DOI: 10.11817/j.ysxb.1004.0609.2020-39422

Al2O3弥散强化铜-锡含油轴承的制备和性能

闫志巧1, 2,陈 峰1,许荣君1,汪 涛2,吴湘涛3,周 仲3

(1. 广东省科学院 广东省材料与加工研究所,广州 510650;

2. 广东省科学院产业技术育成中心,广州 510650;

3. 广东盈峰材料技术股份有限公司,佛山528311)

摘 要:以内氧化法制备的Al2O3弥散强化铜(简称“弥散铜”)粉和雾化锡粉为原料,采用扩散合金化法制备弥散铜-锡合金粉末,经压制、烧结制备弥散铜-锡含油轴承,研究扩散温度对弥散铜-锡粉末合金化程度的影响,并考察烧结温度对含油轴承性能的影响。结果表明:弥散铜-锡混合粉末经700 ℃扩散处理后,锡在弥散铜基体中分布均匀,制备的弥散铜-锡合金粉末的松装密度为2.40 g/cm3、流动性为39.6 s(50 g);轴承压坯在800 ℃及以下温度烧结时,粉末颗粒之间没有发生显著烧结,导致轴承性能较差。当烧结温度为850 ℃时,粉末颗粒之间形成一定的冶金结合,轴承强度显著提升,开孔率小幅降低。在900 ℃及以上温度烧结时,轴承发生显著收缩,开孔率明显降低。850 ℃烧结制备的弥散铜-锡含油轴承的径向、轴向尺寸变化率均约为1.0%,压溃强度为160 MPa,显微硬度为166 HV0.05,开孔率为26.0%。

关键词:Al2O3弥散强化铜;扩散合金化;含油轴承;径向压溃强度;开孔率

文章编号:1004-0609(2020)-04-0801-08 中图分类号:TF124 文献标志码:A

含油轴承是传动的基础,是现代工业中不可缺少的原件。含油轴承主要包括铁基和铜基两大类,其中烧结青铜(Cu-Sn)含油轴承具有优良的抗腐蚀性能和力学性能以及导热率高、工作寿命长等优点,现已广泛应用于航空航天、汽车、电子设备、办公器械和精密机械等领域[1-3]。据统计,全球55%以上的铜粉用于制造含油轴承[4]。

传统的青铜含油轴承主要通过锡元素的固溶强化和/或硬脆相的沉淀强化提高铜基体的强度和硬度,一方面锡的固溶强化效果比较有限,另一方面铜锡中间相在高温下会发生粗化和溶解,导致高温强度不足。在一些高速(≥25000 r/min)电动工具中,要求含油轴承必须具有良好的抗热咬合性、优良的自润滑性和足够的耐磨性[5]。现有的青铜含油轴承难以满足这些使用要求。

纳米相弥散强化可以有效提高合金性能。常用的强化相粒子多为熔点高、高温稳定性好、硬度高的氧化物、硼化物、氮化物以及碳化物等。与析出强化型铜合金时效析出的金属间化合物粒子不同,这些强化相粒子在接近于铜基体熔点的高温下也不会溶解或粗化,因此可以有效地阻碍位错运动和晶界滑移,提高合金的室温和高温强度。当这些强化相以纳米级尺寸均匀弥散分布于铜基体内,不会明显降低合金的导电性、导热性,而且可以提高合金的耐磨性,因此弥散强化铜合金既保留了铜基体优良的导电、导热性能,又显著改善了铜基体的强度,特别是高温强度[6-8]。弥散铜合金的制备方法主要有内氧化法、机械合金化法和化学沉淀法等。但直到1973年,美国SCM公司率先实现了内氧化工艺的精确控制,开发出C15715、C15725和C15760三种牌号的Al2O3弥散强化铜合金,并以Gildcop品牌进行市场推广,以Al2O3弥散强化铜合金为代表的纳米相增强铜合金才主要作为一种电阻焊接电极,在汽车车身焊接上得到大规模应用。与锡的固溶强化相比,Al2O3弥散强化铜合金具有更高的强度和硬度,而且在高温下具有高的硬度保持率和优异的抗高温软化性能[9],预期Al2O3弥散强化铜在改善铜基含油轴承的性能方面具有较好的应用潜力,有望满足日益严苛的使用工况。

本研究以内氧化法制备的弥散铜合金粉末为原料,与锡粉进行扩散处理制备弥散铜-锡合金粉末,经压制、烧结制备弥散铜-锡含油轴承,可为制备新一代高强度高精度铜基含油轴承提供参考,对于开拓弥散铜材料的新应用也具有借鉴意义。

1 实验

以内氧化法制备的粒径小于150 μm的弥散铜(含1.0%Al2O3,质量分数)粉末[10]和平均粒径为10 μm的雾化锡粉为原料,按弥散铜粉、锡粉质量比为90:10将二者混合均匀,在600~800 ℃进行1 h扩散合金化处理,经筛分、合批后制得弥散铜-锡合金粉末。在制备的成分均匀的弥散铜-锡合金粉末中加入0.5%的硬脂酸锌作为成形剂,在粉末冶金机械压机中自动、连续压制成密度为6.10 g/cm3的轴承压坯,其尺寸为 9.16 mm(外径)×d 6.08 mm(内径)×10.00 mm(高)。将轴承压坯置于氢气还原炉中,在750~950 ℃烧结1 h制备轴承试样。

采用X射线衍射(XRD)分析粉末的物相组成,采用霍尔流速计测试松装密度和流动性,采用金相显微镜(OM)和扫描电镜(SEM)观察微观组织和形貌,计算轴承的径向和轴向收缩率,按照GB/T 5163—2006标准测试密度和开孔率,借助显微硬度计测试显微硬度,通过万能试验机测试轴承的压溃强度,计算公式为:

(1)

(1)

式中:K为压溃强度,MPa;p为压溃力,N;D为轴承外径,mm;T为轴承壁厚,mm;b为轴承宽度,mm。

2 结果与讨论

2.1 弥散铜-锡扩散合金粉末的性能

制造青铜含油轴承常用的粉末包括铜粉与锡粉的混合粉、铜锡雾化合金粉和铜锡扩散合金粉。其中以混合粉为原料制成的轴承成分分布不均匀,轴承运转稳定性差,噪音大,使用寿命短;雾化合金粉成型性差,在烧结过程中无孔隙流出过程,开孔率低,轴承含油率难以达到使用要求;扩散合金粉解决了混合粉的偏析问题和雾化合金粉的含油率低等问题,成为制造高性能铜基含油轴承的主要原料[11-12]。本研究为获得成分均匀的粉末、控制烧结尺寸收缩率和获得良好的孔隙结构,采用扩散合金化法制备弥散铜-锡合金粉末。

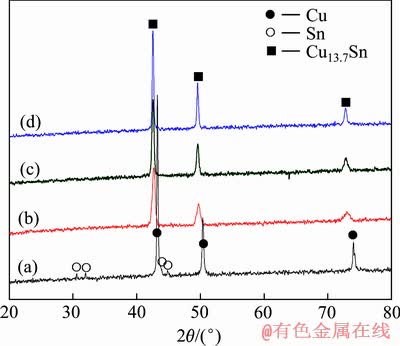

弥散铜-锡混合粉末及其经不同扩散温度处理后的XRD谱见图1所示。在混合粉末中,出现了Cu和Sn的衍射峰,其中Cu(111)面衍射峰的位置为2θ=43.24°,与纯Cu(111)面衍射峰的位置2θ=43.297°高度接近,表明原料粉末的内氧化过程完成得比较彻底,Al从CuAl合金粉中发生了较充分的脱溶生成Al2O3。由于弥散铜粉末中Al2O3含量较低(1.0%),尺寸较小(约为10 nm),图1(a)中未能探测到Al2O3的衍射峰[13]。经600 ℃扩散合金化处理后,衍射峰发生宽化,峰强显著减弱,Sn的衍射峰完全消失(见图1(b))。这是由于在扩散处理过程中,Sn向Cu中发生扩散并固溶于Cu基体中,Sn的原子半径大于Cu的原子半径,Sn的固溶使Cu基体晶格发生膨胀,点阵常数变大,故Cu的衍射峰向小角度发生偏移。经600 ℃扩散处理后Cu(111)面衍射峰位置为2θ=42.70°。当扩散温度提升至700 ℃时,Cu(111)面衍射峰继续向小角度偏移,位置为2θ=42.54°(见图1(c)),表明Sn发生进一步固溶。继续提升扩散温度至800 ℃,Cu(111)面衍射峰位置依然为2θ=42.54°(见图1(d))。与700 ℃相比,800 ℃扩散处理后衍射峰没有继续向小角度发生偏移,表明700 ℃时Sn发生充分固溶,形成成分稳定的α固溶体(Cu13.7Sn)。

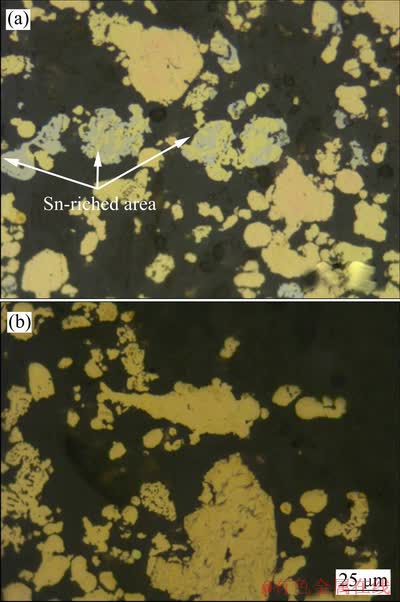

图2所示为弥散铜-锡混合粉末经不同扩散温度处理后的OM像。经600 ℃扩散处理后,粉末中有显著的富锡区存在(见图2(a))[14],这是由于扩散温度较低,锡未扩散均匀所致。当扩散温度提高至700 ℃时,未观察到富锡相,粉末成分均匀(见图2(b)),表明该温度下锡均匀扩散固溶至铜基体中。

图1 不同扩散温度处理后弥散铜-锡粉末的XRD谱

Fig. 1 XRD patterns of ODS copper-tin mixed powder(a) and diffusion alloying at 600 ℃(b), 700 ℃(c) and 800 ℃(d)

图2 不同扩散温度处理后弥散铜-锡粉末的OM像

Fig. 2 OM images of ODS copper-tin powders after diffusion alloying at 600 ℃(a) and 700 ℃(b)

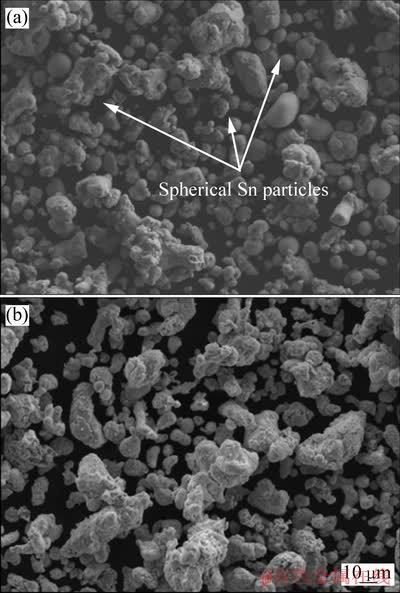

综合图1和图2可知,弥散铜-锡混合粉末适宜的扩散合金化温度为700 ℃,该温度下制备粉末的微观形貌如图3所示。与混合粉末(见图3(a))相比,经700 ℃扩散处理后,球形锡颗粒消失。与弥散铜粉末相比,弥散铜-锡合金粉末的形貌具有一定的“遗传性”和“继承性”[15],呈不规则形状,同时粉末粒径以<74 μm为主,粒径分布范围比较宽,经筛分、合批后,粉末松装密度为2.40 g/cm3,流动性为39.6 s (50 g)。

图3 不同扩散温度处理后弥散铜-锡粉末的SEM像

Fig. 3 SEM images of ODS copper-tin mixed powder(a) and after diffusion alloying at700 ℃(b)

2.2 轴承的烧结性能

2.2.1 微观形貌

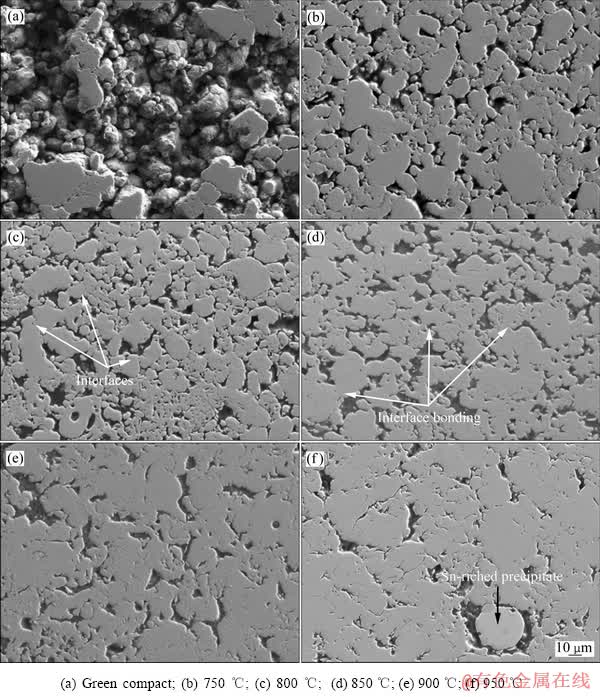

传统的青铜含油轴承在烧结时,当温度高于800 ℃时,由于α固溶体的固溶度开始迅速下降,基体中开始有锡及富锡相析出[16],导致轴承发生严重的尺寸畸变,因此其烧结温度一般不超过750 ℃。对于弥散铜-锡轴承压坯的烧结,考虑到弥散铜粉末的烧结稳定性,在接近铜熔点的温度仍能保持良好的外形[10, 17],因此,本研究采用的烧结温度较高(≥750 ℃)。当轴承压坯经750~900 ℃烧结后,其外观表现完好,没有不均匀的收缩变形。但当温度提升至950 ℃烧结时,轴承产生明显的不均匀变形,并且表面有块状析出物。

不同温度烧结后弥散铜-锡含油轴承的SEM像如图4所示。由于压坯密度较低,压坯中粉末颗粒外形完好,没有显著的压制变形,颗粒之间主要通过成形剂粘结在一起,压坯内存在大量孔隙(见图4(a))。经750 ℃和800 ℃烧结后,颗粒之间的界面大部分比较清晰,表明颗粒之间还没有形成充分的冶金结合。轴承中的孔隙主要为粉末颗粒之间的间隙,且两种烧结温度下的颗粒尺寸、孔隙数量和孔隙形状相近(见图4(b)和4(c))。当烧结温度升高至850 ℃时,颗粒之间形成了比较充分的冶金结合,从图4(d)中可以看到颗粒之间发生了明显的界面融合。与图4(b)和4(c)相比,图4(d)中颗粒间的微小孔数量有一定程度的减少,颗粒内部有一些较大尺寸的孔形成。进一步提升烧结温度至900 ℃,颗粒之间的界面融合更充分,颗粒尺寸也发生了明显长大,颗粒间的孔隙变得狭长,孔隙数量尤其小孔数量进一步减少,颗粒内部孔隙尺寸进一步增加,同时孔隙球化现象明显(见图4(e))。当烧结温度提升至950 ℃时,颗粒长大更加明显,孔隙数量急剧减少(见图4(f))。950 ℃烧结样品中还观察到了球形析出物,能谱结果表明其锡质量含量高达35%,为富锡的析出物,其形成原因是固溶的锡在高温烧结时从合金中发生脱溶所致。

图4 不同温度烧结后弥散铜-锡轴承的SEM像

Fig. 4 SEM images of ODS copper-tin bearings sintered at different temperatures

2.2.2 烧结收缩率

轴承压坯经950 ℃烧结后,尺寸畸变严重,并且表面有球形析出物,因此仅研究了750~900 ℃烧结后轴承的尺寸变化率。轴承烧结收缩率计算公式如下:

径向收缩率为

D=(D1-D2)/D1×100% (2)

轴向收缩率为

H=(H1-H2)/H1×100% (3)

式中:D1、D2分别为烧结前后轴承外径尺寸;H1、H2分别为烧结前后轴承高度尺寸。

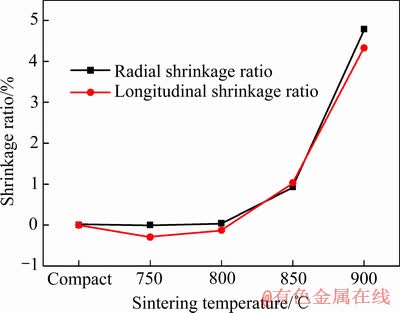

图5所示为不同烧结温度制备的弥散铜-锡含油轴承的收缩率。由图5可以看出,当烧结温度不超过800 ℃时,轴承径向和轴向尺寸变化率非常小,表明压坯没有发生显著的烧结收缩。当烧结温度为850 ℃,轴承的径向和轴向收缩率分别为0.93%和1.03%,两个方向的收缩率数值相近,表明在径向和轴向方向上发生了均匀的收缩,收缩率稳定性较好,方便控制轴承的尺寸,同时符合烧结金属含油轴承尺寸变化率不大于1.2%的要求[18]。当烧结温度提升至900 ℃时,径向和轴向的收缩率分别快速提升至4.79%和4.33%。

图5 不同烧结温度制备弥散铜-锡含油轴承的尺寸变化率

Fig. 5 Dimensional shrinkage ratio of ODS copper-tin oil bearings sintered at different temperatures

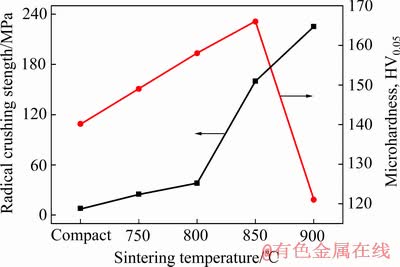

2.2.3 径向压溃强度和显微硬度

含油轴承的径向压溃强度(Radial crushing strength, RCS)直接影响轴承的使用寿命,是衡量轴承性能的重要指标。图6所示为不同温度烧结后制备弥散铜-锡含油轴承的径向压溃强度和显微硬度,由图6可以看出,在800 ℃及以下温度烧结时,轴承径向压溃强度很低,如800 ℃烧结后的压溃强度也仅为38 MPa。但当烧结温度提升至850 ℃时,径向压溃强度迅速提升至160 MPa,进一步提升烧结温度至900 ℃时,压溃强度增大至225 MPa。经750 ℃烧结的显微硬度略高于压坯的显微硬度(即弥散铜-锡合金粉末的显微硬度),在850 ℃以下随烧结温度的升高显微硬度线性增大,850 ℃时达到最大值,为166 HV0.05,而当烧结温度为 900 ℃时,显微硬度大幅下降至121 HV0.05。

烧结轴承的显微硬度主要与Al2O3粒子的弥散强化和锡的固溶强化有关。由于Al2O3在实验温度范围内均能保持良好的尺寸稳定性,所以显微硬度的变化主要与锡的固溶程度有关。虽然经700 ℃扩散合金化后锡已经较好地固溶于弥散铜基体中,但受扩散速率和扩散程度的影响,局部仍然会存在少量锡的成分起伏。随着烧结温度的提升,锡的均匀化程度会进一步提升,同时粉末颗粒之间冶金结合程度也逐渐增加,这些都有利于提升合金的显微硬度。因此在850 ℃以下温度烧结时,显微硬度随烧结温度的提升而增大。在900 ℃烧结时,由于锡从基体中发生脱溶,固溶强化作用减弱,所以显微硬度迅速降低。

图6 不同烧结温度制备弥散铜-锡含油轴承的径向压溃强度和显微硬度

Fig. 6 Radical crushing strength and micro-hardness of ODS copper-tin oil bearings sintered at different temperatures

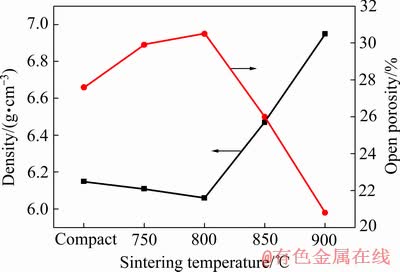

2.2.4 密度和开孔率

含油轴承的开孔隙率即有效孔隙度,是衡量轴承含油性能的重要指标。含油轴承的开孔率在数值上和轴承的含油率相同[18-19]。图7所示为不同温度烧结后制备弥散铜-锡含油轴承的密度和开孔率。由图7可以看出,在800 ℃及以下温度烧结时,由于轴承的轴向尺寸发生轻微膨胀(见图6),因此随烧结温度的升高,轴承密度有轻微的降低,并伴随着开孔率的缓慢提升,800 ℃时含油率达到最大值,为30.5%。此后随烧结温度的提升,轴承密度迅速提升,导致开孔率线性下降,850 ℃和900 ℃时相应的开孔率分别为26.0%和20.8%。

图7 不同烧结温度制备弥散铜-锡含油轴承的密度和开孔率

Fig. 7 Density and open porosity of ODS copper-tin oil bearings sintered at different temperatures

综合图4~7可知,经850 ℃烧结后,粉末颗粒之间形成了较好的冶金结合,轴承试样发生轻微收缩,径向和轴向收缩率均约为1.0%,压溃强度为160 MPa,显微硬度为166 HV0.05,开孔率为26.0%,该温度下制备的含油轴承具有最佳的综合性能,其压溃强度和开孔率均超过美国MPIF标准中青铜低石墨轴承的要求值[20]。

3 结论

1) 弥散铜粉末与锡粉经700 ℃、1 h扩散处理后,制备出成分均匀、松装密度为2.40 g/cm3、流动性为39.6 s (50 g)的弥散铜-锡合金粉末。

2) 弥散铜-锡轴承压坯在800 ℃及以下温度烧结时,粉末颗粒之间难以形成充分的冶金结合,轴承性能较差。当烧结温度为850 ℃时,粉末颗粒之间形成了较充分的冶金结合,轴承强度显著提升,开孔率小幅降低。进一步提升烧结温度至900 ℃及以上,烧结样品发生严重变形,开孔率也显著降低。

3) 850 ℃烧结制备的弥散铜-锡含油轴承具有最佳的综合性能,轴向、径向收缩率均约为1%,径向压溃强度为160 MPa,开孔隙率为26.0%,显微硬度为166 HV0.05。

REFERENCES

[1] MORGAN V T. Copper powder metallurgy for bearings[J]. International Journal of Powder Metallurgy, 1979, 15(4): 279-291.

[2] 贾成厂. 烧结金属含油轴承[J]. 金属世界, 2011(1): 28-34.

JIA Cheng-chang. Sintering metal oilless bearing[J]. Metal World, 2011(1): 28-34.

[3] üNLü B S, ATIK E. Evaluation of effect of alloy elements in copper based CuSn10 and CuZn30 bearings on tribological and mechanical properties[J]. Journal of Alloys and Compounds, 2010, 489: 262-268.

[4] 万新梁. 全球铜及铜合金粉末的生产现状及应用发展趋势[J]. 新材料产业, 2009(4): 28-36.

WAN Xin-liang. Production status and application development trend of global copper and copper alloy powders[J]. New Materials Industry, 2009(4): 28-36.

[5] 严 彪, 吴菊清, 李祖德, 葛昌纯. 现代粉末冶金手册[M]. 北京: 化学工业出版社, 2013: 307-311.

YAN Biao, WU Ju-qing, LI Zu-de, GE Chang-chun. Modern powder metallurgy handbook[M]. Beijing: Chemical Industry Press, 2013: 307-311.

[6] 程建奕, 汪明朴. 高强高导高耐热弥散强化铜合金的研究现状[J]. 材料导报, 2004, 18(2): 38-41.

CHENG Jian-yi, WANG Ming-pu. Progress in research on high-strength high-conductivity and high-heat resistance dispersion strengthened copper alloy[J]. Materials Review, 2004, 18(2): 38-41.

[7] Rajkovic V, Bozic D, Devecerski A, Jovanovic M T. Characteristic of copper matrix simultaneously reinforced with nano- and micro-sized Al2O3 particles[J]. Materials Characterization, 2012, 67: 129-137.

[8] Besterci M, KohUtek I, Velgosová O. Microstructural parameters of dispersion strengthened Cu-Al2O3 materials[J]. Journal of Materials and Science, 2008, 43: 900-905.

[9] YAN Z Q, CHEN F, YE F X, ZHANG D P, CAI Y X. Microstructures and properties of Al2O3 dispersion-strengthened copper alloys prepared through different methods[J]. International Journal of Minerals, Metallurgy and Materials, 2016, 23(12): 1437-1443.

[10] 闫志巧, 陈 峰, 蔡一湘. 高速压制法制备Al2O3弥散强化铜合金[J]. 中国有色金属学报, 2015, 25(3): 747-753.

YAN Zhi-qiao, CHEN Feng, CAI Yi-xiang. Al2O3 dispersion strengthened copper alloy prepared by high-velocity compaction[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(3): 747-753.

[11] 汪礼敏. 铜及铜合金粉末与制品[M]. 长沙: 中南大学出版社, 2010: 96-98.

WANG Li-min. Copper and copper alloy powders and products[M]. Changsha: Central South University Press, 2010: 96-98.

[12] 韩凤麟. 铜基粉末冶金的过去、现状及前景[J]. 粉末冶金工业, 2009, 19(1): 38-48.

HAN Feng-lin. Copper-based PM-part, present and future[J]. Powder Metallurgy Industry, 2009, 19(1): 38-48.

[13] Hwang S J, LEE J. Mechanochemical synthesis of Cu-Al2O3 nanocomposites[J]. Materials Science and Engineering A, 2005, 405(1/2): 140-146.

[14] 徐景杰, 马 飞, 张西超, 汪礼敏, 穆艳如, 刘一浪. 扩散CuSn10粉末烧结膨胀行为及影响因素的研究[J]. 粉末冶金工业, 2015, 25(5): 31-35.

XU Jing-jie, MA Fei, ZHANG Xi-chao, WANG Li-min, MU Yan-ru, LIU Yi-lang. Study on expansion and influence factors of diffusion CuSn10 powder compacts during sintering[J]. Powder Metallurgy Industry, 2015, 25(5): 31-35.

[15] 黄 蓉, 陈仕奇. 草酸盐共沉淀法制备Cu-Sn预合金粉末[J]. 粉末冶金材料科学与工程, 2010, 15(5): 525-529.

HUANG Rong, CHEN Shi-qi. Preparation of Cu-Sn prealloyed powder by oxalate co-precipitation method[J]. Materials Science and Engineering of Powder Metallurgy, 2010, 15(5): 525-529.

[16] 熊 洁, 汪礼敏, 庞鹏沙, 申 思. CuSn10 青铜粉末热压烧结行为及性能的研究[J]. 粉末冶金工业, 2008, 18(3): 18-21.

XIONG Jie, WANG Li-min, PANG Peng-sha, SHEN Si. Study on sintering behaviors and performance of 10%tin bronze powders[J]. Powder Metallurgy Industry, 2008, 18(3): 18-21.

[17] 陈 峰, 闫志巧, 蔡一湘. 内氧化-高速压制法制备Al2O3弥散强化铜合金的性能研究[J]. 功能材料, 2015, 46(8): 8133-8137.

CHEN Feng, YAN Zhi-qiao, CAI Yi-xiang. Properties of Al2O3 dispersion strengthened copper alloy prepared by internal oxidation and high-velocity compaction[J]. Functional Materials, 2015, 46(8): 8133-8137.

[18] 王聪聪, 贾成厂, 申承秀, 王春官, 常宇宏, 盖国胜, 杨玉芬. 球形化处理铜锡粉末制备CuSn10含油轴承[J]. 粉末冶金材料科学与工程, 2013, 18(4): 572-578.

WANG Cong-cong, JIA Cheng-chang, SHEN Cheng-xiu, WANG Chun-guan, CHANG Yu-hong, GAI Guo-sheng, YANG Yu-fen. CuSn10 oilless bearings prepared by sphericized powder[J]. Materials Science and Engineering of Powder Metallurgy, 2013, 18(4): 572-578.

[19] 董小江, 汪礼敏, 张景怀, 刘宇慧, 王林山. 不同形貌部分合金化CuSn10粉末对含油轴承烧结性能的影响[J]. 粉末冶金工业, 2010, 20(4): 28-32.

DONG Xiao-jiang, WANG Li-min, ZHANG Jing-huai, LIU Yu-hui, WANG Lin-shan. Influence of morphology of different partially alloyed CuSn10 powders on the sintering character of self lubricated bearings[J]. Powder Metallurgy Industry, 2010, 20(4): 28-32.

[20] 韩凤麟. 美国MPIF标准35“粉末冶金自润滑轴承材料标准”1998年修订简介[J]. 粉末冶金工业, 2000, 10(3): 36-47.

HAN Feng-lin. The 1998 revised introduction to MPIF Standard 35 material standards for P/M self-lubricating bearings[J]. Powder Metallurgy Industry, 2000, 10(3): 36-47.

Preparation and properties of Al2O3 dispersion-strengthened copper-tin oil bearings

YAN Zhi-qiao1, 2, CHEN Feng1, XU Rong-jun1, WANG Tao2, WU Xiang-tao3, ZHOU Zhong3

(1. Guangdong Institute of Materials and Processing, Guangdong Academy of Sciences, Guangzhou 510650, China;

2. Industrial Technology Incubation Center, Guangdong Academy of Sciences, Guangzhou 510650, China;

3. Infore Material-Tech Corp, Foshan 528311, China)

Abstract: With Al2O3 dispersion-strengthened copper (referred as “ODS copper”) powder prepared by internal oxidation method and atomized tin powder as raw materials, ODS copper-tin alloying powder was synthesized by diffusion alloying method, then pressed and sintered to prepare oil bearings. The effects of the diffusion temperature on the alloying degree of ODS copper-tin and the sintering temperature on performances of the oil bearings were investigated. The results indicate that tin is uniformly distributed in the ODS copper matrix after diffusion alloying at 700℃ for 1h and the as-prepared ODS-tin alloying powder has the apparent density of 2.40 g/cm3 as well as flowability of 39.6 s/(50 g). When the bearing compacts were sintered at temperatures no lower than 800 ℃, no significant metallurgical bonding occurs between the powder particles, which leading to poor performances. When increasing the sintering temperature to 850 ℃, metallurgical bonding is widely observed between powder particles, which remarkably improves the strength and slightly decreases the open porosity of the bearings. Once the sintering temperature exceeds 900 ℃, the bearings shrank significantly combined with sharply reducing of the open porosity. In this research, the ODS copper-tin oil bearings sintered at 850 ℃ have the best comprehensive properties with radial and axial shrinking ratio of about 1.0%, radical crushing strength of 160 MPa, microhardness of 166 HV0.05 and open porosity of 26.0%.

Key words: Al2O3 dispersion-strengthened copper; diffusion alloying; oil bearing; radial crushing strength; open porosity

Foundation item: Project(201907010022) supported by Guangzhou International Cooperation Program, China; Project (2016G1FC0007) supported by Zhongshan-Guangdong Academy of Sciences technology transfer special foundation, China; Project(2018GDASCX-0117) supported by Guangdong Academy of Sciences of Science and Technology Development, China; Project(2017A070701029) supported by Guangdong Public Welfare Research and Capacity Building, China; Projects(201707010145, ZWY201704003) supported by Guangzhou Science and Technology Planning, China

Received date: 2019-05-16; Accepted date: 2019-07-16

Corresponding author: CHEN Feng; Tel: +86-20-61086127; E-mail: chenfengcsu@163.com

(编辑 龙怀中)

基金项目:广州市对外科技合作项目(201907010022);中山市广东省科学院技术转移专项(2016G1FC0007);广东省科学院实施创新驱动发展能力建设专项(2018GDASCX-0117);广东省公益研究与能力建设项目(2017A070701029);广州市科技计划项目(201707010145,ZWY201704003)

收稿日期:2019-05-16;修订日期:2019-07-16

通信作者:陈 峰,高级工程师;电话:020-61086127;E-mail:chenfengcsu@163.com