table 1 Chemical compositions and ratios of sintering raw materials (wt.%)

Table 2 Industrial analysis of coke breeze (dry basis)

Figure 1 Diagram of fuel combustion test device (1-Cylinder; 2-Pressure relief valve; 3-Flowmeter; 4-Mixing cylinder; 5-Thermocouple; 6-Dryer; 7-Gas analyzer; 8-Temperature controller; 9-Quartz tube; 10-Loading cup; 11-Vertical electric heating furnace)

Figure 2 Schematic diagram of main equipment of sintering cup test (Unit: mm): (1-Vacuum chamber; 2-Dryer; 3-Gas analyzer; 4-Temperature display instrument; 5-Thermocouple; 6-Sintering cup)

The generation mechanism of NOx can be divided into three styles [19], namely thermal NOx, fuel NOx, prompt NOx. In general, thermal NOx is formed at the temperature more than about 1500 °C in the air. While the highest temperature during iron ore sintering process is lower than 1400 °C. Therefore, thermal NOx is less likely to be generated. As for prompt NOx, it is usually generated under the condition of low O2 content. Hence, the amount of prompt NOx generated during sintering process is also low. Fuel NOx is considered to be the main source of NOx during sintering process and it comes from the fuel including coke, coal, etc., in the sintering raw mixture [19, 20].

During the process of fuel combustion, only part of fuel N can be converted into NOx. The ratio of NOx actually generated to the theoretical one is defined as the conversion ratio from fuel N to NOx. As most of NOx is NO during the combustion process, the conversion ratio is calculated by the concentration of NO.

(1)

(1)

(2)

(2)

(3)

(3)

where a(FuelN) is the content of N in the fuel, mg/kg; m is the mass of fuel burnt during the period from ts to te, kg;ηN is the conversion ratio of fuel-N, %; [N]a is the mass of fuel-N convert to NO released from ts to te, mg; C(NO) is the concentration of NO at some point, mg/m3; Qtgas is the inlet flow at standard state, m3/min; 0.47 is the percentage of N to NO; [N]o is the mass of N in fuel, of which the mass is m.

3 Results and discussion

3.1 Effect of fuel pretreatment on conversion ratio of N in coke breeze combustion

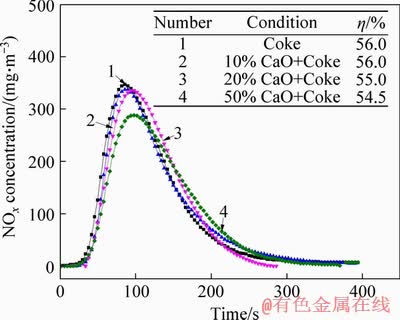

The emission of NOx and the conversion ratio of fuel-N during the combustion process under the heating temperature of 1100 °C in air atmosphere was studied, with the adhesive content of CaO on coke surface kept at 10%, 20%, and 50%, respectively.

From Figure 3, it can be found that the conversion ratio of fuel-N decreased slightly as the amount of CaO increased, and when adhering 50% CaO, the peak value of NOx emission decreased significantly.

Figure 3 Effect of CaO adhesion on NOx emission and fuel-N conversion ratio in coke combustion

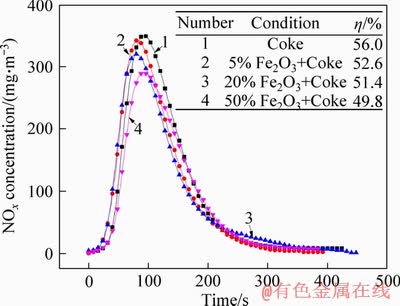

The emission of NOx and the conversion ratio of fuel-N during the fuel combustion process at the roasting temperature of 1100 °C in air atmosphere was analyzed, with the adhesive proportion of Fe2O3 on coke breeze surface kept at 10%, 20%, and 50%, respectively.

From Figure 4, it can be found that the peak value of NOx emission and conversion ratio of N all decreased as the amount of Fe2O3 increased. The conversion ratio of fuel-N reduces from 56% to 49.8% when the surface of coke is adhered with 50% Fe2O3, and the effect of Fe2O3 on the conversion of fuel-N is stronger than that of CaO, but it is difficult for Fe2O3 to be adhered to the surface of coke breeze.

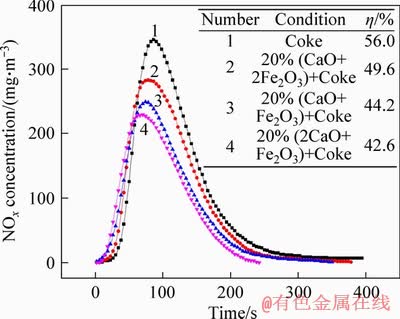

CaO and Fe2O3 were mixed in molar ratio of 1:2, 1:1 and 2:1, respectively. While the ratio of the mixture xCaO+yFe2O3 was kept at 20%. Under the roasting temperature of 1100 °C in air atmosphere, the influence of the relative proportion variation of CaO and Fe2O3 on NOx emission and N conversion in the combustion process of coke breeze is studied, as shown in Figure 5.

Figure 4 Effect of Fe2O3 adhered on NOx emission and fuel N conversion ratio in coke combustion

Figure 5 Effect of CaO to Fe2O3 in adhesion layer on NOx emission and fuel-N conversion ratio in coke combustion

Compared with the single adherence of CaO and Fe2O3, the mixture of CaO and Fe2O3 adhered on the surface of coke breeze greatly improves the inhibition of fuel-N conversion. With the increasing molar ratio of CaO to Fe2O3, the NOx emission and the conversion ratio of N decreased significantly. When the molar ratio of CaO to Fe2O3 was 2:1, the conversion ratio of fuel-N decreased from 56% to 42.6%.

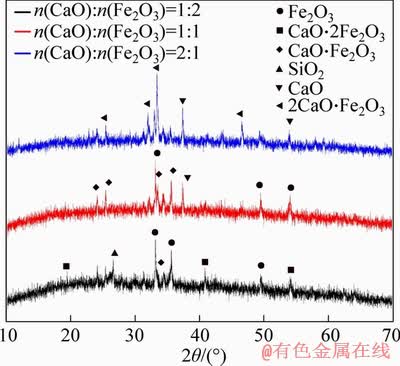

The reaction between CaO and Fe2O3 in adhesion layer and fuel ash in combustion process was studied, as shown in Figure 6. When the molar ratio of CaO to Fe2O3 was 1:2, calcium-diferrite (CaO·2Fe2O3) and a small amount of calcium ferrite (CaO·Fe2O3) were produced. When the molar ratio of CaO and Fe2O3 was 1:1, it was easy to produce calcium ferrite (CaO·Fe2O3). When the molar ratio of CaO to Fe2O3 was 2:1, a large amount of dicalcium-ferrite(2CaO·Fe2O3) was generated.

Figure 6 XRD patterns of combustion residues

To form a kind of calcium-containing ferrite on the surface of the coke breeze during sintering process is the key to realize the process control of low NOx emission. Therefore, the way of accelerating the generation of calcium ferrite through the coke surface modification was studied, and how it affected the pelletizing efficiency, carbon distribution and NOx generation was also researched.

3.2 Effect of fuel pretreatment on granulation effect and carbon distribution in granules

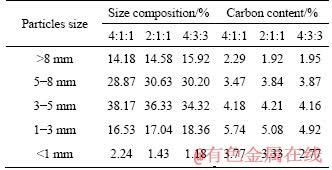

The coke breeze pretreated with lime slurry was used for sintering. Table 3 lists the grain size composition and carbon distribution in granules, of which the mass ratio of coke breeze, quick lime and water was 2:1:1. Compared with the base case, under the condition of fuel pretreatment, the proportion of granules larger than 3 mm increased from 80.08% to 81.50%, and the carbon content of particles larger than 5 mm increased. Coke breeze was easier to participate in the granulating process than that of independent existence. This can be attributed to the function of lime slurry, which has modified the coke breeze’s original hydrophobicity into hydrophilicity and the strong adhesion.

Table 3 Effect of coke breeze pretreatment on grain size composition and carbon distribution of granulated sintering pellets

Not changing the concentration of lime slurry (the mass ratio of quick lime to water is 1:1), the effect of lime slurry adhesion on granulating effect and carbon distribution was studied, as shown in Table 4. As the adhered lime slurry increased, the granulating pellets larger than 5 mm were increased, while the particles less than 1 mm tended to decrease. The carbon content of particles larger than 3 mm increased firstly and then decreased. When the mass ratio of coke breeze, quick lime and water was 2:1:1, the amount of the particles with 3-8 mm, was the largest. Meanwhile, the distribution of carbon content is the most reasonable.

Table 4 Effect of lime slurry adhesion on particle size composition and carbon distribution of granulated sintering pellets

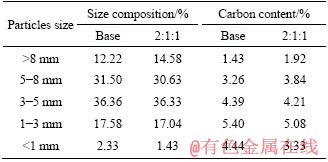

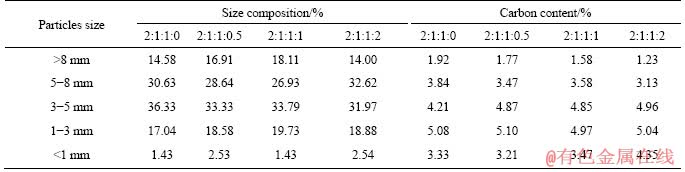

When the mass ratio of coke breeze, quick lime and water was 2:1:1, different amounts of iron ore fines were added in the lime slurry and adhered on the surface of coke breeze. The effect of the amount of iron ore fines on the granulating effect and the carbon distribution was studied. As listed in Table 5, the granulation was not affected obviously when the iron ore fines were added into the lime slurry. The proportion of the particles, whose size was 3-5 mm, decreased slightly. The carbon content of the particles larger than 5 mm tended to decrease as well. Therefore, the amount of the iron ore fines added into the lime slurry should not be excessive due to the deterioration of granulation.

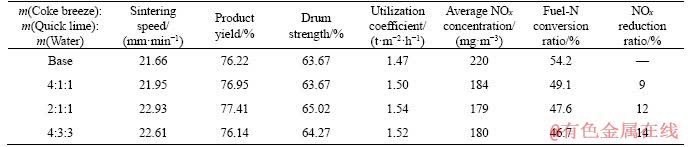

3.3 Effect of fuel pretreatment on NOx generation of sintering flue gas

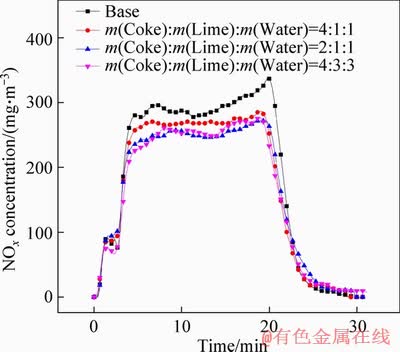

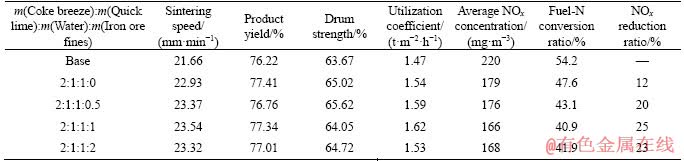

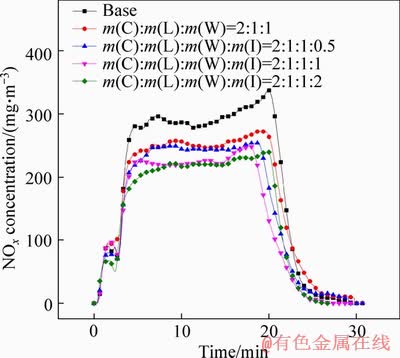

The effects of lime slurry adhesion on sintering index and NOx emission were studied by the sintering pot test. The results are shown in Table 6 and Figure 7. As the adhesion of lime slurry increased, the sintering indexes firstly increased and then decreased. The comprehensive sintering indexes were obtained when the mass ratio of coke breeze, quick lime and water was 2:1:1. As the adhesion increased further, the sintering speed and productivity were negatively affected because the coke breeze was completely wrapped out and the combustion process was affected.

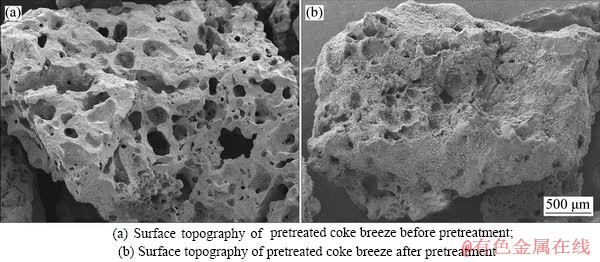

The concentration of NOx in the flue gas and the fuel-N conversion ratio decreased as the adhesion of lime slurry increased, especially when the mass ratio of coke, quick lime and water was 2:1:1. The average NOx emission concentration reduced from 220 mg/m3 to 179 mg/m3, and the conversion ratio of fuel-N decreased from 54.2% to 47.6%. By increasing the amount of adhesion further, the effect of inhibiting the formation of NOx was not obvious. The effect of pretreatment on the surface morphology of coke breeze was studied. The results are shown in Figure 8. When the lime slurry was adhered to the surface of the coke breeze, the pores were filled with CaO and the number of surface pores was reduced, so as to prevent the directly contacting between coke breeze and O2. The CaO on the surface of the coke breeze can react with the FexOy in raw mixture to form calcium ferrite, which can promote the reduction reaction of NOx. In addition, the reduction of O2 content produced reducing gas, which can also promote the reduction of NOx. Finally, NOx was reduced during the combustion process.

Table 5 Effect of amount of iron ore fines in lime slurry on particle size composition and carbon distribution of granulated sintering pellets

Table 6 Effect of thickness of lime milk adhesion layer on sintering index

Figure 7 Effect of amount of lime milk adhesion on NOx emission and fuel-N conversion ratio in sintering process

When the mass ratio of coke breeze, quick lime and water was 2:1:1, by adding different amounts of iron ore fines in the lime slurry and then adhering them on the coke breeze surface, the effects of iron ore fines addition on sintering index and NOx emission were studied. The results are shown in Table 7 and Figure 9. Obviously, the sintering indexes were slightly influenced. The comprehensive sintering indexes were the best when the mass ratio of coke breeze, quick lime, water and iron ore fines was 2:1:1:1. The average NOx emission concentration decreased from 220 mg/m3 to 166 mg/m3. The conversion ratio of N reduced from 54.2% to 40.9%. The NOx reduction ratio can be 25%.

The reason why the NOx was inhibited is that the calcium ferrite was formed quickly on the surface and reacted with NOx during the combustion process. However, the formation of NOx was not inhibited further as the amount of iron ore fines increased further. According to Section 3.1, it can be found that 2CaO·Fe2O3 has the highest NOx reduction ratio. As the amount of iron ore fines increased, the kind of calcium ferrite was changed from 2CaO·Fe2O3 to the mixture of 2CaO·Fe2O3 and CaO·Fe2O3. Therefore, compared with 100% 2CaO·Fe2O3, the mixture has a lower NOx reduction ratio.

Figure 8 Surface microtopography changes before and after pretreatment of coke breeze:

Table 7 Effect of coke breeze adhered with lime milk containing iron ore fines on sintering index

Figure 9 NOx emission and fuel-N conversion ratio of coke breeze adhered with lime milk containing iron ore fines (C-Coke; L-Lime; W-Water; I-Iron ore)

4 Conclusions

1) The conversion of fuel-N to NOx was not inhibited obviously when adhering CaO or Fe2O3. While adhering their mixture on the surface of the coke breeze, the conversion ratio and the emission concentration of NOx can be reduced obviously.

2) The surface modification of coke breeze by lime slurry improved the adhesion of coke breeze surface, and improved the granulation effect and carbon distribution as well. However, the additive amount of the iron ore fines should be controlled in a reasonable range to avoid the negative effects.

3) The pretreatment of coke breeze by lime slurry with iron fines reduced the pores on surface of coke breeze, prevented the directly contacting between coke breeze and O2, and finally inhibited the oxidation reaction of fuel-N to NOx. Calcium ferrite formed on the surface of coke breeze promoted the reduction reaction of NOx. However, the adhesion layer of coke breeze should not be too thick; otherwise, the sintering indexes will be negatively affected. When the mass ratio of coke breeze, quick lime, water and iron ore fines was 2:1:1:1, the average NOx emission concentration was decreased from 220 mg/m3 to 166 mg/m3, and the conversion ratio of fuel-N was reduced from 54.2% to 40.9%, and the NOx reduction ratio was 25%.

References

[1] ZHAO Jia-pei, LOO Chin-eng, YUANG Jin-liang, WANG Fu, WANG Jia-tang, ZHANG Hou-cheng, MIAO He. A fundamental study of the co-combustion of coke and charcoal during iron ore sintering [J]. Energy & Fuels, 2018, 32(8): 8743-8759.

[2] ZHU Ting-yu. Technology of sintering flue gas purification [M]. Beijing: Chemical Industry Press, 2009: 1-10. (in Chinese)

[3] The Ministry of Ecology and Environment of the People’s Republic of China. Bulletin of “Emission standard of air pollutants during sintering and pelletizing of iron and steel industry”[EB/OL]. http://www.mee.gov.cn/xxgk2018/xxgk/ xxgk03/201904/t20190429_701463.html. (in Chinese)

[4] GAN Min, FAN Xiao-hui, JIANG Tao, CHEN Xu-ling, YU Zhi-yuan, JI Zhi-yun. Fundamental study on iron ore sintering new process of flue gas recirculation together with using biochar as fuel [J]. Journal of Central South University, 2014, 21(11): 4109-4114.

[5] ZANDI M, MARTINEZ-PACHECO M, FRAY T. Biomass for iron ore sintering [J]. Minerals Engineering, 2010, 23(14): 1139-1145.

[6] GAN Min, FAN Xiao-hui, CHEN Xu-ling, JI Zhi-yun, LV Wei, WANG Yi, YU Zhi-yuan, JIANG Tao. Reduction of pollutant emission in iron ore sintering process by applying biomass fuels [J]. ISIJ International, 2012, 52(9): 1580- 1584.

[7] LI Jun-jie, WEI Jin-chao, LIU Chang-qi. Combined desulfurization, denitrification and reduction of air toxics using activated coke [J]. Sintering and Pelletizing, 2017, 40(3): 79-85. (in Chinese)

[8] YU Zhi-yuan, FAN Xiao-hui, GAN Min, CHEN Xu-ling. Effect of Ca-Fe oxides additives on NOx reduction in iron ore sintering [J]. Journal of Iron and Steel Research International, 2017, 24(12): 1184-1189.

[9] GAN Min, LI Qiang, JI Zhi-yun, FAN Xiao-hui, LV Wei, CHEN Xu-ling, TIAN Ye, JIANG Tao. Influence of surface modification on combustion characteristics of charcoal and its performance on emissions reduction in iron ore sintering [J]. ISIJ International, 2017, 57(3): 420-428.

[10] PEI Yuan-dong, ZHANG Si-bin, WU Sheng-li, SHI Jiang-shan, FAN Zheng-yun, ZHAO Zhi-xing, YIN You-hao. Sintering surface spraying steam to reduce NOx and dioxin emissions in Shougang [M]// Minerals, Metals and Materials Series. 2018: 53-58.

[11] MO C L, TEO C S, HAMILTON I, MORRISON J. Adding hydrocarbons in raw mix to reduce emission ground to iron ore sintering process [J]. ISIJ, 1997, 37(4): 350-357.

[12] IWAMI Y, YAMAMOTO T, OYAMA N, MATSUNO H, SAITO N, NAKASHIMA K. Improvement of sinter productivity by control of magnetite ore segregation in sintering bed [J]. ISIJ International, 2018, 58(12): 2200-2209.

[13] KATAYAMA, K, KASAMA S. Influence of lime coating coke on NOx concentration in sintering process [J]. ISIJ International, 2016, 56(9): 1563-1569.

[14] GAN Min, FAN Xiao-hui, LV Wei, CHEN Xu-ling, JI Zhi-yun, ZHOU Yang. Fuel pre-granulation for reducing NOx emissions from the iron ore sintering process [J]. Powder Technology, 2016, 301: 478-485.

[15] MAO Xiao-ming, YOU Zhi-xiong, ZHANG Yuan-bo, FAN Zhen-yu, LI Guang-hui, JIANG Tao. Calcium ferrite formation characteristic during iron ore sintering with different oxygen atmospheres [J]. Journal of Central South University, 2014, 21(8): 3043-3048.

[16] QIE Jun-mao, ZHANG Chun-xia, WANG Hai-feng, GUO Yu-hua, WU Sheng-li. Investigation of a granule structure that focused on reducing NOx emissions in sintering process [J]. Metallurgical Research & Technology, 2019, 116(3): 315-322.

[17] WONG Guo-jing, FAN Xiao-hui, GAN Min, JI Zhi-yun, CHEN Xu-ling, TIAN Zhi-yuan, WANG Zhuang-zhuang. Improvement on the thermal cracking performance of pellets prepared from ultrafine iron ore [J]. Powder Technology, 2019, 342: 873-879.

[18] LI Song, CHEN Zhi-chao, HE Erdemtu, JIANG Bing-kun, LI Zheng-qi, WANG Qing-xiang. Combustion characteristics and NOx formation of a retrofitted low-volatile coal-fired 330 MW utility boilers under various loads with deep-air-staging [J]. Applied Thermal Engineering, 2017, 110: 223-233.

[19] LV Wei, FAN Xiao-hui, GAN Min, CHEN Xu-ling, JI Zhi-yun. Formation of nitrogen mono oxide (NO) during iron ore sintering process [J]. ISIJ International, 2018, 58: 236-243.

[20] KENJI T. NOx emission profile determined by in-situ gas monitoring of iron ore sintering during packed-bed coke combustion [J]. Fuel, 2019, 236: 244-250.

(Edited by YANG Hua)

中文导读

基于焦粉预处理的低NOx烧结过程控制技术

摘要:过程控制是降低烧结烟气NOx排放的有效途径。研究了焦粉粘附不同物质时对NOx排放和烧结指标的影响。结果表明,当焦粉粘附CaO和Fe2O3的混合物或者铁酸钙时能减少燃料氮向NOx的转化从而降低NOx排放浓度。用石灰浆和铁矿粉的混合物对焦粉进行预处理,有助于改善制粒效果,优化制粒小球中的碳分布。当焦粉、生石灰、水、铁矿粉以质量比2:1:1:1进行混合预处理后参与烧结,NOx平均排放浓度可由220 mg/m3降至166 mg/m3, 燃料氮转化率可由54.2%降至40.9%。

关键词:铁矿烧结;氮氧化物;过程控制;焦粉预处理

Foundation item: Project(2017YFC0210302) supported by the National Key R&D Program of China; Projects(U1660206, U1760107) supported by the National Natural Science Foundation of China

Received date: 2019-06-08; Accepted date: 2019-12-09

Corresponding author: ZHOU Zhi-an, Senior Engineer; E-mail: 35394690@qq.com; ORCID: 0000-0003-0829-0789