基于片条理论和遗传算法的风力机叶片全局优化设计

傅洁1,何斌1,张慧玲1,范钦珊1,2

(1. 南京工业大学 力学部,江苏 南京,210009;

2. 清华大学 航天航空学院,北京,100084)

摘要:针对水平轴风力机叶片Wilson优化设计法的不足,以片条理论为基础、全年发电量为目标函数对叶片进行全局优化设计。通过遗传算法对设计约束进行最优化搜索,并根据该方法设计在平均风速为7.5 m/s风场下工作的1.5 MW叶片。为保证功率计算的准确性,通过XFOIL和CFD软件计算翼型0?~360?攻角下气动性能,将其设计结果与Wilson法进行比较。研究结果表明:全局优化设计方法能够满足叶片设计要求,设计的叶片在低于额定风速的低风速区性能良好,在平均风速附近(7~9 m/s)的功率系数达0.44。

关键词:片条理论;遗传算法;威尔逊法;XFOIL软件;优化设计

中图分类号:TK83 文献标志码:A 文章编号:1672-7207(2012)08-3025-06

Optimal design of horizontal-axis wind turbines blade based on strip theory and genetic algorithms

FU Jie1, HE Bin1, ZHANG Hui-ling1, FAN Qin-shan1,2

(1. Division of Mechanics, Nanjing University of Technology, Nanjing 210009, China;

2. School of Aerospace, Tsinghua University, Beijing 100084, China)

Abstract: Based on strip theory and genetic algorithms and taking annual generated electrical energy as target, an optimization method for blade design of horizontal-axis wind turbines (HAWT) was designed to improve Wilson method. As an effective optimization tool, genetic algorithm accomplishes the designed goal very well. A blade worked at 7.5m/s mean wind speed for 1.5 MW wind turbine was designed. In order to ensure the accuracy of power calculation, the aerodynamic performances of XFOIL at angle of attack from 0° to 360° were computed by XFOIL and CFD software. The results show that the method satisfies the design requirement and has a good performance at wind speed of 7-9 m/s. The maximum power coefficient of the 1.5 MW wind turbine blade design with this method reaches 0.44, which is close to that of Wilson blade.

Key words: strip theory; genetic algorithms; Wilson method; XFOIL software; optimal design

水平轴风力机叶片设计是一个受多种条件约束的复杂优化设计过程。根据设计偏重点的不同,其设计的最优结果并不唯一。传统的风力机桨叶优化设计方法以桨叶各截面在设计风速下具有最大的功率系数为设计目标,如Glauert优化设计模型及Wilson修正模型[1-2]。据此,Johanse等[3]研究了忽略结构等其他因素完全追求最大功率的叶片。而以设计风速下的气动最优设计的叶片,还需经过设计人员根据经验考虑结构、载荷以及噪声等多种因素进行修改,其性能往往取决于设计者的经验。在一个多目标的优化问题中,对于以单一设计工况为基础的叶片很难说是最佳结果。另外,兆瓦级叶片的设计额定风速多为11~13 m/s,而我国大部分陆上风场的年平均风速低于8 m/s。事实上,国内外已有一些研究者探索以年发电量最大或者最小成本为目标设计叶片[4-5]。在此,本文作者基于片条理论的气动理论,采用遗传算法作为寻优工具,以全年最大输出功率为目标函数,控制叶片弦长和扭角进行全局寻优。并通过与传统的Wilson优化法设计的叶片进行比较,验证这一方法的可行性。叶片翼型采用国外已成熟风力机专用翼型及NACA系列[6],为了保证叶片功率估算的准确性,分别采用XFOIL和CFD软件对翼型失速点前后的气动性能进行计算。

1 气动模型

1.1 片条理论

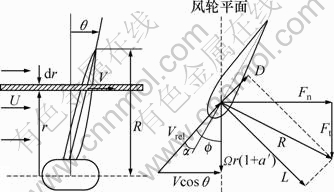

片条理论由Wilson等[1]综合动量理论和叶素理论提出。该理论考虑了叶尖损失、叶栅效应、间隙修正和叶片锥角等因素,使估计的诱导速度更准确。图1所示为叶片截面的来流合成速度以及合成速度角[7-8]。

图1 水平轴风力机截面速度三角形

Fig.1 Velocity triangles at arbitrary radius r of HAWT

(1)

(1)

(2)

(2)

式中:a和a’分别为轴向和切向诱导因子;α为安装角;Ф为入流角;θ为叶片锥角;γc为叶片扭角;λ为尖速比;c为截面弦长;r为截面所处半径;B为叶片数;F为修正系数;R为叶片总长;CD为阻力系数;CL为升力系数;CT为推力系数。只需给定叶片基本参数,迭代计算a和a′使得满足式(1),即可通过式(2)计算推力系数、功率等。

1.2 Wilson优化设计方法

Wilson优化设计方法是基于上述气动理论,将风轮叶片沿展向平均分成若干等份,取1个适合的尖速比λ0,对于风力机叶片的每一个计算截面风能系数可以表示为:

(3)

(3)

要使风力机叶片的整体风能利用系数Cp最大,就要使每个计算截面的CP达到最大。

通过以式(3)为目标函数迭代计算诱导因子a和a’,使诱导因子a和a′在满足以式(1)为约束条件情况下,找出CP最大值,进而可通过式(2)求解叶片的各截面的弦长c和扭角γc。

2 翼型及气动性能

2.1 翼型数据

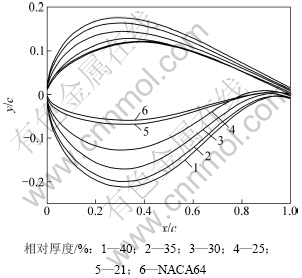

在风力机叶片设计中,早期设计多采用航空翼型。由于航空翼型不能完全满足风力机对于翼型在低风速下的气动要求。各国又发展出各自的风力机专有翼型系列,如荷兰的DU系列、丹麦的FFA系列以及广泛采用的S系列[9]。在本文设计中翼型采用某风力机专用翼型(相对厚度为40%~21%)以及相对厚度为18%的NACA 64,翼型外形见图2。

2.2 气动性能

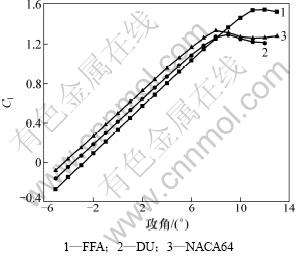

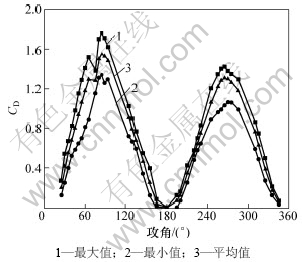

对于风力机专用翼型,其气动数据鲜有公开。另外叶片根部采用的厚翼型为保证与实际情况相一致,还需做钝尾缘处理。要获得翼型准确的气动数据,有必要对翼型进行气动分析。在小攻角情况下即-5°~13°时采用XFOIL软件进行计算。XFOIL由Mark Drela开发,是基于面元法和黏性边界层以及自由附面层-湍流运输模型[10],能够很方便地得到翼型的升阻系数以及压力分布,其在小攻角边界层未分离情况下,计算结果与实验数据非常接近。大攻角下的气动性能则采用求解非定常、可压缩雷诺平均方程和低雷诺数双方程湍流模型进行数值计算。部分计算结果见图3 和4。

图3所示为3种风力机常用薄翼型升力系数。从图3可见:对于风力机专用翼型FFA的气动性能较NACA64的优,其失速点比NACA64的高。图4所示为NACA64的大攻角数值模拟结果。从图4可见:在失速点前,数值模拟结果与实验数据相比非常接近;而失速点之后,到整个全攻角,与相同展弦比下的经验公式比较其气动性能符合度也较高[11-12]。考虑到模拟是在实际翼型基础上展开的,特别是根部厚翼型又对尾缘进行了钝化,所以,本文设计中的气动计算采用模拟的结果更符合实际情况。

图2 风力机翼型外形图

Fig.2 Wind turbine airfoil shapes

图3 几种翼型升力系数

Fig.3 Lift coefficient of airfoils

图4 NACA64阻力系数

Fig.4 Drag coefficient of NACA64

3 叶片优化设计

3.1 全局优化方法

以气动最优方法设计的风力机叶片在设计风速下能够有良好的表现。但大多数风场的平均风速低于8 m/s,风力机很少在设计风速工作,因此,以这种方法设计的风力机叶片不能保证在切入风速到切出风速全局之间有理想的功率曲线。而年度发电量(Annual energy production,AEP)能够反映这种关系[13]。

叶片设计变量为各截面弦长cmax,c1,c2,cn和ctip以及对应的扭角βmax,β1,β2,βn和βtip。全年时间为定值,则以威布尔分布的风速时间也为定值。

(4)

(4)

式中:E为年度发电量;F(U)为超过风速U的时间概率密度;C为尺度参数;k为形状参数;uin和uout分别为切入和切出风速;P(u)为u风速下的叶片气动功率;T为叶片推力,Ω为旋转角速度。

3.2 约束条件

(5)

(5)

其中:r/R=15%,即叶片的桨距角从叶片总长15%处向叶尖递减。叶片补风段即叶片总长的15%~85%处,其最大弦长通常为10%~20%。另外,考虑到叶尖速对功率以及噪声的影响[9],叶尖绝对速度为40~80 m/s。

3.3 最优化算法

本文以遗传算法作为寻优的工具。遗传算法是模拟生物在自然环境中的遗传、进化过程而形成的一种自适应全局优化概率搜索算法。遗传算法的优化机理是从随机生成的初始群体出发, 采用基于优胜劣汰的选择策略选择优良个体作为父代;通过父代个体的复制、杂交和变异来繁衍进化子代种群。经过多代的进化, 种群的适应性会逐渐增强。针对一个具体的优化问题来说, 优化结束时, 具有最大适应值的个体所对应的设计变量值便是优化问题的最优解。遗传算法已经广泛应用于工程设计中[14-15]。

3.4 风速分布

对于传统风力机的叶片设计只需给定设计风速即可。而本文中优化设计方法是以年度发电量为目标设计,需要考虑全年风速的分布。对于给定风场条件的风力机设计以当地风速统计值为设计值,本文风速分布模型采用平均风速7.5 m/s的威布尔分布[9]。

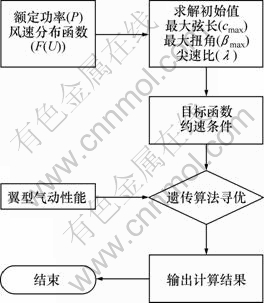

3.5 优化过程

全局优化法是在给定控制方程的情况下,通过寻优算法在全局寻找目标函数的最大值。

图5所示为全局优化方法的示意图。首先给定额定功率以及风速分布函数或者风场的年风速统计。在计算开始前给定初始值如最大弦长、最大扭角以及尖速比。在寻优过程中,目标函数的最大值为年发电量,而计算发电量以片条理论为基础。各截面翼型的气动性能计算结果建立一个数据库以调用。最后目标函数取得最大值时输出叶片几何参数,如叶片总长、弦长和扭角分布等。

图5 全局优化方法流程

Fig.5 Scheme of optimal design

4 实例分析

针对平均风速为7.5 m/s风场,分别采用Wilson优化法以及全局优化法设计1.5 MW风力机叶片,设计额定风速为12 m/s,切入风速为3 m/s,切出风速为25 m/s。

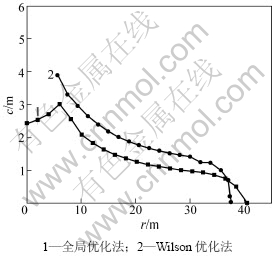

4.1 叶片气动外形设计结果

图6和图7所示为以全局优化方法设计的叶片与Wilson优化法叶片的弦长、扭角对比。从图6可以看到:在相同功率下,以全局优化法设计的叶片较Wilson法的细长。全局优化法设计的叶片全长为40.5 m,最大弦长在叶片15%处,为3.01 m。Wilson优化法设计的叶片总长37.5 m,弦长从尖部到根部逐渐增大。越接近根部其弦长越大,这是因为叶片根部翼型接近圆形,其升力系数可以忽略。以此方法设计的叶片根部0~20%部分的弦长设计取决于结构设计以及设计的经验。而全局优化法通过约束最大弦长和根部最大直径可以完成叶片整体的设计。

图6 叶片弦长对比

Fig.6 Comparison of chord length

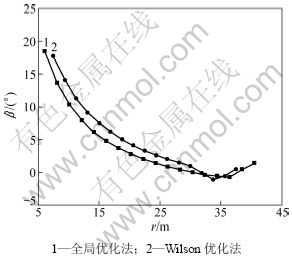

从图7可以看出:2种方法设计的叶片扭角相差不大,全局优化法的扭角在各截面略小于Wilson优化法。对于大型叶片而言扭角越小越便于加工,降低了叶片成本[9]。

4.2 叶片气动性能比较

为了比较2种设计方法的优劣性,以片条理论为气动基础,计算2种叶片在各风速下的气动特性和功率输出。

图7 叶片扭角对比

Fig.7 Comparison of twist angles

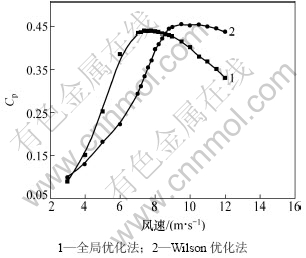

图8 叶片功率系数对比

Fig.8 CP of two wind turbine blades

图8所示为2种叶片在不同风速下的功率系数对比。从图8可以看出:Wilson优化法设计的叶片有着很好的气动特性,最大功率系数发生在风速10 m左右,接近0.45;但在风速低于9 m/s时,功率系数迅速下降。而全局优化法在风速为7 m/s时就达到了最佳工作区间;在7~9 m/s范围内,保持着很好的功率系数。这样,对于全年平均风速为7.5 m/s的风场,显然全局优化法设计的叶片更加适合。

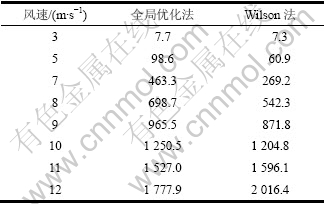

表1所示为不同风速下2种叶片对应的输出功率。可见:2种叶片在风速为11 m/s时均达到了额定功率。在额定风速12 m/s左右,Wilson法设计的叶片较好。而全局优化法设计的叶片更适合在低风速区工作。

表1 各风速下功率对比

Table 1 Power of blade at various work speeds kW

5 结论

(1) 在片条理论基础上,以叶片外形参数为设计变量,利用遗传算法作为搜索工具全局寻优,针对平均风速7.5 m/s的风场设计水平轴风力机叶片。

(2) XFOIL软件在小攻角区域能够较好的描述气动特性。采用CFD数值计算了钝尾缘以及失速点后的翼型气动特性。计算结果保证了叶片功率估算的准 确性。

(3) 本文方法设计的叶片较Wilson法的细长,在低于额定风速的低风速区表现良好,并能在平均风速附近(7~9 m/s)保持高功率系数,在年发电量上有优势。由于风力机补风面积随着叶片长度的增加而增大,在额定风速时风力机控制着功率的输出,因此,在相同的输出功率下,补风面积小的叶片效率较高。

参考文献:

[1] Wilson R E, Walker S N. Performance analysis of horizontal axis wind turbines[M]. Corvallis: Oregon State Univ, 1994: 215-282.

[2] Hansen M O L. Aerodynamics of wind turbines[M]. 2nd ed. London: James & James, 2008: 67-71.

[3] Johanse J, Madsen H A, Gaunaa M, et al. Design of a wind turbine rotor for maximum aerodynamic efficiency[J]. Wind Energy, 2009, 12: 261-273.

[4] 刘雄, 陈严, 叶枝全. 风力机桨叶总体优化设计的复合形法[J]. 太阳能学报, 2001, 22(2): 157-161.

LIU Xiong, CHEN Yan, YE Zhi-quan. Wind turbine global optimum design complex method[J]. Aca Energiae Solaris Sinica, 2001, 22(2): 157-161.

[5] Benini E, Toffolo E. Optimal design of horizontal-axis wind turbines using blade-element theory and evolutionary Computation[J]. Journal of Solar Energy Engineering, 2002, 124: 357-363.

[6] Abbott I H, Doenhoff A E V. Theory of wing sections[M]. New York: Dover Publications, 1959: 584-592.

[7] Spera A. Wind turbine technology[M]. New York: ASME Press, 1994: 47-104.

[8] Fuglsang P, Madsen H A. Optimization method for wind turbine rotors[J]. Journal of Wind Engineering and Industrial Aerodynamics, 1999, 80: 191-206.

[9] Burton T, Sharpe D, Jenkins N, et al. Wind energy handbook[M]. Chichester: J Wiley & Sons, 2001: 120-136.

[10] Drela M. XFoil: An analysis and design system for low Reynolds number airfoils[C]//Conference on low Reynolds number airfoil aerodynamics. Notre Dame: University of Notre Dame, 1989: 1-12.

[11] YUAN Xin, JIANG Xue-zhong. Simulation of low speed separated flows for the nrel airfoil at high angles of attack[J]. Journal of Engineering Thermophysics, 1999, 20: 161-165.

[12] Moriarty P, Hansen C.Aerodyn theorymanual[R]. Golden: National Renewable Energy Laboratory, 2005: 21-24.

[13] Gigue`re P, Selig M S, Tangler J L. Blade design trade-offs using low-lift airfoils for stall-regulated HAWTs[R]. Golden: National Renewable Energy Laboratory, 1999: 5-12.

[14] 刘洁, 杨爱民, 翁培奋. 基于遗传算法的微型飞行器气动力优化设计[J]. 空气动力学学报, 2005, 23(2): 173-177.

LIU Jie, YANG Ai-min, WENG Pei-fen. Aerodynamic optimization for Micro Air Vehicle based upon genetic algorithm[J]. Acta Aerodynamica Sinca, 2005, 23(2): 173-177.

[15] 常彦鑫, 高正红. 遗传算法在气动优化问题中的适应性分析[J]. 空气动力学学报, 2009, 27(2): 167-172.

CHANG Yan-xin, GAO Zheng-hong. Applicability analysis of genetic algorithms using in aerodynamic optimization[J]. Acta Aerodynamica Sinca, 2009, 27(2): 167-172.

(编辑 赵俊)

收稿日期:2011-08-29;修回日期:2011-12-20

基金项目:江苏省高校研究生科研创新计划项目(CX10B_168Z)

通信作者:范钦珊(1937-),男,江苏南通人,教授,从事工程力学研究;电话:025-83587826;E-mail:fqs-dem@mail.tsinghua.edu.cn