文章编号:1004-0609(2015)08-2243-08

低温碱性熔炼分离富集铜阳极泥中的有价金属

郭学益1, 2,许志鹏1, 2,田庆华1, 2,李 栋1, 2

(1. 中南大学 冶金与环境学院,长沙 410083;

2. 中国有色金属工业清洁冶金工程研究中心,长沙 410083)

摘 要:采用低温碱性熔炼处理铜阳极泥(CAS),研究熔炼浸出过程各有价金属的分离富集行为。分析碱料比、熔炼温度、熔炼时间、浸出温度、浸出时间和液固比等6个因素对金属浸出率的影响。结果表明:优化条件为碱料比为0.5,熔炼温度为600 ℃,熔炼时间为60 min,浸出温度为70 ℃,浸出时间为60 min,液固比为12.5 mL/g。在此优化条件下,Se和As 的浸出率分别达95.79%和96.83%,Cu、Pb、Sb和Te的浸出率分别为0.16%、3.36%、1.02%和0.05%,实现了铜阳极泥中有价金属的有效分离和富集。

关键词:低温碱性熔炼;铜阳极泥;有价金属;分离;富集

中图分类号:TF83 文献标志码:A

Valuable metals separation from copper anode slime by low-temperature alkaline smelting process

GUO Xue-yi1, 2, XU Zhi-peng1, 2, TIAN Qing-hua1, 2, LI Dong1, 2

(1. School of Metallurgy and Environment, Central South University, Changsha 410083, China;

2. Cleaner Metallurgical Engineering Research Center, Nonferrous Metal Industry of China, Changsha 410083, China)

Abstract: The valuable metals were separated from copper anode slime (CAS) by low-temperature alkaline smelting process. The effects of the mass ratio of NaOH, smelting temperature, smelting time, leaching temperature, leaching time and liquid-solid ratio on the leaching efficiency of metals were investigated. The results show that the optimum conditions are determined as follows: m(NaOH)/m(CAS) is 0.5, smelting temperature is 600 ℃, smelting time is 60 min, leaching temperature is 70 ℃, leaching time is 60 min and liquid-solid ratio is 12.5 mL/g. Under the optimum conditions, leaching efficiencies of Se and As are 95.79% and 96.83%, while the leaching efficiencies of Cu, Pb, Sb and Te are 0.16%, 3.36%, 1.02% and 0.05%, respectively, leading to the separation and enrichment of valuable metals from copper anode slime relatively.

Key words: low-temperature alkaline smelting; copper anode slime; valuable metal; separation; enrichment

铜阳极泥是铜电解精炼过程中产出的一种重要副产品,它是由阳极铜在电解精炼过程中不溶于电解液的各种物质所组成[1-2],通常含有Au、Ag、Cu、Pb、Se、Te、As、Sb、Ni、Bi、S、Sn、Fe、SiO2、Al2O3、铂族金属和水分,是提取稀贵金属的重要原料[3]。铜阳极泥的处理应首先脱除部分贱金属,然后再用火法或湿法溶解的技术富集并产出贵金属合金或粉末,最后经过精炼产生贵金属产品[4],这些处理过程环环相扣,构成一个完整的阳极泥处理工艺,相对来说预处理过程是决定铜阳极泥处理工艺优劣的最为重要的环节[5]。预处理过程的目的是尽可能脱除Cu、Se和Te等金属并进一步富集贵金属,有报道的阳极泥预处理方法很多,如纯碱焙烧法[6]、硫酸化焙烧法[7]、氧化焙烧法[8]、加压氧化酸浸法[9-10]和加压氧化碱浸法[11-12]。纯碱焙烧法的优点是处理量大、能较好地将硒、碲与贵金属分离、有利于回收贵金属,且不存在设备腐蚀问题,缺点是操作复杂、污染较大、回收率低;硫酸化焙烧法具有焙烧温度低、硒和铜脱除率高等优点,但设备腐蚀快、辅助工序长、环境污染严重、砷分散问题突出;氧化焙烧法主要优点是硒的回收率较高、能实现碲和硒的分离,但生产周期长、能耗较高;加压氧化酸浸法的优点是铜脱除率高、工艺过程短,但存在设备易腐蚀、硒碲脱除率低、砷分散问题突出等缺点;加压氧化碱浸法优点是硒、砷脱除率高、工艺过程短,但存在设备要求高、操作复杂、碲回收率低等缺点。因此,如何有效、环保地分离富集铜阳极泥中有价金属是当前亟待解决的问题。

低温碱性熔炼[13]是在碱性介质中、在相对低的熔融温度条件下,将某些难回收金属元素形态转型为易于后续分离提取的金属形态,包括熔融温度下的氧化、还原、固化和硫化等,从而应用于分解含氧酸盐矿以及从精矿或尾渣中分离酸性或者两性物质的反应过程,在处理复杂资源时表现出金属直收率高、污染小、能耗低等诸多优点,是一种具有广泛应用前景的低碳重金属清洁冶金方法[14-17]。为了选择性分离铜阳极泥中的砷、硒以及富集铜、铅、锑、碲及贵金属,避免有价金属分散,提高资源利用率以及保护环境,本文作者采用低温碱性熔炼法预处理铜阳极泥,对熔炼及浸出过程的金属行为及分离工艺条件进行系统研究,以期为铜阳极泥的清洁回收提供理论和工艺依据。

1 实验

1.1 实验原料

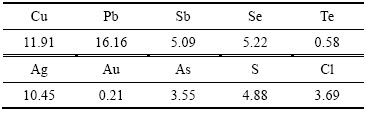

实验原料为国内某铜冶炼厂的铜阳极泥,在110 ℃下干燥24 h,破碎后,过孔径为180 mm筛。表1所列为其主要成分。

由表1可知,该阳极泥中重金属Cu、Pb和Sb,稀散金属Se、Te以及贵金属Au、Ag含量都较高,具有较高的回收价值。

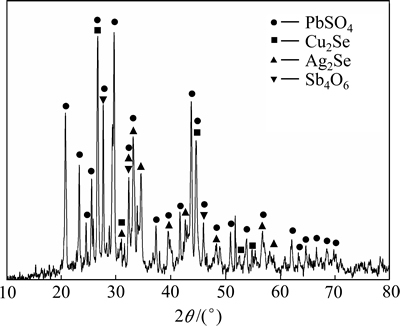

为了明晰铜阳极泥中各元素的存在形态,进行了XRD分析。图1所示为铜阳极泥的XRD谱。由图1可以看出,铜阳极泥中主要的物相为PbSO4、Ag2Se、Cu2Se和Sb4O6。

表1 铜阳极泥的化学成分

Table 1 Chemical composition of copper anode slime (mass fraction, %)

图1 铜阳极泥XRD谱

Fig. 1 XRD pattern of copper anode slime

1.2 实验方法

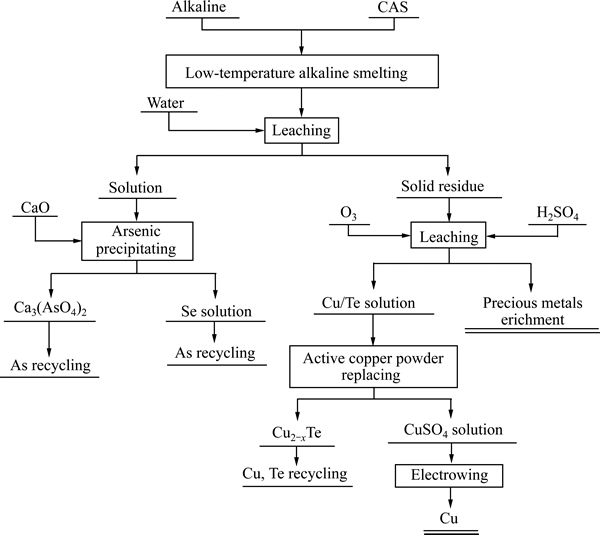

将4 g铜阳极泥与一定量的NaOH充分混合后,置于电阻炉中恒温熔炼一定时间,冷却后粉碎,加去离子水恒温振荡浸出一定时间(振荡频率为2~3 s-1),过滤后,取滤液进行检测,图2所示为实验流程图。通过测定溶液中金属离子浓度判断金属的浸出率(R),计算公式如式(1)所示:

(1)

(1)

式中:R为金属的浸出率,%; 为金属离子浓度,g/L;V为溶液体积,L;m为铜阳极泥质量,g;w为该金属在铜阳极泥中所占质量分数,%。

为金属离子浓度,g/L;V为溶液体积,L;m为铜阳极泥质量,g;w为该金属在铜阳极泥中所占质量分数,%。

采用北京瑞利分析仪器公司生产的WEX120型原子分光光度计检测滤液中的Cu、Pb、Sb浓度,采用电感耦合等离子体-原子发射光谱仪(Optimal 5300DV,Perkin-Elmer公司生产)检测Se、As、Te 浓度。

1.3 实验原理

图2 实验流程图

Fig. 2 Schematic diagram of experimental flow sheet

铜阳极泥在低温碱性熔炼过程中,其中的Ag2Se和Cu2Se被空气中的氧气氧化,银被氧化为Ag2O,而Ag2O不与碱反应,在高温条件下极易分解为不溶于水的银单质[18];Cu2Se易被氧化为CuO和SeO2,CuO在低碱度条件下基本不反应,而SeO2易被高活性熔融NaOH捕捉生成易溶于水的Na2SeO3;PbSO4与高活性熔融碱NaOH反应转化为PbO,PbO在碱度低时,不溶于碱溶液;Sb4O6和As2O3与高活性熔融NaOH反应生成不溶于水的Na2Sb4O7和可溶的NaAsO2。浸出过程中,硒和砷大部分进入浸出液,而铜、铅、锑、碲及金银等贵金属进入浸出渣,能有效地实现铜阳极泥中有价金属的分离和富集,主要的化学反应方程式如式(2)~(7)所示:

2Ag2Se+4NaOH+3O2=2Ag2O+2Na2SeO3+2H2O (2)

2Ag2O=4Ag +O2↑ (3)

Cu2Se+2O2+2NaOH=Na2SeO3+2CuO+H2O (4)

PbSO4+2NaOH=PbO+Na2SO4+H2O (5)

Sb4O6+2NaOH=Na2Sb4O7+H2O (6)

As2O3+2NaOH=2NaAsO2+H2O (7)

2 结果与讨论

2.1 熔炼过程实验

2.1.1 碱料比对金属浸出率的影响

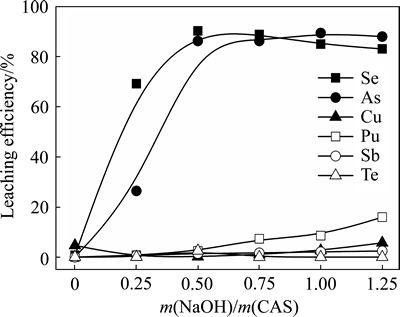

在熔炼温度为500 ℃、熔炼时间为60 min、浸出温度为40 ℃、浸出时间为60 min、液固比(浸出体积/铜阳极泥质量)为12.5 mL/g等条件下,研究了碱料比(m(NaOH)/m(CAS))分别为0、0.25、0.5、0.75和1.25时Cu、Pb、Sb、Te、Se和As的浸出率。图3所示为碱料比对金属浸出率的影响。

由图3可知,硒和砷的浸出率在碱料比小于0.5时,随着碱料比的增大快速上升,这是由于碱料比增大,反应体系中OH-的活度增强,促进硒和砷转化为易溶于碱溶液的Na2SeO3和NaAsO2,在碱料比0.5时,硒和砷浸出率分别达到最高90.28%和86.27%。当碱料比大于0.5时,硒和砷的浸出率基本保持稳定;而铜和铅在碱料比小的时侯基本不浸出,但随着碱料比的增加缓慢上升,这是因为Cu2Se和PbSO4在反应过程生成的CuO和PbO会与高浓度的OH-反应,生产易溶于碱溶液的Cu(OH)42-和PbO22-,在碱料比1.25时,铜和铅达到最高5.70%和15.94%,锑和碲的浸出率几乎为0。综上所述,碱料比选0.5为宜。

图3 碱料比对金属浸出率的影响

Fig. 3 Effect of mass ratio of NaOH on leaching efficiency of metals

CuO和PbO溶解在高碱性溶液的反应式如式(8)和(9)所示:

CuO+H2O+2OH-=Cu(OH)42- (8)

PbO+2OH-=PbO22-+H2O (9)

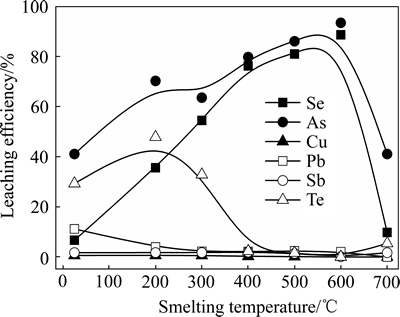

2.1.2 熔炼温度对金属浸出率的影响

在碱料比为0.5、熔炼时间为60 min、浸出温度为40 ℃、浸出时间为60 min、液固比为12.5 mL/g等条件下,研究了熔炼温度分别为25、200、300、400、500、600和700 ℃时Cu、Pb、Sb、Te、Se和As的浸出率。图4所示为熔炼温度对金属浸出率的影响。

图4 熔炼温度对金属浸出率的影响

Fig. 4 Effect of smelting temperature on leaching efficiency of metals

由图4可知,硒和砷的浸出率在熔炼温度低于600 ℃时快速上升,当熔炼温度600 ℃时,分别达到最高88.84%和93.66%,但当熔炼温度高于600 ℃时,浸出率急剧下降;碲的浸出率随着熔炼温度的升高先上升后下降,最后当熔炼温度高于500 ℃后,浸出率几乎为0;铅的浸出率随着熔炼温度的升高,先下降然后基本维持在2.15%左右;铜和锑的浸出率几乎为0;造成上述现象的可能原因是:熔炼温度升高,熔体黏度降低,流动性增强,化学反应速率及反应物、产物的扩散速率不断加快;同时,熔炼温度升高,熔体中O2溶解度减小[19],对各元素氧化作用减弱。在两种相互制约的因素作用下,各元素浸出率呈现先升高后降低的趋势。因此,适宜的熔炼温度为600 ℃。

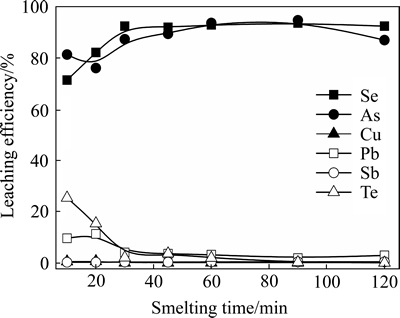

2.1.3 熔炼时间对金属浸出率的影响

在碱料比为0.5、熔炼温度为600 ℃、浸出温度为40 ℃、浸出时间为60 min、液固比为12.5 mL/g等条件下,研究了熔炼时间分别为10、20、30、45、60、90和120 min时Cu、Pb、Sb、Te、Se和As的浸出率。图5所示为熔炼时间对金属浸出率的影响。

图5 熔炼时间对金属浸出率的影响

Fig. 5 Effect of smelting time on leaching efficiency of metals

由图5可知,随着熔炼时间的延长,硒的浸出率快速上升,在熔炼时间为30 min时达到最高92.43%;砷的浸出率随着熔炼时间的延长先缓慢上升,在熔炼时间为60 min时达到最高91.55%,这是由于熔炼时间的延长有利于硒和砷向易溶于碱溶液的Na2SeO3和NaAsO2转化,当熔炼时间达到60 min后,硒和砷已经反应完全,因此,浸出率保持不变;而随着熔炼时间的延长,碲和铅的浸出率逐渐下降,在熔炼时间为60 min分别达到最低1.89%和3.15%;铜和锑由于生成不溶于碱溶液的CuO和Na2Sb4O7,因此,浸出率几乎为0,不随熔炼时间变化。综上所述,适宜的熔炼时间为60 min。

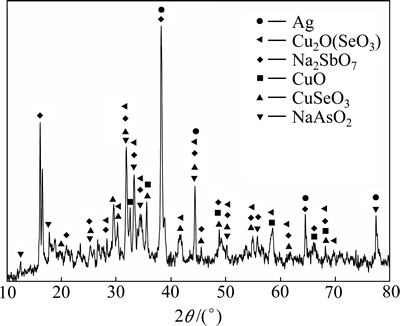

2.1.4 熔炼产物XRD分析

图6所示为熔炼最优条件下所得产物的XRD谱。由图6可知,铜阳极泥熔炼产物中主要的物相为Ag、Cu2O(SeO3)、Na2Sb4O7、CuO、CuSeO3和NaAsO2。因此,铜阳极泥在熔炼过程中,Ag2Se转化为Ag2O,Cu2Se被氧化为Cu2O(SeO3)、CuSeO3和CuO,Sb4O6转化为Na2Sb4O7,As2O3转化为NaAsO2。

CuO、Na2Sb4O7及贵金属均不溶于水,而NaAsO2易溶于水,且Cu2O(SeO3)和CuSeO3在水浸过程中会与NaOH反应,得到CuO和可溶于碱溶液的Na2SeO3。因此,将熔炼产物进行水浸,硒和砷进入浸出液,而铜、铅、锑、碲及金银等贵金属进入浸出渣,能实现铜阳极泥中有价金属的分离和富集。

图6 熔炼产物XRD谱

Fig. 6 XRD pattern of smelting product

2.2 浸出过程实验

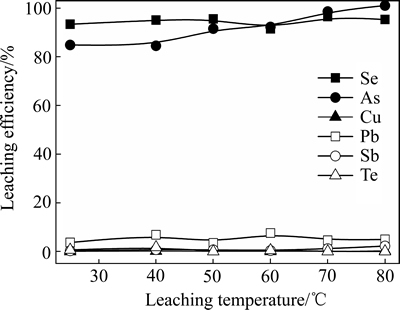

2.2.1 浸出温度对金属浸出率的影响

在碱料比为0.5、熔炼温度为600 ℃、熔炼时间为60 min、浸出时间为60 min、液固比为12.5 mL/g等条件下,研究了浸出温度分别为25、40、50、60、70和80 ℃时Cu、Pb、Sb、Te、Se和As的浸出率。图7所示为浸出温度对金属浸出率的影响。

由图7可知,随着浸出温度的升高,As的浸出率逐渐升高,在浸出温度为80 ℃时达到最高,这是因为随着浸出温度的升高,NaAsO2的溶解度增大,因此,其浸出率升高;而Se、Cu、Pb、Sb和Te的浸出率基

图7 浸出温度对金属浸出率的影响

Fig. 7 Effect of leaching temperature on leaching efficiency of metals

本不变,分别为95%、0.05%、5%、1.0%和0,说明浸出温度对各元素的浸出率影响不大。综合考虑能耗和浸出率,适宜的浸出温度为70 ℃。

2.2.2 浸出时间对金属浸出率的影响

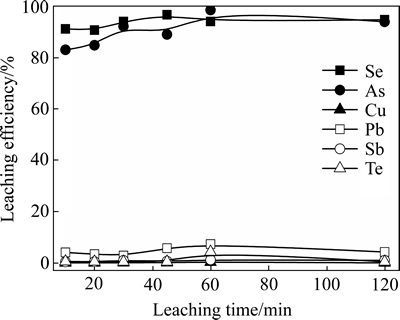

在碱料比为0.5、熔炼温度为600 ℃、熔炼时间为60 min、浸出温度为70 ℃、液固比为12.5 mL/g等条件下,研究了浸出时间分别为10、20、30、45、60和120 min时Cu、Pb、Sb、Te、Se和As的浸出率。图8所示为浸出时间对金属浸出率的影响。

图8 浸出时间对金属浸出率的影响

Fig. 8 Effect of leaching time on leaching efficiency of metals

由图8可知,随着浸出时间的延长,NaAsO2的溶解更加充分,砷的浸出率逐渐升高,同时,Cu2O(SeO3)及CuSeO3转化为Na2SeO3更为彻底,硒的浸出率亦不断升高,在浸出时间为60 min时,硒和砷的浸出率分别达到最高96.50%和98.59%;而铜、铅、锑和碲等由于生成了不溶于碱溶液的物质,因此,浸出时间对其浸出率基本没有影响。综合考虑,适宜的浸出时间为60 min。

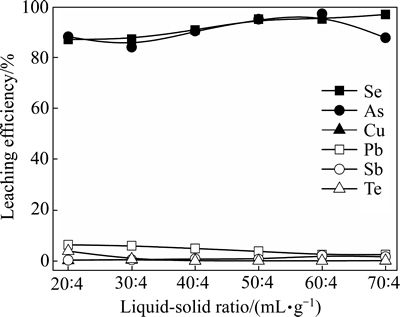

2.2.3 液固比对金属浸出率的影响

在碱料比为0.5、熔炼温度为600 ℃、熔炼时间为60 min、浸出温度为70 ℃、浸出时间为60 min等条件下,研究了液固比分别为20:4、30:4、40:4、50:4、60:4和70:4 mL/g时Cu、Pb、Sb、Te、Se和As的浸出率。图9所示为液固比对金属浸出率的影响。

由图9可知,随着液固比的增加,熔炼产物在液体中更分散,反应物混合更均匀,有利于反应物的扩散,而且碱溶液对NaAsO2和Na2SeO3的溶解能力增加,因此硒和砷的浸出率先逐渐升高,当溶液中硒和砷的浓度达到平衡后浸出率基本保持不变,在液固比为50:4 mL/g时,达到最高95.07%和95.07%;液固比对铜、铅、锑和碲的浸出率基本没有影响。一般来讲,液固比增加,钠盐间的同离子效应减弱,溶解反应更彻底,金属浸出升高;为尽量提高硒和砷的浸出率,同时又减少后续工序废液的体积,选液固比50:4 mL/g为宜。

图9 液固比对金属浸出率的影响

Fig. 9 Effect of liquid-solid ratio on leaching efficiency of metals

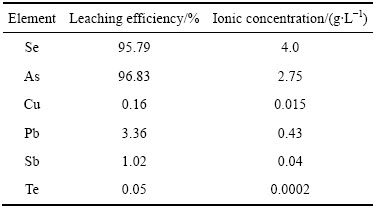

2.3 优化条件实验

通过以上的系列实验研究,可得出铜阳极泥低温碱性熔炼的优化工艺条件如下:碱料比为0.5、熔炼温度为600 ℃、熔炼时间为60 min、浸出温度为70 ℃、浸出时间为60 min、液固比为12.5 mL/g。在此优化条件下进行验证实验。表2所列为优化条件的实验结果。

表2 优化条件实验结果

Table 2 Experiment results of optimum experiment

由表2可知,在此优化条件下,铜阳极泥中大部分硒和砷进入浸出液中,硒、砷的浸出率分别为95.79%和96.83%,含硒、砷的碱溶液可用生石灰对其中的砷进行固定,使硒和砷有效分离,然后采用现有工艺可对硒和砷进行回收,而铜、铅、锑和碲几乎全部进入浸出渣中,其浸出率分别为0.16%、3.36%、1.02%和0.05%。因此,采用低温碱性熔炼处理铜阳极泥能实现铜阳极泥中有价金属的分离和富集。

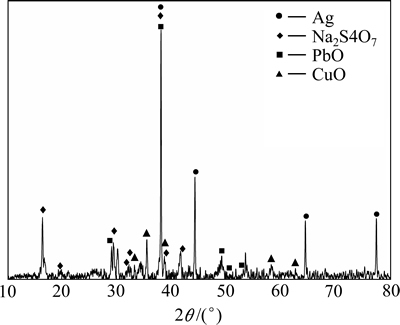

图10所示为此条件下得到的浸出渣的XRD谱。由图10可以看出,浸出渣中主要物相为Ag、Na2Sb4O7、PbO、CuO。而As和Se由于反应充分,残留于渣中的含量低,在XRD谱上未能显示。该浸出渣可以采用硫酸进行浸出,使其中的Cu、Te进入浸出液,而其他稀贵金属进入硫酸浸出渣中,从而进一步实现铜阳极泥中有价金属的有效分离和富集。

图10 浸出渣的XRD谱

Fig. 10 XRD pattern of leaching residue

3 结论

1) 采用低温碱性熔炼处理铜阳极泥,能避免传统工艺中有价金属的分散,使其中的硒和砷大部分进入浸出液中,而铜、铅、锑、碲和金银等金属几乎全部富集在浸出渣中,能实现铜阳极泥中有价金属的有效分离和富集。

2) 低温碱性熔炼处理铜阳极泥的适宜条件如下:碱料比为0.5、熔炼温度为600 ℃、熔炼时间为60 min、浸出温度为70 ℃、浸出时间为60 min、液固比为12.5 mL/g。在此条件下,Se、As、Cu、Pb、Sb和Te在溶液的中浸出率分别为95.79%、96.83%、0.16%、3.36%、1.02%、0.05%。

3) 低温碱性熔炼处理铜阳极泥,熔炼过程占主导作用,在熔炼过程中,各金属转化为可溶性与不溶性钠盐,浸出过程实现可溶性与不溶性钠盐的分离。

4) 低温碱性熔炼处理铜阳极泥所得的含硒、砷碱溶液可利用生石灰对其中的砷进行固定,使硒和砷有效分离,然后采用现有工艺可对硒和砷进行回收,而浸出渣可采用硫酸氧化浸出,使其中的Cu、Te进入浸出液,而其他稀贵金属进入硫酸浸出渣中,进一步实现铜阳极泥中有价金属的有效分离和富集。

REFERENCES

[1] 黄旺银, 苏庆平. 铜湿法冶金现状及发展趋势[J]. 安徽化工, 2011, 37(2): 13-14.

HUANG Wang-yin, SU Qing-ping. The situation and development of copper hydrometallurgy[J]. Anhui Chemical, 2011, 37(2): 13-14.

[2] 陈国宝, 杨洪英, 郭 军, 李雪娇. 铜阳极泥选冶富集金银的粗选研究[J]. 贵金属, 2013, 34(3): 32-33.

CHEN Guo-bao, YANG Hong-ying, GUO Jun, LI Xue-jiao. The rougher flotation process of copper anode slime for collecting gold and silver[J]. Precious Metals, 2013, 34(3): 32-33.

[3] 李雪娇, 杨洪英, 佟琳琳, 陈国宝. 铜阳极泥的工艺矿物学[J].东北大学学报(自然科学版), 2013, 34(4): 560-561.

LI Xue-jiao, YANG Hong-ying,TONG Lin-lin,CHEN Guo-bao. Technological mineralogy of copper anode slime[J]. Journal of Northeastern University (Natural Science), 2013, 34(4): 560-561.

[4] 刘伟锋. 碱性氧化法处理铜/铅阳极泥的研究[D]. 长沙: 中南大学, 2011: 120-128.

LIU Wei-feng. Study on copper/lead anode slimes treated by alkaline oxidative leaching[D]. Changsha: Central South University, 2011: 120-128.

[5] 郭学益, 肖彩梅, 钟菊芽, 田庆华. 铜阳极泥处理过程中贵金属的行为[J]. 中国有色金属学报, 2010, 20(5): 990-998.

GUO Xue-yi, XIAO Cai-mei, ZHONG Ju-ya, TIAN Qing-hua. Behaviors of precious metals in process of copper anode slime treatment[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(5): 990-998.

[6] 谢明辉, 王兴明, 陈后兴, 罗仙平. 碲的资源, 用途与提取分离技术研究现状[J]. 四川有色金属, 2005(1): 5-8.

XIE Ming-hui, WANG Xing-ming, CHEN Hou-xing, LUO Xian-ping. Resources, applications and up-to-date development of extraction separation technology of Te[J]. Sichuan Nonferrous Metals, 2005(1): 5-8.

[7] 谢红艳, 王吉坤, 路 辉. 从铜阳极泥中回收碲研究现状[J]. 湿法冶金, 2010, 29(3): 143-146.

XIE Hong-yan, WANG Ji-kun, LU Hui. Recovery of tellurium from copper anode slime research status[J]. Hydrometallurgy of China, 2010, 29(3): 143-146.

[8] 李运刚. 湿法处理铜阳极泥工艺研究(Ⅰ): 铜、硒、碲的浸 出[J]. 湿法冶金, 2000, 19(3): 41-45.

LI Yun-gang. Study on hydrometallurgical processing for copper-bearing anode mud(Ⅰ): Selective leaching of Cu, Se and Te[J]. Hydrometallurgy of China, 2000, 19(3): 41-45.

[9] 钟清慎, 贺秀珍, 马玉天, 刘玉强. 铜阳极泥氧压酸浸预处理工艺研究[J]. 有色金属(冶炼部分), 2014, 7: 5.

ZHONG Qing-shen, HE Xiu-zhen, MA Yu-tian, LIU Yu-qiang. Study of oxygen pressure acid leaching pretreatment technology for copper anode slime[J].Nonferrous Metals (Extractive Metallurgy), 2014, 7: 5.

[10] SCHLESINGER M E, KING M J, SOLE K C, DAVENPORT W G I. Extractive metallurgy ofcopper[M]. UK: Elsevier, 2011: 304-308

[11] 刘伟锋, 杨天足, 刘又年, 陈 霖, 张杜超, 王 安. 脱除铜阳极泥中贱金属的预处理工艺[J]. 中南大学学报(自然科学版), 2013, 44(4): 1332-1333.

LIU Wei-fen, YANG Tian-zu, LIU You-nian, CHEN Lin, ZHANG Du-chao, WANG An. Pretreatment process for removing base metals from copper anode slime[J]. Journal of Central South University (Science and Technology), 2013, 44(4): 1332-1333.

[12] LIU Wei-feng, YANG Tian-zu, ZHANG Du-chao, CHEN Lin, LIU You-nian. Pretreatment of copper anode slime with alkaline pressure oxidative leaching[J]. International Journal of Mineral Processing, 2014, 128: 48-54.

[13] 赵由才, 张承龙, 蒋家超. 碱介质湿法冶金技术[M]. 北京: 冶金工业出版社, 2009: 10-16.

ZHAO You -cai, ZHANG Cheng- long, JIANG Jia- chao. Hydrometallurgy technology in alkaline medium[M]. Beijing: Metallurgical Industry Press, 2009: 10-16.

[14] 唐谟堂, 唐朝波, 陈永明, 杨建广, 杨声海, 何 静, 欧 召. 一种很有前途的低碳清洁冶金方法——重金属低温熔盐冶金[J]. 中国有色冶金, 2010(4): 49-53.

TANG Mo-tang, TANG Chao-bo, CHEN Yong-ming, YANG Jian-guang, YANG Sheng-hai, HE Jing, OU Zhao. A promising low carbon clean metallurgical method: Low-temperature molten salt metallurgy of heavy metal[J]. China Nonferrous Metallurgy, 2010(4): 49-53.

[15] 胡宇杰, 唐朝波, 唐谟堂, 杨建广, 陈永明, 杨声海, 何 静.一种再生铅低温清洁冶金的绿色工艺[J]. 有色金属(冶炼部分), 2013, 8: 1-4.

HU Yu-jie, TANG Chao-bo, TANG Mo-tang, YANG Jian-guang, CHEN Yong-ming, YANG Sheng-hai, HE Jing. A clean and green process of low-temperature for smelting of secondary lead[J]. Nonferrous Metals (Extractive Metallurgy)2013, 8: 1-4.

[16] 郭学益, 刘静欣, 田庆华. 废弃电路板多金属粉末低温碱性熔炼过程的元素行为[J]. 中国有色金属学报, 2013, 23(6): 1757-1763.

GUO Xue-yi, LIU Jing-xin, TIAN Qing-hua. Elemental behavior of multi-component metal powders from waste printed circuit board during low-temperature alkaline smelting[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(6): 1757-1763.

[17] 刘静欣, 郭学益, 田庆华, 李 栋. 低温碱性熔炼分离提取废弃电路板粉末中两性金属[J]. 北京科技大学学报, 2014, 36(7): 875-879.

LIU Jing-xin, GUO Xue-yi, TIAN Qing-hua, LI Dong. Separation and extraction of amphoteric metals from waste printed circuit board powders by low-temperature alkaline smelting[J]. Journal of University of Science and Technology Beijing, 2014, 36(7): 875-879.

[18] 钟 勇. 从高含硒、碲和贵金属富料中分离提取硒、碲的研究[D]. 昆明: 昆明理工大学, 2008.

ZHONG Yong. Research of Selenium and tellurium separation and extraction from high selenium, tellurium and precious metal-rich compound[D]. Kunming: Kunming University of Science and Technology, 2008.

[19] 彭 中, 阎文艺, 王少娜, 郑诗礼, 杜 浩, 张 懿. NaOH溶液中碱浓度、氧气压力以及温度对Pt电极上氧气还原反应的影响[J]. 物理化学学报, 2014(1): 67-74.

PENG Zhong, YAN Wen-yi, WANG Shao-na, ZHENG Shi-li, DU Hao, ZHANG Yi. Effect of alkali concentration, oxygen partial pressure and temperature on oxygen reduction reaction on Pt electrode in NaOH solution[J]. Acta Physico-Chimica Sinica, 2014(1): 67-74.

(编辑 王 超)

基金项目:国家自然科学基金重点项目(51234009);国家自然科学基金面上项目(51074190);湖南省自然科学基金青年基金资助项目(14JJ3017);教育部博士点基金资助项目(20110162110049)

收稿日期:2014-09-22;修订日期:2015-05-07

通信作者:李 栋,讲师,博士;电话:0731-88876255;E-mail: yejin013_18@163.com