文章编号:1004-0609(2008)10-1807-06

添加重熔料后ZL205A合金的组织与性能

李 敏,王宏伟,朱兆军,徐晓阳,魏尊杰

(哈尔滨工业大学 材料与工程学院,哈尔滨 150001)

摘 要:通过向ZL205A合金铸锭中添加不同比例的重熔料,进行重熔、浇注。对利用ZL205A合金组织遗传性细化合金晶粒、提高合金力学性能进行初步研究。结果表明,ZL205A合金添加不同含量重熔料后,合金组织均有所细化;合金性能随着重熔料含量的增加先增大后减小。当重熔料含量为20%时,合金组织最为细小,晶粒尺寸达到33 μm左右;铸态力学性能达到最优,抗拉强度比原料ZL205A合金抗拉强度提高了11.6%,屈服强度和伸长率均较高,分别为87.6 MPa及7.5%。进一步增加重熔料含量,合金组织粗化,力学性能逐渐恶化。

关键词:ZL205A合金;重熔料;组织;性能

中图分类号:TG 245 文献标识码: A

Microstructure and mechanical properties of

ZL205A alloy with returns

LI Min, WANG Hong-wei, ZHU Zhao-jun, XU Xiao-yang, WEI Zun-jie

(School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China)

Abstract: Applications of structure heredity of returns of ZL205A alloy on grain refinement and improving mechanical properties were investigated. The results show that the addition of returns is contributed to refining the grains of alloy, and with increasing returns content, the mechanical properties increase first, and then decrease. The maximum as-cast performance is achieved when returns content is 20%(mass fraction), which is shown by the following indications: the average particle size is measured to be 33 μm, and the tensile strength is improved by 11.6% compared with primary alloy, and the yield strength and elongation are also comparatively higher, 87.6 MPa and 7.5%, respectively. But with further increasing the returns content, the microstructure coarsened and the mechanical properties deteriorate.

Key words: ZL205A alloy; returns; microstructure; properties

随着现代科技的发展,铝及铝合金被大量应用,其用量仅次于钢铁[1]。而铝铜系合金由于具有高的强度、良好的塑性、韧性和抗蚀能力等使其在高强度铝合金中占据主要地位。铝铜合金系中ZL205A 合金是我国自行研制的高强度铸造铝合金,是目前世界工业生产中强度较高的铸造铝合金之一,广泛的应用于航空、航天、汽车、机械等行业[2]。

在铝合金的铸造生产过程中,由于合金的特性和某些铸件的重要性,为消除缩松,减少熔体的氧化夹杂进入到铸件中,往往对浇注系统和冒口设计具有较高的要求,其设计所占金属量可达50%~70%。因此应在保证铸件质量的前提下最大限度的使用废旧料率[3]。废旧料的组织和性能对重熔后合金的组织和性能有什么影响,是许多科研及生产工作者关心的问题。现代的研究和生产实际表明,铸造合金生产过程中存在着遗传现象,对铸件的性能和组织都有很大的影响。铸造合金的遗传现象很早就被人们发现,20世纪20年代,法国的LEVI就对铸铁的遗传性进行了研究[4-5],20世纪40年代GILLETT对铸铁中的组织遗传性进行了更深入的研究[6],至20世纪60年代,许多前苏联学者开始研究炉料组织对有色合金重熔后组织和性能的影响[6-10]。近些年国内很多学者也进行了这方面的研究[11-12]。目前,对铝铜合金的组织遗传性的研究还很少报道。因此,本文作者针对目前应用最为广泛且强度最高的铸造铝铜合金ZL205A,通过添加不同比例但化学成分相同的重熔料,研究了重熔料添加量对合金组织与性能的影响,以期有效的降低铝铜合金的耗用量。

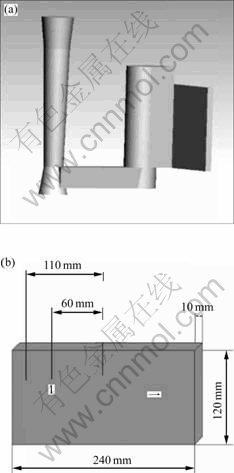

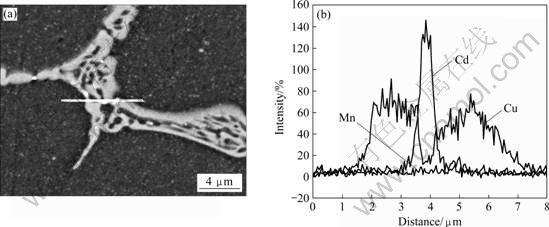

1 实验

实验所用原料采用高纯铝、纯镉、Al-Cu、Al-Mn、Al-Zr、Al-V和Al-Ti-B中间合金,配置成为ZL205A合金。重熔料为缝隙式浇注系统下板件浇道、冒口(重熔料添加量(质量分数)分别为0%、10%、20%、30%、40%)。采用砂型铸造,电阻坩锅炉进行熔炼,旋转喷吹法除气,熔炼温度为710~730 ℃。Al-Cu、Al-Mn、Al-V、Al-Zr等中间合金及重熔料与纯铝在室温下同时装炉,待溶液熔化后,熔体温度至710 ℃左右时加入纯Cd,720~730 ℃加入Al-Ti-B细化剂,保温30 min,待熔体温度降至710 ℃时浇注成长宽高分别为240 mm×120 mm×10 mm板件。合金的化学成分如表1所列,板件如图1所示。

图1 缝隙式浇注系统下板件形状及截取试样位置

Fig.1 Shape of casting and sampling positions: (a) Shape of casting; (b) Sampling positions

表1 ZL205A合金的化学成分

Table 1 Chemical composition of ZL205A alloy (mass fraction, %)

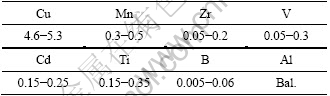

为保证实验结果的可比性,在铸件左侧截取金相试样,右侧相应位置截取拉伸试样。金相试样规格为:10 mm×10 mm×10 mm,经180#~1000#金相砂纸磨光,然后抛光,抛光液为Cr2O3。腐蚀液为99.5%H2O+ 0.5%HF。拉伸试样为厚度为2 mm的标准试样,规格如图2所示。在OLYMPUS光学显微镜及S5700型扫描电子显微镜下观察显微组织,在美国instron1186型电子万能实验机上进行拉伸实验。

图2 标准拉伸试样

Fig.2 Dimensions of tensile experiment sample (unit: mm)

2 结果及分析

2.1 重熔料含量对合金组织的影响

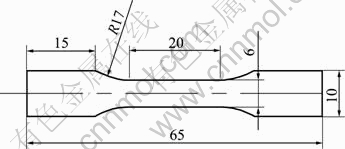

借助Al-Cu-Mn及Al-Cu-Ti三元相图可知,ZL205A合金的结晶过程为:首先是α(Al)结晶,然后有L→α(Al)+θ(Al2Cu)二元共晶或L→α(Al)+θ(Al2Cu)+ T(Al12CuMn2)三元共晶反应,一直到完全凝固为止。因此,ZL205A合金铸态显微组织为:基体相α(Al)固溶体,晶界或枝晶间为网状的白色组织θ(Al2Cu)相及少量细网状灰色组织T(Al12CuMn2)。此外,单质Cd相以球形质点的形式分布在晶界上及少量的灰色块状ZrAl3相,条状Al3Ti相分布在α(Al)基体上。图3所示为ZL205A合金铸态下微观组织,穿越晶界处白色亮点进行化学成分线扫描,测得其化学成分为Cd、Mn、Cu,分布如图3(b)所示。

图3 ZL205A合金的微观组织及元素分布

Fig.3 Microstructure (a) and distribution (b) of elements of ZL205A alloy

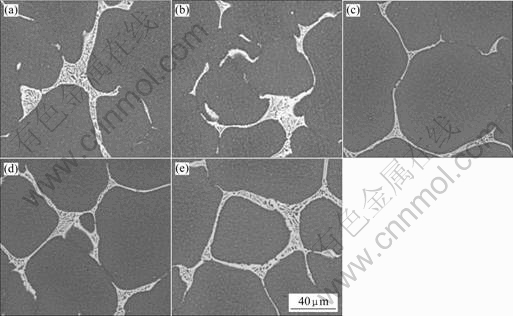

图4所示为添加不同比例重熔料ZL205A合金铸态显微组织形貌。图中可以看出,添加不同比例重熔料得到的ZL205A合金组织形貌与原料合金组织形貌基本相同,均为胞状晶。添加不同比例重熔料后合金晶粒均有所细化,并且随着重熔料含量的增加晶粒尺寸先减小后增大。添加10%重熔料时,合金晶粒大小与原料合金晶粒大小基本相同,平均尺寸为60 μm左右,进一步增加重熔料含量至20%时,合金晶粒明显细化,此时晶粒尺寸最为细小仅为33 μm左右。增加重熔料含量至30%时,合金晶粒比添加20%重熔料得到的合金晶粒稍大,平均尺寸为40 μm左右。继续增加重熔料含量至40%,可以看到,合金晶粒继续增大,平均尺寸增至44 μm左右。

图4 重熔料含量对ZL205A合金显微组织的影响

Fig.4 Microstructures of ZL205A alloy manufactured from: (a) primary alloy: 10%; (c) 20%; (d) 30%; (e) 40%

由图5可以看出,ZL205A合金添加重熔后,晶界处析出θ(Al2Cu)相的形貌与原料ZL205A合金晶界处θ(Al2Cu)相形貌相类似,均为网状结构。添加少量重熔料时合金晶界与原料ZL205A合金晶界相似,均较宽,重熔料含量增加至20%时,晶界变得窄而长,此时θ(Al2Cu)相的析出形貌仍为网状结构。继续增加重熔料含量,合金晶界处θ(Al2Cu)相网状结构比添加20%重熔料时合金晶界处θ(Al2Cu)相的网状结构粗大,且晶界又变得较宽。

图5 添加不同比例重熔料时ZL205A合金背散射电子像

Fig.5 Backscattered electron SEM images of ZL205A alloy: (a) 0%; (b) 10%; (c) 20%; (d) 30%; (e) 40%

2.2 重熔料含量对合金性能的影响

由于重熔料添加量的变化造成组织上的变化,从而导致了性能的变化。图6所示为不同重熔料添加量对ZL205A合金铸态力学性能的影响。由图6可以看出,受重熔料组织的影响,随着重熔料添加量的增加,合金的抗拉强度及屈服强度均呈先增大后减小趋势,延伸率则随着重熔料的增加而减小但变化幅度不大。当重熔料含量为20%时,合金抗拉强度与屈服强度达到最大值,分别比原料ZL205A合金抗拉强度及屈服强度提高11.6%和7%。

图6 重熔料含量对ZL205A合金铸态力学性能的影响

Fig.6 Mechanical properties of as cast ZL205A alloy as function of returns content

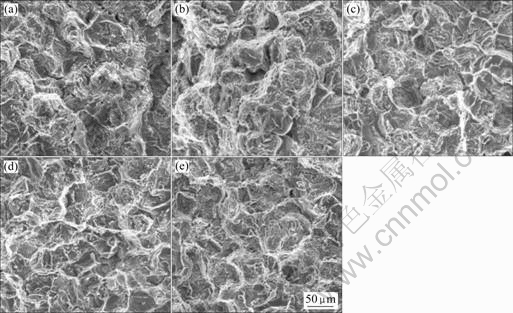

图7所示为原料ZL205A合金及添加重熔料10%、20%、30%和40%时的ZL205A合金拉伸断口形貌。对比可知:不添加重熔料的ZL205A合金拉伸断口形貌主要为沿晶断裂及少量的韧窝断裂,添加10%重熔料后断口形貌仍主要为沿晶断裂但是韧窝断裂变得更少,随着重熔料含量增至20%时,断口的沿晶断裂数量继续增加,进一步增加重熔料含量其断口形貌与添加20%重熔料得到的ZL205A合金断口形貌相近,但是拉伸断口的韧窝越来越少,说明该合金的韧性随着重熔料的增加有所恶化,但是变化并不明显。

图7 重熔料含量对ZL205A合金断口形貌的影响

Fig.7 Effects of returns content on fracture of ZL205A alloy: (a) 0%; (b) 10%; (c) 20%; (d) 30%; (e) 40%

3 讨论

晶体的主要熔化机制是以原子集团为单位,采取逐渐分裂的方式进行[13]:

(1)

(1)

式中 αn为含有n个原子的集团;αin为聚集了i个原子集团的集合体。

原料ZL205A合金组织是不均匀的,如存在着共晶体、α-(Al) 初晶体、各种金属间化合物,诸如 Al3Zr、Al3Ti等。根据上述熔化机制,ZL205A合金熔化时,熔体中存在着大量的游离于液态合金中的短程有序原子集团。因此,添加重熔料时,这些短程有序的原子集团使得重熔料对熔体具有组织遗传作用。许多学者的研究及合金的生产实践已证实[14-15],在液固态的结构和性质之间存在着遗传联系。固态合金存在着微观不均匀结构,而产生这种现象的原因就是合金化学成分的不均匀性。熔体在过热度较小的条件下,其结构、热运动的特点和一系列力学性能与晶体有较大的相似性,晶体的熔化消除了三维的周期性,但在一定程度上仍保持着相对稳定的原子排列的短程序即式(1)中所示含有n个原子的纳米尺度的集团,可以将它视为传递结构信息的遗传因子[16-17]。

在本实验中,熔体最高温度为735 ℃,而纯铝本身的熔化温度为660 ℃,其过热度很小,为75 ℃。因此,由重熔料所构成的熔体中存在着大量的具有与原料组织结构特性相似的短程有序。此外,熔体中还存在着一些细小颗粒(杂质)及细化剂(Al3Ti颗粒)。ZL205A合金凝固时,熔体中的有序原子集团、杂质颗粒及Al3Ti颗粒将发挥晶核作用,它们的结构、尺寸和化学成分都会对凝固后的铸件产生影响。这些外来晶核在细化α(Al)相的同时也细化θ(Al2Cu)相。当添加少量重熔料时(即外来晶核较少时),晶界处θ(Al2Cu)相的细化最为显著,由原来的树枝交叉而形成的网状结构变为细小的较圆润渔网状结构。随着重熔料的增加,异质形核源亦增加,此时外来晶核对α(Al)相的细化起到主导作用,合金的组织变得细小致密。由图4可以看到,当添加重熔料量至20%时,可以得到组织最为细小的合金,其铸态性能也达到最优。当重熔料加入量至40%时,重熔料对合金的细化效果开始下降,重新出现了粗大的枝晶组织,可见过多的加入重熔料不但达不到细化晶粒的效果,反而降低了合金的力学性能,这是因为外来晶核增加,它们将聚集长大,成为大的晶核质点,从而失去有效结晶晶核的作用,除此之外,重熔料中存在着一定数量的杂质,随着重熔料添加量的增加,杂质数量亦增加,在重熔保温过程中,它不能以浮渣的方式完全析出时,便会出现杂质聚集进入到铸件中,从而严重的影响合金的力学性能[18]。

4 结论

1) ZL205A合金中加入重熔料后,其组织形态没有发生明显的变化。但是重熔料的加入使合金铸态显微组织得到细化,当重熔料添加量达到20%时,合金组织最为细小,此时合金晶粒尺寸最为细小仅为33 μm左右,进一步增加重熔料含量,合金组织又被粗化。

2) 由于重熔料的增加造成组织上的变化,从而导致了性能的变化,当重熔料添加量为20%时得到的ZL205A合金铸态抗拉强度达到最大,比原料ZL205A合金抗拉强度提高了11.6%;合金的韧性随着重熔料含量的增加而降低,但是变化幅度不大;屈服强度则在重熔料含量为10%时达到最大值。

REFERENCES

[1] 高洪吉, 许斌牛, 玉 超. 浇注条件对Al-Cu合金组织的影响[J]. 特种铸造及有色合金, 2006(1): 1-12.

GAO Hong-jie, XU Bin-niu, YU Chao. The effect of pouring conditions on the microstructure of Al-Cu alloy[J]. Special Casting & Nonferrous Alloys. 2006(1): 1-12.

[2] 郑来苏. 铸造合金及其熔炼[M]. 西安: 西北工业大学出版社, 1994.

ZHENG Lai-su. Casting alloy and melting[M]. Xi’an: Northwestern Polytechnical University Press, 1994.

[3] 方元杰. 回炉料在轻合金生产中的合理利用[J]. 特种铸造及有色合金, 1989(1): 51-53.

FANG Yuan-jie. The utilization of recycled scrap at production of light alloys[J]. Special Casting and Nonferrous Alloys, 1989(1): 51-53.

[4] LEVI A. Heredity in cast iron[J]. The Iron Age, 1927(6): 960-965.

[5] GILLETT H W. Heredity in cast iron[J]. Metals and Alloy, 1934: 5.

[6] 耿浩然, 叶以富, 马家骥. 铸铁合金的遗传效应及其利用[J]. 钢铁研究学报, 1996, 8(4): 37-41.

GENG Hao-ran, YE Yi-fu, MA Jia-ji. Effects and application of inheritance to cast iron[J]. Journal of Iron and Steel Research, 1996, 8(4): 37-41.

[7] 张作贵, 刘相法, 边秀房. Al-Ti-B中间合金的遗传性研究与推广应用[J]. 铸造, 2000, 49(10): 758-763.

ZHANG Zuo-gui, LIU Xiang-fa, BIAN Xiu-fang. Heredity study and application of Al-Ti-B master alloy[J]. Foundry, 2000, 49(10): 758-763.

[8] LI Pei-jie, ZHANG Yan-fei, NIKITIN V I. Hereditary effect of Al-based modifier and grain refiners on the structure and properties of A356.2 alloys [J]. Trans Nonferrous Met Soc China, 2002, 12(2): 233-237.

[9] LIU Xiang-fa, BIAN Xiu-fang, QI Xiao-gang. Structural heredity between Al5TiB and AlTi, AlB master alloys [J]. Trans Nonferrous Met Soc China, 1999, 9(4): 806-809.

[10] 李培杰, 曾大本, 贾 均. 铝硅合金中的结构遗传及其控制[J]. 铸造, 1996(6): 10-14.

LI Pei-jie, ZENG Da-ben, JIA Jun. Structure heredity and control of Al-Si alloy[J]. Foundry, 1996(6): 10-14.

[11] 边秀房, 王伟民, 李 辉. 金属熔体结构[M]. 上海: 上海交通大学出版社, 2003.

BIAN Xiu-fang, WANG Wei-min, LI Hui. Metal Melt Structure[M]. Shanghai: Shanghai Jiao Tong University Press, 2003.

[12] BIAN Xiu-fang, WANG Wei-min, YUAN Shu-juan. Structure factors of modified liquid Al-Si alloys[J]. Science and Technology of Advanced Materials, 2001(2): 19-23.

[13] 李培杰, 曾大本, 贾 均, 李庆春. 合金熔体遗传现象的热力学分析[J]. 铸造, 1999(10): 12-15.

LI Pei-Jie, ZENG Da-ben, JIA Jun, LI Qing-chun. Thermodynamics analysis of heredity phenomena in alloy melt[J]. Foundry, 1999(10): 12-15.

[14] 李培杰. 铝硅合金熔体的物性及结构遗传[D]. 哈尔滨工业大学, 1994 .

LI Pei-Jie. Physical properties and heredity of structure of Al-Si alloy[D]. Haerbin Institute of Technology, 1994.

[15] 赵 宇, 周 宏, 陈 莉. 添加回炉料后AZ91D镁合金遗传性研究[J]. 铸造, 2007(3): 297-302.

ZHAO Yu, ZHOU Hong, CHEN Li. Study on the hereditary of AZ91D magnesium alloy with recycled scrap[J]. Foundry, 2007(3): 297-302.

[16] BRODOVA I G, POPEL P S. ESKIN G I. Liquid metal processing applications to aluminium alloy production[R]. London and New York: London and Breach, 2004: 269.

[17] 张 军, 何良菊, 李培杰, KANDALOVA E G. 炉料微观组织对ZA91D镁合金重熔行为的影响[J]. 中国有色金属学报, 2006, 16(3): 428-435.

ZHANG Jun, He Liang-ju, LI Pei-jie, KANDALOVA E G. Effect of primary microstructure on re-melting behavior of AZ91D magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(3): 428-435.

[18] WARDLOW G D. Recycling must be carefully controlled[J]. Foundry Trade Journal, 1999(2): 18-21.

收稿日期:2008-03-24;修订日期:2008-06-10

通讯作者:李 敏,博士研究生;电话:0451-86403150,传真:0451-86413150;E-mail: limin04s@163.com

(编辑 何学锋)