Densification mechanism of stereolithographical dense Si3N4 ceramics with CeO2 as sintering additive by field assisted sintering

来源期刊:中南大学学报(英文版)2021年第4期

论文作者:刘绍军 饶为栋 刘耀 程立金

文章页码:1233 - 1243

Key words:stereolithography; silicon nitride ceramics; sintering mechanism; densification; field assisted sintering

Abstract: Combining sintering additive with field assisted sintering, stereolithographical dense Si3N4 ceramics was successfully fabricated. Owing to a large amount of polymer during the stereolithography, the green parts have the characteristics of low powder loading and high porosity. Adjusting the process parameters such as sintering temperature and soaking time can effectively improve the density of the specimens. The stress exponent n of all specimens is in a range of 1 and 2, which is derived from a modified sintering kinetics model. The apparent activation energy Qd of stereolithographic Si3N4 ceramics sintered with applied pressures of 30 MPa, 40 MPa, and 50 MPa is 384.75, 276.61 and 193.95 kJ/mol, respectively, suggesting that the densification dynamic process is strengthened by raising applied pressure. The grain boundary slipping plays a dominating role in the densification of stereolithographic Si3N4 ceramics. The Vickers hardness and fracture toughness of stereolithographic Si3N4 ceramics are HV10/10 (1347.9±2.4) and (6.57±0.07) MPa·m1/2, respectively.

Cite this article as: RAO Wei-dong, LIU Yao, CHENG Li-jing, LIU Shao-jun. Densification mechanism of stereolithographical dense Si3N4 ceramics with CeO2 as sintering additive by field assisted sintering [J]. Journal of Central South University, 2021, 28(4): 1233-1243. DOI: https://doi.org/10.1007/s11771-021-4631-z.

J. Cent. South Univ. (2021) 28: 1233-1243

DOI: https://doi.org/10.1007/s11771-021-4631-z

RAO Wei-dong(饶为栋)1, 2, LIU Yao(刘耀)1, 3, CHENG Li-jing(程立金)4, LIU Shao-jun(刘绍军)1, 2

1. State Key Laboratory for Powder Metallurgy, Central South University, Changsha 410083, China;

2. Shenzhen Research Institute, Central South University, Shenzhen 518007, China;

3. College of Mechanical and Electronic Engineering, Pingxiang University, Pingxiang 337000, China;

4. School of Mechanical Engineering, Hebei University of Technology, Tianjin 300130, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2021

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2021

Abstract: Combining sintering additive with field assisted sintering, stereolithographical dense Si3N4 ceramics was successfully fabricated. Owing to a large amount of polymer during the stereolithography, the green parts have the characteristics of low powder loading and high porosity. Adjusting the process parameters such as sintering temperature and soaking time can effectively improve the density of the specimens. The stress exponent n of all specimens is in a range of 1 and 2, which is derived from a modified sintering kinetics model. The apparent activation energy Qd of stereolithographic Si3N4 ceramics sintered with applied pressures of 30 MPa, 40 MPa, and 50 MPa is 384.75, 276.61 and 193.95 kJ/mol, respectively, suggesting that the densification dynamic process is strengthened by raising applied pressure. The grain boundary slipping plays a dominating role in the densification of stereolithographic Si3N4 ceramics. The Vickers hardness and fracture toughness of stereolithographic Si3N4 ceramics are HV10/10 (1347.9±2.4) and (6.57±0.07) MPa·m1/2, respectively.

Key words: stereolithography; silicon nitride ceramics; sintering mechanism; densification; field assisted sintering

Cite this article as: RAO Wei-dong, LIU Yao, CHENG Li-jing, LIU Shao-jun. Densification mechanism of stereolithographical dense Si3N4 ceramics with CeO2 as sintering additive by field assisted sintering [J]. Journal of Central South University, 2021, 28(4): 1233-1243. DOI: https://doi.org/10.1007/s11771-021-4631-z.

1 Introduction

The stereolithography (SLA) is traditionally considered a promising additive manufacturing technique for polymer based on the polymerization reaction between monomer and oligomer activated by ultraviolet (UV) [1-5]. Recently, it has attracted intensive attention on additively manufacturing ceramic, including Al2O3 [6, 7], ZrO2 [8], and Si3N4 ceramics [9, 10] due to its capability of high precision and complex geometric shapes. However, it is still a main challenge to sinter dense ceramics with comparative mechanical properties to counterparts by conventional dry pressing technique. Given the low powder loading of green parts and high porosity of debound green parts owing to a large amount polymer during the stereolithography [11-13], it is notoriously difficult to sinter ceramics with strong covalent, such as nitrides, carbonates, and borides.

Although the physical properties could be degraded, the sintering additives can be used to effectively improve the densification and tailor the structure and mechanical properties of silicon nitride (Si3N4) ceramics [14-18]. LIU et al [9] successfully fabricated the stereolithographical dense Si3N4 ceramics (ρ=3.28 g/cm3) using 5 wt% Y2O3 and 3 wt% Al2O3 as the sintering additives. In contrast, activated sintering techniques, including gas pressure sintering (GPS), hot isostatic sintering (HIS), spark plasma sintering (SPS) and/or flash sintering, could be more efficient to fabricate high performance ceramics by tailoring the structure/ microstructure during the sintering processing [19-21]. The densification of ceramic is a vital part in the sintering processing. Fundamental understanding of densification mechanism will be significantly beneficial to reduce the gap between the technological and fabrication achievements. Therefore, it is clear that it is of crucial importance to understand the sintering mechanism of stereolithographical ceramics, which is paid much less attention. However, the precision dilatometers for measuring linear expansion coefficient devoted to the study of densification mechanism are seldom equipped in gas pressure sintering or hot isostatic sintering. As a result, it is hard to obtain the densification curves in these approaches. In contrast, the shrinkage curves are involved with the displacement of indenters throughout SPS processing, which makes the spark plasma sintering (SPS) and/or flash sintering a promising and powerful technologies to rapidly prepare dense ceramics.

Existing works have thoroughly investigated the densification model of covalent ceramics with sintering additives. For example, BABINI [22] proposed a diffusion model for the oxidation of hot pressed Si3N4-Y2O3-SiO2 materials. ZHANG [23] systematically studied the densification models of boron carbide (B4C) with low-melting-point sintering aid during SPS processing and employed a more accurate effective stress to consider the deviation of the internal stress caused by the presence of the sintering aid. However, the densification mechanism of stereolithographic ceramics with sintering additives by field assisted sintering processing was rarely reported. In addition, research on the densification mechanism of stereolithographic ceramics is indeed of great significance for simplifying technological processes and optimizing its parameters to further improve the performance of materials. In order to systematically study stereolithographic ceramic materials, there is a great need to confirm the densification mechanism of stereolithographic ceramics with low melting point sintering additives. Many previous studies have shown that rare earth metal oxides are ideal sintering aids in silicon nitride (Si3N4) ceramic systems.

This paper aims to clarify the densification mechanism of dense Si3N4 ceramics by stereolithography during the field assisted sintering. The cerium oxide (CeO2) with relatively low melting point is used as sintering additive.

2 Experimental procedure

Si3N4 powders with an average diameter of ~800 nm (purity>99.5%, Shanghai Aladdin Biological Co., Ltd.), sintering aid CeO2 powders (purity>99.99%, Shanghai Aladdin Biological Co., Ltd.), silane coupling agent KH560 (purity>99.99%, Nanjing Reagent Co., Ltd.), prepolymer (epoxy acrylate: EA, Shanghai BASF Chemical Co., Ltd.), reactive diluent (1,6-hexanediol diacrylate: HDDA, Shanghai BASF Chemical Co., Ltd.), photoinitiator (2,4,3 methylbenzoyl: TPO, Shanghai BASF Chemical Co., Ltd.) were prepared for the experiments.

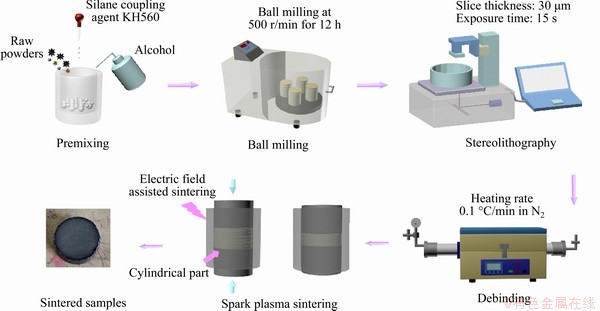

The simplified flowchart for preparing stereolithographic Si3N4 ceramics is shown in Figure 1. In the interest of gaining appropriate grain sizes that can yield a steady-state slurry, commercial Si3N4 powders were firstly placed in a jar, and refined by ball milling at 500 r/min for 24 h. Then, the fine Si3N4 powders, silane coupling agent KH560 and sintering aid CeO2 were uniformly mixed with alcohol as ball milling medium at 500 r/min for 12 h, followed by being dried in a vacuum oven at 80 °C. Subsequently, the mixture was ground and filtered through an 175 μm sieve to obtain modified agglomerate-free powders. Next, the prepolymer, reactive diluent and photoinitiator were poured into the resultant powders in an appropriate ratio. Finally, well-dispersed and stable curing slurry was prepared by vacuum stirring after 10 min [9].

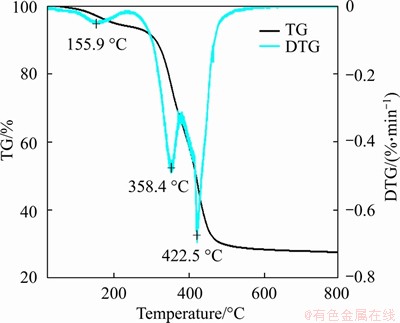

Green bodies were prepared by stereolithography with a diameter of 30 mm. The more detailed procedures were described elsewhere [10]. Briefly, a cylindrical print model was designed using Pro/Engineer: diameter 30 mm, height 5 mm; Then, the modified slurry was homogeneously coated on the molding table using a blade at room temperature (25 °C) and ready for printing. The printing parameters were set as slice thickness 30 μm, exposure time 15 s. The green part after curing was placed in a synchronous thermal analyzer (STA-449F3, NETZSCH GmbH, Germany) for thermal analysis, and the holding temperatures for debinding were determined to be 155.9, 358.4 and 422.5 °C, respectively, as shown in Figure 2.

Figure 1 Simplified flowchart for preparing stereolithographic Si3N4 ceramics

Figure 2 TG and DTG curves of stereolithographic Si3N4 ceramic

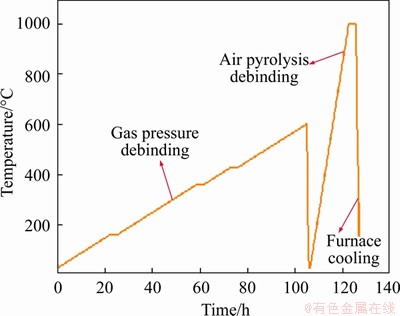

Air pyrolysis debinding integrated with gas pressure debinding, which is collectively named two-step debinding, was employed in the preparation processing of stereolithographic Si3N4 ceramic: 1) The specimen was firstly placed in a pipe furnace (OTF-1200X-II, Kejing Ltd., China) for gas pressure debinding (heating rate: 0.1 °C/min), and the gas pressure was adjusted to control the pyrolysis rate of organics to reduce the adverse impact on the weak interlayer bonding. 2) Subsequently, the cylindrical part was transferred to a box furnace (KSL-1700X-A1, Kejing Ltd., China) for air debinding (heating rate: 0.1 °C/min) to further remove the residual carbon element in the green body. The schematic representation of the two-step debound route is shown in Figure 3.

Figure 3 Schematic representation of two-step debound route

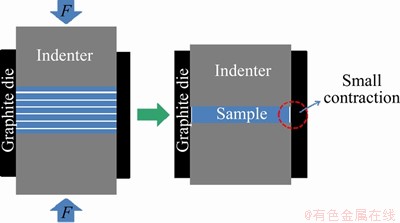

After that, the printed green bodies were put into a graphite die which matches the diameter of the green part well and sintered by a SPS apparatus (FCT SPS Systems GmbH, Germany) with a heating rate of 100 °C/min, a soaking time of 30 min, and applied pressures of 30-50 MPa in a temperature range from 1550 to 1700 °C. The schematic representation of the spark plasma sintering (SPS) and/or flash sintering processing of stereolithographic Si3N4 ceramic is shown in Figure 4. The sintering density of the samples was measured by the Archimedes method at least 5 times.

Figure 4 Schematic representation of spark plasma sintering (SPS) and/or flash sintering processing of stereolithographic Si3N4 ceramics

High-accuracy results including time and the corresponding instantaneous displacement of indenters during the sintering processing were recorded through the controller (HNC 100, Boschrexroth Ltd., Germany). Before characterization, the surfaces of specimens were treated as necessary. They were ground and polished with diamond powders to remove the carburized layer on the surface of stereolithographic Si3N4 ceramics. The average diameters of diamond powders are 5, 1, 0.5 μm, respectively. The microstructure and chemistry of the grain boundary of the sintered Si3N4 ceramics were characterized by a transmission electron microscope (TEM; Titan G2 60-300, FEI, USA) equipped with an energy dispersive spectrometer (EDS). TEM specimens were prepared by focused ion beam (FIB; Helios Nanolab 600i, FEI, USA) using an accelerated Ga ion beam irradiation induced by 30 kV voltage. The hardness of the specimens with a smooth surface (Ra ≤0.2 μm) was measured by a Vickers hardness tester. The load force was set to 10 kg, and the loading time was 10 s. 3-5 square cone indentations were random taken from each specimen. The fracture toughness of stereolithographic Si3N4 ceramics was determined by indentations, combined with the elastic modulus E, HV hardness, load force F and half length of indentation C of the samples.

3 Results and discussion

3.1 Sintering behaviors

Based on the fundamental understanding of SPS device, the instantaneous height L of the samples was calculated by the displacement of the upper and lower indenters. Due to the small contraction in the direction of diameter, the change in sample length could be converted into the change in relative density [23], so the instantaneous relative density, D, is indicated by the equation below:

(1)

(1)

where Lf is the final height of the samples; Df is the final sintering density of samples.

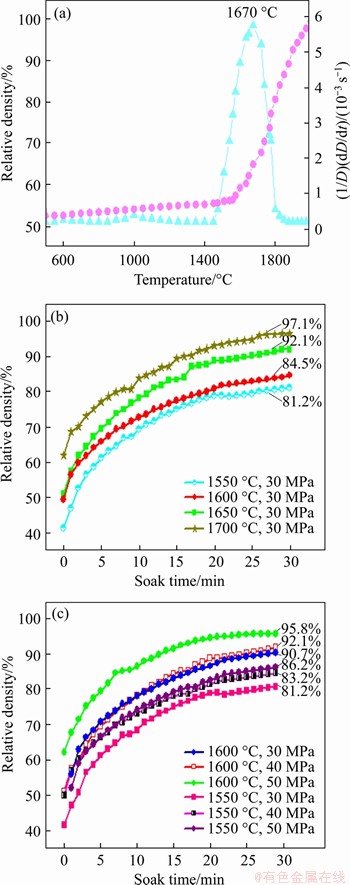

Similar to the sintering process of traditional approach, the densification of stereolithographic Si3N4 ceramics commences in the early stage. Exceeding the corresponding sintering temperature of the maximum densification rate (Tmax), the two steps including grain growth and porosity elimination mainly occur. The instantaneous relative density and densification rate were firstly investigated during the field assisted sintering processing. Figure 5(a) shows the dependence of the derived instantaneous sintering density and densification rate (1/D(dD/dt)) of stereolithographic Si3N4 on the sintering temperature. As shown, the parts start to shrink at ~1450 °C and the maximum densification rate appears at ~1670 °C. The sintering density is relatively low (~80%) at 1800 °C as compared to that of the parts by conventional pressureless sintering. When the sintering temperature is 1900 °C, the sintering density is still low (~90%). It is believed to be attributed to the low powder loading and high porosity of the debound stereolithographic Si3N4 ceramics. The existence of large interstices can directly reduce the wetting angle between the oxynitride liquid phases and grains, which may slowdown the solution-precipitation processing. Besides, heating up to achieve sufficient reconstruction from α to β will encounter decomposition, which leads to an adverse effect on the boost of sintering density. The dependence of the sintering density on the sintering temperature and applied pressure is shown in Figures 5(b) and (c), respectively. Figure 5(b) indicates that the sintering density increases to 97.1% from 81.2% when the sintering temperature increases to 1700 °C from 1550 °C. This shows that the sintering temperature plays a dominant role in determining the densification of stereolithographic Si3N4 ceramics [24, 25]. The temperature of sintering has a great effect on the dissolution of α-Si3N4 in the liquid phases. At a low temperature range, dissolution of α-Si3N4 in the liquid phases and transformation of α-Si3N4 to β-Si3N4 are difficult to complete. At this moment, the reorganization of α-Si3N4 particles under liquid surface tension and applied pressure is the dominating mechanism for densification. On the contrary, the complete dissolution of α-Si3N4 in the liquid phase is enabled when the temperature is elevated, and the β-Si3N4 is rapidly and massively transformed via precipitating to further increase the relative density of the samples. However, when the sintering temperature elevated sharply, the growth rate of the relative density of the sintered sample will slow down or even decrease. As the sintering temperature rises, the precipitated β-Si3N4 grains gradually increase and grow. The mechanical interlocking structure between the needle-like grains is formed, which induces the internal pores of the samples and reduces the overall relative density. Especially for stereolithographic specimens, its green part feature (high porosity) gives the resulting interlocking structure a larger scope of action, which prevents the further densification of grains in a larger area. Besides, the decomposition of silicon nitride ceramics appears at elevated temperature (over 1650 °C), which leads to a negative effect on the boost of relative density as well.

Figure 5 Dependence of sintering density and densification rate on sintering temperature (a), dependence of sintering density on sintering temperature and soaking time (b) and dependence of sintering density on applied pressure and soaking time (c) for stereolithographic Si3N4 ceramics by field assisted sintering

In addition to the surface-tension force, extra sintering driving force can be provided by the applied pressure during the SPS. If the applied pressure is large enough, the surface-tension force becomes less dominant. As expected, the applied pressure can significantly improve the sintering density as well. As revealed in Figure 5(c), when the applied pressure increases to 50 MPa from 30 MPa, the relative density significantly increases to 95.8% from 90.7%. The improved sintering density of the Si3N4 ceramics is due to the rearrangement of powder particles and shrinkage of the pores during the SPS processing [26]. In general, the effect of the sintering temperature on the relative density is more pronounced than that of the applied pressure. Dense stereolithographic ceramics can be achieved after considering these conclusions comprehensively.

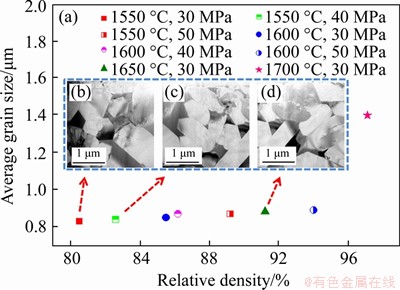

Figure 6(a) shows the effect of the applied pressure and sintering temperature on the grain size and sintering density. In contrast, Figures 6(b) and (c) show the bright-field TEM images of samples sintered at 1550 °C for 30 min under applied pressures of 30 and 40 MPa, respectively. As shown in Figure 6(d), the sintering density and grain size increase noticeably when the sintering temperature is elevated by 100 °C. The raising applied pressure during SPS process can induce the shrinkage of pores and the growth of grains, both of which promote the relative density of the samples. A same trend is detected by increasing the sintering temperature as well. And it is instructive to compare the effect of applied pressure and sintering temperature on the final relative density and grain growth during SPS processing. When the applied pressure rises to 40 MPa, the grain size increases slightly to ~840 nm. However, the difference in sintering density is small (2.8%). When the sintering temperature increases by 100 °C, the difference in grain size is 70 nm that is much larger than 10 nm and its sintering density improves significantly (13.7%). We would like to mention that the interlocking structure between the needle-like grains is presented in the sintered Si3N4 ceramics, a typical feature that shows the dissolution of α-Si3N4 in the liquid phase and phase transformation from α-Si3N4 to β-Si3N4.

Figure 6 Dependence of sintering temperature and applied pressure on average grain size and sintering density with 30 min soaking time for stereolithographic Si3N4 ceramics by field assisted sintering (a); Bright-field TEM images of stereolithographic Si3N4 ceramics by field assisted sintering: (b) 1550 °C, 30 MPa; (c) 1550 °C, 40 MPa; (d) 1650 °C, 30 MPa

The sintering processing of SPS can be divided into densification stage and non-densification stage [27]. When the maximum densification rate temperature (Tmax) is reached, the non-densification is dominant in which the grain growth and pores elimination take place [28]. The non-densification stage of stereolithographic Si3N4 ceramics with CeO2 as sintering additive appears at a lower sintering temperature (T≤1650 °C) in which the sample undergoes the densification, but the grain growth is not obvious. At a relatively high temperature (T>1650 °C), grains grow rapidly without distinct densification.

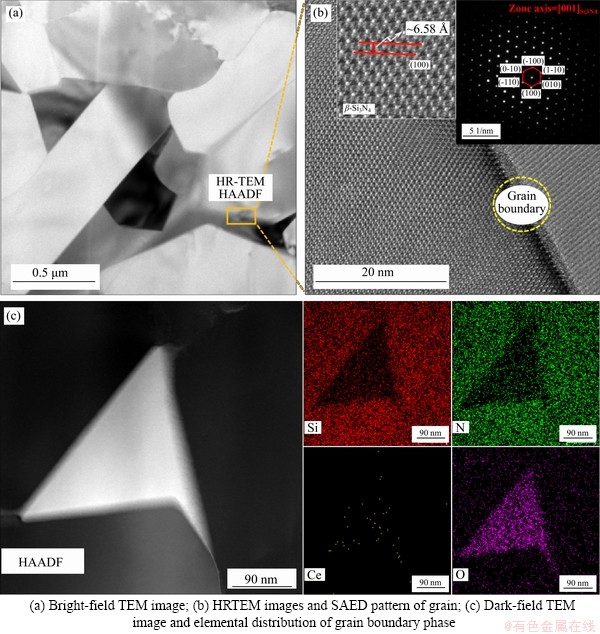

3.2 Microstructure and elemental analysis

The role of sintering additives contributed to the densification of Si3N4 ceramics has been studied in dry pressing and pressureless sintering. The densification mechanism of samples prepared by stereolithography and evolution of CeO2 during the field assisted sintering processing have been further verified in the current study. Figure 7(a) shows the TEM images of stereolithographic Si3N4 ceramics by field assisted sintering. The soaking period at 1650 °C was set as 30 min accompanied with a 30 MPa applied pressure. Again, typical β-Si3N4 phase grains with needle-like grains morphology and grain boundary phases (rendered in dark) can be observed. Figure 7(b) further shows the Si3N4 grains by high-resolution TEM images and selected area electronic diffraction (SAED) pattern observed along [001] zone axis. It is clear that the stereolithographic Si3N4 ceramics sintered by SPS are fully transformed to β-Si3N4 phase in the form of acicular (needle-like) grains as well, leading to an interlocking grain microstructure with high fracture toughness.

It is well known that the phase transformation from α- to β-Si3N4 phase is reconstructive and occurs slowly, but it could be significantly accelerated if a liquid phase is present [29]. Since the high-angle annular dark field TEM is sensitive to the atomic number contrast, the grain boundary phase and elemental analysis are further shown in Figure 7(c). It is observed that the grain boundary phases located in the center of image are rich in elements such as O, Ce, Si and N, while Ce element rarely exists in the grains. These results clearly show that CeO2 as sintering additive in Si3N4 ceramics is segregated in the grain boundaries and insoluble into the Si3N4 grains. A small amount of oxynitride liquid phases is present due to the oxygen from CeO2 sintering additive and/or oxygen impurity in Si3N4 grains.

3.3 Densification kinetics

To make a research concerning which mechanism governs the densification and which factor strengthens the densification process of the stereolithographic Si3N4 ceramics, it is necessary to confirm the related parameters including n and Qd.

Figure 7 TEM images of stereolithographic Si3N4 ceramics by field assisted sintering at 1650 °C with an applied pressure of 30 MPa for 30 min:

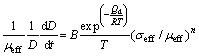

The relevant data during the SPS processing were recorded, aiming to further study the densification mechanism of CeO2-added stereolithographic Si3N4 ceramics. The stress exponent n calculated by the sintering kinetics equation was used to judge the densification mechanism that is being addressed. As shown in Figure 6(a), the difference in the grain size of all specimens is very small, so it can be assumed to keep constant when the sintering temperature is in a range from 1550 to 1600 °C and the applied pressure varies from 30 to 50 MPa. The simplified sintering kinetics equation below can be applied [30]:

(2)

(2)

where μeff is the instantaneous shear modulus; t is the time; D is the instantaneous relative density; B is a constant; Qd is apparent activation energy; R is the ideal gas constant; T is the thermodynamic temperature; and σeff is the instantaneous effective macro stress field acting on the powder bed; n is the stress exponent. The stress exponents n of ceramics could be an indicator of densification mechanism [28]. The dominant densification mechanism is considered grain boundary slipping when the stress exponent n is ≤2.

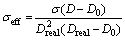

The stress exponent n can be derived by plotting ln[(1/μeff)(1/D)(dD/dt)] against ln(σeff/μeff) using the equation above. Figure 8 shows the effect of sintering temperature and applied pressure on the stress exponent n. The stress exponent n is ~1.05 for Si3N4 ceramics by SPS with 30 MPa applied stress and 1600 °C sintering temperature (the rightmost line in Figure 8). While the applied pressure increases to 50 MPa, the value of n increases to ~1.33 for SPS-ed Si3N4 ceramics with 50 MPa applied press (three lines arranged regularly in the right part of Figure 8). Under fixed applied pressure, the stress exponent n increases with increase sintering temperature. Temperature-dependence of stress exponent n in the stereolithographic samples is presented clearly. The stress exponent n of all SPS-ed Si3N4 ceramics is in a range between 1 and 2. Combining the presence of liquid phase in the grain boundary during the SPS processing, it is clear that the grain boundary slipping plays a dominating role in the densification process of stereolithographic Si3N4 ceramics. Normally, different stress exponents n represent different regimes of densification mechanism. For the densification mechanism revealed by a lower stress exponent (n kept 1-2), scholars have conducted relative research using the same sintering kinetics model. For instance, GENDRE [31] studied the creep behavior of zirconium oxycarbide and proposed that the densification mechanism is grain boundary slipping when the stress exponent n≤2. ANTOU [32] proposed that the grain boundary glide governed the densification processing when the stress exponent n=1-2. Therefore, the densification mechanism whose stress exponent n varies between 1 and 2 is clearly verified. And it is reasonably believed that the mechanism of grain boundary slipping plays a dominating role in the densification process of stereolithographic Si3N4 ceramics, which also validates the previous idea.

Knowing the value of n, the apparent activation energy Qd can be evaluated as well. It is well known that the apparent activation energy Qd is sensitive to pressure. The apparent activation energies of samples, with applied pressures of 30, 40 and 50 MPa respectively, were calculated to further understand the densification process of stereolithographic silicon nitride ceramics. The apparent sintering activation energy (Qd) can be derived by the equation as follows:

(3)

(3)

where K is a constant.

Figures 8(b)-(d) plot the densification rate (1/D)(dD/dt) of Si3N4 ceramics as a function of relative sintering density under the applied pressures in a range from 30 to 50 MPa. An appropriate value of (1/D)(dD/dt) is chosen in Figures 8(b)-(d) (the (1/D)(dD/dt) value in this experiment is all selected as 1×10-3 s-1), and the corresponding relative densities suffered various soaking temperatures at this densification rate are confirmed (indicated by the blue dotted lines). The values of μeff and σeff are obtained by the equations below [33]:

(4)

(4)

(5)

(5)

where Eth is the elastic modulus (Eth=310 GPa for dense silicon nitride ceramics); υeff is the Poisson ratio (υeff is 0.25 for silicon nitride ceramics); D0 is the initial density of green body; Dreal is the effective density after removing sintering aids.

Figure 8(e) shows the 1/T dependence of ln[(T/μeff)(μeff/σeff)n(1/D)(dD/dt)]. The slope of straight line fitted from each point equals -Qd/R and the apparent activation energy of stereolithographic Si3N4 ceramics with 30-50 MPa applied pressures is derived as 384.75, 276.61 and 193.95 kJ/mol, respectively. Results indicate that the applied pressure plays an important role in promoting the densification process of sample. The apparent activation energy of ceramics appears to decline as the applied pressure continues to increase, accompanied by a boost in the degree of densification. These values are lower than the apparent activation energy of hot pressed Si3N4 ceramics as reported. BABINI [22] calculated the apparent activation energy of hot pressed Si3N4 ceramics with Y2O3-SiO2 as sintering additive (Qd=544 kJ/mol). SANTOS et al [34] proposed the apparent activation energy of hot pressed Si3N4 ceramics with RE2O3-Al2O3 as sintering additive is in a range from 461 to 866 kJ/mol (RE2O3 refers to rare earth oxides). This difference might be attributed to the pulse current passing through the graphite die into the powder particles that can generate a strong electric field across the Si3N4 ceramics particles. It is well established that the plasma discharge phenomenon and the Joule heating generated by the current can effectively heat the powder particles and increase the amplitude of atomic vibration to further reduce the apparent activation energy. Meanwhile, the electric-field induced non-equilibrium defects have been proposed to explain the low value of apparent activation energy as well [35]. The Vickers hardness and fracture toughness of stereolithographic Si3N4 ceramics (ρ=3.19 g/cm3) by field assisted sintering are HV10/10 (1347.9±2.4) and (6.57±0.07) MPa·m1/2, respectively.

Figure 8 Dependence of sintering temperature and applied pressure on stress exponent n of Si3N4 ceramics by field assisted sintering (a); Variation of 1/D(dD/dt) as a function of the sintering density D for ceramics sintered with applied pressure of 50 MPa (b), 40 MPa (c), and 30 MPa (d); Dependence of apparent activation energy Qd of Si3N4 ceramics on applied pressures (e)

4 Conclusions

In summary, dense stereolithographic Si3N4 ceramics with needle-like grains morphology were fabricated successfully by combining CeO2 as sintering additive and field assisted sintering. During the field assisted sintering process, CeO2 as sintering additive in Si3N4 ceramics segregates in the grain boundaries and is insoluble into the Si3N4 grains. A small amount of oxynitride liquid phase is present due to the oxygen atoms from CeO2 and/or oxygen impurity in Si3N4 grains. The grain boundary slipping plays a dominating role in the densification process of stereolithographic Si3N4 ceramics. The dense Si3N4 ceramics by stereolithography with good mechanical properties can be fabricated by combining the field assisted sintering with sintering additive.

Contributors

The overarching research goals were developed by RAO Wei-dong, LIU Yao, CHENG Li-jing, and LIU Shao-jun. RAO Wei-dong provided the measured raw data, and analyzed the measured data. RAO Wei-dong, LIU Yao, CHENG Li-jing and LIU Shao-jun analyzed the calculated results. The initial draft of the manuscript was written by RAO Wei-dong. All authors replied to reviewers’ comments and revised the final version.

Conflict of interest

RAO Wei-dong, LIU Yao, CHENG Li-jing, and LIU Shao-jun declare that they have no conflict of interest.

References

[1] ADAKE CV, BHARGAVA P, GANDHI P. Effect of surfactant on dispersion of alumina in photopolymerizable monomers and their UV curing behavior for microstereolithography [J]. Ceramics International, 2015, 41(4): 5301-5308. DOI: 10.101 6/j.ceramint.2014.12.066.

[2] HALLORAN JW. Ceramic stereolithography: Additive manufacturing for ceramics by photopolymerization [J]. Annual Review of Materials Research, 2016, 46: 19-40. DOI: 10.1146/ annurev-matsci-070115-031841.

[3] HINCZEWSKI C, CORBEL S, CHARTIER T. Ceramic suspensions suitable for stereolithography [J]. Journal of the European Ceramic Society, 1998, 18: 583. DOI: 10.1016/S09 55-2219(97)00186-6.

[4] GRIFFITH M L, HALLORAN JW. Freeform Fabrication of Ceramics via Stereolithography [J]. Journal of the American Ceramic Society, 1996, 79: 2601. DOI: 10.1111/j.1151-2916.1996.tb09022.x.

[5] HELi, SONGXuan. Supportability of a high-yield-stress slurry in a new stereolithography-based ceramic fabrication process [J]. JOM, 2018, 70(3): 407-412. DOI: 10.1007/ s11837-017-2657-3.

[6] HINCZEWSKI C, CORBEL S, CHARTIER T. Stereolithography for the fabrication of ceramic three-dimensional parts [J]. Rapid Prototyping Journal, 1998, 4(3): 104-111. DOI: 10.1108/ 13552549810222867.

[7] DOREAU F, CHAPUT C, CHARTIER T. Stereolithography for manufacturing ceramic parts [J]. Advanced Engineering Materials, 2010, 2(8): 493-496. DOI: 10.1002/1527-2648(200008)2:8<493::AID-ADEM493>3.0.CO;2-C.

[8] FUXiang-song, ZOUBin, XINGHong-yu, LI Lei, LI Yi-shang, WANG Xin-feng. Effect of printing strategies on forming accuracy and mechanical properties of ZrO2 parts fabricated by SLA technology [J]. Ceramics International, 2019, 45(14): 17630. DOI: 10.1016/j.ceramint.2019.05.32 8.

[9] LIU Yao, ZHANLi-na, HE Yu, ZHANG Jun, HU Jian-jun, CHENG Li-jin, WU Qiu-mei, LIU Shao-jun. Stereolithographical fabrication of dense Si3N4 ceramics by slurry optimization and pressure sintering [J]. Ceramics International, 2019, 46(2): 2063. DOI: 10.1016/j.ceramint.2019.09.186.

[10] LIUYao, CHENG Li-jin, LI Hao, LI Qing, SHI Yuan, LIU Fei, WU Qiu-mei, LIU Shao-jun. Formation mechanism of stereolithography of Si3N4 slurry using silane coupling agent as modifier and dispersant [J]. Ceramics International, 2020, 46(10): 14583-14590. DOI: 10.1016/j.cerami nt.2020.02.258.

[11] TIANZhuo, YANGYu-ping, WANG Yong, WU Hai-dong, LIU Wei, WU Shang-hua. Fabrication and properties of a high porosity h-BN-SiO2 ceramics fabricated by stereolithography-based 3D printing [J]. Materials Letters, 2019, 236(2): 144-147. DOI: 10.1016/j.matlet.2018.10.058.

[12] PFAFFINGER M, MITTERAMSKOGLER G, GMEINER R, STAMPFL J. Thermal debinding of ceramic-filled photopolymers [J]. Materials Science Forum, 2015, 75: 825-826.

[13] LIUWei, WUHai-dong, ZHOU Mao-peng, HE Rong-xuan, JIANG Qiang-guo, WU Zi-wei, CHENG Yan-ling, SONG Xuan, CHEN Yong. Fabrication of fine-grained alumina ceramics by a novel process integrating stereolithography and liquid precursor infiltration processing [J]. Ceramics International, 2016, 42(15): 17736-17741. DOI: 10.1016/ j.ceramint.2016. 08.09 9.

[14] OGWU A A, DAVIES T J. Effect of transition/rare earth metal oxide additives on densification during sintering of Si3N4 [J]. Materials Science and Technology, 1993, 9: 945. DOI: 10.1179/0267083 93790171665.

[15] LEE K M, LEE WH, KOH Y H, CHOI J J, KIMHE, BAEK S S. Microstructural evolution and mechanical properties of gas-pressure-sintered Si3N4 with Yb2O3 as a sintering aid [J]. Journal of Materials Research, 1999, 14(5): 1904-1909. DOI: 10.1557/JMR.1999.0255.

[16] STRECKER K, GONZAGA R, RIBEIRO S, HOFFMANN M J. Substitution of Y2O3 by a rare earth oxide mixture as sintering additive of Si3N4 ceramics [J]. Materials Letters, 2000, 45(1): 39-42. DOI: 10.1016/S0167-577X (00)00071-9.

[17] XUPeng, YANG Jian, QIU Tai, CHEN Xing. Effect of annealing on microstructure and properties of Si3N4-AlN composite ceramics [J]. Journal of Central South University of Technology, 2011, 18(4): 960-965. DOI: 10.1007/s11771-011-0787-2.

[18] GAOQiang-jian, JIANG Xin, WEI Guo, SHEN Feng-man. Effects of MgO on densification and consolidation of oxidized pellets [J]. Journal of Central South University, 2014, 21(3): 877-883. DOI: 10.1007/s11771-014-2013-5.

[19] CHAIM R. Densification mechanisms in spark plasma sintering of nanocrystalline ceramics [J]. Materials Science and Engineering A, 2007, 443: 25. DOI: 10.1016/ j.msea.2006.07.092.

[20] MACAK, POUCHLY V, BODISOVAK, SVANCAREK P, GALUSEK D. Densification of fine-grained alumina ceramics doped by magnesia, yttria and zirconia evaluated by two different sintering models [J]. Journal of the European Ceramic Society, 2014, 34(16): 4363-4372. DOI: 10.1016/ j.jeurceramsoc.2 014.06.030.

[21] SAHEBN, HAKEEM A S, KHALIL A, AL-AQEELIN, LAOUI T. Synthesis and spark plasma sintering of Al-Mg-Zr alloys [J]. Journal of Central South University, 2013, 20(1): 7-14. DOI: 10.1007/s117 71-013-1452-8.

[22] BABINI G N, BELLOSI A, VINCENZINI P. A diffusion model for the oxidation of hot pressed Si3N4-Y2O3-SiO2 materials [J]. Journal of Materials Science, 1984, 19(3): 1029-1042. DOI: 10.1007/BF00540473.

[23] ZHANGMei, YUAN Tie-chui, LI Rui-di, XIE Si-yao, WANG Min-bo, WENG Qi-gang. Densification mechanisms and microstructural evolution during spark plasma sintering of boron carbide powders [J]. Ceramics International, 2018, 44(4): 3571-3579. DOI: 10.101 6/j.ceramint.2017.11.061.

[24] KUZJUKEVICS A, ISHIZAKIK. Sintering of silicon nitride with YAlO3 additive [J]. Journal of the American Ceramic Society, 1993, 76: 2373. DOI: 10.1111/ j.1151-2916.1993.tb07780.x.

[25] HIROSAKI N, OKADA A, MATOBA K. Sintering of Si3N4 with the addition of rare-earth oxides [J]. Journal of the American Ceramic Society, 1988, 71(3): 144. DOI: 10.1111/ j.1151-2916.1988.tb05036.x.

[26] ANJia-xin, XUEWen-dong,ZHAI Feng-rui, XU Ruo-meng, SUN Jia-lin. Effect of sintering pressure on mechanical properties of BN-Si3N4 ceramic composites prepared by spark plasma sintering [J]. Key Engineering Materials, 2016, 697: 188-192. DOI: 10.4028/www. scientific.net/KEM.697.188.

[27] CHENGLi-jin, JIANGShao-wen, MA Qing, SHANG Zhen-gang, LIU Shao-jun. Sintering behavior and microwave properties of dense 0.7CaTiO3–0.3NdAlO3 ceramics with sub-micron sized grains by spark plasma sintering [J]. Scripta Materialia, 2016, 115: 80. DOI: 10.1016/j.scriptama t.2016.01.003.

[28] LIUGuang-hong, LIRui-di, YUAN Tie-chui, ZHANG Mei, ZENG Fan-hao. Spark plasma sintering of pure TiCN: Densification mechanism, grain growth and mechanical properties [J]. International Journal of Refractory Metals and Hard Materials, 2017, 66: 68-75. DOI: 10.1016/j.ijrmhm. 2017.02.008.

[29] YOKOTA H, YAMADA S, IBUKIYAMA M. Effect of large β-Si3N4 particles on the thermal conductivity of β-Si3N4 ceramics [J]. Journal of the European Ceramic Society, 2003, 23: 1175. DOI: 10.1016/S0955-2219(02)00291-1.

[30] BERNARD-GRANGERG, GUIZARD C. Spark plasma sintering of a commercially available granulated zirconia powder: I. Sintering path and hypotheses about the mechanism(s) controlling densification [J]. Acta Materialia, 2007, 55(10): 3493-3504. DOI: 10.1016/j.actamat.2007. 01.048.

[31] GENDRE M, MAITRE A, TROLLIARD G. A study of the densification mechanisms during spark plasma sintering of zirconium (oxy-)carbide powders [J]. Acta Materialia, 2010, 58(7): 2598-2609. DOI: 10.1016/ j.actamat.2009.12.046.

[32] ANTOU G, PRADEILLES N,GENDREM, MAITRE A. New approach of the evolution of densification mechanisms during spark plasma sintering: Application to zirconium (oxy-)carbide ceramics [J]. Scripta Materialia, 2015, 101: 103. DOI: 10.1016/j.scriptamat.2015.01.028.

[33] ZHANGMei, LIRui-di, YUAN Tie-chui, FENG Xiao, XIE Si-yao. Effect of low-melting-point sintering aid on densification mechanisms of boron carbide during spark plasma sintering [J]. Scripta Materialia, 2019, 163: 34-39. DOI: 10.1016/j.script amat.2018.12.036.

[34] SANTOS C,STRECKERK, BARBOZA M R J, NETO F P, SILVA O M M, DA SILVA C R M. Compressive creep behavior of hot-pressed Si3N4–CRE2O3–Al2O3 ceramics [J]. Materials Research Bulletin, 2004, 39(9): 1279-1289. DOI: 10.1016/ j.materresbul l.2004.04.006.

[35] REN K, LIU J. Flash sintering of yttria-stabilized zirconia: Fundamental understanding and applications [J]. Scripta Materialia, 2020, 187: 371-378. DOI: 10.1016/j.scriptamat. 2020.06.040.

(Edited by HE Yun-bin)

中文导读

光固化氮化硅陶瓷烧结致密化的机理研究

摘要:采用电场辅助烧结技术结合低熔点的烧结助剂,成功制备出致密的光固化氮化硅陶瓷。利用光固化增材制造技术成形的生坯具有粉末装载量低、孔隙率高的特性,调节烧结过程中烧结温度、保温时间等工艺参数可以有效地提高试样的致密度。在烧结致密化过程中,不同的应力指数n代表不同的致密化机理,通过简化后的烧结动力学模型,计算出所有试样的应力指数n均介于1到2之间,表明晶界滑移在光固化氮化硅陶瓷的致密化过程中起主导作用。在施加压力为30、40和50 MPa的条件下,光固化氮化硅陶瓷在烧结过程的表观活化能Qd分别为384.75,276.61,193.95 kJ/mol,说明压力的升高强化了试样的致密化过程。此外,光固化氮化硅陶瓷的维氏硬度和断裂韧性分别为HV10/10 (1347.9±2.4)和(6.57±0.07) MPa·m1/2。

关键词:光固化;氮化硅陶瓷;烧结机制;致密化;场辅助烧结

Foundation item: Project(20170410221235842) supported by Shenzhen Technical Innovation and Tackling Program, China; Project(2019zzts859) supported by the Fundamental Research Funds for the Central Universities, China; Project(20203BBE53053) supported by Key R&D Project of Jiangxi Provincial Department of Science and Technology, China

Received date: 2020-11-24; Accepted date: 2021-02-18

Corresponding author: LIU Shao-jun, PhD, Professor; Tel: +86-13974953502; E-mail: liumatthew@csu.edu.cn; ORCID: https://orcid.org/ 0000-0001-9814-9011