文章编号:1004-0609(2016)-07-1383-08

7075-T6铝合金温成形损伤演化实验与仿真

盈 亮1,刘文权2,王丹彤1,胡 平1,王 琪3

(1. 大连理工大学 汽车工程学院,大连 116024;

2. 大连理工大学 工程力学系,大连 116024;

3. 吉林大学 材料科学与工程学院,长春 130022)

摘 要:基于GTN损伤模型,采用实验与有限元仿真相结合的方式对高强度7075-T6铝合金在温成形HFQ工艺过程中的损伤演化进行研究。通过扫描电镜观测得铝合金板材在变形中的损伤演化符合孔洞长大、形核、聚合和最终断裂的规律;采用中心复合试验设计法构造拉伸曲线关键变量关于GTN损伤参数的响应曲面模型,进而结合遗传算法确定铝合金板材的损伤参数;通过有限元软件ABAQUS仿真预测不同温度下铝合金方盒拉深过程中的损伤分布情况。结果表明:提高成形温度可使得铝合金板材的成形性得到有效改善,实验观测的板材开裂行为和开裂位置与损伤预测结果相一致,证明了GTN损伤模型在铝合金温冲压成形性仿真分析中的适用性。

关键词:7075-T6铝合金;温成形;GTN损伤模型;损伤识别;数值模拟

中图分类号:TG146.2 文献标志码:A

近年来,汽车轻量化的应用趋势使得铝合金冲压结构件在汽车车身中的应用与日俱增[1]。7075铝合金由于其质量轻、比强度高、无磁性、耐腐性好等特点被大量应用在航空航天及汽车等领域[2]。然而高强度7075-T6铝合金在常温下成形性较差,难以使用冷冲压工艺成形结构复杂的车身结构件[3]。针对上述问题,结合近年来业界兴起的一种新型铝合金板材温热成形工艺,即固溶处理-热成形-淬火一体化HFQ工艺[4],可先将7075-T6铝合金板料加热至其固溶处理温度区间,保温一段时间使其充分固溶,随后在冷模具中进行冲压成形并完成快速冷却淬火,使得7075-T6铝合金可在较高温度和应变率下获得成形性能优良的复杂结构件。

7075-T6铝合金板材的成形性能受温度影响非常明显,其成形过程中损伤开裂行为是不可回避的问题,对这一问题进行合理的仿真预测是指导工艺优化的重要手段。而运用传统的弹塑性理论并不能准确描述这一过程。许多学者尝试采用损伤力学的方法来分析金属板材成形过程的失效行为。LIN等[5]基于连续介质损伤力学方法分析了AA5754铝合金温成形过程的损伤行为,提出了一种新的平面应力弹塑性损伤本构模型用于不同形状的铝合金温冲压成形极限预测;庄蔚敏等[6]基于试验并结合单轴连续介质损伤本构方程预测了7075-T6铝合金板材在不同温度和应变率下的成形极限曲线;苌群峰等[7]针对AZ31镁合金板材温热成形过程中的损伤破裂问题,建立考虑温度效应的板材温热成形韧性破坏准则;马闻宇等[8]对AA6082铝合金在不同温度、应变率下的热变形行为进行了实验研究,并建立了AA6082铝合金热变形统一粘塑性损伤本构模型。上述研究工作均基于连续介质损伤方法且很少涉及金属板材在成形过程中的损伤分布预测。另一方面,细观损伤力学在金属板材成形性分析中得到了广泛的应用[9-10],而细观损伤参数的准确确定是合理描述材料损伤行为的关键[11]。王瑞泽等[12]采用有限元仿真与拉伸实验相结合的方式确定AZ31镁合金的Gurson模型损伤参数并对镁合金板材温热冲压成形过程中的材料损伤演化行为进行了预测,但上述研究忽视不同温度对损伤参数的影响。因此,针对7075铝合金在不同温度成形过程中的损伤演化行为进行研究并实现仿真预测,将能实现对其成形性能更加准确的评价。

本文作者以7075-T6铝合金板材为研究对象,分析了其在不同温度下变形过程中的损伤演化规律,开展了铝合金板材在不同温度下的方盒拉深成形实验,结合响应曲面法和遗传优化算法确定了7075-T6铝合金GTN细观损伤特征参数,并进一步基于GTN损伤模型对7075-T6铝合金板材成形性能进行仿真研究,进一步结合实验对比损伤预测的准确性。

1 GTN损伤模型

GURSON[13]提出了有限大基体中含微孔洞的体胞模型并推导出多孔延性损伤模型,之后由TVERGARRD等[14]和NEEDLEMAN等[15]对其进行修正,得到了能更加准确描述材料在塑性变形过程中损伤劣化行为的Gurson-Tvergarrd-Needleman(GTN)损伤模型。该模型考虑了孔洞间的相互作用以及孔洞聚合的加速演化过程,被广泛用于预测延性金属的韧性损伤破坏。对于含球形孔洞的基体材料,GTN模型( )具有如下具体形式:

)具有如下具体形式:

(1)

(1)

式中: 为宏观Von Mises等效应力;

为宏观Von Mises等效应力; 为宏观静水应力;

为宏观静水应力; 为基体材料的屈服应力;q1、q2、q3为TVERGARRD等[14]提出的修正参数;f *为等效孔洞体积分数,用以解释孔洞聚合而导致材料承载能力迅速下降的现象。当f *=0时,GTN模型退化为经典的von Mises屈服准则。定义f *为

为基体材料的屈服应力;q1、q2、q3为TVERGARRD等[14]提出的修正参数;f *为等效孔洞体积分数,用以解释孔洞聚合而导致材料承载能力迅速下降的现象。当f *=0时,GTN模型退化为经典的von Mises屈服准则。定义f *为

(2)

(2)

式中:f为孔洞体积分数;k为孔洞长大加速因子, ;fC为材料的临界孔洞体积分数;fF是材料发生破裂时的孔洞体积分数;fu表示应力承载能力为零时的极限孔洞体积分数,

;fC为材料的临界孔洞体积分数;fF是材料发生破裂时的孔洞体积分数;fu表示应力承载能力为零时的极限孔洞体积分数, 。

。

对于基体材料的塑性行为,可通过宏观塑性功率与细观塑性功率相等进行确定,即

(3)

(3)

式中: 为基体材料的等效塑性应变增量;

为基体材料的等效塑性应变增量; 为宏观塑性应变增量;

为宏观塑性应变增量; 和

和 分别为宏观应力张量和塑性应变张量,且基体遵循硬化法则:

分别为宏观应力张量和塑性应变张量,且基体遵循硬化法则:

(4)

(4)

式中:H为基体材料当前应变硬化系数。

金属材料在变形过程中的损伤演化可定义为两部分:一为原有孔洞的长大,二为新孔洞形核,即

(5)

(5)

式中: 是由孔洞长大引起的孔洞体积分数变化,假设基体材料不可压缩,根据质量守恒定律,可得

是由孔洞长大引起的孔洞体积分数变化,假设基体材料不可压缩,根据质量守恒定律,可得

(6)

(6)

式中:I为二阶单位张量。

采用应变控制的形核方式,新孔洞的形核引起的洞体积分数变化 可表示为[16]

可表示为[16]

(7)

(7)

(8)

(8)

式中:A为孔洞形核形数;fN为可形核粒子的体积分数;εN为孔洞成核时的平均应变;sN为形核应变的标准差。

2 7075-T6铝合金温成形实验分析

2.1 实验材料

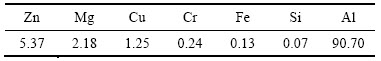

本文作者采用厚度为2mm的美国Kaiser铝业7075-T6板材进行相关实验,材料化学成分如表1所列。

表1 7075-T6铝合金的化学成分

Table 1 Chemical composition of 7075-T6 alloy (mass fraction, %)

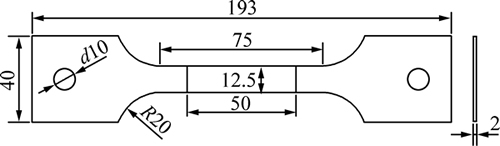

2.2 高温拉伸实验

拉伸样件制备参考国家标准GB/T 4338—2006《金属材料高温拉伸试验方法》相关规定,标距取为50mm,其具体尺寸如图1所示。实验在WDW-100多功能热力模拟实验机上开展,实验过程采用引伸计对试件轴向变形进行记录,同时采用K型热电偶对试件温度进行实时监控。实验应变率为0.1s-1,温度分别为200、300和400℃。

图1 拉伸试件几何尺寸

Fig. 1 Dimension of thermal tensile test specimen (Unit: mm)

2.3 方盒温成形实验

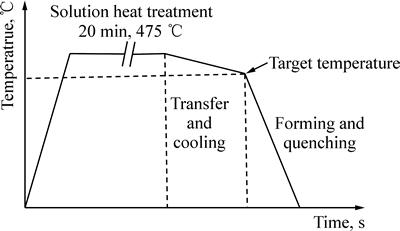

7075-T6铝合金板材在常温下的延展性较差且不能保证成形件的尺寸精度要求,而提升变形温度可使铝合金的韧性得到有效提高,同时改善成形性。为研究高强度7075-T6铝合金在温热成形中的成形性能,开展以典型方盒拉深为实验对象的7075-T6铝合金温成形冲压实验研究。

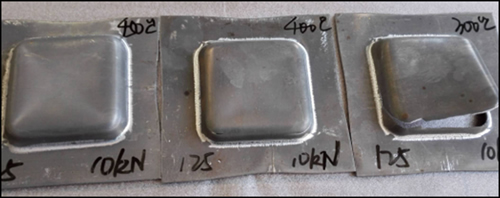

参考HFQ淬火一体化工艺,设计了如图2所示的实验工艺流程。首先将板料在加热炉中加热至7075-T6铝合金的多相共晶温度475℃,并保温30min,使其充分固溶。随后迅速将板料转移到方盒模具中,冷却至不同初始温度下(300、400、450℃)进行冲压成形并保压淬火。实验提供压边力为10kN,拉深行程统一控制为23mm。

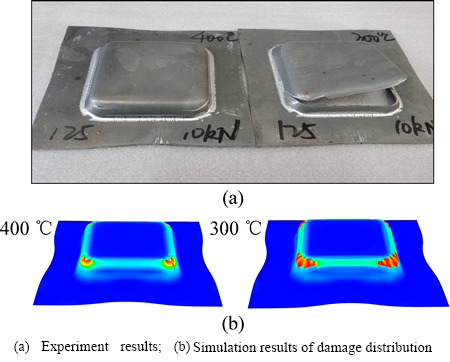

7075-T6铝合金板材成形后结果如图3所示。由图3可以看出:在300℃温度下成形,试件发生了大面积开裂;在400℃温度下成形,试件仅在圆角处出现了轻微开裂现象;当成形温度提升到450℃时,试件成形良好并达到最大成形深度。上述结果表明:在一定温度范围内(300~450℃时),随着温度的升高,7075-T6铝合金板材温冲压成形性可得到有效改善。

图2 铝合金温成形HFQ工艺流程图

Fig. 2 Schematic diagram for warm forming HFQ process of aluminum alloy

图3 不同成形温度下7075-T6铝合金方盒实验结果

Fig. 3 Square box experimental results of 7075-T6 alloy at different forming temperatures

2.4 断裂机理分析

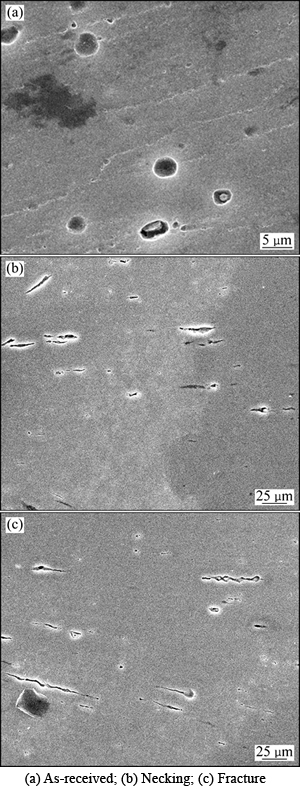

为了更加深入研究7075-T6铝合金在变形过程中的损伤演化直至断裂的微观机理,对2.2节200℃拉伸试件在不同变形阶段的微观形貌进行了扫描电镜观测。实验分别获取了拉伸试件在变形前、颈缩发生时和断裂后的SEM扫描电镜图片,如图4所示。从图4中可以看出,铝合金板材在变形前(见图4(a))存在少量的微小孔洞缺陷,这是由轧制工艺等原因造成的;随着变形的发生,试件在发生颈缩时,原有孔洞发生了明显的长大,同时在二相粒子周围出现了新孔洞的形核,部分孔洞间发生了聚合现象(见图4(b));而当试件断裂后,孔洞已发生大范围的聚合并最终贯穿整个材料区域(见图4(c))。由此可见,铝合金板材的断裂过程可解释为原有孔洞的长大、新孔洞的形核、孔洞间的聚合导致板材最终断裂过程的发生。

图4 7075-T6铝合金板材不同变形阶段孔洞损伤形貌

Fig. 4 Damage morphologies of 7075-T6 alloy at different deformation phases:

3 GTN特征损伤参数识别

GTN 细观损伤模型考虑实际材料内部的损伤行为,使得模型中的损伤参数具有明确的物理意义。损伤参数的准确确定是正确描述温成形过程损伤演化行为的必要条件。损伤参数的识别通常包括两种方法:1) 金相学观测法;2) 有限元反向标定法。前者需耗费大量的人力、物力,同时对样件的制备和测量精度都有很高的要求,一般可用于定性的研究板材在变形过程中的损伤演化机理。因此,本文作者采用有限元反向标定法对损伤参数进行确定。

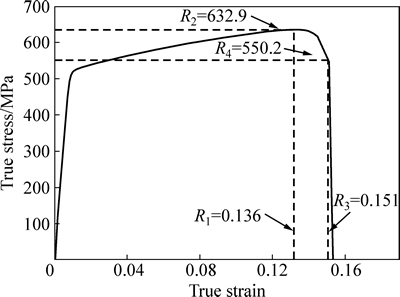

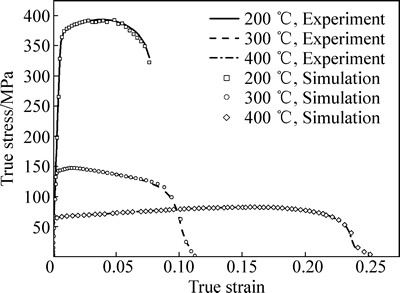

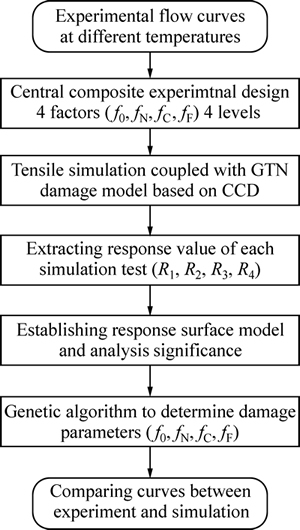

GTN 损伤模型中有9个待定的特征参数,对于大部分金属材料q1=1.5,q2=1和q3=q12都是适用的[11];其中εN和sN被假定为常数εN=0.1,sN=0.1[17]。f0、fN、fC、fN则需通过有限元反向方法进行求解确定,以拉伸真应力-真应变曲线的两个关键点(峰值点、断裂点),4个关键量(拉伸曲线峰值处的应变值R1、应力值R2、拉伸曲线断裂处的应变值R3以及应力值R4)作为标定指标,如图5所示。即仿真曲线关键点与实验曲线关键点相重合时,仿真所采用的损伤参数即为材料的真实损伤参数值。以7075-T6铝合金板材400℃损伤参数识别为例,具体实现步骤如下。

图5 基于真应力-应变曲线测定损伤特征参数的关键点

Fig. 5 Key points to determine feature damage parameters from true stress-strain curve of test alloy

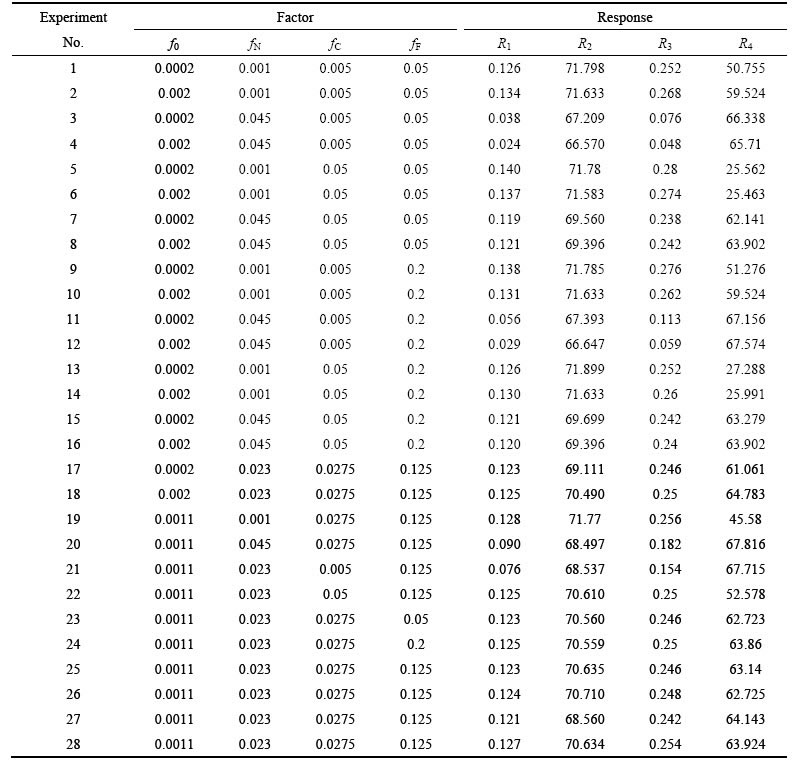

1) 采用中心复合试验设计法(CCD)设计4因素3水平的28组仿真实验,以4个关键量为响应值分别建立响应曲面模型。CCD实验设计如表3所列,依次进行28组拉伸仿真实验,获取对应的4个响应值(见表2)。

响应值与损伤参数间的关系采用二次多项式模型进行回归分析,其一般形式可表示为

(9)

(9)

式中:Y为响应变量,分别为R1、R2、R3、R4;b0、bi、bii、bij分别为回归方程的相关系数;Xi、Xj分别代表4个独立的求解变量f0、fN、fC、fF。

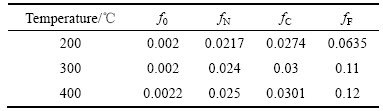

2) 采用遗传算法,以真实拉伸实验获取的应力-应变曲线的4个关键量R1、R2、R3、R4为目标值,调用遗传算法程序对上述获取的响应模型进行求解以获取材料的损伤参数f0、fN、fC、fF。通过表3可以获取铝合金板材在不同变形温度下的损伤参数值。

3) 将获取的损伤参数赋予有限元仿真模型,再次对单向拉伸过程进行数值模拟,进一步验证损伤参数的准确性。

上述拉伸实验仿真均采用与2.2节所述尺寸相同的有限元模型,并设置与实验工况相同的边界条件。实验与仿真获取的单向拉伸真应力-应变曲线对比结果如图6所示。从图6中可以看出,实验曲线与仿真曲线具有较高的匹配度,验证本研究所用损伤参数确定方法以及损伤模型的合理性。图7对上述损伤参数识别流程进行了总结。

4 方盒温成形数值仿真及讨论

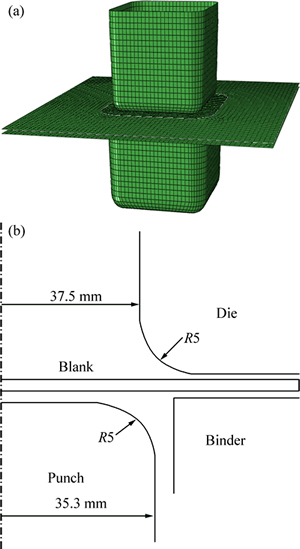

为深入研究7075-T6铝合金板材在复杂温成形过程中的损伤开裂行为,本节对2.3节所述的铝合金方盒拉深成形过程进行了数值仿真研究。板料为厚度2mm,边长125mm的铝合金方板。为节省计算时间,模具和板料均采用壳体建模,考虑成形过程的瞬时性,同时,为了研究以温度为单一变量对板材成形性能的影响,仿真过程中板料温度保持恒定并采用4边形壳单元进行网格划分;模具同样采用壳单元划分并定义为耦合刚体。采用ABAQUS动力显式求解器进行仿真分析,其中损伤参数和材料属性分别来自上文的识别方法和拉伸实验,有限元模型及尺寸如图8所示。

表2 中心复合实验设计(CCD)方案及响应值

Table 2 Central composite experimental design (CCD) arrangement and responses

表3 7075-T6铝合金高温损伤特征参数

Table 3 Thermal damage feature parameters of 7075-T6 alloy

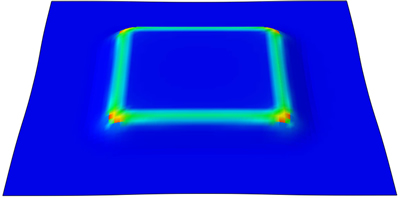

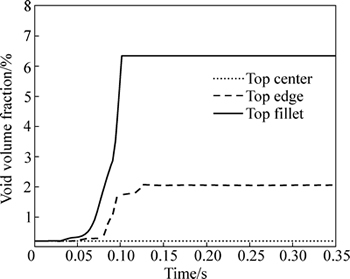

成形温度200℃,板料在0.098s时的孔洞分布情况如图9所示。由图9可以看出,在方盒拉深成形过程中,试件的损伤分布是不均匀的,孔洞主要集中在试件减薄最严重的圆角处,与方盒实验的开裂部位相一致。因此,在有限元仿真预测中,可将孔洞的分布情况作为评价板材是否开裂的标准。同时,为进一步研究板材不同位置的损伤演化情况,分别提取成形件圆角处,顶部中心和顶部边缘处附近3个单元表面积分点的孔洞体积分数随成形时间的变化规律并绘于图10。由图10可以看出,在成形初期,由于板料整体塑性变形较小,各单元的孔洞体积分数基本保持在初始值f0;随后,3条曲线开始分离(0.05s),而圆角处单元的孔洞演化速度明显快于其它两个单元,这是由变形主要集中在圆角处而造成的;当板料临近断裂时(0.1s),孔洞间的聚合长大导致圆角处单元的孔洞体积分数发生突变;板料发生断裂后,各单元孔洞体积分数基本保持不变。

图6 实验与GTN损伤模型仿真预测应力-应变曲线对比

Fig. 6 Comparison between experimental true stress-strain curves and predicted curves obtained by GTN model

图7 GTN损伤参数识别流程

Fig. 7 Identification schedule of GTN damage parameters

图8 方盒冲压模具有限元模型及几何尺寸

Fig. 8 FEM model and geometric size of square box stamping tool

图11对比300~400℃成形时实验板材产生裂纹位置与ABAQUS有限元预测的孔洞损伤分布结果。通过观察可以发现,当成形相同深度时, 300℃板材开裂严重,相应位置的损伤聚集尤为明显,而400℃板材圆角处只出现轻微破损,实验结果与有限元预测结果相互吻合。

图9 200℃时方盒温成形0.098s时孔洞分布

Fig. 9 Void distribution of square box under warm forming process at 0.098s and 200℃

图10 200℃时板料不同位置单元的孔洞演化情况

Fig. 10 Void evolution condition of different positions of blank at 200℃

图11 300和400℃时成形实验与有限元损伤预测比较

Fig. 11 Comparison between experiment and simulation results at 300 and 400℃:

5 结论

1) 通过观察7075-T6铝合金试件在不同变形阶段的微观组织形貌,发现其断裂机理可以归结为初始孔洞缺陷的长大,新孔洞的形核和孔洞间的聚合造成损伤的加速演化,最终造成板材发生开裂破坏,这一过程与GTN损伤模型描述的孔洞损伤演化相一致。

2) GTN损伤模型在铝合金温成形仿真预测中的应用难点在于损伤特征参数的确定。采用中心复合实验设计构建二阶响应曲面模型,基于有限元反向标定法并结合遗传算法对7075-T6铝合金板材成形过程的损伤特征参数进行了准确识别和确定,单向拉伸仿真与实验对比结果的一致性验证了该方法的正确性。

3) 开展7075-T6铝合金方盒拉深温成形实验,用以研究温度对铝合金成形性能的影响,结果表明:在实验温度范围内,铝合金的成形性能随着温度的升高而改善。采用GTN损伤模型对7075-T6铝合金方盒温成形过程进行了仿真分析,结果表明:方盒圆角处是最容易出现缺陷或断裂的区域,与实验结果相一致,证明了GTN损伤模型在描述板材成形过程中损伤演化的合理性。

REFERENCES

[1] 盈 亮, 戴明华, 胡 平, 闫巧云. 6061-T6 铝合金高温本构模型及温成形数值模拟[J]. 中国有色金属学报, 2015, 25(7): 1815-1821.

YING Liang, DAI Ming-hua, HU Ping, YAN Qiao-yun. Thermal constitutive model and numerical simulation of hot forming for 6061-T6 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(7): 1815-1821.

[2] WANG H, LUO Y, FRIEDMAN P, CHEN M, GAO L. Warm forming behavior of high strength aluminum alloy AA7075[J].Transactions of Nonferrous Metals Society of China, 2012, 22(1): 1-7.

[3] ZHOU J, WANG B, LIN J, FU L, MA W. Forming defects in aluminum alloy hot stamping of side-door impact beam[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(11): 3611-3620.

[4] FAKIR O E, WANG L, BALINT D, DEAR J P, LIN J G, DEAN T A. Numerical study of the solution heat treatment, forming, and in-die quenching (HFQ) process on AA5754[J]. International Journal of Machine Tools and Manufacture, 2014, 87(2014): 39-48.

[5] LIN J, MOHAMED M, BALINT D, DEAN T. The development of continuum damage mechanics-based theories for predicting forming limit diagrams for hot stamping applications[J]. International Journal of Damage Mechanics, 2014, 23(5): 684-701.

[6] 庄蔚敏, 曹德闯, 叶 辉. 基于连续介质损伤力学预测7075铝合金热冲压成形极限图[J]. 吉林大学学报(工学版), 2014, 44(2): 409-414.

ZHUANG Wei-min, CAO De-chuang, YE Hui. Prediction of FLD for AA7075 under hot stamping based on continuum damage mechanics[J]. Journal of Jilin University (Engineering and Technology Edition), 2014, 44(2): 409-414.

[7] 苌群峰, 彭颖红, 杜朝辉. 镁合金板材温热成形韧性破裂准则[J]. 机械工程学报, 2009, 45(10): 294-299.

CHANG Qun-feng, PENG Ying-hong, DU Zhao-hui. Ductile fracture criterion for warm deep drawing of magnesium alloy sheet[J]. Journal of Mechanical Engineering, 2009, 45(10): 294-299.

[8] 马闻宇, 王宝雨, 周 靖, 唐学峰. AA6082 铝合金热变形损伤本构模型[J]. 中国有色金属学报, 2015, 25(3): 591-601.

MA Wen-yu, WANG Bao-yu, ZHOU Jing, TANG Xue-feng. Damage constitutive model for thermal deformation of AA6082 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(3): 591-601.

[9] 陈志英, 董湘怀. 基于 GTN 细观损伤模型的板料成形过程损伤分析[J]. 工程力学, 2009, 26(7): 238-244.

CHEN Zhi-ying, DONG Xiang-huai. Ductile damage analysis for fracture in sheet metal forming based on GTN mesoscopic damage model[J]. Engineering Mechanics, 2009, 26(7): 238-244.

[10] TENG Bu-gang, YUAN Shi-jian, CHEN Zeng-tao, JIN Xue-run. Plastic damage of T-shape hydroforming[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(S2): s294-s301.

[11] BENSEDDIQ N, IMAD A. A ductile fracture analysis using a local damage model[J]. International Journal of Pressure Vessels and Piping, 2008, 85(4): 219-227.

[12] 王瑞泽, 陈章华, 臧 勇. 基于Gurson模型的镁合金板材温热冲压成形研究[J]. 北京科技大学学报, 2014, 36(4): 459-466.

WANG Rui-ze, CHEN Zhang-hua, ZHANG Yong. Thermal stamping formability of magnesium alloy sheet based on the Gurson model[J]. Journal of University of Science and Technology Beijing, 2014, 36(4): 459-466.

[13] GURSON A L. Continuum theory of ductile rupture by void nucleation and growth: Part I—Yield criteria and flow rules for porous ductile media[J]. Journal of Engineering Materials and Technology, 1977, 99(1): 2-15.

[14] NEEDLEMAN A, TVERGAARD V. An analysis of ductile rupture in notched bars[J]. Journal of the Mechanics and Physics of Solids, 1984, 32(6): 461-490.

[15] TVERGAARD V, NEEDLEMAN A. Analysis of the cup-cone fracture in a round tensile bar[J]. Acta Metallurgica, 1984, 32(1): 157-169.

[16] CHU C C, NEEDLEMAN A. Void nucleation effects in biaxially stretched sheets[J]. Transactions of the ASME. Journal of Engineering Materials and Technology, 1980, 102(3): 249-256.

[17] HE M, LI F, WANG Z. Forming limit stress diagram prediction of aluminum alloy 5052 based on GTN model parameters determined by in situ tensile test[J]. Chinese Journal of Aeronautics, 2011, 24(3): 378-386.

Experimental and simulation of damage evolution behavior for 7075-T6 aluminum alloy in warm forming

YING Liang1, LIU Wen-quan2, WANG Dan-tong1, HU Ping1, WANG Qi3

(1. School of Automotive Engineering, Dalian University of Technology, Dalian 116024, China;

2. Department of Engineering Mechanics, Dalian University of Technology, Dalian 116024, China;

3. College of Materials Science and Engineering, Jilin University, Changchun 130022, China)

Abstract: Based on GTN damage model, both experimental and FEM method were used to research the damage evolution of high strength 7075-T6 aluminum alloy during warm forming HFQ process. Through the microstructure observation, the damage evolution within tested material corresponds to the process of void growth, nucleation, coalescence and subsequent fracture. The response surface model between GTN parameters and critical points of tensile curve was built based on central composite design. Then, the genetic algorithm was adopted to determine damage parameters of this aluminum alloy. After that, damage distribution during square cup deep-drawing process was predicted by finite element software ABAQUS. The results show that the formability of aluminum alloy can be improved significantly with the temperature increasing. The fracture behavior and location obtained by experiment consist with those by prediction. So, it demonstrates the applicability of GTN damage model in analyzing formability of aluminum alloy during warm forming.

Key words: 7075-T6 aluminum alloy; warm forming; GTN damage model; damage identification; numerical simulation

Foundation item: Project(11272075) supported by the Key Project of the National Natural Science Foundation of China; Project(2014M561223) supported by China Postdoctoral Science Foundation; Project (DUT16RC(4)28) supported by the Fundamental Research Funds for the Central Universities, China

Received date: 2015-10-12; Accepted date: 2016-01-20

Corresponding author: HU Ping; Tel: +86-411-84702775; E-mail: pinghu@dlut.edu.cn

(编辑 李艳红)

基金项目:国家自然科学基金重点资助项目(11272075);中国博士后科学基金资助项目(2014M561223);中央高校基本科研业务费专项资金项目联合资助(DUT16RC(4)28)

收稿日期:2015-10-12;修订日期:2016-01-20

通信作者:胡 平,教授,博士;电话:0411-84702775;E-mail:pinghu@dlut.edu.cn