DOI: 10.11817/j.ysxb.1004.0609.2021-35990

热还原石墨烯纳米片对铜基复合材料性能的影响

熊财梓,李多生,叶 寅,邹爱华,王国波,冯庆晓,王 凯,官冀原

(南昌航空大学 材料科学与工程学院,南昌 330063)

摘 要:采用热还原法和放电等离子烧结技术制备石墨烯纳米片/铜(rGO/Cu)复合材料,研究不同含量的还原氧化石墨烯(rGO)对制备复合材料的影响。结果表明:氧化石墨烯在铜粉表面均匀分散。在烧结后,rGO与铜粉紧密结合在一起,形成良好的结合界面。随着rGO含量的增加,复合材料的维氏硬度和电导率先增加后降低。rGO含量(质量分数)为0.1%时,rGO/Cu复合材料硬度有最高值112.7HV;rGO含量为0.25%时,复合材料电导率有最高值56.5 MS/m。rGO/Cu复合材料摩擦性能随着rGO含量的增加而降低,rGO含量达到0.5%时,复合材料的摩擦因数最低为0.402。

关键词:热还原法;氧化石墨烯;复合材料;电导率;摩擦性能

文章编号:1004-0609(2021)-06-1516-10 中图分类号:TB333 文献标志码:A

引文格式:熊财梓, 李多生, 叶 寅, 等. 热还原石墨烯纳米片对铜基复合材料性能的影响[J]. 中国有色金属学报, 2021, 31(6): 1516-1525. DOI: 10.11817/j.ysxb.1004.0609.2021-35990

XIONG Cai-zi, LI Duo-sheng, YE Yin, et al. Effect of thermally reduced graphene nanosheets on properties of copper matrix composites[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(6): 1516-1525. DOI: 10.11817/j.ysxb.1004.0609.2021-35990

铜基复合材料具有优异的力学性能、高电导率和热导率等,在结构材料、电子电器中应用广泛[1]。随着材料应用领域的不断扩大,人们对铜材料的力学性能有了更高的要求。经研究后发现,在铜基体中加入铁、锰、碳化钨等增强体,可以增强复合材料的力学性能,但是随着其他增强体的添加,往往会导致铜基复合材料电导率和热导率的降低[2-3]。

石墨烯是一种二维的、具有sp2杂化,单原子厚度的蜂窝状材料[4-5]。石墨烯具有高的比表面积,良好的力学性能,出众的电导率和热导率等性能,因此常常作为更好的增强体来提高铜基复合材料的性能[6-8]。然而,铜-碳之间润湿性较差,如何改善铜-碳之间的界面结合一直是困扰人们的难题。研究者们制备出结构、性质与石墨烯相近的氧化石墨烯来代替石墨烯作为增强体[9]。通过Hummers法[10]制得的氧化石墨烯具有丰富的含氧官能团,例如羟基、羰基和羧基等[11],使得氧化石墨烯容易分散在水和无水乙醇等溶剂中,形成稳定的悬浮液。为了制备出具有良好铜-石墨烯界面结合的复合材料,研究者采用球磨法和分子水平混合法来制备石墨烯/铜复合粉末,利用冷等静压、真空热压、热等静压烧结等方式来获取rGO/Cu复合材料[12-15],但是往往难以得到预期中满意的性能结果。

本文以氧化石墨烯为增强体,利用其表面带有含氧官能团的特点,来提高在铜粉中的分散,再经过热还原处理后,降低含氧官能团带来的结构缺陷,从而获得复合粉末。然后采用放电等离子烧结技术来制得rGO/Cu复合材料,同时探究rGO的含量对复合材料的摩擦性能和导电性能的影响,并揭示相关的增强机理。

1 实验

1.1 复合粉末的制备

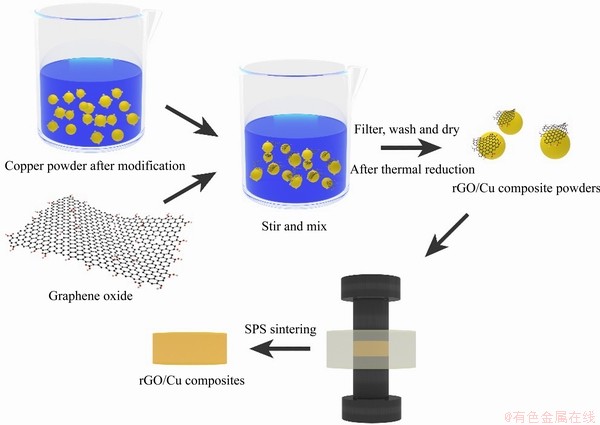

以氧化石墨烯为增强体(层数约为3层,片层直径0.5~5 μm),用分析天平按比例(0.1%、0.25%、0.5%,质量分数)称取相应质量的氧化石墨烯,将氧化石墨烯加入到无水乙醇中进行超声分散,时间为2 h,期间每隔20 min再进行搅拌10 min,周期为4次,以增加在无水乙醇中的分散程度,最后分散成0.5 mg/mL的悬浮液。在30 ℃下配制质量分数为1.5%的十六烷基三甲基溴化铵(CTAB)溶液,以平均粒径为5 μm的球形铜粉(纯度>99.9%)为基体材料,将30 g铜粉倒入150 mL CTAB溶液中,充分搅拌混合2 h,对铜粉表面进行改性。混合均匀后再将分散好的氧化石墨烯悬浮液加入到改性后的铜粉浆液中,充分搅拌混合,最后过滤、洗涤、干燥。对干燥后的复合粉末进行热还原,热还原工艺为V(H2):V(Ar)=30:70,还原温度为450 ℃,保温时间60 min。复合材料的制备流程示意图如图1所示。

1.2 复合材料的制备

将复合粉末加入到内径为20 mm的碳化钨模具中,在放电等离子烧结炉中通入Ar作为保护气体,利用脉冲电流产生的等离子体快速加热复合粉末。加热速率为100 ℃/min,烧结温度为800 ℃,保温时间6 min,烧结压力为70 MPa。制备出直径为20 mm、高为8 mm的rGO/Cu复合材料。

1.3 性能表征

采用红外光谱仪(EMIA-920V2)拉曼光谱(Renishaw in Via)、X射线电子能谱(Axis Ultra DLD)对氧化石墨烯和rGO进行分析。采用金相显微镜(OM,XJP-6A)、扫描电子显微镜(Quanta 200,FEI)、能谱(Oxford INCA 250X-Max50)和透射电子显微镜(FEIG2-20-TWIN)分析原材料和复合材料的微观形貌。采用维氏硬度计(HVS1000)测量复合材料的显微硬度。采用FQR涡流导电仪(厦门星鲨仪器有限公司生产,中国)测量复合材料的导电率。采用可控气氛摩擦磨损试验仪(WTM-2E)测量复合材料的摩擦性能。

图1 rGO/Cu复合材料制备流程示意图

Fig. 1 Schematic diagram of rGO/Cu composites preparation process

2 结果与讨论

2.1 粉末表征

图2所示为原材料的SEM像。从图2(a)中可以看出球形铜粉的直径为3~5 μm。从图2(b)可以看出,氧化石墨烯具有皱褶状结构。

图2 原材料的SEM像

Fig. 2 SEM images of raw material

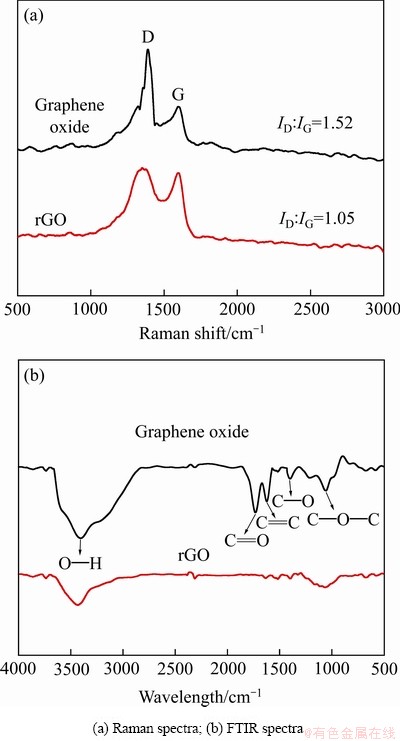

图3所示为氧化石墨烯和rGO的拉曼光谱图和红外光谱(FTIR)。从图3(a)可以看出,拉曼光谱中1350 cm-1和1580 cm-1位置为D峰和G峰,分别表示氧化石墨烯的结构缺陷程度和sp2杂化程度[16]。可以看出rGO的D峰峰型较宽,强度小于氧化石墨烯。通过D峰和G峰的强度比(ID:IG)可知,经过H2热还原后,氧化石墨烯结构缺陷得到部分修复,含氧官能团减少[17]。图3(b)显示了氧化石墨烯和rGO的红外光谱图。对于氧化石墨烯样品,在3430 cm-1处有一个—OH的拉伸振动峰,同样在1731 cm-1、1619 cm-1 和1395 cm-1的位置分别对应的是C=O拉伸振动峰、C—C拉伸振动峰和C—O的拉伸振动峰,剩下的1065 cm-1位置对应的是C—O—C振动峰。对比于氧化石墨烯的红外光谱图,rGO相应位置的峰强出现明显的减弱[18-19]。这说明氧化石墨烯在450 ℃、H2的还原下,还原效果明显,含氧官能团数量降低。

图3 氧化石墨烯和rGO的拉曼光谱图和红外光谱图

Fig. 3 Raman spectra and FTIR of graphene oxide and rGO

图4所示为氧化石墨烯和rGO的XPS光谱。如图4(a)所示,XPS光谱定量估计了氧化石墨烯和rGO上C、O的含量,分析在H2气氛下进行的热还原对氧化石墨烯还原程度影响。氧化石墨烯在450 ℃、H2作用下进行热还原,氧化石墨烯含氧量从28.68%降到9.97%。此外,为了研究H2热还原过程对氧化石墨烯的影响,在通过线性背景校正后,使用高斯洛伦兹峰形状拟合了C 1s光谱。如图4(b)和(c)所示,位于284.5 eV是C—C峰,而286.4 eV和288.5 eV的峰分别来自C—O和C=O[20-22]。

图4 氧化石墨烯和rGO的XPS光谱

Fig. 4 XPS spectra of graphene oxide and rGO

正如前面红外光谱显示的那样,H2热还原对氧化石墨烯有还原作用,降低含氧官能团的数量,提高氧化石墨烯的结构完整度。

2.2 复合粉末的微观结构

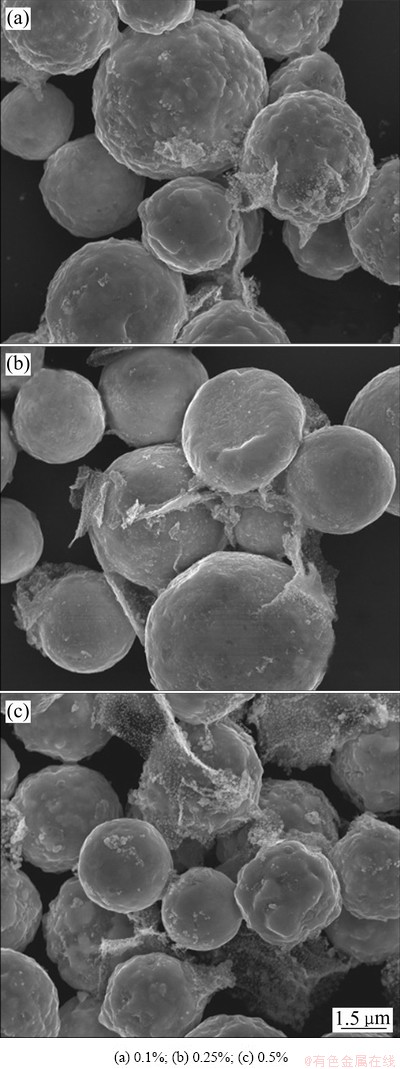

图5所示为不同氧化石墨烯添加的复合粉末SEM像。使用氧化石墨烯作为增强体,利用氧化石墨烯表面带有丰富含氧官能团的特点,让氧化石墨烯在水溶液中均匀分散。因为含氧官能团的存在,所以氧化石墨烯分散液显示负电[23]。使用阳离子活性剂CTAB对铜粉表面进行改性,改性后铜粉表面带正电荷[24]。从图5中可以看出,氧化石墨烯在铜粉中分散效果较好,但是当含量不断增加到一定量时,会存在少部分团聚现象。

图5 不同氧化石墨烯含量的复合粉末SEM像

Fig. 5 SEM images of composite powders with different contents of graphene oxide

2.3 复合材料的微观结构

图6 纯铜、复合材料的SEM像和晶粒尺寸统计图

Fig. 6 SEM images and grain size statistics of pure copper and rGO/Cu composites

图6所示为纯铜和不同rGO含量的rGO/Cu复合材料的SEM像和平均晶粒尺寸统计图。如图6(a)~(c)所示,经过放电等离子烧结后,复合材料孔隙率低。从图6(d)中可以看到,随着rGO添加量的不断增加,复合材料在晶界处的孔洞也会随之增加,这可能是rGO团聚所造成。图6(a′)~(d′)分别为纯铜、rGO含量为0.1%、0.25%、0.5%复合材料的平均晶粒尺寸统计图,使用Nano Measurer软件对复合材料晶粒尺寸进行统计,统计得出材料的平均晶粒尺寸分别约为7.15 μm、3.75 μm、3.37 μm、3.86 μm。从材料的平均晶粒尺寸大小中可以看出rGO对晶粒的细化作用比较明显,复合材料的平均晶粒尺寸小于纯铜的晶粒尺寸。这说明rGO对铜晶粒有很好的钉扎作用,可以抑制晶粒长大。

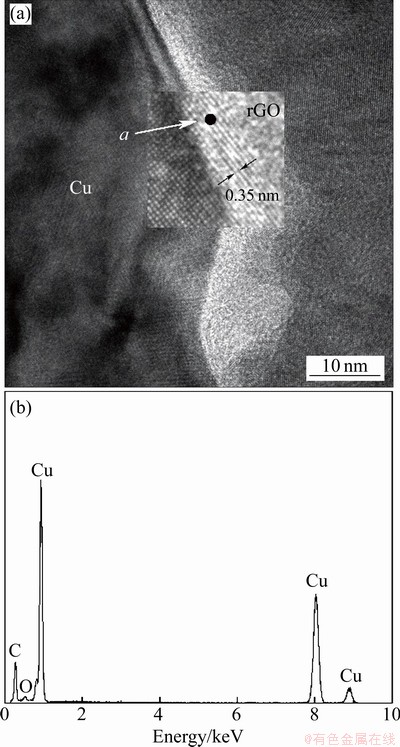

图7所示为0.5% rGO/Cu复合材料TEM像和a点EDS谱。如图7(a)所示,白色区域为rGO,可以看出rGO与铜之间存在良好的界面结合,没有孔隙。从图7(b)中可以知道,铜与rGO的界面处是有微量残余氧的存在。CHEN等[25]通过放电等离子烧结法制备出石墨烯-碳纳米管/铜复合材料,残余氧的扩散在界面出形成Cu—O键,并提出可能的演化机制。

图7 0.5%rGO/Cu复合材料TEM像和a点EDS图

Fig. 7 TEM image(a) and EDS spectrum(b) of 0.5% rGO/Cu composites

2.4 复合材料的相对密度

表1所示为rGO/Cu复合材料的相对密度的测试结果。从表1中可看出,随着rGO的含量(质量分数)不断增加,复合材料的相对密度也在不断降低,当rGO含量为0.5%时,复合材料的相对密度有最小值为97.73%。

表1 rGO/Cu复合材料的相对密度

Table 1 Relative density of rGO/Cu composites

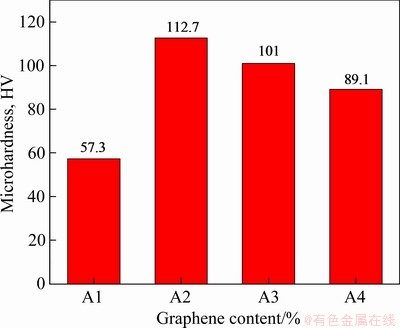

2.5 复合材料的硬度

图8所示为rGO/Cu复合材料显微硬度的测试结果。A1、A2、A3、A4分别为纯铜、rGO含量为0.1%、0.25%、0.5%的rGO/Cu复合材料。图8表明复合材料的硬度随着rGO含量的增加,先升高后降低。当rGO含量为0.1%和0.25%的复合材料具有较高的硬度值,分别为112.7HV和101HV,与纯铜相比提高了97.1%和76.3%。

复合材料硬度的增强机制可能是:一方面,添加rGO后,rGO钉扎在基体材料的晶界处。当外加载荷施加到材料时,处于晶界处的rGO对晶界有钉扎作用,阻碍外加载荷所产生的位错运动。另一方面,烧结过程中位于晶粒之间的rGO可以抑制铜晶界的迁移,影响晶粒长大,从而起到细化晶粒的目的[26]。随着rGO的含量继续添加,使得rGO开始分布不均,复合材料的孔隙率也在持续降低,所以在rGO含量为0.5%时,复合材料的硬度降低比较明显。

图8 rGO/Cu复合材料的显微硬度

Fig. 8 Microhardness of rGO/Cu nanocomposites

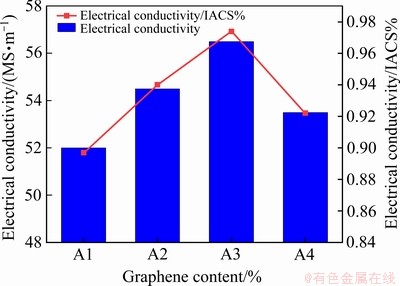

2.6 复合材料的导电性能

图9所示为rGO/Cu复合材料电导率的测试结果。结果表明,加入rGO后,复合材料的电导率有明显提升,随rGO添加量的增加,复合材料的电导率先增加后降低。其中纯铜电导为89.7% IACS(~52 MS/m),当rGO含量为0.25%时的复合材料,此时电导率有最大值(约56.5 MS/m),为97.4% IACS,比纯铜提升了8.6%。

图9 rGO/Cu复合材料的电导率

Fig. 9 Conductivity of rGO/Cu composites

石墨烯具有超强的导电性能,因此,将rGO添加到铜基体中可以有效的提高复合材料的电导率。其增强原理如下:第一、rGO上残余氧在烧结过程中进行扩散,铜-碳界面处可能有Cu—O共价键生成,Cu—O共价键有利复合材料界面强度的提高,并实现导电性能的增强[27];第二、在放电等离子方法的烧结下,因为升温速度快,保温时间短,纯铜和复合材料晶粒长大不明显,它们晶界对电子散射的影响程度差异较小,晶粒尺寸对电导率的影响小于rGO对电导率的增强作用;第三、由于rGO与铜粉在制备过程中良好的电荷吸附效果和高强烧结压力的作用下,他们之间形成良好的界面结合,致密化程度高,有利于电子的传输。复合材料电导率与密度的计算如式(1)所示[28]:

(1)

(1)

式中: 和

和 是复合材料和纯固体材料的电导率;

是复合材料和纯固体材料的电导率; 和

和 分别为复合材料和纯固体的密度。

分别为复合材料和纯固体的密度。

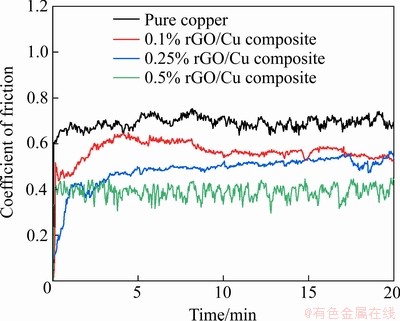

2.7 复合材料的摩擦性能

如图10所示,显示了在5 N载荷下,摩擦速度为120 r/min、旋转半径为3 mm的rGO/Cu复合材料的摩擦曲线图。图10中显示在经过前2 min磨合的过渡期后,复合材料摩擦因数趋于稳定,rGO的添加对复合材料摩擦性能会有极大的改善作用。纯铜的平均摩擦因数高达0.691,当rGO的添加量为0.1%、0.25%、0.5%,复合材料的平均摩擦因数依次降低到约为0.572、0.491、0.402。复合材料随着rGO含量的增加,摩擦性能在不断的提升。

图10 rGO/Cu复合材料的摩擦曲线

Fig. 10 Friction curves of rGO/Cu composites

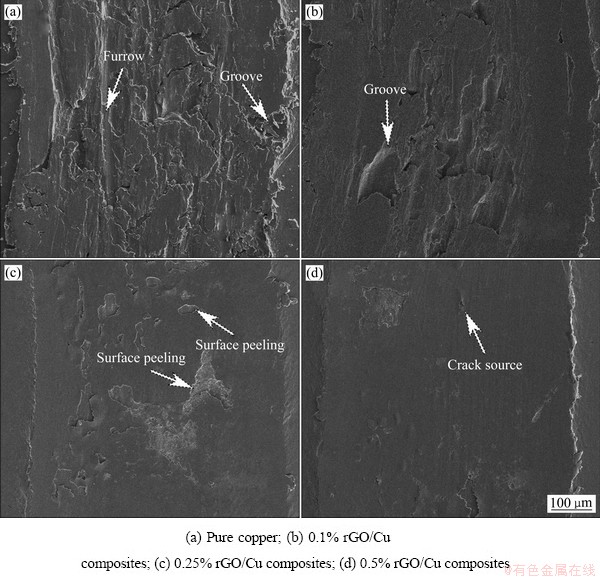

图11所示为rGO/Cu复合材料在5 N载荷的摩擦接触面的SEM像。为了研究rGO/Cu复合材料的磨损机理,对纯铜和不同rGO含量的rGO/Cu复合材料进行了探究。从图11(a)可以看出,纯铜材料与摩擦副之间的接触面发生典型的塑性变形,相邻的铜颗粒之间在摩擦的过程中产生黏附现象。此外,图中还可以看到少量的铜颗粒在摩擦过程中会产生剥离的现象,而剥离出的颗粒在压力和推动力作用下,使材料表面发生迁移,剪切两边的界面形成犁沟。因此,在剪切阻力和犁沟阻力共同作用下,纯铜的摩擦因数一直处在较高的水平。如图11(b)所示,在添加0.1% rGO后,rGO位于复合材料的晶界处,对晶界有钉扎作用,可以阻碍相邻铜颗粒进行的黏附作用,防止界面发生塑性变形。另外,rGO在经过摩擦副摩擦后,会在摩擦表面形成具有减磨作用的润滑膜。由于润滑膜的存在,使得材料在滑动时剪切阻力降低。但是rGO含量较低,形成的润滑膜不够完整,在材料表面依然出现了凹槽,使得材料摩擦因数降低的不明显。从图11(c)中可以看出,rGO含量0.25%复合材料的摩擦表面仍然存在少量表面剥离的现象。这是因为rGO含量较低,经过长时间的摩擦,在部分不存在rGO的界面处,铜颗粒之间还在发生部分黏附现象。随着rGO含量的继续增加,润滑膜变得连续且厚度逐渐增加,复合材料摩擦界面的剥离现象得到很好的改善。如图11(d)所示,接触面只出现了部分裂纹的扩展和小部分的缺陷,此时摩擦因数最小。

图11 rGO/Cu复合材料在5 N载荷的摩擦接触面的SEM像

Fig. 11 SEM images of friction contact surface of rGO/Cu composites under 5 N load

3 结论

1) 通过电荷吸附制备的rGO/Cu复合粉末可以成功的将rGO均匀的分散在Cu基体中,并能保证rGO的结构完整性。通过热还原法对复合粉末进行还原可以降低rGO结构的缺陷,从而使得复合材料性能得到增强。

2) 放电等离子烧结技术具有升温速度快,保温时间短的特点,因此制备的rGO/Cu复合材料的晶粒尺寸较小,硬度、导电性能和耐摩擦性能得到极大的改善。随着rGO含量的增加,复合材料的维氏硬度和电导率先增加后降低。当rGO含量为0.1%时,硬度有最高值112.7HV。当rGO含量为0.25%时,电导率最高值56.5 MS/m。此外,随着rGO含量的增加,复合材料的摩擦性能也在不断加强。这表明采用热还原和放电等离子烧结的方法在制备铜基复合材料方面中具有良好的潜力。

REFERENCES

[1] LI D S, YE Y, LIAO X J, et al. A novel method for preparing and characterizing graphene nanoplatelets/aluminum nanocomposites[J]. Nano Research, 2018, 11(3): 1642-1650.

[2] REN S B, CHEN J H, HE X B, et al. Effect of matrix-alloying-element chromium on the microstructure and properties of graphite flakes/copper composites fabricated by hot pressing sintering[J]. Carbon, 2018, 127: 412-423.

[3] 李多生, 吴文政, QIN Qing-hua, 等. 石墨烯/Al 复合材料的微观结构及力学性能[J]. 中国有色金属学报, 2015, 25(6): 1498-1504.

LI Duo-sheng, WU Wen-zheng, QIN Qing-hua, et al. Microstructure and mechanical properties of graphene/Al composites[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(6): 1498-1504.

[4] ZHAO Wen-min, BAO Rui, YI Jian-hong, et al. Fabrication of RGO/Cu composites based on electrostatic adsorption[J]. Transactions of Nonferrous Metals Society of China, 2020, 30(4): 982-991.

[5] 林奎鑫, 李多生, 叶 寅, 等. 扭转双层石墨烯物理性质, 制备方法及其应用的研究进展[J]. 物理学报, 2018, 67(24): 13-25.

LIN Kui-xin, LI Duo-sheng, YE Yin, et al. Review of fabrication methods, physical properties, and applications of twisted bilayer graphene[J]. Chinese Journal of Physics, 2018, 67(24): 13-25.

[6] LAWAL A T. Graphene-based nano composites and their applications: A review[J]. Biosensors and Bioelectronics, 2019: 111384.

[7] 卢晓通, 张志刚, 罗洪杰, 等. 石墨烯/铜复合材料的制备与摩擦性能测试[J]. 中国有色金属学报, 2019, 29(1): 66-73.

LU Xiao-tong, ZHANG Zhi-gang, LUO Hong-jie, et al. Preparation of graphene/copper composites and its friction performance[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(1): 66-73.

[8] FU S, CHEN X, LIU P. Preparation of CNTs/Cu composites with good electrical conductivity and excellent mechanical properties[J]. Materials Science and Engineering A, 2020, 771: 138656.

[9] WEI X, TAO J M, LIU Y C, et al. High strength and electrical conductivity of copper matrix composites reinforced by carbon nanotube-graphene oxide hybrids with hierarchical structure and nanoscale twins[J]. Diamond and Related Materials, 2019, 99: 107537.

[10] HUMMERS J W S, OFFEMAN R E. Preparation of graphitic oxide[J]. Journal of the American Chemical Society, 1958, 80(6): 1339-1339.

[11] FAN L Z, LIU J L, UD-DIN R, et al. The effect of reduction time on the surface functional groups and supercapacitive performance of graphene nanosheets[J]. Carbon, 2012, 50(10): 3724-3730.

[12] CHEN F, YING J, WANG Y, et al. Effects of graphene content on the microstructure and properties of copper matrix composites[J]. Carbon, 2016, 96: 836-842.

[13] AYYAPPADAS C, MUTHUCHAMY A, ANNAMALAI A R, et al. An investigation on the effect of sintering mode on various properties of copper-graphene metal matrix composite[J]. Advanced Powder Technology, 2017, 28(7): 1760-1768.

[14] PONRAJ N V, AZHAGURAJAN A, VETTIVEL S C, et al. Graphene nanosheet as reinforcement agent in copper matrix composite by using powder metallurgy method[J]. Surfaces and Interfaces, 2017, 6: 190-196.

[15] 李秀辉, 燕绍九, 洪起虎, 等. 石墨烯添加量对铜基复合材料性能的影响[J]. 材料工程, 2019, 47(1): 11-17.

LI Xiu-hui, YAN Shao-jiu, HONG Qi-hu, et al. Influence of graphene content on properties of Cu matrix composites[J]. Journal of Materials Engineering, 2019, 47(1): 11-17.

[16] FERRARI A C. Raman spectroscopy of graphene and graphite: Disorder, electron-phonon coupling, doping and nonadiabatic effects[J]. Solid State Communications, 2007, 143(1/2): 47-57.

[17] EIGLER S, DOTZER C, HIRSCH A. Visualization of defect densities in reduced graphene oxide[J]. Carbon, 2012, 50(10): 3666-3673.

[18] LORYUENYONG V, TOTEPVIMARN K, EIMBURANAPRAVAT P, et al. Preparation and characterization of reduced graphene oxide sheets via water-based exfoliation and reduction methods[J]. Advances in Materials Science and Engineering, 2013, 2013: 923403.

[19] HWANG J, YOON T, JIN S H, et al. Enhanced mechanical properties of graphene/copper nanocomposites using a molecular-level mixing process[J]. Advanced Materials, 2013, 25(46): 6724-6729.

[20] ZHANG Q, CAI C, QIN J W, et al. Tunable self-discharge process of carbon nanotube based supercapacitors[J]. Nano Energy, 2014, 4: 14-22.

[21] YANG D X, VELAMAKANNI A, BOZOKLU G, et al. Chemical analysis of graphene oxide films after heat and chemical treatments by X-ray photoelectron and Micro- Raman spectroscopy[J]. Carbon, 2009, 47(1): 145-152.

[22] YANG Z, WANG L D, SHI Z D, et al. Preparation mechanism of hierarchical layered structure of graphene/ copper composite with ultrahigh tensile strength[J]. Carbon, 2018, 127: 329-339.

[23] ASGHARZADEH H, ESLAMI S. Effect of reduced graphene oxide nanoplatelets content on the mechanical and electrical properties of copper matrix composite[J]. Journal of Alloys and Compounds, 2019, 806: 553-565.

[24] GAO X, YUE H Y, GUO E J, et al. Mechanical properties and thermal conductivity of graphene reinforced copper matrix composites[J]. Powder Technology, 2016, 301: 601-607.

[25] CHEN X, TAO J, LIU Y, et al. Interface interaction and synergistic strengthening behavior in pure copper matrix composites reinforced with functionalized carbon nanotube-graphene hybrids[J]. Carbon, 2019, 146: 736-755.

[26] CHEN F Y, YING J M, WANG Y F, et al. Effects of graphene content on the microstructure and properties of copper matrix composites[J]. Carbon, 2016, 96: 836-842.

[27] YANG M, WENG L, ZHU H, et al. Simultaneously enhancing the strength, ductility and conductivity of copper matrix composites with graphene nanoribbons[J]. Carbon, 2017, 118: 250-260.

[28] FENG Y, ZHENG H W, ZHU Z G, et al. The microstructure and electrical conductivity of aluminum alloy foams[J]. Materials chemistry and physics, 2003, 78(1): 196-201.

Effect of thermally reduced graphene nanosheets on properties of copper matrix composites

XIONG Cai-zi, LI Duo-sheng, YE Yin, ZOU Ai-hua, WANG Guo-bo, FENG Qing-xiao, WANG Kai, GUAN Ji-yuan

(School of Materials Science and Engineering, Nanchang Hangkong University, Nanchang 330063, China)

Abstract: The thermal reduction method and spark plasma sintering technology were used to prepare graphene nanosheets/copper (rGO/Cu) composites, and the effect of different content of reduced graphene oxide (rGO) on the preparation of composites was studied. The results show that graphene oxide(GO) is uniformly dispersed on the surface of copper powder. After sintering, GO and copper powder are tightly combined to form a good bonding interface, and the hardness, electrical conductivity and friction properties of the composites are also improved respectively. With the increase of rGO content, the hardness and conductivity of the composites first increase and then decrease. When the rGO content is 0.1%, the hardness of rGO/Cu composites has the highest value of 112.7 HV, and when the rGO content is 0.25%, the composites conductivity has the highest value of 56.5 MS/m. The friction performance of composites decreases with the increase of rGO content. When the rGO content reaches 0.5%, the friction coefficient of the composites is at least 0.402.

Key words: thermal reduction method; graphene oxide; composites; electrical conductivity; friction performance

Foundation item: Project(51562027) supported by the National Natural Science Foundation of China; Project (20201BBE51001) supported by the Key Research and Development Program of Jiangxi Province, China; Project(20181BCB24007) supported by the Provincial Dominant Science and Technology Innovation Team Project of Jiangxi Province, China

Received date: 2020-08-01; Accepted date: 2020-12-24

Corresponding author: LI Duo-sheng; Tel: +86-18170089973; E-mail: duosheng.li@ nchu.edu.cn

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(51562027);江西省重点研发计划重点项目(20201BBE51001);江西省省级优势科技创新团队项目(20181BCB24007)

收稿日期:2020-08-01;修订日期:2020-12-24

通信作者:李多生,副教授,博士;电话:18170089973;E-mail:duosheng.li@nchu.edu.cn