脉冲电场下制备AZ91D镁合金部分重熔过程的组织演变

周 全, 杨院生, 唐军立, 胡壮麒

(中国科学院 金属研究所, 沈阳 110016)

摘 要: 研究利用低压脉冲电场技术制备的AZ91D镁合金在部分重熔过程中的组织演变, 考察加热温度和保温时间对不同脉冲电压制备的AZ91D合金初生相形态和尺寸的影响。 结果表明: 经低压脉冲电场处理后, 将AZ91D镁合金进行部分重熔可得到非枝晶的半固态合金, 随坯料制备的脉冲电压增加, 重熔时初生相变得圆整且尺寸减小, 但制备坯料的脉冲电压过高, 重熔时初生相尺寸有所增加; 脉冲电场处理后的AZ91D镁合金坯料经适当的部分重熔处理可获得具备触变过程所需要的组织状态。

关键词: AZ91D镁合金; 低压脉冲电场; 半固态合金; 部分重熔 中图分类号: TG146.2

文献标识码: A

Microstructure evolution of magnesium alloy AZ91D prepared by electric current pulse discharge during partial remelting

ZHOU Quan, YANG Yuan-sheng, TANG Jun-li, HU Zhuang-qi

(Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: The non-dendritic semi-solid magnesium alloy AZ91D is prepared by reheating the AZ91D alloy treated by low-voltage electric current pulse (LVECP) technique. The microstructure evolution of magnesium alloy AZ91D prepared by LVECP during partial remelting, and the effects of heating temperature and holding time on the partial remelted microstructure of the alloy treated with different pulse voltages were investigated. The results show that when heating temperature and holding time are constant, the primary grains become small with the increment of pulse voltage. If the pulse voltage is too high, the primary grains will be coarse. The alloy treated by LVECP and partially remelted has fine microstructure suitable for thixoforming.

Key words: magnesium alloy AZ91D; low-voltage electric current pulse; semi-solid alloy; partial remelting

利用半固态成形技术, 可以有效细化铸造组织和提高铸件性能[1, 2]。 近年来, 对于半固态镁合金也开展了研究, 结果表明半固态成形可有效解决镁合金晶粒粗大等问题[3, 4]。 用于制备半固态金属的方法主要包括机械搅拌法[5]、 电磁搅拌法[6]、 应力激活法[7]、 低温浇注法[8]、 喷射沉积法[9]、 半固态保温处理法[10]等, 其中如电磁搅拌法和应力激活法已经在工业上成功应用。 最近的研究[11]表明低压脉冲电场可作为一种新的制备半固态合金方法, 应用低压脉冲电场制备的AZ91D半固态镁合金, 其初生相由发达的树枝晶可转变为蔷薇状晶体或退化的枝晶, 凝固组织被显著细化。

部分重熔是半固态触变成形的主要技术环节之一, 其目的是使坯料具有所需的固相体积分数和细小的等轴球状组织以降低触变成形时的剪切抗力[12]。 重熔过程中组织变化与合金的原始组织有密切关系, 文献[13]对于AZ91D镁合金的原始组织对部分重熔的影响进行了研究, 指出熔化后的半固态组织中固态颗粒的尺寸与形貌主要与初始组织的形貌、 加热过程中非平衡组织的溶解速度与加热速度有关。 本文作者研究低压脉冲电场下制备的AZ91D镁合金坯料在部分重熔过程中的组织演变规律, 以及加热温度和保温时间对不同脉冲电压制备的AZ91D镁合金初生相形态和尺寸的影响。

1 实验

实验合金为工业用AZ91D镁合金, 化学成分(质量分数, %)为: Al 9.03, Zn 0.64, Mn 0.33, Be 0.0014, Si 0.031, Cu 0.0049, Fe 0.0011, Ni 0.0003, 余量为Mg。 该合金在平衡相图中的液相线和固相线温度分别为595℃和470℃[14]。

首先在脉冲电场下制备出AZ91D合金试棒, 试棒大小为d15mm×60mm。 制备工艺参数为: 脉冲放电周期为6s, 脉冲电压分别为100、 200、 300和400V, 合金冷却速度约为30℃/min。 然后将合金试棒加工成d15mm×5mm的试样, 在电阻炉中加热进行重熔, 热电偶置于样品表面, 加热温度为560~590℃, 控温精度为土1℃。 重熔过程中采用氩气保护。 当试样表面温度升至设定温度后开始保温, 保温时间分别为0、 5、 10、 15和20min, 到达保温时间后立即取出试样进行水淬。 水淬后的试样制备成金相样品, 用5 %的柠檬酸浸蚀, 用光学显微镜观察组织。

2 实验结果

2.1 部分重熔前的微观组织

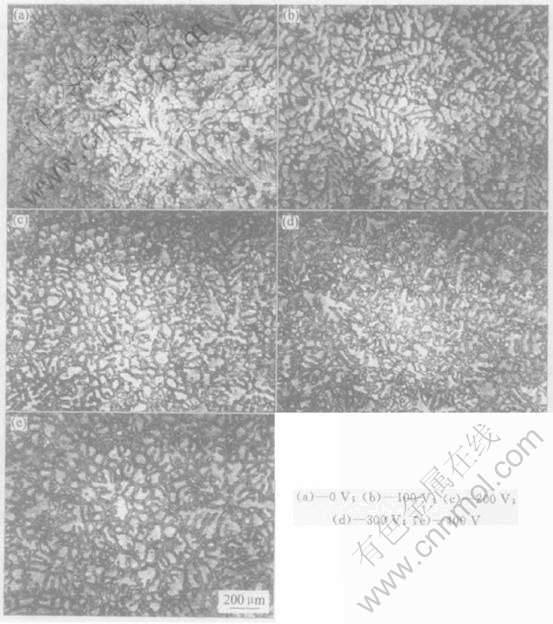

不同脉冲电压下制备的AZ91D合金样品在部分重熔前的组织如图1所示。 从图中可以看出, 未经脉冲电场处理的初生相为典型的树枝晶; 当脉冲电压为100V时, 初生相为细化的枝晶; 当脉冲电压为200V时, 初生相中的一次、 二次枝晶分枝不是很明显, 柱状枝晶退化为等轴枝晶; 当脉冲电压为300V时, 枝晶已不明显, 初生相由许多枝晶碎[CM(22]片和退化的枝晶组成; 当脉冲电压为400V时, 初生相由退化的枝晶、 等轴枝晶和少量的粒状晶组成, 有所粗化且不均匀。

图1 脉冲电压对合金试样凝固组织的影响

Fig.1 Microstructures of AZ91D alloy solidified at different discharging voltages

2.2 脉冲电压对半固态微观组织的影响

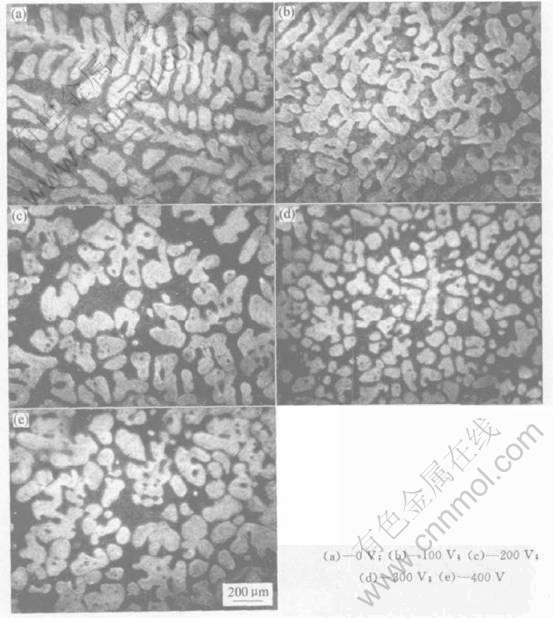

不同脉冲电压作用下制备的试样在570℃保温15min的微观组织如图2所示。 从图2(a)中可以看出: 未经过脉冲电场处理的试样在570℃保温15min时, 共晶体己经重熔, 液相分布在初生相周围, 与重熔前相比, 枝晶的主干变粗, 二次枝晶臂也合并粗化, 粗化后的二次枝晶臂仍然排列有序, 保持枝晶的基本形态。 从图2(b)~(e)中可以看出, 在保温15min时, 随着制备坯料样品时的脉冲电压增加, 枝晶主干逐渐消失, 球化的二次枝晶臂逐渐增多。 当脉冲电压为100V时, 仍然能够观察到枝晶形态。 当脉冲电压为200V时, 枝晶已经变得不明显, 初生相已经发生球团化。 当脉冲电压达到300V时, 初生相变得更加圆整和细小。 但是当脉冲电压达到400V时, 初生相尺寸有所增加。

2.3 加热温度对半固态微观组织的影响

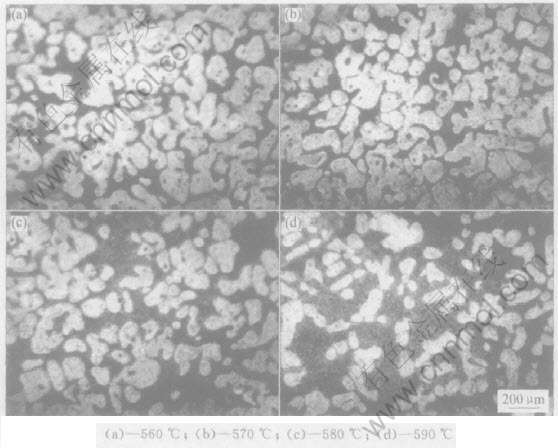

300V脉冲电场作用下制备的镁合金坯料在560、 570、 580和590℃时保温10min的半固态组织如图3所示。 从图中可以看出, 保温温度越高, 合金熔化的体积分数越大。 在560℃保温l0min时, 晶界已经重熔, 初生相边缘部分熔化; 当温度提高到570℃时, 初生相开始发生团球化, 有少量液相存在初生相中间, 其余液相分布在初生相之间; 当温度达到580℃时, 块状初生相开始分离出细小的块状或粒状组织; 当温度进一步上升到590℃时, 初生相已经完全分离, 枝晶的形貌已经不存在, 初生相边缘更加圆整, 其尺寸和形貌趋于均匀化, 因保温时间较短, 初生相尚未发生熟化长大, 其晶粒度反而有所减小。

2.4 保温时间对半固态微观组织的影响

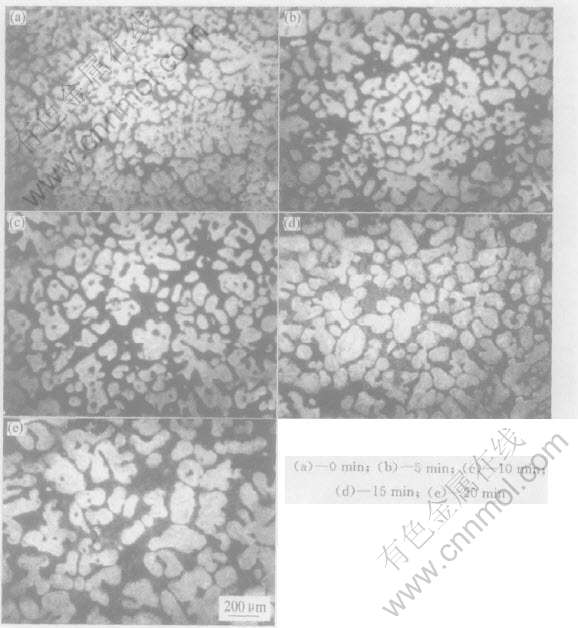

在300V脉冲电场下制备的合金坯料经过570℃不同时间保温的组织演化如图4所示。 可以看出, 在部分重熔的过程中, 退化的枝晶或蔷薇状晶体先转变为尺寸不同的不规则块状, 随保温时间延长, 块状初生相开始分离, 大小趋于均匀, 形状趋于圆整。 当温度刚达到570℃时, 只有极少部分晶界重熔, 初生相基本无变化; 当保温5min时, 共晶组织已完全重熔, 初生相边缘部分熔化; 当保温10min时, 初生相的形貌有明显改变, 发生团球化, 并有少量液相存在初生相内部, 其余液相均匀分布在初生相之间; 当保温时间增加到15min时, 初生相更加圆整, 粒径约在50~80μm之间; 当保温时间进一步增加到20min时, 初生相变粗变圆, 有所长大, 并出现合并现象, 但基本形貌没有显著变化。

图2 不同脉冲电压下制备合金试样的部分重熔组织

Fig.2 Reheated microstructures of AZ91D alloy prepared at different pulse voltages

图3 不同加热温度下的微观组织

Fig.3 Reheated microstructures of AZ91D alloy held at different temperatures

图4 不同保温时间下的微观组织

Fig.4 Reheated microstructures of AZ91D alloy held for different times

3 讨论

由实验结果可知, AZ91D合金坯料部分重熔时, 只有经过一定脉冲电压的脉冲电场处理后的坯料经保温处理才可获得球状或近球状初生相的半固态组织, 这表明脉冲电场对加快枝晶组织向球状或近球状初生相的半固态组织演变具有重要作用。 合金坯料在脉冲电场作用下凝固时产生激烈流动和温度起伏, 破碎了枝晶, 也促使二次枝晶臂的缩颈和熔断使初生相被细化, 在坯料重熔时, 晶粒形态的转变过程是通过Mg原子和Al原子的扩散实现的, 由于脉冲电场下制备合金坯料组织细化, 原子扩散距离缩短, 因此加速了半固态重熔时初生相的球化进程。 在凝固过程中不加以脉冲电场处理, 坯料组织不具备脉冲电场处理坯料的蔷薇状晶体或退化的枝晶组织特征, 在半固态重熔时无法获得球状或近球状初生相的半固态组织。 当脉冲电压达到400V时, 其凝固组织同脉冲电压为300V时的凝固组织相比要粗大一些, 因此, 其部分重熔组织也要比脉冲电压为300V时的粗大。

AZ91D镁合金在升温过程中, 分布在晶间的共晶相会溶入初生相中, 使得二次枝晶臂合并, 形成具有一次枝晶大小的块状组织。 这是由于以下3个原因: 1) 在升温过程中, 由于温度升高使晶粒内部的成分均匀化及固溶度提高; 2) 枝晶臂之间的曲率不同, 造成枝晶臂附近溶质浓度的差别, 枝晶臂曲率半径越小, 附近溶质浓度越低, 这样, 两个枝晶臂(一次枝晶臂与二次枝晶臂或二次枝晶臂之间)之间建立起一个扩散偶, 溶质浓度梯度的存在将促使溶质从粗枝处向细枝处扩散, 造成细枝熔化或溶解, 甚至从细枝根部熔断; 3)在先前的凝固过程中, 低熔点的相后凝固而存在于枝晶间或晶粒之间, 熔化时这些组织首先发生熔化。 随着温度的进一步升高或保温时间的延长而使温度均匀化, 存在于初生相中的共晶体来不及完全溶解扩散就开始熔化, 熔点较高的初生相则仍为固态[15]。

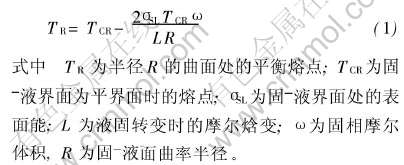

合金试样在部分重熔时的初始阶段, 晶间的共晶组织和少量初生相前沿熔化, 由于初生相枝晶根部溶质浓度较高, 相应其熔点较低, 从而使枝晶熔断分离成初生相颗粒。 此时初生相表面凹凸不平, 呈不规则形状, 不同部位的曲率半径不同。 在界面张力作用下, 曲率不同的界面将具有不同的固相平衡熔点。 由凝固热力学可知, 合金的平衡熔点与固相界面的曲率之间有如下关系[16]:

从式(1)可以看出, 初生相的曲率半径越小即曲率越大, 其平衡熔点越低。 由于界面曲率的作用, 使凸出部分的平衡熔点下降。 因此, 初生相凸出部位容易熔化, 从而使初生相向球状颗粒演变。

在液固相比例平衡后, 仍继续保温, 那么粒状晶的颗粒大于平均尺寸的初生相将长大, 而小于平均尺寸的初生相将溶解, 并且有些初生相会发生异常长大, 这一现象可由Ostwald熟化理论(Ostwald Ripening Theory)予以解释[17]。

4 结论

1) 低压脉冲电场下制备的AZ91D镁合金坯料经过部分重熔处理, 可获得具有初生相为球状或近球状的非枝晶组织半固态合金。

2) 制备AZ91D镁合金坯料时的脉冲电压对重熔组织演化有显著影响。 随脉冲电压增加, 重熔组织中的初生相形态变得圆整, 其尺寸减小, 但当脉冲电压过高时, 初生相尺寸有所增加。

3)当重熔处理的保温时间一定时, 随加热温度提高, AZ91D半固态组织的球化过程加快; 当加热温度一定时, 随保温时间延长, AZ91D半固态组织中的初生相愈加圆整, 但保温时间过长, 初生相有所长大。

REFERENCES

[1]谢水生, 黄声宏. 半固态金属加工技术及其应用[M]. 北京: 冶金工业出版社, 1999. 1-13.

XIE Shui-sheng, HUANG Sheng-hong. Technology and Application of Semi-solid Metals Process[M]. Beijing: Metallurgical Industry Press, 1999. 1-13.

[2]Kirkwood D H. Semisolid metal processing[J]. International Materials Reviews, 1994, 39(5): 173-189.

[3]Harutoshi M, Toshio S, Mamoru N. Present developmental status of super light material of magnesium alloys[J]. Material, 1999, 38(4): 317-320.

[4]Shigcharu K, Yo O. Specificity and orientation of magnesium alloys used to punch[J]. Material, 1999, 38(4): 285-290.

[5]Flemings M C. Behavior of metal alloys in the semi-solid state[J]. Metall Trans, 1991, 22A: 973-974.

[6]Vives C. Elaboration of semi-solid alloys by means of new electromagnetic rheocasting processes[J]. Metall Trans B, 1992, B23: 189-205.

[7]吉泽升, 李庆芬, 刘兆晶, 等. 应变诱发AZ91D镁合金半固态组织形态及形成机理[J]. 中国有色金属学报, 2003, 13(5): 1156-1160.

JI Ze-sheng, LI Qing-fen, LIU Zhao-jing, et al. Structure shape and forming mechanism of semi-solid material of AZ91D magnesium alloy by SIMA process[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(5): 1156-1160.

[8]Xia K, Tausing G. Liquidus casting of a wrought aluminum alloy 2618 for thixoforming[J]. Mater Sci Eng A, 1998, A246: 1-10.

[9]Mclelland A R, Atkinson H V. Thixoforming spray formed aluminum/silicon carbide metal matrix composites[J]. Materials Letter, 1991, 11(12): 26-30.

[10]李元东, 郝远, 阎峰云, 等. AZ91D镁合金在半固态保温热处理中的组织演变[J]. 中国有色金属学报, 2001, 11(4): 571-575.

LI Yuan-dong, HAO Yuan, YAN Feng-yun, et al. Structural evolution of AZ9lD magnesium alloy during semi-solid isothermal heat treatment[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(4): 571-575.

[11]Yang Y S, Zhou Q, Hu Z Q. The influence of electric current pulses on the microstructure of magnesium alloy AZ91D[J]. Material Science Forum, 2005, 488-489: 201-204.

[12]乐启炽, 张新建, 崔建忠, 等. AZ91D镁合金近液相线铸造半固态坯料的部分重熔[J]. 金属学报, 2002, 38(12): 1266-1272.

LE Qi-chi, ZHANG Xin-jian, CUI Jian-zhong, et al. Remelting of SSM ingot prepared by the near-liquidus casting of AZ91D magnesium alloy[J]. Acta Metallurgica Sinica, 2002, 38(12): 1266-1272.

[13]李元东, 郝远, 陈体军, 等. 原始组织对半固态AZ91D镁合金重熔行为的影响[J]. 中国有色金属学报, 2004, 14(3): 366-371.

LI Yuan-dong, HAO Yuan, CHEN Ti-jun, et al. Effects of different primary microstructure on semi-solid melting behavior of AZ91D magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(3): 366-371 .

[14]中国铸造专业学会. 铸造手册—铸造非铁合金[M]. 北京: 机械工业出版社, 1995. 171-172.

The Chinese Foundry Association. Casting Manual—Casting Nonferrous Alloys[M]. Beijing: China Machine Press, 1995. 171-172.

[15]李元东, 郝远, 陈体军, 等. 保温热处理工艺对AZ91D镁合金半固态组演变和成形性的影响[J]. 中国有色金属学报, 2002, 12(6): 1143-1148.

LI Yuan-dong, HAO Yuan, CHEN Ti-jun, et al. Effect of isothermal heat-treatment on microstructure evolution and formability of AZ9lD magnesium alloy in semi-solid state[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(6): 1143-1148.

[16]Kukushkin S A. Theory of the Ostwald ripening of new-phase nuclei in single-component melts[J]. Acta Metal, 1994, 42(2): 715-722.

[17]Hardy S C, Voorhees P W. Ostwald ripening in a system with high volume fraction of coarsening phase[J]. Metall Trans A, 1988, A19: 2713-2721.

(编辑何学锋)

基金项目: 国家基础研究重大项目

收稿日期: 2005-08-01; 修订日期: 2006-04-03

通讯作者: 杨院生, 研究员; 电话: 024-23971728; E-mail: ysyang@imr.ac.cn