Microdefects and electron densities in NiTi shape memory alloys studied by positron annihilation

HU Yi-feng(胡益丰)1, 2, DENG Wen(邓 文)1, HAO Wen-bo(郝文博)1,

YUE Li(岳 丽)1, HUANG Le(黄 乐)1, HUANG Yu-yang(黄宇阳)1, XIONG Liang-yue(熊良钺)3

1. College of Physics Science and Technology, Guangxi University, Nanning 530004, China;

2. Department of Basic Science, Jiangsu Teachers University of Technology, Changzhou 213001, China;

3. Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China

Received 16 February 2006; accepted 16 July 2006

Abstract: The microdefects and free electron densities in B2, R and B19′ phases of Ni50.78Ti49.22 alloy were studied by positron lifetime measurements. Comparing the lifetime parameters of the Ni50.78Ti49.22 alloy measured at 295 K and 225 K, it is found that the free electron density of the R phase is lower than that of the B2 phase; the open volume of the defects of the R phase is larger, while the concentration of these defects is lower than that of the B2 phase. The Ni50.78Ti49.22 alloy exhibits B19′ phase at 115 K. In comparison with the R phase, the free electron density of the B19′ phase increases, the open volume of the defects of the B19′ phase reduces, and the concentration of these defects increases. The microdefects and the free electron density play an important role during the multi-step transformations (B2→R→B19′ phase transformations) in Ni50.78Ti49.22 alloy with the decrease of temperature.

Key words: NiTi alloy; microdefect; electron density; martensite transformation

1 Introduction

NiTi alloys are the most successful shape memory alloys as a result of their combination of good functional properties and excellent mechanical strength[1,2]. The thermal and mechanical shape memory behavior in these alloys is dependent upon their martensitic transformation, as has been discussed by numerous sources in the literatures[3, 4]. It is well established that two martensite phases, R-phase and B19′, are prone to form in NiTi alloys from the high temperature cubic B2 phase on cooling. Due to thermoelasticity and crystal invertibility of martensite transformation, parent phase can be restored on heating, consequently showing shape memory effect.

The defect and the electronic structure strongly affect the physical properties of the alloy[5, 6]. The NiTi alloy showing good reversible shape memory effect needs to contain some structural defects, neither too much nor too little[7]. ZHENG et al[8] have pointed out that the superelasticity of the moderately cold-drawn NiTi alloy is associated with the appearance and disappearance of micro-twinning. SHABALOVSKAJA et al[9] showed that the electron structure changed in martensite transformation. Up to now, a variety of methods have been used in the studies of NiTi alloys. However, experimental investigations by positron annihilation on the microdefects and electronic structure of different phases in NiTi alloy are very limited.

Positron is very sensitive to microdefects in metals and alloys[10]. Positron annihilation technique is useful for studies on microdefects and electron structure of materials, which can provide information about size and concentration of microdefects, electron density and so on [11]. In this work, positron lifetime spectra of single crystal Ni, polycrystal Ti, and the B2, R, B19′ phases of Ni50.78Ti49.22 alloy are measured and analyzed. The microdefects and electron density of different phases of Ni50.78Ti49.22 alloys are studied.

2 Experimental

The Ni50.78Ti49.22 alloy was prepared from pure Ni and Ti. The purity of raw materials used in this study was 99.97% Ni and 99.8% Ti (mass fraction). The electrode mixture of Ni and Ti materials was firstly melted by using vacuum consumable electrode arc, and then melted in vacuum induction furnace for the second time. After homogenizing for 4 h at 1 123 K, the ingot was calcined and hot rolled as rods with a diameter of 10 mm. Since the mass loss ratio after arc melting was less than 0.01 %, the alloy used in this study is expressed as the nominal chemical composition. Slices with the thickness of 1 mm were cut from the sample rods for positron lifetime measurements. For comparison, single crystal Ni and polycrystal Ti specimens were also prepared. Before test, the surfaces of the specimens were polished. In order to recover the defects, the Ni and Ti specimens were annealed at 1 000 ℃ for 2 h in vacuum furnace with a pressure of about 5?10-5 Pa, and then furnace cooled.

The critical points of phase transformation temperatures of the Ni50.78Ti49.22 alloy were measured by differential scanning calorimetry, and the results are as follows, Ms=222 K, Mf=197.2 K, As=237.5 K, Af=255.5 K. The R phase occurs between 270 K and 223 K.

The positron lifetime experiments were carried out by using a fast-fast coincidence ORTEC system. The samples were cooled by a cryostat system and the temperatures of the samples can be changed from 300 K to 15 K. A 0.76 Mbq source of 22Na was sandwiched between two identical sample pieces. The temperature of the Ni50.78Ti49.22 alloys started to decrease from 300 K and the positron lifetime spectra were measured at 295K, 225K and 115 K which corresponded to the B2, R and B19′ phases of the alloy, respectively. The positron lifetime spectra of single crystal Ni and polycrystal Ti were measured at 295 K. About 106 counts were accumulated for each spectrum.

3 Results and discussion

After source corrections and background subtractions, the spectra of the Ni50.78Ti49.22 alloys were analyzed using three decay lifetime components. The values of the lifetimes (τ1, τ2, τ3) and the corresponding intensities( ,

, ,

, ) vary with the samples. The long-life component τ3 (≈1 200 ps) in each spectra with a small intensity

) vary with the samples. The long-life component τ3 (≈1 200 ps) in each spectra with a small intensity  (<1%) is considered to be the result of positron annihilated at the surfaces of the samples. It is disregarded in our discussion. Renormalize the first two intensities

(<1%) is considered to be the result of positron annihilated at the surfaces of the samples. It is disregarded in our discussion. Renormalize the first two intensities  and

and  and mark them as I1 and I2. The intermediate-life component τ2 is the lifetime of positrons annihilated at the defects, and the corresponding positron annihilation rate in defects, λd, can be expressed as λd =

and mark them as I1 and I2. The intermediate-life component τ2 is the lifetime of positrons annihilated at the defects, and the corresponding positron annihilation rate in defects, λd, can be expressed as λd = . The positron annihilation rate and the lifetime in bulk, λb and τb, can be written as λb=I1

. The positron annihilation rate and the lifetime in bulk, λb and τb, can be written as λb=I1 +I2

+I2 , τb=

, τb= respectively[10].

respectively[10].

The electron densities in bulk and defects, nb and nd, can be estimated by the following formula given by BRANDT and REINHEIMER[12],

n=(λ-2)/134 (1)

where λ is the positron annihilation rate in ns-1, n is the electron density in atomic unit or a.u. (for electron density, n, 1a.u. =6.755×1030m-3).

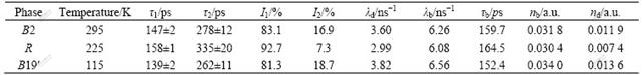

The parameters of positron lifetime spectra and electron densities in the bulk and the defects of the Ni50.78Ti49.22 alloy at 295, 225 and 115 K are shown in Table 1.

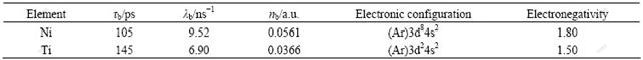

Only one lifetime component has been found in the spectra of the annealed single crystal Ni and polycrystal Ti. The bulk positron lifetimes, positron annihilation rates, electron densities, electronic configurations and electronegativities of pure Ni and Ti metals are listed in Table 2.

The positron annihilation rate in an alloy can be calculated by the local density approximation[13,14]. Especially, in a binary alloy consisting of metal elements of A and B, the positron annihilation rate in the alloy λcb(alloy) can be expressed as[11]

λcb(alloy)=xAλb(A)+xBλb(B) (2)

where λb(A) and λb(B) are the positron annihilation rates of the pure metals A and B; xA and xB are the mole fractions of metal elements A and B in the alloys, respectively.

Table 1 Parameters of positron lifetime spectra and electron densities of B2, R and B19′ phases of Ni50.78Ti49.22 alloy

Table 2 Bulk positron lifetimes, positron annihilation rates, electron densities, electronic configurations and electronegativities of Ni and Ti metals

At 295 K, the NiTi alloy is composed of B2 phase. In the B2 phase of Ni50.78Ti49.22 alloy, if we suppose that the bonding nature in the alloy is pure metallic bonds, the positron annihilation rate in the bulk of Ni50.78Ti49.22 alloy λcb(B2-NiTi) can be calculated by Eqn.(2). Let λb(Ni)=9.52 ns-1, λb(Ti)=6.90 ns-1 (Table 2), xNi=0.507 8 and xTi=0.492 2 in Eqn.(2), and then let λcb(B2-NiTi) in Eqn.(1), one can calculate the positron annihilation rate and the electron density in the bulk of the Ni50.78Ti49.22 alloy: λcb(B2-NiTi)=8.23 ns-1 and ncb(B2-NiTi)=0.046 5 a.u.

The electron density in the bulk of Ni50.78Ti49.22 alloy obtained from the present experiment is nb(B2)= 0.031 8 a.u. as shown in Table 1. It is lower than ncb(B2-NiTi). Thus, the bonding nature in Ni50.78Ti49.22 alloy is not a pure metallic bond.

The electronic configuration of Ni atom (3d84s2) is shown in Table 2. There are some 3d electrons without being coupled. The electronegativity of Ti (1.5) is smaller than that of Ni (1.8). When Ni atoms bond with Ti atoms, the electrons from Ti atoms may couple with these localized 3d electrons to form covalent bonds. Because of the localization of the covalent electrons, the free electron density in the bulk of the Ni50.78Ti49.22 alloy (nb) is low relative to the calculation (ncb). Our present results are in agreement with the results of JIA et al[15] which were calculated by using EET method.

The positron lifetime increases with the open volume of the defect[10]. The lifetime of positron annihilated in defects of the B2 phase of Ni50.78Ti49.22 alloy (τ2(B2) =(278±12)ps, Table 1) is larger than that in a monovacancy of Ni (τv(Ni)=170 ps)[16]. This indicates that there are not only the vacancies, dislocations but also the large-open-volume defects such as column cavities existing on the grain boundaries of NiTi alloy. The second lifetime component of the B2 phase with an intensity of I2(B2)=16.9% shows that there are some defects in the B2 phase of NiTi alloy. That is, some dislocations, grain boundaries and subgrain boundaries exist in the B2 phase of the NiTi alloy. The stress fields of these defects provide the preferential places for the nucleation of martensites and make the martensites grow regularly and homogeneously. It has been found that the presence of some dislocations in the NiTi alloy gives rise to the stable martensite transformation, and the alloy shows good shape memory effect[17].

At 225 K, the NiTi alloy is R phase. The free electron density of the R phase of the alloy (nb(R)= 0.030 4 a.u.) is lower than that of the B2 phase (nb(B2)= 0.031 8 a.u.) as shown in Table 1. This indicates that more valence electrons are localized to form covalent bonds in the R phase.

The second component lifetime of the R phase of NiTi alloy (τ2(R)=(335±20) ps) is longer than that of the B2 phase (τ2(B2)=(278±12) ps), and the intensity of the second lifetime component of the B2 phase (I2(R)=7.3%) is smaller than that of the B2 phase (I2(B2)=16.9%) (Table 1). That is, the open volume of the defects of the R phase is larger, while the concentration of defects is lower than that of the B2 phase. The above findings can be interpreted as follows: the phase transformation of B2→R is due to the forming and growing of the nucleation of asymmetric martensites. With the decrease of the temperature, at the beginning of the phase transformation, R-phase slices start to form at different dislocations and connect to each other; finally, the R-phase forms in the whole field, which leads to the decrease of the concentration of defects. On the other hand, the strong order atom arrangement and high ordering energy of R phase make its grain boundaries very little relaxed, which results in the increase of the open volume of grain boundaries.

At 115 K, the NiTi alloy is B19′ phase. The free electron density of the B19′ phase of the alloy (nb(B19′)= 0.034 0 a.u.) is larger than that of the R phase (nb(R)= 0.030 4 a.u.) as shown in Table 1. This means that more valence electrons participate in metallic bonds in the B19′ phase, and the valence electrons participating in covalent bonds are relatively fewer. KATSUYAMA et al [18] measured the variation of electrical resistivity vs temperature, and the results showed that the electrical resistivity of B19′ phase is less than that of R phase and the stability of covalent bonds in B19′ phase decreases.

It can be seen in Table 1 that τ2(B19′)(=(262±11)ps) is lower than τ2(R)(=(335±20)ps), and I2(B19′)(=18.7%) is larger than I2(R)(=7.3%). That is, the open volume of the defects of the B19′ phase is smaller, but the concentration of defects is higher than that of the R phase. This can be understood by the following explanation. With the decrease of temperature, the martensite transformation starts at Ms=222 K and finishes at Mf=197.2 K. During the formation of martensites, the parent phases accommodate to form high concentration of defects which in turn prevent the martensite from growing up further[19]. Due to lower symmetry of martensites, single-orientation parent phase may transform to 24 variants of martensites, whose sub- structure is twinning with the model of <011>Ⅱ[20]. On the other hand, the atom arrangements of the B19′ structure, being monoclinic space group, are relatively compact. Our experimental results demonstrate that the existence of high concentration of twinning defects in B19′ phase leads to the increase of the traps of positrons and thus the intensity of the second lifetime component I2(B19′) is increased, while the open volume of the twinning defects is smaller than that of the defects in the R phase.

In general, as the temperature decreases from 295 K to 115 K, the phase transformations of B2→R→B19′ take place in the Ni50.78Ti49.22 alloy. At 295, 225 and 115 K the Ni50.78Ti49.22 alloy exhibits the B2, R and B19′ phases, respectively. It has been shown in Table 1 that nb(B19′)>nb(B2)>nb(R) and nd(B19′)>nd(B2)>nd(R). The results of JIA et al[21] obtained by using EET method showed that the covalent electrons decrease from 4.640 7 per atom of B2-phase to 2.252 2 per atom of B19′-phase; the electrical resistivity decreases from 100 μΩ·cm of B2-phase to 70 μΩ·cm of B19′-phase; and the elastic modulus decreases from 75 GPa of B2-phase to 40 GPa of B19′-phase. Our results are in agreement with the results of JIA et al.

4 Conclusions

1) The concentration of microdefects and the free electron density of the B2, R and B19′ phases in the Ni50.78Ti49.22 alloy are very different. They play an important role during the multi-step martensite transformations (B2→R→B19′ phase transformations) in Ni50.78Ti49.22 alloy with the decrease of temperature.

2) The positron lifetime measurements on the Ni50.78Ti49.22 alloy at temperatures of 295 K and 225 K show that the free electron density in the R phase is lower than that of the B2 phase; the open volume of the defects of the R phase is larger; while the concentration of these defects is lower than that of the B2 phase.

3) As the Ni50.78Ti49.22 alloy is at temperatures of 225 K and 115 K, the free electron density in the B19′ phase is larger than that of the R phase; the open volume of the defects of the B19′ phase is smaller; but the concentration of these defects is higher than that of the R phase.

References

[1] SCHMIDT I, LAMMERING R. The damping behavior of superelastic NiTi components [J]. Materials Science and Engineering A, 2004, 378: 70-75.

[2] XING Ting-yong, ZHENG Yan-jun, CUI Li-shan. Recovery stress characteristics of TiNi alloy wires after partial martensitic transformation under different constraint conditions [J]. Trans Nonferrous Met Soc China, 2005, 15(2): 336-339.

[3] HITOSHI M. Transformation behavior with thermal cycling in NiTi alloys [J]. Journal of Alloys and Compounds, 2003, 350: 213-217.

[4] CHU C L, CHUNG J CY, CHU P K. Effects of heat treatment on characteristics of porous Ni-rich NiTi SMA prepared by SHS technique [J]. Trans Nonferrous Met Soc China, 2006, 16(1): 49-53.

[5] DENG W, GUO J T, BRUSA R S, KARWASZ G P, ZECCA A. Effects of Zr and Nb on d electrons in NiAl alloy studied by coincidence positron annihilation spectroscopy [J]. Materials Letters, 2005, 59: 3389-3392.

[6] DENG W, HUANG Y Y, BRUSA R S. The 3d-shell electrons in NiAl-based alloys containing Cr and Co studied by positron annihilation [J]. Journal of Alloys and Compounds, 2005, 386: 103-106.

[7] YOU Fu-qiang, YIN Jun-lin, XIA Chao-hui, GAO Guo-hua. Positron study of microdefects in TiNi shape memory alloys [J]. Shanghai Iron and Steel Research, 2004(3): 55-63. (in Chinese)

[8] ZHENG Y F, HUANG B M, ZHANG J X, ZHAO L C. The microstructure and linear superelasticity of cold-drawn TiNi alloy [J]. Materials Science and Engineering A, 2000, 279: 25-35.

[9] SHABALOVSKAJA S A, LOTKOV A I. Valence band evolution and structural instability nature of intermetallic compounds of TiNi-TiPd system [J]. Solid State Communications, 1987, 62: 93-95.

[10] WEST R N. Positron studies of condensed mater [J]. Adv Phys, 1973, 22(3): 263-383.

[11] DENG Wen, HUANG Yu-yang, Wu Dao-hong, XIONG Liang-yu, WANG Shu-he, GUO Jian-ting. Influence of chemical on microdefects and composition and alloying elements electron density in Ni-Al alloys [J]. Trans Nonferrous Met Soc China, 2002, 12: 370-374.

[12] BRANDT W, REINHEIMER J. Theory of semiconductor response to charged particles [J]. Phys Rev B, 1970, 2(8): 3104-3112.

[13] LACK D G, WEST R N. Positron annihilation in disordered binary alloys [J]. J Phys F: Met Phys, 1974, 4(12): 2179-2188.

[14] STOTT M J, KUBICA P. New approach to the positron distribution in metals and alloys [J]. Phys Rev B, 1975, 11(1): 1-10.

[15] JIA Di, DONG Zhi-zhong, YU Shen-jun, LIU Wen-xi. Analysis of the valence electron structure and calculation of cohesive energy of NiTi alloys [J]. Chinese Journal of Rare Metals, 1998, 22(2): 103-105. (in Chinese)

[16] LI Yu-fang, GUO Jian-ting, SHEN Yi-fu. Influence of recrystallization and environment on tensile behavior of cold-rolled Ni3Al (Zr) alloys [J]. Trans Nonferrous Met Soc China, 2006, 16(2): 368-375.

[17] LIU Xiao-shan, HE Guo-qiu, DING Xiang-qun, YIN Jun-lin. A study of TiNi shape memory alloy by SEM and TEM [J]. Shanghai Iron and Steel Research, 2004(3): 20-23. (in Chinese)

[18] KATSUYAMA J, ARAKI H, MIZUNO M, SHIRAI Y. Pre- martensitic phenomena of thermoelastic martensitic transformation of NiTiCu alloys studied with positron annihilation lifetime spectroscopy [J]. Science and Technology of Advanced Materials, 2004, 5: 41-45.

[19] XU Zu-yao. Martensitic Transformation and Martensite [M]. Beijing: Science Press, 1980. (in Chinese)

[20] KIM J I, MIYAZAKI S. Effect of nano-scaled precipitates on shape memory behavior of Ti-50.9at.%Ni alloy [J]. Acta Materialia, 2005, 53: 4545-4554.

[21] JIA Di, DONG Zhi-zhong, YU Shen-jun, LIU Wen-xi. Valence electron structure and martensite transformation of NiTi shape memory alloys [J]. Chinese Journal of Atomic and Molecular Physics, 1998, 15(3): 421-426. (in Chinese)

(Edited by YUAN Sai-qian)

Foundation item: Project(50361002) supported by the National Natural Science Foundations of China; Project(0448006) supported by the Natural Science Foundation of Guangxi Province, China

Corresponding author: DENG Wen; Tel: +86-771-3232666; Fax: +86-771-3237386; E-mail: wdeng@gxu.edu.cn