文章编号:1004-0609(2010)S1-s0514-04

BTi-62421S合金高温变形流动应力模型

张慧芳1,张治民1,张 星1,李保成1,马鸿海2

(1. 中北大学 材料科学与工程学院,太原 030051;

2. 宝钛集团有限公司 科技部,宝鸡 721014)

摘 要:在Gleeble-3800型热加工模拟实验机上,对BTi-62421S合金在变形程度70%、变形温度850~1 050 ℃、应变速率0.01~30 s-1范围内进行高温压缩实验。通过真应力—真应变曲线,分析流动应力随变形热力参数的变化规律。结果表明:BTi-62421S合金高温变形的流变应力随温度的升高和应变速率的降低而减小;随着应变的增大,合金的真应力—真应变曲线在经历了明显的加工硬化阶段后达到最大值,然后出现流变“软化”现象。以经典的双曲正弦形式模型为基础建立了BTi-62421S合金高温变形的本构方程,同时通过对数据回归处理计算了合金高温变形的应力指数n、应变激活能Q。

关键词:BTi-62421S;高温变形;流动应力;本构模型

中图分类号:TG146.2 文献标志码:A

Constitutive model of flow stress for high temperature deformation of BTi-62421S alloy

ZHANG Hui-fang1, ZHANG Zhi-min1, ZHANG Xing1, LI Bao-cheng1, MA Hong-hai2

(1. College of Materials Science and Engineering, North University of China, Taiyuan 030051, China;

2. Scientific and Technical Department, Baoti Group Co., Ltd., Baoji 721014, China)

Abstract: The high temperature compression tests of BTi-62421S titanium alloy were carried out in the temperature range of 850-1 050 ℃ and strain rate range of 0.01-30 s-1 using the Gleeble3800 thermal-mechanical simulator. The change of flow stress with deformation thermal parameters was revealed from true stress—true strain curves. The results show that the true stress of high temperature deformation of BTi-62421S alloy increases with the decrease of deformation temperature and the increase of strain rate. With the increase of true strain, due to the work hardening of the alloy, the true stress attains the peak, and then flow softening occurs. The constitutive equation for high temperature deformation of BTi-62421S alloy is obtained on the basis of hyperbolic sine form model, and the material constants, including activation energy Q and stress exponent n are also obtained.

Key words: BTi-62421S Ti alloy; high temperature deformation; flow stress; constitutive equation

BTi-62421S合金是宝钛集团自主研发的一种新型近α高温钛合金,具有比强度高、蠕变性能及热强性能好等突出优点,可满足高结构效益、高可靠性结构件的使用,具有良好的应用前景。高温钛合金在获得最终产品之前,需要在β单相区或α+β两相区进行热加工[1]。而钛合金材料的成形温度范围较窄,其变形抗力对变形温度和变形速率很敏感[2-4],与其它合金材料相比,钛合金更难成形[5-6]。为了提高钛合金零件的塑性成形能力,各国学者对钛合金的高温变形行为及其成形性能进行了大量的研究[7-11]。由于 BTi- 62421S是一种新型合金,目前尚未见其高温成形的相关研究报道。本文作者通过热压缩实验,研究了BTi-62421S合金流动应力随温度、等效应变和应变速率等变形参数的变化情况,建立了流动应力模型,以期为该合金塑性成形工艺的研究和计算机数值模拟提供理论基础。

1 实验

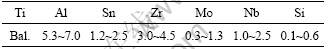

实验所用材料为 BTi-62421S合金铸块,尺寸为155 mm×115 mm×90 mm,状态为热等静压,其β相转变点为1 010 ℃,其主要化学成分见表1。

表1 BTi-62421S合金的化学成分(质量分数,%)

Table 1 Chemical compositions of BTi-62421S alloy (mass fraction, %)

热模拟试样尺寸为d 8 mm×12 mm,实验在Gleeble-3800型热模拟实验机上进行,压缩温度分别为850、900、950、1 000、1 050 ℃,变形速率分别为0.01、0.1、1、10、30 s-1,变形量为70%(真应变1.2)。实验加热速度为10 ℃/s,达到预定温度后保温5 min。压缩变形完成后立即水淬试样,以保持高温变形组织形态。

2 结果与讨论

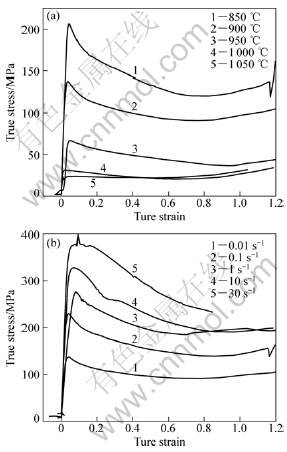

BTi-62421S合金热压缩变形的真应力—真应变曲线如图1所示。由图1可以看出,在不同条件下,BTi-62421S合金的真应力—真应变曲线表现为相似特征。变形初期(达到真应力峰值前),流动应力随应变的增加迅速增加,当应变超过一定值后,流动应力开始下降并逐渐趋于稳定,出现稳态流动特征。BTi-62421S合金对变形温度非常敏感(见图1(a)),给定应变速率,流动应力随着温度的升高而显著降低,且合金流动应力进入稳态流动时所需的应变也随着温度的升高而减小。产生这一现象的物理本质可能是:随着温度的升高,材料热激活作用增强,原子平均动能和扩散速率增加,导致由动态作用引起的软化作用增强,从而使得流动应力值变小,当加工硬化作用与软化作用达到平衡时,所需要的应变值变小。

BTi-62421S合金对应变速率非常敏感(见图1(b)),给定变形温度,流动应力随着应变速率的增加而增加,且峰值应变(峰值应力对应的应变)随着应变速率的增加而增加。这是由于变形速度增加时,变形过程缩短,而要在短时间内驱使数目更多的位错同时运动,会使位错交滑移、扩散、攀移更加困难,必然会导致金属晶体的临界剪应力升高,使变形困难。

图1 BTi-6421S合金的真应力—真应变曲线

Fig.1 True stress—true strain curves of BTi-6421S alloy: (a) Strain rate of 0.01 s-1; (b) At 900 ℃

3 流动应力模型

金属的高温变形是热力学参数所支配的一个热激活过程。温度和应变速率对流动应力的综合影响通常采用受热激活控制的动力学方程来分析。目前, 在金属的热变形过程中, 常用的力学模型是 Arrhenius 型方程[12-14]:

(1)

(1)

式中: 为应变速率;A1、A 2、A、n1、n、α、β均为与温度无关的常数;A为结构因子;n为应力指数;α、β和n1之间满足α=β/n1;σ为流动应力;Q为变形激活能;R为气体常数;T为热力学温度。

为应变速率;A1、A 2、A、n1、n、α、β均为与温度无关的常数;A为结构因子;n为应力指数;α、β和n1之间满足α=β/n1;σ为流动应力;Q为变形激活能;R为气体常数;T为热力学温度。

ZENER和HOLLOMON[15]提出并实验验证了应变速率 和变形温度T 的关系可用Zener-Hollomon 参数Z表示:

和变形温度T 的关系可用Zener-Hollomon 参数Z表示:

(4)

(4)

对式(1)和(2)两边取自然对数,并假设Q 与T 无关,则可得

(5)

(5)

(6)

(6)

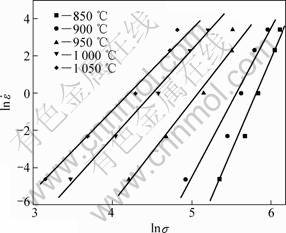

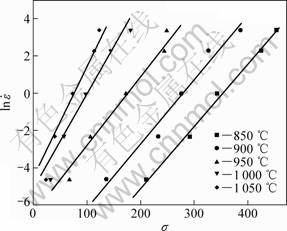

将峰值应力代入式(5)和(6),得到 —lnσ关系曲线如图2所示,

—lnσ关系曲线如图2所示, —σ关系曲线如图3所示。由式(5)和(6)可知,当温度一定时,n1和β分别为

—σ关系曲线如图3所示。由式(5)和(6)可知,当温度一定时,n1和β分别为 —lnσ,

—lnσ, —σ曲线的斜率。取平均值得到n1和β值分别为n1=5.26、β=0.021,则α=0.004 1。

—σ曲线的斜率。取平均值得到n1和β值分别为n1=5.26、β=0.021,则α=0.004 1。

假设热变形激活能Q 与T 无关,对式(3)两边取自然对数,则可得

(7)

(7)

对式(7)的两边取偏微分

(8)

(8)

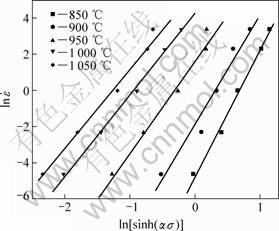

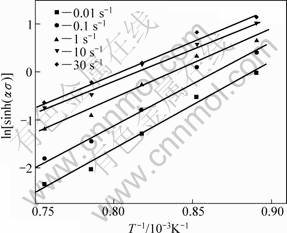

将不同变形温度下BTi-62421S合金的流动应力σ和应变速率 值带入式(7),绘制出相应的

值带入式(7),绘制出相应的  -ln[sinh(ασ)]关系曲线(见图4)和ln[sinh(ασ)]-(1/T)关系曲线(见图5)。从图4可以看出,

-ln[sinh(ασ)]关系曲线(见图4)和ln[sinh(ασ)]-(1/T)关系曲线(见图5)。从图4可以看出, 和ln[sinh(ασ)]较好地满足线性关系。由式(7)可知,图4 中直线斜率即为n值,取平均值,得n=5.38。

和ln[sinh(ασ)]较好地满足线性关系。由式(7)可知,图4 中直线斜率即为n值,取平均值,得n=5.38。

双曲正弦函数关系可用于描述合金所有应力水平下σ和 之间的关系[14],因而能较准确地为通过改变应变速率来控制热加工的应力水平和力学参数提供理论依据。从图5可以看出,σ的双曲正弦对数项和温度的倒数之间满足线性关系,这表明,BTi-62421S合金高温压缩流动应力和变形温度之间满足Arrhenius 关系,同时意味着BTi-62421S合金高温变形是受热激活过程控制的。由图5可求出各直线斜率的平均值为15147.3。并由式(8)求得Q值为678.36 kJ/ mol。

之间的关系[14],因而能较准确地为通过改变应变速率来控制热加工的应力水平和力学参数提供理论依据。从图5可以看出,σ的双曲正弦对数项和温度的倒数之间满足线性关系,这表明,BTi-62421S合金高温压缩流动应力和变形温度之间满足Arrhenius 关系,同时意味着BTi-62421S合金高温变形是受热激活过程控制的。由图5可求出各直线斜率的平均值为15147.3。并由式(8)求得Q值为678.36 kJ/ mol。

由式(7)及图5可知, -ln[sinh(ασ)]关系直线的截距,即为lnA-Q/RT的值,将Q,R,T值代入即可求得不同温度下的ln A值,取其平均值,ln A= 54.87。则材料常数A值为6.73×1023。

-ln[sinh(ασ)]关系直线的截距,即为lnA-Q/RT的值,将Q,R,T值代入即可求得不同温度下的ln A值,取其平均值,ln A= 54.87。则材料常数A值为6.73×1023。

根据式(4)以及反双曲正弦函数的定义,可将流变应力表达为 Zener-Hollomon 参数Z值的函数,并将以上所求的 α、A、n 值代入得

σ=ln{(Z/(6.73×1023)1/5.38+

[Z/(6.73×1023)2/5.38+1]1/2}/0.0041

式中Z= exp(678.36×103/RT)

exp(678.36×103/RT)

图2  -

- 关系曲线

关系曲线

Fig.2 Relationship between  and

and

图3  -

- 关系曲线

关系曲线

Fig.3 Relationship between  and σ

and σ

图4  -ln[sinh(ασ)]关系曲线

-ln[sinh(ασ)]关系曲线

Fig.4 Relationship between  and ln[sinh(ασ)]

and ln[sinh(ασ)]

图5  -σ关系曲线

-σ关系曲线

Fig.5 Relationship between ln[sinh(ασ)] and 1/T

3 结论

1) BTi-62421S合金对变形温度敏感,在同一应变速率下,BTi-62421S合金的流变应力和进入稳态流动时所需的应变随温度的升高而降低。

2) BTi-62421S合金对应变速率敏感,在同一变形温度下,BTi-62421S合金的流变应力和峰值应变随应变速率的增大而提高,说明该合金是正应变速率敏感材料。

3) 可采用 Zener-Hollomon 参数的双曲正弦函数来描述BTi-62421S合金高温流变应力σ。

REFERENCES

[1] 崔文芳, 洪 权, 刘春明, 周 廉. Ti-1100/0.1Y高温钛合金等温热压缩变形行为[J]. 东北大学学报, 2003, 24(6): 572-575.

CUI Wen-fang, HONG Quan, LIU Chun-ming, ZHOU Lian. Hot deformation behaviours of Ti-1100/0.1Y alloy through isothermal hot compression tests[J]. Journal of Northeastern University (NaturalScience), 2003, 24(6): 572-575.

[2] XU Wen-chen, SHAN De-bin,L? Yan, LI Chun-feng. Effects of hot deformation parameters on flow stress and establishment of constitutive relationship system of BT20 titanium alloy[J]. Trans Nonferrous Met Soc China, 2005, 15(Special 2): 167-172.

[3] CHEN Hui-qin, CAO Chun-xiao, GUO Ling, LIN Hai. Hot deformation mechanism and microstructure evolution of TC11 titanium alloy in β field[J]. Trans Nonferrous Met Soc China, 2008, 18(5): 1021-1027.

[4] 罗 皎, 李淼泉, 李 宏, 于卫新. TC4 钛合金高温变形行为及其流动应力模型[J]. 中国有色金属学报, 2008, 18(8): 1395-1401.

LUO Jiao, LI Miao-quan, LI Hong, YU Wei-xin. High temperature deformation behavior of TC4 titanium alloy and its flows stress model[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(8): 1395-1401.

[5] ODENBERGER E L, PEDERSON R, OLDENBURG M. Thermo-mechanical material response and hot sheet metal forming of Ti-6242[J]. Materials Science and Engineering A , 2008, 489: 158-168.

[6] SUN Sheng-di, GUO Bin, SHAN De-bin, ZHONG Ying-ying. Research on elevated temperature deformation behavior of Ti-6Al-4V sheets[J]. Rare Metals, 2009, 28(6): 550-553.

[7] MOMENI A, ABBASI S M. Effect of hot working on flow behavior of Ti-6Al-4V alloy in single phase and two phase regions[J]. Materials and Design, 2010, 31: 3599-3604.

[8] ZHAO Zhang-long, GUO Hong-zhen, WANG Xiao-chen, YAO Ze-kun. Deformation behavior of isothermally forged Ti-5Al-2Sn-2Zr-4Mo powder compact[J]. Journal of Materials Processing Technology, 2009, 209(15/16): 5509-5513.

[9] NARAYANA MURTY S V S, NAGESWARA RAO B. On the flow localization concepts in the processing maps of titanium alloy Ti-24Al-20Nb[J]. Journal of Materials Processing Technology, 2000, 104(1/2): 103-109.

[10] WANJARA P, JAHAZI M, MONAJATI H, YUE S. Influence of thermomechanical processing on microstructural evolution in near-αalloy IMI834[J]. Materials Science and Engineering A, 2006, 416(1/2): 300-311.

[11] SESHACHARYULU T, MEDEIROS S C, FRAZIER W G, PRASAD Y V R K. Hot working of commercial Ti-6Al-4V with an equiaxed α-β microstructure: materials modeling considerations[J]. Materials Science and Engineering A, 2000, 284(1/2): 184-194.

[12] SESHACHARYULU T, MEDEIROS S C, MORGAN J T, MALAS J C, FRAZIER W G, PRASAD Y V R K. Hot deformation and microstructural damage mechanisms in extra-low interstitial (ELI) grade Ti-6Al-4V[J]. Materials Science and Engineering A, 2000, 279(1/2): 289-299.

[13] SESHACHARYULU T, MEDEIROS S C, FRAZIER W G, PRASAD Y V R K. Microstructural mechanisms during hot working of commercial grade Ti-6Al-4V with lamellar starting structure[J]. Materials Science and Engineering A, 2002, 325(1/2): 112-125.

[14] 赵为纲, 李 鑫, 鲁世强, 刘志和, 王克鲁, 李臻熙, 曹春晓. TC11钛合金高温变形本构关系研究[J]. 塑性工程学报, 2008, 15(3): 123-127.

ZHAO Wei-gang, LI Xin, LU Shi-qiang, LIU Zhi-he, WANG Ke-lu, LI Zhen-xi, CAO Chun-xiao. Study on constitutive relationship of TC11 titanium alloy during high temperature deformation[J]. Journal of Plasticity Engineering, 2008, 15(3): 123-127.

[15] IMBERT C, RYAN N D, MCQEEN H J. Hot workability of three grade of tool steel[J]. Metall Trans A, 1984, 15(10): 1855-1864.

(编辑 袁赛前)

基金项目:国家自然科学基金资助项目(50735005)

通信作者:张慧芳;电话:13513648327;E-mail:zhf990715@163.com