DOI:10.19476/j.ysxb.1004.0609.2019.11.09

感应熔覆原位合成TiC/Ti复合涂层的显微组织演变规律

于鹤龙1,魏 敏2, 3,张梦清1,李恩重1,张 伟2, 3,徐滨士1

(1. 陆军装甲兵学院装备再制造技术国防科技重点实验室,北京 100072;

2. 河北京津冀再制造产业技术研究有限公司,河间 062450;

3. 北京睿曼科技有限公司,北京100043)

摘 要:以石墨和Ti粉为原料,在Ti6Al4V基体表面感应熔覆原位合成了TiC增强Ti基复合涂层,研究了预置反应物粉末中C含量和熔覆工艺参数对复合涂层微观组织演变、物相组成、增强体形态与分布、界面结合行为以及显微硬度的影响规律。结果表明,复合涂层内部原位自生TiC增强体分布均匀,与Ti基质相结合紧密、界面洁净,TiC增强体的最终形态与分布主要受涂层成分、凝固过程和自身晶体结构的影响。随着石墨含量升高,TiC增强体形态逐渐由短纤维状演变为等轴晶状,尺寸和体积分数以及涂层显微硬度逐渐增大。随着热输入量增加,TiC尺寸逐渐增大,界面过渡区宽度及基体热影响也随之增加。

关键词:原位合成;碳化钛;感应熔覆;显微组织;钛基复合材料

文章编号:1004-0609(2019)-11-2524-09 中图分类号:TG174,TB33 文献标志码:A

非连续增强钛基复合材料兼具高比强度和良好的承载能力,特别是原位合成钛基复合涂层可显著改善钛合金的性能[1-2]。不同于外加颗粒法直接将硬质相分散在涂层内部,原位合成技术在涂层制备过程中通过原料中不同成分间的化学反应原位生成强化相,克服了传统复合涂层制备工艺中存在的增强体尺寸不可控、分布不均、界面不纯净等问题,在钛合金表面防护技术领域引起了较大关注[3-4]。在众多的增强体材料中,TiC具有高硬度和高弹性模量,其泊松比与钛接近,二者在热力学上具有良好的相容性,是当前钛合金增强体材料研究的热点[5-6]。

目前钛基复合涂层原位合成方法主要包括激光熔覆[7]、钨极惰性气体保护焊[8]、烧结[9]、等离子熔覆[10]等,其中激光熔覆技术由于具备稀释率低、冷却速率高、变形量小等优点,广泛应用于原位自生钛基复合材料的制备。HAMEDI等[7]以石墨和Ti粉为原料,采用激光熔覆方法在纯Ti基体表面原位合成了硬度达到1700HV的TiC枝晶增强钛基复合涂层。LANGELIER等[11]以石墨、Ti、Co粉末为原料,激光熔覆原位合成了硬度为1125HV的TiC枝晶增强钛钴基复合涂层。ZHANG等[12]以Cr2C3和Ti粉为原料,在Ti6Al4V表面激光原位制备了等轴晶TiC增强钛基复合涂层。

感应加热技术具有高效节能、易于实现自动化等优点,近年来逐渐应用于金属基复合涂层的原位合成。WANG等[13]采用感应熔覆技术制备了原位TiC增强Ni基复合涂层,涂层硬度高达1200HV0.2,约为基体16Mn钢的5倍。但目前关于感应熔覆原位合成钛基复合涂层的相关报道较少,特别是未见关于C含量和熔覆工艺对涂层结构和性能影响的研究。基于此,本文采用预置Ti/石墨粉末结合高频感应加热熔化的方法,在Ti6Al4V表面制备了TiC/Ti复合涂层,研究了预置反应物粉末中石墨含量和熔覆工艺参数对涂层微观组织、物相组成、增强体形貌与分布、界面结合行为以及显微硬度的影响规律。

1 实验

实验用海绵钛粒度25 μm,纯度99.7%。实验用石墨为光谱纯,呈片层状,片层直径2~3 μm,厚度200~500 nm。利用三维混合机对钛粉和石墨进行混合处理,时间24 h,转速90 r/min。混合粉末中石墨质量分数分别为2.7%、5.9%、9.7%和14.3%,对应的C原子摩尔分数分别为10%、20%、30%和40%。以TC4(Ti6Al4V)热轧钛合金厚板为基体材料,试样尺寸为50 mm×30 mm×10 mm,采用喷砂方法去除表面氧化层和油污,用石油醚溶液清洗处理后基体表面。将混合后的Ti和石墨粉末与粘结剂(松香:松节油为1:3,质量比)混合制成膏状物,均匀涂于TC4基体表面,并在真空干燥箱中进行烘干处理,温度150 ℃,时间2 h,获得表面预置厚度1.6~1.7 mm反应物粉末的待熔覆样品。

图1所示为感应熔覆原位合成钛基复合涂层过程的示意图[14]。熔覆过程中试样放置在充满氩气的石英玻璃罩内。采用平面感应线圈进行熔覆,线圈外形尺寸为30 mm×50 mm×8 mm、方形铜管尺寸8.0 mm×8.0 mm、壁厚0.5 mm。采用表1所列优化后的工艺参数进行熔覆实验。其中,P为功率,v为线圈扫描速度,Q为热输入量,a为线圈与预置粉末表面的距离。

图1 感应熔覆原位合成钛基复合涂层工艺过程示意图

Fig. 1 Schematic diagram showing set-up of induction cladding of in-situ Ti matrix composite coating

表1 涂层感应熔覆工艺参数

Table 1 Processing parameter of coating induction cladding

采用Bruker D8 Advance型X射线衍射仪分析涂层物相组成,用FEI Nova NanoSEM 450型场发射扫描电镜分析腐蚀后涂层截面金相组织,用JEM-2100型透射电镜分析复合涂层微观结构,用Buehler micromet 6030型显微硬度计测量涂层显微硬度。

2 结果与讨论

2.1 涂层物相组成

图2所示为预置粉末和复合涂层的XRD谱。从图2可以看出,不同成分的感应熔覆涂层XRD谱中均可识别明显的TiC特征峰,同时未见明显的石墨和氧化物特征峰,表明熔覆过程中石墨与Ti完全反应生成TiC。通过对比可知,不同石墨含量下制备得到的复合涂层物相组成相同,不同之处在于TiC衍射峰的强度随石墨含量的增加而增强,表明复合涂层中TiC增强相的体积分数逐渐增多。此外,涂层基质相由大量α-Ti和少量β-Ti构成。

图2 感应熔覆前预置粉末和熔覆后复合涂层的XRD谱

Fig. 2 XRD patterns of preplaced powders before cladding and composite coating after cladding

2.2 涂层显微组织

图3所示为感应熔覆TiC/Ti复合涂层截面的SEM 像(预置粉末中C含量为30%)。从图3可以看出,涂层表面平整,组织致密、厚度均匀,内部和界面无孔隙和裂纹,与钛合金基体形成了良好的冶金结合。涂层内部析出相以等轴晶为主,其中一部分沿晶界析出,一部分弥散分布在晶粒内部,尺寸约为1~2 μm。由图3(d)可见,涂层与基体界面处形成了一定宽度的过渡区,该区域内析出相呈短纤维状,直径和长度分别约为1 μm和3 μm。在实际观察中发现,当预置粉末中C含量超过10%(摩尔分数)后,涂层内部增强相形貌与分布特征较为相似,TiC均为等轴晶。而C含量在10%或以下时,涂层内TiC以短纤维状为主。

图3 感应熔覆钛基复合涂层典型形貌的SEM像

Fig. 3 Cross-sectional SEM images of in-situ TiC/Ti composite coating

为进一步确定涂层内析出相的构成,采用TEM结合选区电子衍射分析了等轴晶和纤维状增强体的微观结构,结果如图4所示。由图4可见,增强体与基质相界面洁净,结合紧密,未发现孔隙、裂纹等缺陷及明显的界面反应产物。SAD分析结果表明,等轴晶增强体与条形增强体均为TiC颗粒。原位自生TiC颗粒与基质相的良好结合为其作为增强相改善涂层的力学性能提供了良好的基础。

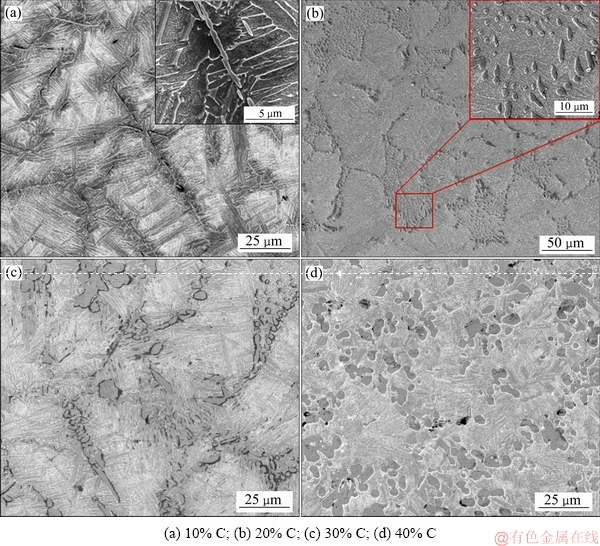

图5所示为不同石墨含量预置粉末在工艺1条件下获得的涂层截面SEM像。由图5可以看出,C含量为10%条件下,TiC增强体呈短纤维状,平均直径约为500 nm,长度约为2~4 μm,短纤维状TiC沿直线排列构成长约20~30 μm的条状增强相,均匀分布在涂层内部。当C含量增至20%时,TiC由短纤维演变为等轴状和近似等轴状颗粒,粒径约为0.5~2.0 μm。等轴状TiC颗粒一部分沿晶界析出,一部分弥散分布在晶粒内。当C含量为30%时,增强体形态和分布与20%石墨条件下获得的涂层情况相似,但TiC尺寸和含量进一步增大。当C含量达到40%时,TiC以等轴晶为主,均匀分布在整个涂层内部,尺寸为2~8 μm。

图6所示为不同石墨含量预置粉末在工艺2条件下获得的涂层截面SEM像。由图6可见,当C含量为10%时,涂层内TiC同样呈短纤维状,但其尺寸同工艺1条件下获得的涂层内增强体相比略有增大;当C含量为20%时,TiC形状和分布与相同成分下由工艺1制备的涂层相似,短纤维状TiC逐渐向等轴状转变,增强体尺寸略有增大,约为0.8~4.0 μm;当C含量增至30%时,等轴状增强体尺寸明显增大,且仍一部分沿晶界析出,一部分弥散分布在晶粒内,尺寸为2~10 μm;当C含量增至40%后,短纤维状增强体完全消失,TiC以等轴状和近似等轴状均匀分布。

图4 复合涂层内部增强体与基质相的TEM形貌及选区电子衍射花样

Fig. 4 TEM images and SAD patterns of reinforcement and matrix of composite coating

图5 工艺1条件下不同成分预置粉末经熔覆后获得的复合涂层截面形貌的SEM像

Fig. 5 SEM images of cross-sectional morphologies of composite coatings with different chemical compositions in raw powders, and synthesized under conditions of P=16.5 kW and v=2.7 mm/s

图6 工艺2条件下不同成分预置粉末经熔覆后获得的复合涂层截面形貌的SEM像

Fig. 6 SEM images of cross-sectional morphologies of composite coatings with different chemical compositions in raw powders, and synthesized under conditions of P=13 kW and v=1.9 mm/s

图7所示为不同石墨含量预置粉末在工艺3条件下获得的涂层截面SEM像。由图7可见,在对应的C含量下,复合涂层内部TiC增强体的形态与分布同工艺1和工艺2条件下获得的涂层相似,但其尺寸进一步增大,特别是当C含量为40%时,部分TiC颗粒尺寸甚至超过20 μm。

综合图5~7所示结果可以得出,相同工艺条件下,随着预置粉末中石墨含量的增加,TiC/Ti复合涂层内TiC增强体的含量增多,尺寸增大,形状由短纤维状向等轴状转变,分布由沿晶界析出和在晶粒内部弥散分布向整个涂层内均匀分布转变。在预置粉末成分相同的条件下,随着感应熔覆功率和相应感应线圈扫描速度的增加,即随着热输入量的降低,TiC增强体尺寸逐渐减小。此外,根据图像灰度处理方法计算得到的涂层内部TiC体积分数结果显示,不同工艺条件下相同成分的复合涂层内部TiC增强相含量接近,预置粉末中C含量分别为10%、20%、30%和40%条件下获得的复合涂层,其内部TiC的体积分数分别近似为3.8%、13.6%、16.9%和26.7%。

2.3 界面结合行为

图8所示为C含量为20%的预置粉末在不同熔覆工艺下获得的复合涂层界面区域的OM照片。由图8可以看出,感应熔覆钛基复合涂层界面区域沿涂层至基体方向存在明显的过渡区和热影响区,其宽度随工艺条件变化,过渡区与涂层内部的增强体形状不同。如前所述,C含量为20%的预置粉末经熔覆后获得的涂层,其内部TiC以等轴晶为主,沿晶界析出同时弥散分布在部分晶粒内部。而过渡区内TiC呈短纤维状,分布均匀。总体上,随着热输入量的增加,涂层界面处的过渡区逐渐变宽,临近基体一侧形成了明显的组织粗化,晶粒逐渐增大,表明涂层热影响区不断增大。

图7 工艺3条件下不同成分预置粉末经熔覆后获得的复合涂层截面形貌的SEM像

Fig. 7 SEM images of cross-sectional morphologies of composite coatings with different chemical compositions in raw powders, and synthesized under conditions of P=10 kW and v=1.2 mm/s

图8 不同熔覆工艺条件下TiC/Ti复合涂层界面区域的OM像

Fig. 8 OM images of interface regions of TiC/Ti composite coatings prepared under different cladding processing parameters (20% C)

2.4 涂层显微硬度

图9所示为不同石墨含量的预置粉末经感应熔覆后得到的复合涂层截面显微硬度变化曲线。由图9可见,随着C含量增加,TiC/Ti复合涂层显微硬度逐渐升高。由涂层物相和微观组织分析可知,涂层内部TiC增强体的体积分数随预置粉末中C含量增加而升高,TiC颗粒对涂层的强化作用引起了涂层显微硬度的升高。

图9 TiC/Ti复合涂层的截面显微硬度分布曲线

Fig. 9 Microhardness profile of cross section of TiC/Ti composite coating

2.5 涂层显微组织演变机理分析

已有的研究结果表明[15],Ti与C之间的自蔓延高温合成反应在1500 K以下即可发生,而原位反应形成TiC后增强体的生长机制可归纳为扩散机制和溶解–析出机制。文献[16-17]通过进行热力学和动力学计算后发现,TiC的长大在温度低于1554 K时以扩散机制为主,在温度高于1554 K时以溶解–析出机制为主。通常情况下,当反应合成温度高于液相线温度时,增强相的原位生长机制为溶解–析出机制[18]。根据前期研究结果[14],感应熔覆钛基复合涂层的合成温度超过2000 ℃,远高于Ti的液相线温度。按照Ti-C二元相图,在熔覆过程中,TiC增强体已完全溶解在液相中,TiC在凝固过程中以形核并长大的方式从液相中析出并不断生长。在TiC生长过程中,成分、凝固过程和自身晶体结构对其最终形态与分布具有重要影响[14, 18]。

尽管由于溶质再分配导致固液两相溶质无法均匀化,使快速凝固过程无法按照平衡相图描述的过程进行,但非平衡凝固过程仍遵循平衡凝固过程中的基本规律。因此,基于经典假设的平衡相图仍有助于认识和理解非平衡凝固现象。预置粉末中C含量为10%的情况下,复合涂层内部TiC呈短棒状,根据TiC体积分数计算结果可知,该成分涂层内部C原子的摩尔分数约为3.2%,接近共晶点成分。而在共晶析出过程中,在二相之一的体积分数小于30%的情况下,共晶体中的该相以棒状分布时总的相界面表面积最小,界面能也因此最低,容易在析出过程中形成纤维状[19]。当C含量为20%和30%时,复合涂层内的实际TiC含量分别为10.8%和13.2%。在此条件下,T-C相图的L+TiC液相线逐渐趋于平缓,同时由于非平衡凝固过程,使液相线进一步发生移动,不易形成成分过冷,液相中析出的TiC由于其NaCl型晶体结构的特点更容易长大形成等轴晶[14, 18, 20]。在TiC含量较高时,由于感应熔覆过程所能达到的最高温度有限,导致TiC无法在熔池内全部溶解,而是仅发生大尺寸TiC颗粒的部分溶解或局部区域的TiC溶解;在随后的冷却凝固过程中,溶解的TiC析出长大形成小尺寸的TiC增强体,而未溶解或部分溶解的TiC则形成大尺寸的增强体颗粒。

此外,表1所列的感应熔覆工艺参数中,随着功率的增加,为避免涂层过熔,与之匹配的线圈扫描速度也相应增加,而总体上的热输入有所下降。其中,线圈扫描速度主要影响涂层的加热和冷却速度,特别是随着感应线圈扫描速度的增加,涂层凝固过程中的冷却速度加快,使析出过程中的TiC晶体来不及进一步长大,从而有利于增强体尺寸的降低;反之,则TiC在熔池内析出长大的时间进一步增加,导致复合涂层内部TiC增强体的尺寸随着热输入量的升高而不断增大。

3 结论

1) 感应熔覆原位合成TiC/Ti复合涂层的组织致密、表面平整,与基体形成了冶金结合。涂层内部原位自生TiC分布均匀,与基质相结合紧密、界面洁净。

2) TiC增强体的长大机制主要为溶解-析出机制,涂层成分、凝固过程和TiC晶体结构对其最终形态与分布具有重要影响。

3) 石墨含量一方面影响复合涂层内部原位自生TiC的形态、含量、粒径与分布,另一方面因TiC的弥散强化作用而影响涂层硬度。随着石墨含量增加,涂层内TiC由短纤维状演变为等轴晶状,其尺寸、体积分数及涂层硬度逐渐增大。

4) 熔覆工艺影响增强体粒径以及涂层与基体的界面结合行为:随着热输入量增加,TiC尺寸逐渐增大,界面过渡区宽度及基体热影响随之加大。

REFERENCES

[1] 袁有录, 张 屹, 李铸国. 原位自生TiC-M7C3粒柱混杂结构及其干滑动摩擦学特征[J]. 中国有色金属学报, 2017, 27(10): 2062-2071.

YUAN You-lu, ZHANG Yi, LI Zhu-guo. Hybrid structure and dry sliding tribological characteristics of in-situ synthesizing TiC-M7C3[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(10): 2062-2071.

[2] 兰志俊, 张德闯, 杨 飞, 罗致春, 林建国. Ti-7.5Nb-4Mo-2Sn合金碳硅元素激光表面合金化涂层的显微组织及耐磨性能[J]. 中国有色金属学报, 2014, 24(8): 2100-2106.

LAN Zhi-jun, ZHANG De-chuang, YANG Fei, LUO Zhi-chun, LIN Jian-guo. Microstructures and wear properties of coating on Ti-7.5Nb-4Mo-2Sn alloy prepared by laser surface alloying of C-Si powders[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(8): 2100-2106.

[3] HONG X, TAN Y F, WANG X L, TAN H. Effects of nitrogen flux on microstructure and tribological properties of in-situ TiN coatings deposited on TC11 titanium alloy by electrospark deposition[J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 3329-3338.

[4] BAO Y, HUANG L J, AN Q, JIANG S, GENG L, MA X X. Wire-feed deposition TiB reinforced Ti composite coating: Formation mechanism and tribological properties[J]. Materials Letters, 2018, 229: 221–224.

[5] 张长江, 张树志, 侯赵平, 林 鹏, 孔凡涛, 陈玉勇. (TiBw+TiCp)/Ti复合材料的高温拉伸力学行为与失效机理[J]. 中国有色金属学报, 2016, 26(11): 2287-2295.

ZHANG Chang-jiang, ZHANG Shu-zhi, HOU Zhao-ping, LIN Peng, KONG Fan-tao, CHEN Yu-yong. Tensile mechanical behavior and failure mechanism of (TiBw+TiCp)/Ti composites at elevated temperature[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(11): 2287-2295.

[6] SAVALANI M M, NG C C, LI Q H, MAN H C. In situ formation of titanium carbide using titanium and carbon-nanotube powders by laser cladding[J]. Applied Surface Science, 2012, 258: 3173-3177.

[7] HAMEDI M J, TORKAMANY M J, SABBAGHZADEH J. Effect of pulsed laser parameters on in-situ TiC synthesis in laser surface treatment[J]. Optics and Lasers in Engineering, 2011, 49: 557-563.

[8] YANG R J, LIU Z D, YANG G, WANG Y T. Study of in-situ synthesis TiCp/Ti composite coating on alloy Ti6Al4V by TIG cladding[J]. Procedia Engineering. 2012, 36: 349-354.

[9] ZHOU W, ZHAO Y G, LI W, MEI X L, JIANG Q C. The in situsynthesis and wear performance of a metal matrix composite coating reinforced with TiC-TiB 2 particulates, formed on Ti-6Al-4V alloy by a low oxygen partial pressure fusing technique[J]. Surface and Coatings Technology, 2008, 202: 1652-1660.

[10] 吴玉萍, 林萍华, 王泽华. 等离子熔覆原位合成TiC陶瓷颗粒增强复合涂层的组织与性能[J]. 中国有色金属学报, 2004, 14(8): 1335-1339.

WU Yu-ping, LIN Ping-hua, WANG Ze-hua. Microstructure and properties of in-situ synthesis of TiC particle reinforced composite coating by plasma cladding[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(8): 1335-1339.

[11] LANGELIER B C, ESMAEILI S. In-situ laser-fabrication and characterization of TiC-containing Ti-Co composite on pure Ti substrate[J]. Journal of Alloys and Compounds, 2009, 482: 246-252.

[12] ZHANG S, WU W T, WANG M C, MAN H C. In-situ synthesis and wear performance of TiC particle reinforced composite coating on alloy Ti6Al4V[J]. Surface and Coatings Technology, 2001, 138: 95-100.

[13] WANG Z T, WANG Y D. Microstructure and properties of in-situ synthesis of TiC particle reinforced composite coating by induction cladding[J]. Key Engineering Materials, 2007, 336/338: 1725-1727.

[14] YU H L, ZHANG W, WANG H M, JI X C, SONG Z Y, LI X Y, XU B S. In-situ synthesis of TiC/Ti composite coating by high frequency induction cladding[J]. Journal of Alloys and Compounds, 2017, 701: 244-255.

[15] NUKAMI T, FLEMINGS M C. In situ synthesis of TiC particulate-reinforced aluminum mateix composites[J]. Metallurgical and Materials Transactions A, 1995, 26(7): 1877-1884.

[16] TONG X C, FANG H S. Al-TiC composites in situ-processed by ingot metallurgy and rapid solidification technology: Part I. Microstructural evolution[J]. Metallurgical and Materials Transactions A, 1998, 29: 875-891.

[17] TONG X C, FANG H S. Al-TiC composites in situ-processed by ingot metallurgy and rapid solidification technology: Part II. Mechanical behavior[J]. Metallurgical and Materials Transactions A, 1998, 29: 893-902.

[18] 吕维洁, 杨志峰, 张 荻, 张小农, 吴人洁. 原位合成钛基复合材料增强体TiC的微结构特征[J]. 中国有色金属学报, 2002, 12(3): 511-515.

Lü Wei-jie, YANG Zhi-feng, ZHANG Di, ZHANG Xiao-nong, WU Ren-jie. Microstructural characterization of TiC in in situ synthesized titanium matrix composites[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(3): 511-515.

[19] 李 超. 金属学原理[M ]. 哈尔滨: 哈尔滨工业大学出版社, 1990.

LI Chao. Principles of metallography[M]. Harbin: Harbin Institute of Technology Press, 1990.

[20] JEITSCHKO W, POTTGEN R, HOFFMAN R D. Structural chemistry of hard materials, in: R. Riedel (Ed.), Handbook of ceramic hard materials[M]. New York: Wiley-VCH, 2003.

Microstructure evolution mechanism of in-situ TiC/Ti composite coating by induction cladding

YU He-long1, WEI Min2, 3, ZHANG Meng-qing1, LI En-zhong1, ZHANG Wei2, 3, XU Bin-shi1

(1. National Key Laboratory for Remanufacturing, Army Academy of Armored Forces, Beijing 100072, China;

2. Hebei Jingjinji Institute of Remanufacturing Industry & Technology Co., Ltd., Hejian 062450, China;

3. Beijing Ruiman Technologies Co., Ltd., Beijing 100043, China)

Abstract: TiC/Ti composite coating was in-situ synthesized on Ti6Al4V substrate using the powder mixture of Ti and graphite by induction cladding method. The effects of chemical composition of raw materials and processing parameter on the microstructure, phase structure, morphology and distribution of the reinforcements, interface bonding behavior and microhardness of the composite coating were studied. The results indicate that fine TiC reinforcements, with a clean interface and tight bond with the matrix, are in-situ formed and uniformly dispersed in the coating. The morphology and distribution of TiC reinforcements in coating are mainly influenced by the composition, solidification process and crystal structure of TiC. With the increase of graphite content, the morphology of the in-situ TiC gradually evolves from short fiber to equiaxed crystal, and its size and volume fraction and the coating hardness increase. With the increase of heat input, the size of TiC increases, and the width of the interface transition region and the heat effect on the substrate also increase.

Key words: in-situ synthesis; TiC; induction cladding; microstructure; Ti matrix composite

Foundation item: Projects(2017YFB0310703, 2017YFF0207905) supported by the National Key Research and Development Program of China

Received date: 2018-04-03; Accepted date: 2019-06-24

Corresponding author: YU He-long; Tel: +86-18811025912; E-mail: helong.yu@163.com

(编辑 何学锋)

基金项目:国家重点研发计划资助项目(2017YFB0310703,2017YFF0207905)

收稿日期:2018-04-03;修订日期:2019-06-24

通信作者:于鹤龙,副研究员,博士;电话:18811025912;E-mail:helong.yu@163.com