文章编号:1004-0609(2015)-03-0634-07

浸锌工艺对铝/电镀镍结合强度的影响

罗 扬1,崔景毅1,石高锋1, 2,杨文慧1,田文怀1

(1. 北京科技大学 材料科学与工程学院,北京 100083;

2. 湖北新冶钢有限公司 中信特钢研究院新冶钢分院,黄石 435001)

摘 要:为了研究浸锌工艺对铝的表面形貌以及铝/电镀镍之间结合强度的影响规律,分别对铝进行一次浸锌和二次浸锌处理,然后进行电镀操作并得到铝/电镀镍试样。通过拉伸试验测量铝/电镀镍之间的结合强度,并利用扫描电子显微镜(SEM)和能谱仪(EDS)考察铝表面、铝/电镀镍试样的截面及拉伸断面的形貌和化学成分。结果表明:铝在电镀前经一次浸锌处理后,铝/电镀镍结合强度为10.7MPa;经二次浸锌处理后,铝/电镀镍结合强度优于一次浸锌处理的,可达28.5 MPa。硅在一次浸锌层中形成夹杂物,导致铝受到镀液的腐蚀,是造成一次浸锌处理后铝/电镀镍结合强度较差的主要原因。

关键词:浸锌层;铝;电镀镍;结合强度

中图分类号:TQ153.4 文献标志码:A

Effect of zinc coating process on bonding strength of aluminium/electroplated nickel

LUO Yang1, CUI Jing-yi1, SHI Gao-feng1, 2, YANG Wen-hui1, TIAN Wen-huai1

(1. School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. Xinyegang Branch of Special Steel Research Institute of China International Trust and Investment Corporation,

Hubei Xingyegang Steel Co., Ltd., Huangshi 435001, China)

Abstract: In order to investigate the effect of zinc coating process on the surface morphology of aluminium and the bonding strength of aluminium/electroplated nickel, aluminium was coated with single and secondary zinc layer before electroplating, respectively. And then, aluminium/electroplated nickel specimens were prepared. The bonding strength of aluminium/electroplated nickel was measured by tensile tests. The morphologies of aluminum surfaces, the cross sections and tensile fractures of the aluminium/electroplated nickel specimens were investigated by scanning electron microscopy (SEM), and the chemical compositions were measured by energy disperse spectroscopy (EDS). The results indicate that the bonding strength of aluminium/electroplated nickel with single zinc coated before electroplating is 10.7 MPa, while that after secondary zinc coating before electroplating is higher than that after single zinc coating, up to 28.5 MPa. It is the silicon inclusions in the single zinc coating layer that lead aluminium corroded by the electroplating solution, which is the main reason for the poor bonding strength after single zinc coating.

Key words: zinc coating; aluminium; electroplated nickel; bonding strength

铝和镍都是制备破甲弹药型罩的常用材料[1-2]。电沉积法具有精度高、微观组织可控等优点,是制备镍及镍合金药型罩的重要方法[3-4]。采用电沉积方法制备铝/镍双层金属药型罩,不仅可以利用铝、镍两种金属反应释放的能量来提高侵彻威力[5],而且能够发挥电沉积工艺的独特优势,是值得探索的技术途径。制定合理的镀前处理工艺,使铝和镀镍层之间的结合强度能够满足后续机加工的要求,是电沉积法制备铝/镍双层金属药型罩的关键所在。

然而,由于铝容易受到镀液腐蚀,而且表面也容易产生氧化层,因此,铝和镀层之间难以获得良好的结合力[6-7]。为了提高结合强度,铝及铝合金通常采用浸锌、化学镀镍等镀前处理工艺[8-12]。浸锌是利用铝和碱性锌酸盐溶液反应,在铝表面沉积一层金属锌膜(浸锌层),锌膜可以防止铝受到镀液的腐蚀并阻止氧化层的产生,从而提高镀层和基体之间的结合力[8-9]。而化学镀镍一般是在浸锌的基础上进行的[11-12],所以工艺也往往比浸锌更复杂。因此,综合考虑理论和实际操作,浸锌可以作为制备铝/镍双层金属药型罩的候选前处理工艺。浸锌工艺包括一次浸锌和二次浸锌两类[6],但适用于铝/电镀镍双层药型罩的合理浸锌工艺尚需实验来确定。同时,不同的浸锌工艺对铝表面形貌、化学成分以及铝/电镀镍之间结合强度的影响研究也鲜见报道。

在此,本文作者分别研究一次浸锌和二次浸锌对铝表面形貌和化学成分的影响,探讨不同的浸锌工艺对铝/电镀镍之间结合强度的影响规律及其原因,拟为制备铝/镍双层金属药型罩寻求合理的镀前处理方法。

1 实验

1.1 铝的镀前处理和电镀镍操作

实验所用的铝为厚度2 mm的工业纯铝片,其中铝的质量分数≥99.4%,硅的质量分数≤0.6%。铝片在电镀之前,分别进行一次浸锌和二次浸锌处理。

一次浸锌处理包括除油和浸锌两个步骤。除油是将铝片浸泡在80 ℃的碱性除油液中,120 s后取出并用去离子水将铝片表面残留的除油液清洗干净。浸锌是将除油后的铝片浸泡在25 ℃的一次浸锌溶液中,60s后取出,再用去离子水将铝片表面残留的浸锌溶液清洗干净。碱性除油液的配方如下:碳酸钠(Na2CO3)30 g/L,磷酸(Na3PO4·12H2O)30 g/L,OP乳化剂2 mL/L。一次浸锌溶液的配方如下:氧化锌(ZnO)100 g/L,氢氧化钠(NaOH)500g/L,三氯化铁(FeCl3·6H2O)2 g/L,酒石酸钾钠(KNaC4H4O6·4H2O)10 g/L。

二次浸锌处理是在一次浸锌之后进行的,包括退锌和再次浸锌两个步骤。退锌是将一次浸锌处理后的铝片浸泡在25 ℃、质量分数为34%的硝酸溶液中,30 s后取出,再用去离子水将铝片清洗干净。再次浸锌是将退锌后的铝片浸泡在25℃的二次浸锌溶液中,60 s后取出,然后用去离子水将铝片表面残留的浸锌溶液清洗干净。二次浸锌溶液的配方如下:氧化锌(ZnO)20 g/L,氢氧化钠(NaOH)120 g/L,三氯化铁(FeCl3·6H2O)2 g/L,酒石酸钾钠(KNaC4H4O6·4H2O)10 g/L,硝酸钠(NaNO3)1 g/L。

经过一次浸锌或二次浸锌处理后的铝片,即可进行电镀镍操作。电镀所用的阳极材料为含硫镍,其中镍的质量分数≥99.96%,硫的质量分数约为0.03%。阴极为浸锌后的铝片。镀液温度为50 ℃,采用氨基磺酸镍作为主盐,pH=4.0±0.5,阴极电流密度4A/dm2。在电镀过程中,当阴极表面的镍镀层达到一定沉积厚度(≥2 mm)时,停止通电,然后将镀层和阴极一起从镀液中取出,即得到铝/电镀镍试样。

1.2 结合强度的测量及扫描电镜观察

参考GB/T 5270-1985金属基体上的金属覆盖层(电沉积层和化学沉积层)附着强度试验方法,采用拉伸试验来测量铝/电镀镍之间的结合强度。用线切割方法从铝/电镀镍试样上切取尺寸为10 mm×10 mm的方形试片,然后用环氧树脂胶粘剂将试片组装成拉伸试样(见图1)。除了上述试片之外,拉伸试样的其他部分用不锈钢制成。待胶粘剂充分固化后,即可进行拉伸试验。拉伸所用的试验机为CMT 4105型微控拉伸试验机,拉伸速率为2 mm/min。

利用LEO-1450型扫描电子显微镜观察经镀前处理的铝片表面、铝/电镀镍试样的截面以及拉伸断面的微观形貌,并通过EDS能谱仪考察上述部位的化学成分及元素分布。

图1 拉伸试样示意图

Fig. 1 Sketch of tensile specimen (Unit: mm)

2 结果与讨论

2.1 镀前处理对铝表面形貌及化学成分的影响

图2所示为经除油处理后铝的表面形貌和EDS能谱分析结果。图2(a)和(b)表明,经过除油处理后,铝表面出现了大量的颗粒物(见图2(b)箭头所指)。图2(c)表明,经过除油处理后,在铝的表面部位,硅的质量分数高达15.08%。而在铝中,硅的质量分数≤0.6%。图2(d)表明,铝表面出现的颗粒物正是硅颗粒。在除油过程中,碱性除油液会对铝造成一定程度的腐蚀。在铝受到除油液腐蚀的同时,铝中的硅不会与除油液发生作用,因而残留在铝的表面。因此,经除油处理后,硅元素会以颗粒物的形态在铝的表面富集。

图2 经除油处理后铝的表面形貌和EDS能谱

Fig. 2 Surface morphologies and corresponding EDS spectra of aluminium after degreasing

图3所示为经一次浸锌处理后铝的表面形貌和EDS能谱分析结果。图3(a)和(b)表明,经过一次浸锌处理后,铝的表面被浸锌层覆盖,浸锌层主要含有铝、锌、铁和硅这4种元素。浸锌层往往不是由纯锌组成,其成分取决于浸锌溶液的配方以及基体金属的成分[13],由于浸锌溶液中含有三氯化铁,而且浸锌是在铝的表面进行的,因此,一次浸锌层中含有铁和铝。此外,在一次浸锌层中存在夹杂物(见图3(a)箭头所指),夹杂物主要由硅元素组成(见图3(c))。可以认为,除油后富集在铝表面的硅颗粒是浸锌层中硅夹杂物的主要来源。

图4所示为经退锌和二次浸锌处理后铝的表面形貌和EDS能谱分析结果。图4(a)表明,经退锌处理后,铝表面的一次浸锌层被硝酸溶液溶解,同时浸锌层中的硅夹杂物也一起被去除。退锌后的铝表面没有出现硅元素的富集现象(见图4(c))。图4(b)表明,退锌后的铝经二次浸锌处理后,表面再次被浸锌层覆盖,浸锌层中没有夹杂物。二次浸锌层主要含有铝、铁和锌3种元素,但没有硅元素存在(见图4(d))。由于二次浸锌溶液的配方与一次浸锌不同,因此,二次浸锌层中铝、铁和锌3种元素的含量也与一次浸锌层存在差异。此外,由于退锌后的铝表面没有出现硅元素的富集现象,所以二次浸锌层中没有发现硅夹杂物,也没有找到硅元素的存在。

2.2 浸锌工艺对铝/电镀镍之间结合强度的影响

图5所示为铝/电镀镍试样截面的背散射电子像和元素线扫描分析结果。图5(a)和(b)表明,铝在电镀前无论是经过一次浸锌还是二次浸锌处理,在铝/电镀镍试样中,铝和电镀镍之间都存在浸锌层;浸锌层与铝以及浸锌层与电镀镍之间的结合方式都是以机械咬合为主。图5(a′)和(b′)表明,电镀时浸锌层的成分发生了变化:电镀前,浸锌层中主要含有锌、铝和铁等元素,但不含镍元素;而在电镀完成之后,浸锌层中出现了镍元素。这是由于浸锌层与镀液中的镍盐发生反应造成的。

图3 经一次浸锌处理后铝的表面形貌和EDS能谱

Fig. 3 Surface morphology and corresponding EDS spectrum of aluminium after single zinc coating

图4 经退锌和二次浸锌处理后铝的表面形貌和EDS能谱

Fig. 4 Surface morphologies and corresponding EDS spectra of aluminium after zinc removal and secondary zinc coating

图6所示为铝/电镀镍试样的拉伸应力-位移曲线。由图6可以看出,铝在镀前经一次浸锌处理后,铝/电镀镍之间的结合强度为10.7 MPa;经二次浸锌处理后,铝/电镀镍之间的结合强度优于一次浸锌的,可达28.5 MPa。从结合强度的角度讲,在利用电沉积方法制备铝/镍双层金属药型罩时,二次浸锌可以作为比较合适的镀前处理工艺。

图5 铝/电镀镍试样截面的背散射电子像和元素线扫描分析

Fig. 5 Backscattered electron images ((a), (b)) and corresponding elemental linear distributions ((a′), (b′)) of cross section of aluminium /electroplated nickel specimen

图6 铝/电镀镍试样的拉伸应力-位移曲线

Fig. 6 Stress-displacement curves of aluminium/electroplated nickel specimens

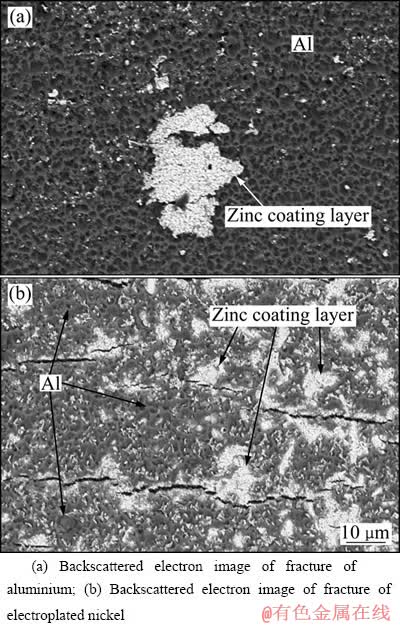

图7所示为电镀前经一次浸锌处理后的铝/电镀镍试样的拉伸断面形貌和EDS能谱分析。图7(a)和(b)表明,浸锌层和铝、浸锌层和电镀镍之间的结合力都比较差,在拉伸断裂时,浸锌层与铝之间以及浸锌层与电镀镍之间均存在不同程度的剥离。此外,在铝侧断面可以观察到腐蚀孔洞(见图7(a)黑色箭头所指),同时,在浸锌层中可以观察到腐蚀产物。EDS分析结果表 明,腐蚀产物主要含有氧、镍、锌、铝和铁5种元素(见图7(c))。腐蚀孔洞和腐蚀产物的存在,表明一次浸锌得到的浸锌层不能起到很好的保护作用,从而导致在电镀过程中,铝受到了镀液的腐蚀。

图8所示为电镀前经二次浸锌处理后的铝/电镀镍试样的拉伸断面形貌。图8(a)表明,铝侧断面存在浸锌层和大量的韧窝。图8(b)表明,电镀镍侧断面被浸锌层覆盖,浸锌层中存在裂纹,而且在浸锌层表面也有铝附着。在拉伸断面两侧都有铝的存在,而且铝的断面都存在韧窝,表明在拉伸断裂时,铝的内部发生了延性断裂。同时,拉伸断面两侧也都存在浸锌层,而且浸锌层中存在裂纹,表明在拉伸断裂时,浸锌层的内部也发生了脆性断裂。此外,在拉伸断面部位没有发现腐蚀孔洞及腐蚀产物,表明二次浸锌层能够保护铝免受镀液的腐蚀。因此,在电镀前经二次浸锌处理的铝/电镀镍试样中,浸锌层和铝、浸锌层和电镀镍之间的结合情况都优于一次浸锌的;在拉伸断裂时,断裂发生在铝的内部以及浸锌层内部。

图7 电镀前经一次浸锌处理后的铝/电镀镍试样的拉伸断面形貌和EDS能谱

Fig. 7 Tensile fracture morphologies and corresponding EDS spectrum of aluminium/electroplated nickel specimen prepared after single zinc coating

铝在电镀前经一次浸锌处理后,铝/电镀镍之间的结合强度较差,仅为10.7 MPa;经二次浸锌处理后,铝/电镀镍之间的结合强度优于一次浸锌的,可达28.5 MPa。对比一次浸锌和二次浸锌工艺可知,由于一次浸锌是在除油的基础上进行的,而且除油后的铝表面有硅颗粒富集(见图2),所以一次浸锌层中含有硅夹杂物(见图3);二次浸锌则是在退锌的基础上进行的,而且退锌后的铝表面不存在硅元素的富集现象,所以二次浸锌层中没有硅夹杂物(见图4)。浸锌是铝和锌酸盐溶液中的锌离子之间发生的置换反应,体现为电负性小的金属置换电负性大的金属;同时,浸锌也是一种电化学反应,在浸锌过程中,铝作为阳极发生溶解,锌离子作为阴极发生还原反应并在铝表面沉积金属锌,并且在阴极和阳极之间存在电流[14-16]。当铝表面存在硅时,因为硅的电负性(1.90)大于锌的(1.65),而且硅不导电,有阻碍电流的作用,所以在浸锌时,硅所占据的表面不会沉积锌[14]。也就是说,硅在浸锌层中形成夹杂物的同时,也破坏了浸锌层的连续性。浸锌层的作用是防止铝受到镀液的腐蚀并阻止氧化层的产生,从而提高镀层和基体之间的结合力[8-9]。如果浸锌层的连续性受到破坏,那么铝和浸锌层都可能会遭受腐蚀,进而严重影响浸锌层与铝、浸锌层与镀层之间的结合力[17]。一次浸锌层中存在硅夹杂物,同时在铝/电镀镍试样的拉伸断面部位存在腐蚀孔洞和腐蚀产物(见图7),均表明一次浸锌得到的浸锌层不能起到很好的保护作用,从而导致在电镀过程中,铝受到了镀液的腐蚀。二次浸锌层中没有硅夹杂物,在铝/电镀镍试样的拉伸断面部位没有发现腐蚀孔洞及腐蚀产物(见图8),表明二次浸锌层能够保护铝免受镀液的腐蚀。由此可以认为,一次浸锌层中的硅夹杂物是导致铝受到镀液腐蚀,造成一次浸锌处理后铝/电镀镍结合强度较差的主要原因。从结合强度的角度讲,在利用电沉积方法制备铝/镍双层金属药型罩时,二次浸锌可以作为比较合适的镀前处理工艺。

图8 电镀前经二次浸锌处理后的铝/电镀镍试样的拉伸断面形貌

Fig. 8 Tensile fracture morphologies of aluminium/ electroplated nickel specimen prepared after secondary zinc coating

3 结论

1) 一次浸锌工艺得到的浸锌层中主要含有铝、锌、铁和硅4种元素,其中硅是以夹杂物的形式存在于一次浸锌层中。二次浸锌得到的浸锌层中主要含有铝、锌和铁3种元素,没有硅夹杂物。

2) 铝在电镀前经一次浸锌处理后,由于浸锌层中存在硅夹杂物,造成铝受到镀液的腐蚀,因此,铝/电镀镍之间的结合强度较差,仅为10.7 MPa。经二次浸锌处理后,铝/电镀镍之间的结合强度优于一次浸锌的,可达28.5 MPa。

REFERENCES

[1] 樊 菲, 李伟兵, 王晓鸣, 李文彬, 郑 宇, 朱 亮. 药型罩材料对JPC成型的影响[J]. 火炸药学报, 2010, 33(2): 36-39.

FAN Fei, LI Wei-bing, WANG Xiao-ming, LI Wen-bin, ZHENG Yu, ZHU Liang. Effect of liner material on jetting projectile charge formation[J]. Chinese Journal of Explosives & Propellants, 2010, 33(2): 36-39.

[2] SARAN S, AYISIT O, YAVUZ M S. Experimental investigations on aluminum shaped charge liners[J]. Procedia Engineering, 2013, 58: 479-486.

[3] YANG Feng, LI Chun-hua, CHENG Sheng-wei, WANG Lei, TIAN Wen-huai. Deformation behavior of explosive detonation in electroformed nickel liner of shaped charge with nano-sized grains[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(8): 1397-1402.

[4] 成生伟, 田文怀. 电铸Ni-W合金热压缩变形的流变行为[J]. 中国有色金属学报, 2013, 23(1): 116-121.

CHENG Sheng-wei, TIAN Wen-huai. Flow stress behavior of electroformed Ni-W alloy under hot compression deformation[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(1): 116-121.

[5] 张子敏, 许碧英, 阎 峰, 刘丰旺, 郭惊雷, 付 伟. 活性金属药型罩射孔弹破甲试验研究[J]. 爆破器材, 2013, 42(4): 53-56.

ZHANG Zi-min, XU Bi-ying, YAN Feng, LIU Feng-wang, GUO Jing-lei, FU Wei. Penetrating test of active metal charge liner perforating bullet[J]. Explosive Materials, 2013, 42(4): 53-56.

[6] 曾领才, 文 伟, 谢 辉. 铝及铝合金电镀前处理工艺的改进[J]. 电镀与涂饰, 2012, 31(3): 15-17.

ZENG Ling-cai, WEN Wei, XIE Hui. Improvement of pretreatment process for aluminum and its alloys before plating[J]. Electroplating & Finishing, 2012, 31(3): 15-17.

[7] 张 宇, 王 军, 赵永新, 邵忠财. 铸造铝合金表面处理方法的研究进展[J]. 电镀与精饰, 2014, 36(2): 13-16, 28.

ZHANG Yu, WANG Jun, ZHAO Yong-xin, SHAO Zhong-cai. Progress in the methods of surface treatment on cast aluminum alloy[J]. Plating and Finishing, 2014, 36(2): 13-16,28.

[8] HUANG Xiao-mei, LI Ning, LI De-yu, JIANG Li-min. Zincate mechanism on cast Al-Si alloy in non-cyanide multi-metal zincate solutions[J]. Transactions of Nonferrous Metals Society of China, 2006, 16(2): 414-420.

[9] EGOSHI S, AZUMI K, KONNO H, EBIHARA K, TAGUCHI Y. Effects of minor elements in Al alloy on zincate pretreatment[J]. Applied Surface Science, 2012, 261: 567-573.

[10] 孔德军, 付贵忠. 5052铝合金表面化学镀Ni-P镀层的组织与性能[J]. 中国有色金属学报, 2012, 22(5): 1360-1364.

KONG De-jun, FU Gui-zhong. Microstructure and properties of Ni-P coatings prepared by chemical plating on surface of 5052 aluminium alloy[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(5): 1360-1364.

[11] HINO M, MURAKAMI K, MITOOKA Y, MURAOKA K, KANADANI T. Effects of zincate treatment on adhesion of electroless Ni-P coating onto various aluminum alloys[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(4): 814-818.

[12] YAZDI S S, ASHRAFIZADEH F, HAKIMIZAD A. Improving the grain structure and adhesion of Ni-P coating to 3004 aluminum substrate by nanostructured anodic film interlayer[J]. Surface and Coatings Technology, 2013, 232: 561-566.

[13] KOERNER C, SCHWANKL M, HIMMLER D. Aluminum–aluminum compound castings by electroless deposited zinc layers[J]. Journal of Materials Processing Technology, 2014, 214(5): 1094-1101.

[14] 黄晓梅, 李 宁, 蒋丽敏, 黎德育. 铝及其合金浸锌技术的发展及现状[J]. 电镀与精饰, 2006, 28(3): 22-26.

HUANG Xiao-mei, LI Ning, JIANG Li-min, LI De-yu. Current status and development of zincate treatment technique for aluminum and its alloys[J]. Plating and Finishing, 2006, 28(3): 22-26.

[15] 黄晓梅, 李 宁, 蒋丽敏, 黎德育. 铝及铝合金电镀的浸锌工艺[J]. 电镀与环保, 2005, 25(2): 1-4.

HUANG Xiao-mei, LI Ning, JIANG Li-min, LI De-yu. Zincation for aluminum and its alloys plating[J]. Electroplating & Pollution Control, 2005, 25(2): 1-4.

[16] 冯绍彬, 苏 畅, 李振兴. 铝材浸锌的电化学机理[J]. 材料保护, 2011, 44(12): 16-18.

FENG Shao-bin, SU Chang, LI Zhen-xing. Electrochemical mechanism of zinc immersion of aluminum[J]. Materials Protection, 2011, 44(12): 16-18.

[17] ZELLEY W G. Formation of immersion zinc coatings on aluminum[J]. Journal of the Electrochemical Society, 1953, 100(7): 328-333.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(50671012)

收稿日期:2014-07-20;修订日期:2014-12-11

通信作者:田文怀,教授,博士;电话:010-62333934;E-mail:wenhuaitian@sina.com