文章编号:1004-0609(2012)04-1094-08

AZ91D镁合金等离子喷涂Ni-Al/陶瓷涂层的组织和性能

陈 燕1,芦 笙1,陈 静2,段珍珍1

(1. 江苏科技大学 材料科学与工程学院,镇江 212003;

2. 江苏科技大学 机械工程学院,镇江 212003)

摘 要:以Ni-Al为粘结层,在AZ91D镁合金基体上等离子喷涂Ni-Al/Al2O3、Ni-Al/Al2O3-13%TiO2 (Ni-Al/AT13)、Ni-Al/Al2O3-20%TiO2(Ni-Al/AT20)复合涂层及Ni-Al/Al2O3/Al2O3-13%TiO2/Al2O3-20%TiO2 (Ni-Al/Al2O3/AT13/AT20) 梯度涂层,利用SEM、EDS和XRD分析涂层的微观组织特征,通过硬度、拉伸和热震实验研究涂层硬度、结合强度和抗热震性能,并与直接喷涂Al2O3、AT20的涂层进行比较。结果表明:Ni-Al粘结层因“自粘结”效应与基体形成较为致密并具有冶金结合的界面,且与Al2O3、AT13和AT20陶瓷层互有渗透、交叉和啮合,涂层致密性及结合力大为提高,表现出优良的抗热震性能。Al2O3涂层主要由亚稳态γ-Al2O3组成,AT20涂层以Al2O3和Al2TiO5为主。镁合金表面喷涂Al2O3陶瓷层后硬度大幅提高,由于加入TiO2,AT13和AT20涂层的硬度略低于Al2O3涂层的。Ni-Al/Al2O3-TiO2复合陶瓷的涂层结合强度高于Ni-Al/Al2O3单一陶瓷涂层的,而Ni-Al/ Al2O3/AT13/AT20梯度涂层的结合强度比Ni-Al/AT20涂层的更高。

关键词:镁合金;等离子喷涂;Ni-Al粘结层;陶瓷涂层;结合强度

中图分类号:TG174.45 文献标志码:A

Microstructure and properties of Ni/Al/ceramic coatings plasma-sprayed on AZ91D magnesium alloy

CHEN Yan1, LU Sheng1, CHEN Jing2, DUAN Zhen-zhen1

(1. School of Materials Science and Engineering, Jiangsu University of Science and Technology, Zhenjiang 212003, China;

2. School of Mechanical Engineering, Jiangsu University of Science and Technology, Zhenjiang 212003, China)

Abstract: By means of plasma spraying, Ni-Al/Al2O3, Ni-Al/Al2O3-13%TiO2 (Ni-Al/AT13) and Ni-Al/Al2O3-20%TiO2 (Ni-Al/AT20) composite coatings as well as Ni-Al/Al2O3/Al2O3-13%TiO2/Al2O3-20% TiO2 (Ni-Al/Al2O3/AT13/AT20) gradient coating were fabricated on the AZ91D magnesium alloy with Ni-Al as the base coating. The microstructure characteristics of the coatings were investigated by scanning electron microscopy (SEM), energy dispersive X-ray spectroscopy (EDS) and X-ray diffractometry (XRD). The hardness, bonding strength and thermal shock properties of the coatings were evaluated by microhardness, tensile and thermal shock tests. The coatings with Ni-Al as the base coating were compared with Al2O3 and AT20 coatings without Ni-Al. The results show that denser interface with metallurgical bonding forms between Ni-Al and AZ91D substrate due to Ni-Al base coating’s self adhesive effect. Ni-Al coating can interpenetrate into, cross and gear with Al2O3, AT13 and AT20 coatings, thus remarkably improving the compactness, bonding strength and resistance to thermal shock. Al2O3 coating is mainly composed of metastable γ-Al2O3 while AT20 coating mainly consists of Al2O3 and Al2TiO5. After plasma sprayed with Al2O3 coating, the surface hardness of AZ91D alloy increases evidently. The hardness of AT13 as well as AT20 coatings is slightly lower than that of Al2O3 coating because of the addition of TiO2. The bonding strength of Ni-Al/Al2O3-TiO2 composite ceramic coating is higher than that of Ni-Al/Al2O3 single ceramic coating and Ni-Al/Al2O3/AT13/AT20 gradient coating shows high bonding strength than Ni-Al/AT20 coating.

Key words: magnesium alloy; plasma-spraying; Ni-Al coating; ceramic coating; bonding strength

镁合金密度低,比强度、比刚度高,具有良好的导热、减振及电磁屏蔽性能,且切削加工性能优良, 被认为是电器壳体、运输工具与航天飞行器零部件制造等最具潜力的材料[1-2]。但镁合金表面硬度低,耐蚀 性、耐磨性差,通过热喷涂、微弧氧化等表面改性方法制备表面涂层,从而提高其整体性能与使用寿命已成必然趋势[3-5]。

等离子喷涂技术是常用的一种金属或陶瓷涂层制备方法,已在耐磨、减磨、耐蚀、抗高温氧化、热障涂层等方面得到应用。但有关镁合金等离子喷涂的研究和应用较少[6],主要原因是镁合金熔点低,喷涂过程中易氧化,难以实施喷涂,且基体与涂层的结合力差。PARCO等[7]在AZ91和AE42基体上等离子喷涂Al、NiAl5及Al2O3涂层,研究了不同涂层颗粒的扁平化效应和涂层的粘结机理。TSUJIKAWA等[8]在3 mm冷轧Mg-Li板上等离子喷涂50~300 μm厚的纯Al涂层,发现喷涂过程基体温升很小,耐腐蚀性能得到改善。BAKKAR等[9]通过“等离子喷涂+激光重熔”两步法制备Al-12Si涂层,显著提高了短纤维强化AS41复合材料的耐腐蚀性。GAO等[10]研究发现,AZ91HP等离子喷涂Al2O3涂层后再激光重熔,涂层分为3个不同区域,即α-Al2O3柱状晶区、团状烧结区和疏松的残余等离子喷涂区。研究表明[11-13],在表面等离子喷涂Al2O3、TiO2、A12O3-TiO2陶瓷涂层后,镁合金的硬度、耐磨性和耐蚀性能明显提高。

由于Al2O3、TiO2等陶瓷涂层与镁合金基体的性能和组织结构相差非常大,结合界面处的物化性能及组织结构存在突变,成为残余应力和缺陷的集聚处,容易导致材料承载时失效。通过设计双层或多层涂层结构,每层各具不同功能,粘结底层主要提高基体与涂层之间的结合强度,外层或表面层主要满足零件服役性能,梯度结构则可大幅度减小陶瓷涂层与基体之间的热膨胀不匹配性,减小热应力、延长使用寿命[4]。

本文作者在对镁合金等离子喷涂Al2O3-13%TiO2复合陶瓷涂层研究的基础上[14],以Ni-Al为粘结层,在镁合金基体上制备Ni-Al/Al2O3、Ni-Al/Al2O3-13% TiO2 (Ni-Al/AT13)、Ni-Al/Al2O3-20%TiO2 (Ni-Al/AT20)复合涂层,以及Ni-Al/Al2O3/Al2O3-13%TiO2/Al2O3- 20%TiO2(Ni-Al/Al2O3/AT13/AT20)梯度复合涂层,研究等离子喷涂复合陶瓷及梯度涂层的组织与性能特点,为开发高质量镁合金涂层提供理论和实验依据。

1 实验

以AZ91D镁合金为基体,线切割成d 25 mm×12 mm和30 mm×20 mm×10 mm的喷涂试样;喷涂材料以镍包铝Ni-(17%~20%)Al(质量分数)为粘结层,粉末粒度为45~109 μm;工作涂层分别选用α-Al2O3、Al2O3-13% TiO2(质量分数)和Al2O3-20% TiO2(质量分数)粉末,粒度均为38~75 μm。喷涂前预热粉末,并对基体进行除油清洗和喷砂预处理(粒度为550 μm石英砂,喷砂压力0.41~0.55 MPa)。喷砂处理后2 h内实施喷 涂,以尽量减少裸露基体的氧化。采用Praxair/TAFA 3710等离子喷涂系统,SG-100喷枪,枪外送粉。以Ar为主气和载气,He为辅气,Ni-Al为粘结层,喷枪移动速度200 mm/s,步距3.2 mm,按表1所示工艺喷涂各涂层,分别制备Ni-Al/Al2O3、Ni-Al/AT13、Ni-Al/AT20复合涂层,以及Ni-Al/Al2O3/AT13/AT20梯度涂层,涂层总厚度控制为200~300 μm。

采用JSM-6480扫描电镜观察分析涂层厚度和微观组织,用所附INCA能谱仪分析微区成分;利用XRD-6000X射线衍射仪分析涂层物相。采用MH-5D显微硬度计测定涂层硬度,加载50 g,保持10 s,随机取涂层5点测量,取平均值。参照GB/T 8642—2002“热喷涂抗拉结合强度的测定”的对偶试样拉伸法测定涂层结合强度,基体尺寸d 25 mm×12mm,用E-7高温胶粘结,试样对接夹紧后常温放置4~5 h,再 100 ℃保温4 h。采用加热-淬冷法进行涂层抗热震实验,试样尺寸30 mm×20 mm×10 mm,试样加热到一定温度,保温15 min后水淬急冷完成一次热冲击循环,如此反复,以涂层非边角处出现剥落为失效判据。

表1 喷涂工艺参数

Table 1 Process parameters of plasma spraying

2 结果与分析

2.1 涂层组织

2.1.1 涂层表面形貌

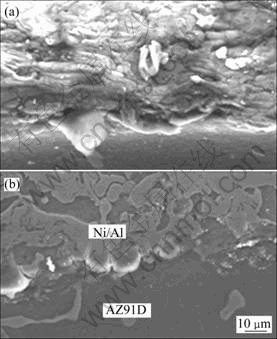

Ni-Al/Al2O3、Ni-Al/AT13、Ni-Al/AT20以及Ni-Al/ Al2O3/AT13/AT20 4种涂层的表面形貌大致相同,典型表面特征如图1所示。涂层表面陶瓷颗粒呈类椭球层片状结构,交互叠加形成相对平整的表面,但与AT13、AT20涂层相比,Al2O3涂层表面更加粗糙,局部存在更多的显微疏松、裂纹和较大的空隙。

图1 Al2O3和AT13涂层表面SEM像

Fig. 1 Surface SEM images of Al2O3(a) and AT13(b) coatings

研究表明[7, 15],在等离子喷涂过程中,熔化及半熔化的颗粒以一定的速度撞击基体后出现扁平化效应,在一定程度上得到展开、铺平,因此,涂层均呈层片结构。Al2O3陶瓷粉末的熔点较高(2 050 ℃),喷涂时未熔化颗粒形成生粉夹杂在涂层中,无法充分变形、展开、平铺而凝固成扁平粒子,而周围其他变形颗粒则发生凝固收缩,Al2O3液态与固态的密度及收缩率均不同,所以孔隙容易在生粉颗粒周围形成。等离子喷涂陶瓷涂层由微米级陶瓷熔滴在高速运动中冲击基底或涂层表面堆积而成,因此,孔隙的形成也可能是粒子的不完全重叠或一定量气体溶解于熔融的粒子内造成。因为喷涂过程中扁平粒子往往不能完全重 叠,尤其是对于具有较低速度和温度的粒子,其变形不充分,更容易形成不完全重叠,从而形成孔隙。此外,在涂层形成过程中,由于空气在熔滴中溶解及冲击平铺到工件表面时高速冷却析出但来不及从粒子内逸出,也会形成多孔及显微裂纹的涂层组织。对AT13、AT20复合陶瓷涂层而言,TiO2熔点较低(1 830~ 1 850 ℃),喷涂时高熔点的Al2O3形成多孔的骨架,而熔点相对较低的TiO2会被熔融,填充在Al2O3的孔隙中,从而显著提高涂层的致密程度和粘结强度。

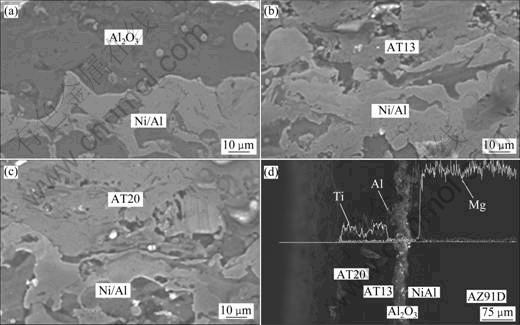

2.1.2 涂层截面特征

镁合金基体直接与Al2O3、Ni-Al形成涂层的 SEM形貌如图2所示,其界面较为平整。Al2O3涂层与下方AZ91D之间的结合不够致密(见图2(a)),界面以机械结合为主。熔化及软化的喷涂粒子以一定的温度和速度撞击经过净化和粗化处理后凹凸不平的基材表面,使其纵横交错的沟槽填满变形粒子,冷凝收缩后颗粒与基材表面的凹凸处机械咬合在一起,即通常所说的“抛锚效应”。由于Al2O3和AZ91D两者之间导热系数和膨胀系数等理化性能的不同,界面产生严重的热应力,导致出现空隙、裂纹和破碎现象。

而由图2(b)可见,AZ91D/Ni-Al之间结合良好,Ni-Al粘结层与镁合金基体形成了致密的结合界面。这是因为Ni-Al复合粉末具有“自粘结”效应[16],在热喷涂过程中,Ni与Al能发生化学反应,生成金属间化合物,并释放大量热量,这一反应过程甚至能持续到粉末碰撞到基体表面时,从而提高粘结底层与基体之间的结合强度。AZ91D基体还含约9% Al (质量分数), 基于Ni-Al的“自粘结”效应,这十分有利于Ni-Al变形粒子与基体表面形成微区冶金结合。PARCO等[7]的研究证实,在Mg-Al系合金基体等离子喷涂NiAl5可熔化基体表面,并能使基体局部形变,涂层结合以冶金结合为主。

图2 镁合金与Al2O3和Ni-Al涂层的界面SEM像

Fig. 2 Interfacial SEM images of AZ91D/Al2O3(a) and AZ91D/Ni-Al(b) coatings

图3所示为Ni-Al/Al2O3、Ni-Al/AT13、Ni-Al/AT20以及Ni-Al/Al2O3/AT13/AT20 4种涂层的截面组织和形貌像。显而易见,Ni/Al粘结层与Al2O3、AT13、AT20陶瓷层均形成了良好结合,且涂层之间互有渗透、交叉和啮合,呈波浪或齿状界面。由于Al2O3、TiO2的熔点分别为2 050 ℃、1 840 ℃,而Ni-A1涂层加热至700 ℃左右即可引发Ni-A1放热反应,使涂层局部处于高温状态,微区出现液相[17]。这样后续喷涂的Al2O3、AT13、AT20粉末颗粒就有可能进入Ni-A1粘结层,并相互进行扩散与反应,形成冶金结合,从而使得Ni-Al粘结层与Al2O3、AT13、AT20涂层之间相互交叉咬合,形成“冶金+机械”的混合结合界面,这非常有利于改善热喷涂层的结合性能。图3(d)显示出Ni-Al/Al2O3/AT13/AT20梯度涂层的形貌,其能谱线扫描结果表明涂层表面含Al、Mg、Ti、Ni和O等元素,其中Al、Mg和Ti等元素的浓度分布规律与涂层的梯度结构基本吻合。

如前所述,由于Al2O3粉末熔点较高,喷涂时存在生粉和颗粒部分熔化的现象,导致层片之间接触不紧密,容易留下孔隙。因此,图3(a)中Al2O3涂层有较多的生粉颗粒夹杂于涂层中, 其周围形成疏松组织和空洞,与图1(a)表面形貌特征非常相似。而由图3(a)、(b)可见,由于AT13、AT20复合陶瓷涂层中的TiO2熔点较低,喷涂时高熔点的Al2O3形成多孔骨架,而熔点相对较低的TiO2则以熔融态填充在Al2O3的孔隙中,因此涂层更加致密。

2.1.3 涂层物相分析

图4所示为Al2O3和AT20涂层的XRD谱。喷涂使用的Al2O3原始粉末为α-Al2O3相,而TiO2为金红石相。等离子喷涂后,Al2O3涂层主要由亚稳态γ-Al2O3组成,并残存部分α-Al2O3。这与γ-Al2O3临界自由能较低、可优先成核有关。根据MCPHERSON[18]的计算,低于1 740 ℃时,γ-Al2O3的临界成核自由能低,比α-Al2O3相的成核速率高得多。等离子喷涂时,Al2O3熔滴高速撞击到Al2O3陶瓷涂层或基体表面上铺展,其冷却速度能够达到105~106 K/s,为典型的快速凝固过程,满足γ-Al2O3的临界成核热力学条件,因此涂层中含有大量的亚稳相γ-Al2O3。涂层中还有部分α-Al2O3相存在,一方面是由于喷涂过程中生粉或部分熔化的α-Al2O3颗粒的晶种作用,促进了α-Al2O3形 成[19];另一方面加热至1 200 ℃,γ-Al2O3可全部转化为α-Al2O3,由于等离子焰流加热与层片之间的热传输对已凝固层片的加热作用,会使部分亚稳态γ-Al2O3向稳态α-Al2O3转变。

在AT20涂层的XRD谱中(见图4(b)),Al2O3和Al2TiO5的衍射峰值较高,而TiO2峰较低,表明AT20涂层以Al2O3(γ相+α相)和Al2TiO5为主,而TiO2量减少,这说明等离子喷涂过程中发生了如下反应:

Al2O3+TiO2→Al2TiO5 (1)

图3 Ni-Al/Al2O3、Ni-Al/AT13、Ni-Al/AT20及Ni-Al/Al2O3/AT13/AT20涂层的截面组织

Fig. 3 Cross-section microstructures of Ni-Al/Al2O3(a), Ni-Al/AT13(b), Ni-Al/AT20(c) and Ni-Al/Al2O3/AT13/AT20(d) coatings

图4 Al2O3和AT20涂层的XRD谱

Fig. 4 XRD patterns of Al2O3(a) and AT20(b) coatings

研究表明[20],Al2O3和TiO2在1 400 ℃烧成时可反应生成Al2TiO5,该反应的进行程度对烧结体的力学性能有决定性影响。杨元政等[21]研究了等离子喷涂Al2O3+13%TiO2(质量分数)陶瓷涂层激光重熔处理后陶瓷熔化层的组织结构及硬度变化特征,结果证实,激光重熔区亚稳相γ-Al2O3转变成为稳定相α-Al2O3,而TiO2与Al2O3反应生成TiAl2O5,陶瓷熔化层致密、无孔隙、少裂纹或无裂纹。以上关于Al2O3与TiO2反应及其产物的研究与本实验结果相符。Al2TiO5 的熔点与TiO2相近,为1 860 ℃,AT13和 AT20喷涂过程中熔点较高的Al2O3形成了多孔的骨架,而熔点相对较低的TiO2和Al2TiO5熔融后填充在Al2O3孔隙之中。因此,如图3(b)、(c)所示,在同样喷涂工艺下,AT13、AT2涂层中因含有较多的低熔点TiO2,粉末熔融程度高,故生粉含量较低,孔隙较少,空隙尺寸也小,层片间的结合更为紧密,致密度明显提高。

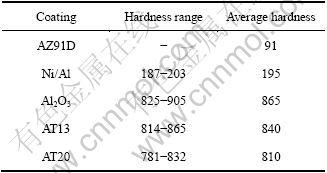

2.2 涂层硬度

由于等离子喷涂涂层为交错叠加的层片状结构,成分和组织分布不均匀,较疏松,并存在一定的空隙,因此测量的硬度值存在一定的起伏。在本实验中对每层涂层截面采集5点显微硬度,取平均硬度值。结果表明,涂层硬度主要与涂层材料的成分和组织有关,相同涂层的硬度基本相近。如在Ni-Al/AT13与Ni-Al/Al2O3/AT13/AT20两种涂层中,AT13分涂层的硬度值差别不大。由表2所列各涂层硬度可知,镁合金基体喷涂Al2O3基陶瓷层后表层硬度大大提高,且Al2O3涂层的硬度略高于AT13、AT20陶瓷层的。这主要是由于Al2O3莫氏硬度为9,而TiO2的为6左右,后者硬度较低,两者的反应产物TiAl2O5的硬度也不高。因此AT13、AT20加入TiO2后涂层的硬度下降,且TiO2含量越高硬度值越低。

表2 涂层的显微硬度

Table 2 Microhardness of coatings

图5所示为Ni-Al/AT20复合涂层与Ni-Al/Al2O3/ AT13/AT20梯度涂层从粘结层到工作层的显微硬度分布曲线,每点间隔0.02 mm。显然,AT20涂层硬度随着与基体距离的增加而提高,前两点在粘结层上故硬度值较低,第3点开始到达AT20涂层,其硬度值突然增大,随后基本保持平缓。而Ni-Al/Al2O3/AT13/ AT20梯度涂层中,陶瓷层的硬度由里向外逐渐降低。这主要与梯度涂层中的TiO2有关,由于TiO2及TiAl2O5的硬度比Al2O3的低,所以随着TiO2含量的增加涂层硬度随之减小。当然,陶瓷涂层的显微硬度还受涂层残余应力大小、分布及涂层致密度的影响,而后者还与冷却速度及涂层的理化特性等相关[19]。

图5 涂层的显微硬度分布曲线

Fig. 5 Microhardness distribution of coatings along coating cross-section: (a) AT20 coating; (b) Ni-Al/Al2O3/AT13/AT20 coating

2.3 涂层结合强度及抗热震性能

根据GB/T 8642—2002制备涂层拉伸试样,并以165 N/S匀速进行拉伸实验,获得各涂层的拉伸强度如表3所列。可见,直接在镁合金基底喷涂Al2O3、AT20陶瓷时,断裂都发生在涂层界面,涂层抗拉强度较低;而使用Ni-Al作为粘接底层再喷涂陶瓷层后,各涂层的抗拉强度都大为提高,且涂层最薄弱的环节已不在涂层与基体的界面结合处,断裂转而发生在涂层中间。

拉伸实验结果与前述涂层的组织形貌特点相符合。Al2O3、AT20涂层与镁合金之间的结合不够致密,为机械结合,且陶瓷与镁合金之间的热物理参数等性能差异较大,喷涂过程导致界面热应力,并引发涂层出现空隙、裂纹和破碎等缺陷,因此界面结合力最弱。而以具有“自粘结”效应的Ni-Al作粘结层,改善了涂层与基体的物理相容性,降低了涂层和基体之间的内应力,且Ni-Al层与基体表面形成了“冶金+机械”结合;同时,Ni-Al粘结层与Al2O3、AT13、AT20涂层之间相互交叉咬合,也是“冶金+机械”结合界面,因此,涂层的总体结合强度大幅提高。

表3 各种涂层的结合强度

Table 3 Bonding strength of coatings

同时注意到,Ni-Al/AT13、Ni-Al/AT20及Ni-Al/Al2O3/AT13/AT20等具有复合陶瓷结构涂层的结合强度均高于Ni-Al/Al2O3单一陶瓷涂层的,这一方面是由于AT13、AT20复合陶瓷涂层中低熔点TiO2 和Al2TiO5以熔融态填充Al2O3的孔隙使涂层更加致密,另一方面Al2TiO5具有较低的热膨胀系数,可缓解涂层的热应力,减少涂层应力集中和裂纹。Ni-Al/Al2O3/AT13/AT20梯度涂层的结合强度比Ni-Al/AT20双层涂层的结合强度高出10%,说明该梯度结构设计有效减小了涂层内部的应力,加强了陶瓷层之间的结合。

一般地,以涂层无损经历热冲击循环的次数来评价涂层的抗热震能力。在本研究中,对Ni-Al/Al2O3、Ni-Al/AT13、Ni-Al/AT20及Ni-Al/Al2O3/AT13/AT20等陶瓷涂层分别在250 ℃下循环20次,300 ℃下循环15次后,涂层中均未出现裂纹,表现出较好的抗热震性能。研究表明[22],在800 ℃条件下Al2O3陶瓷涂层在35次后涂层剥落,而Ni-Al/AT13涂层54次后才开始剥落。这说明以Ni-Al打底粘接镁合金基体并喷涂以复合陶瓷,改善了涂层致密度和结合力,可明显提高陶瓷涂层的抗热震性能。由于镁合金熔点低,一般抗热震实验都不超过400 ℃,今后有必要通过更多的热冲击循环实验评价Ni-Al/AT20、Ni-Al/Al2O3/AT13/ AT20等复合涂层和梯度涂层的抗热震性能。

3 结论

1) 直接在AZ91D镁合金基底等离子喷涂Al2O3或AT20陶瓷,涂层组织不致密,界面以机械结合为主,涂层结合力较低(抗拉强度9~15 MPa),断口位于涂层与基体结合面。

2) 用Ni-Al作为粘接底层再喷涂Al2O3或AT13、AT20陶瓷层,Ni-Al粘结层因“自粘结”效应与基体形成了较为致密并具有冶金结合的界面,且与AT13、AT20陶瓷层互有渗透、交叉和啮合,形成“冶金+机械”的混合结合界面,涂层结合力大为提高(抗拉强度20~22 MPa),断裂转而发生在涂层中间。

3) Al2O3涂层主要由亚稳态γ-Al2O3组成,并残存部分α-Al2O3;AT20涂层以Al2O3(γ相+α相)和Al2TiO5为主,并残存少量 TiO2。

4) 镁合金基体喷涂Al2O3陶瓷层后表层硬度大大提高(825~905 HV),由于AT13和AT20涂层中加入了TiO2,涂层硬度(781~865 HV)略低于Al2O3的;且陶瓷涂层在250 ℃下循环20次,300 ℃下循环15次,均未出现裂纹,表现出优良的抗热震性能。

5) 具有Ni-Al/Al2O3-TiO2复合陶瓷的涂层的结合强度均比Ni-Al/Al2O3单一陶瓷涂层的高,而Ni-Al/Al2O3/AT13/AT20梯度涂层的结合强度也比Ni-Al/AT20涂层的高,这说明复合陶瓷结构及梯度结构设计可有效减小涂层内部的应力,加强涂层之间的结合。

REFERENCES

[1] PEKGULERYUZ M O, KAPLAN H, NEELAMEGGHAM R, HRYN J, NYBERG E, POWELL B, COLE G A, NIE J F. Magnesium technology 2002 (Part Ⅰ): Primary production, environmental issues, high-temperature alloys[J]. Journal of the Minerals, Metals and Materials Society, 2002, 54(8): 18-21.

[2] 余 琨, 黎文献, 王日初, 马正青. 变形镁合金的研究、开发及应用[J]. 中国有色金属学报, 2003, 13(2): 277-288.

YU Kun, LI Wen-xian, WANG Ri-chu, MA Zheng-qing. Research, development and application of wrought magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 277-288.

[3] GRAY J E, LUAN B. Protective coatings on magnesium and its alloys —A critical review[J]. Journal of Alloys and Compounds, 2002, 336(1/2): 88-113.

[4] 刘纯波, 林 锋, 蒋显亮. 热障涂层的研究现状与发展趋势[J]. 中国有色金属学报, 2007, 17(1): 1-13.

LIU Chun-bo, LIN Feng, JIANG Xian-liang. Current state and future development of thermal barrier coating[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(1): 1-13.

[5] 席俊杰, 党旭丹. 新型镁合金及其热处理和表面改性技术[J]. 金属热处理, 2011, 36(2): 1-6.

XI Jun-jie, DANG Xu-dan. New magnesium alloys and their heat treatment and surface modification[J]. Heat Treatment of Metals, 2011, 36(2): 1-6.

[6] FRIEDRICH C, GADOW R, SCHERER D. Functional ceramic and metallurgical coatings on magnesium components[C]//ASM Thermal Spray Society, DVS German Welding Society, International Institute of Welding. Proceedings of the International Thermal Spray Conference. Stuttgart, Germany: ASM International, 2001: 41-47.

[7] PARCO M, ZHAO L D, ZWICK J, BOBZIN K, LUGSCHEIDER E. Investigation of particle flattening behaviour and bonding mechanisms of APS sprayed coatings on magnesium alloys[J]. Surface & Coatings Technology, 2007, 201(14): 6290-6296.

[8] TSUJIKAWA M, ADACHI S I, NAKATA K, KAMITA M, OKI S. Plasma thermal deposition of aluminum on Mg-Li work- hardened alloy[J]. Ceramic Transactions, 2007, 198: 453-460.

[9] BAKKAR A, GALUN R, NEUBERT V. Laser cladding of carbon/magnesium metal matrix composites[J]. Lasers in Engineering, 2005, 15(1/2): 63-73.

[10] GAO Y L, WANG C S, YAO M, LIU H B. The resistance to wear and corrosion of laser-cladding Al2O3 ceramic coating on Mg alloy[J]. Applied Surface Science, 2007, 253(12): 5306-5311.

[11] 马 壮, 邹积峰, 李智超. 镁合金热喷涂Al2O3纳米陶瓷涂层性能研究[J]. 兵器材料科学与工程, 2010, 33(4): 39-42.

MA Zhuang, ZOU Ji-feng, LI Zhi-chao. Properties of Al2O3 based nanostructured ceramic coatings on magnesium alloy surface by thermal spraying[J]. Ordnance Materials Science and Engineering, 2010, 33(4): 39-42.

[12] BUCHMANN M, GADOW R. Mechanical and tribological characterization of APS and HVOF sprayed TiO2 coatings on light metals[C]//BERNDT C C, KHOR K A, LUGSCHEIDER E F. Thermal Spray: New Surface for a New Millennium. Ohio, USA: ASM International Materials Park, 2001: 1003-1008.

[13] 叶 宏, 张 津, 孙智富, 杨 惠, 詹 捷. 镁合金表面等离子喷涂纳米陶瓷涂层研究[J]. 武汉理工大学学报, 2004, 26(4): 9-11.

YE Hong, ZHANG Jin, SUN Zhi-fu, YANG Hui, ZHAN Jie. Research on plasma spraying nano Al2O3+3%TiO2 ceramics onto surface of magnesium alloy[J]. Journal of Wuhan University of Technology, 2004, 26(4): 9-11.

[14] LU S, CHEN Y, CHEN J, FU L. Process, microstructure and properties of plasma-sprayed ceramic coating on AZ91D magnesium alloy[J]. Advanced Materials Research, 2011, 189/193: 1292-1295.

[15] LIN Xin-hua, ZENG Yi, LEE S W, DING Chuan-xian. Characterization of alumina-3wt.% titania coating prepared by plasma spraying of nanostructured powders[J]. Journal of the European Ceramic Society, 2004, 24(4): 627-634.

[16] 郭永明, 王海军, 谢兆钱, 李绪强. 超音速等离子制备Al/Ni涂层的性能特点[J]. 装甲兵工程学院学报, 2010, 24(4): 69-72.

GUO Yong-ming, WANG Hai-jun, XIE Zhao-qian, LI Xu-qiang. Characteristic of supersonic plasma spraying Al/Ni coatings[J]. Journal of Academy of Armored Force Engineering, 2010, 24(4): 69-72.

[17] 侯世香, 刘东雨, 刘宗德, 马一民. NiAl金属间化合物的研究概述[J]. 金属热处理, 2007, 32(7): 60-64.

HOU Shi-xiang, LIU Dong-yu, LIU Zong-de, MA Yi-min. Research overview of NiAl intermetallic compound[J]. Heat Treatment of Metals, 2007, 32(7): 60-64.

[18] MCPHERSON R. On the formation of thermally sprayed alumina coatings[J]. Journal of Materials Science, 1980, 15(12): 3141-3149.

[19] SCHLICHTING K W, PADTURE N P, JORDAN E H. Failure modes in plasma-sprayed thermal barrier coatings[J]. Materials Science and Engineer A, 2003, 342: 120-130.

[20] 漆 虹, 邢卫红, 范益群. 保温时间对低温烧成管式多孔陶瓷膜支撑体性能的影响[J]. 硅酸盐学报, 2011, 39(3): 507-511.

QI Hong, XING Wei-hong, FAN Yi-qun. Effect of holding time on properties of macroporous support sintered at low temperature[J]. Journal of the Chinese Ceramic Society, 2011, 39(3): 507-511.

[21] 杨元政, 刘志国, 刘正义, 庄育智. 等离子喷涂Al2O3+13wt%TiO2陶瓷涂层的激光重熔处理[J]. 激光杂志, 2000, 21(1): 46-47, 50.

YANG Yuan-zheng, LIU Zhi-guo, LIU Zheng-yi, ZHUANG Yu-zhi. Laser remelting of plasma sprayed Al2O3+13wt%TiO2 ceramic coating[J]. Laser Journal, 2000, 21(1): 46-47, 50.

[22] 饶晓晓, 罗 成, 胡树兵, 李行志. 等离子喷涂氧化铝基陶瓷涂层的性能研究[J]. 热加工工艺, 2010, 39(20): 99-103.

RAO Xiao-xiao, LUO Cheng, HU Shu-bing, LI Xing-zhi. Study on performance of Al2O3-based ceramics coating prepared by plasma spraying[J]. Hot Working Technology, 2010, 39(20): 99-103.

(编辑 龙怀中)

基金项目:国家外专局资助项目(T110511045);江苏高校优势学科建设工程资助项目(苏政办[2011]6);江苏省先进焊接技术重点实验室资助项目(JSAWT-11);江苏省研究生创新计划2010年资助项目(CXLX11_0290)

收稿日期:2010-07-20;修订日期:2011-12-20

通信作者:芦 笙,教授,博士;电话:0511-84407569;E-mail: lusheng119@yahoo.com.cn