文章编号:1004-0609(2010)10-2019-06

内氧化-冷轧制备Al2O3弥散强化铜合金的组织与性能

高 翔1,罗丰华1, 2,谭永菊1,付晓虎1,陈春辉1,崔建民2

(1. 中南大学 粉末冶金国家重点实验室,长沙 410083;

2. 莱芜钢铁集团粉末冶金有限公司,莱芜 271105)

摘 要:以Cu-0.15%(质量分数)Al合金粉末为原料、Cu2O为氧化剂,采用内氧化-冷轧法制备Al2O3弥散强化铜合金,研究合金的组织与性能。结果表明:由内氧化-冷轧法制备的合金的σb>520 MPa、σ0.2/σb>90%、电导率(IACS)也保持在80%以上;经950 ℃退火后,合金的σb>400 MPa;此合金具有高强、高导和优良的抗高温软化性能;冷轧态弥散强化铜合金的组织呈拉长变形的纤维状,试样断口分布有一定数量的韧窝;经950 ℃退火后,合金的纤维组织宽化,试样断口表面韧窝增多、变深,塑性提高。

关键词:铜合金;弥散强化铜合金;内氧化;冷轧

中图分类号:TB331 文献标志码:A

Microstructure and properties of Al2O3 dispersion strengthened copper alloys prepared by internal oxidation and cold rolling

GAO Xiang1, LUO Feng-hua1, 2, TAN Yong-ju1, FU Xiao-hu1, CHEN Chun-hui1, CUI Jian-min2

(1. State Key Laboratory for Powder Metallurgy, Central South University,Changsha, 410083, China;

2. Laiwu Iron & Steel Group Powder Metallurgy Co., Ltd., Laiwu 271105, China)

Abstract: With Cu-0.15%Al alloy powder and Cu2O powder as oxidant, alumina dispersion strengthened copper (ADSC) alloys were prepared by internal oxidation and cold rolling method. The properties and microstructures of those alloys were investigated. The results indicate that, σb values of the ADSC alloys are higher than 520 MPa; σ0.2/σb and relative conductivities of those alloys are more than 90% and 80% (IACS), respectively. Even after being annealed at 950 ℃, σb values of the alloys are more than 400 MPa. Those alloys have properties of high strength and high conductivity and possess appreciable ability to resist softening at higher temperature. The cold-rolled alloys show very fine, highly elongated fiber morphology; there are a certain amount of dimples in the fracture surface of the alloys. After being annealed at 950 ℃, those alloys show widened fiber morphology, increased amount of deepened dimples, resulting in improved tensile ductility.

Key words: copper alloys; dispersion strengthened copper alloys; internal oxidation; cold rolling

纯铜的室温、高温强度均较低,从而限制其在某些要求高电导率、高强度的元器件方面的应用[1-2]。Al2O3弥散强化铜合金拥有很高的室温和高温强度,且其导电、导热性能与纯铜相比相差不大,因此可以广泛应用于集成电路的引线框架、大型电气机车的架空导线、汽车和彩管行业中的电阻焊电极、大推力火箭发动机内衬等元器件[3-4],也可以应用于气割枪喷嘴、连铸机结晶器内衬等与导电性无直接关系而与导热性能有关的热交换装置[5-7]。

弥散强化铜的制备方法包括内氧化法、机械合金化法和溶胶-凝胶法等。其中,内氧化法是目前制备Al2O3弥散强化铜合金的实用方法[7-8]。传统内氧化法的工艺流程如下:Cu-Al合金熔炼→雾化制粉→添加氧化剂→内氧化→还原→压制→烧结→热挤压→机加工。

然而,传统内氧化法具有以下不足:由于热挤压成形前的烧结体是采用粉末冶金方法制得的,制品内会有一定量的孔隙存在,在高温下氧气容易扩散进入孔隙,从而与其反应。所以,现有的内氧化工艺中采用热挤压来使烧结体成形会导致制品的氧化,使最终产品的组织、性能不佳;而若采用气氛保护或在真空下进行热挤压等操作又需增加额外的设备,从而使成本大幅增加且工序繁杂。因此,本文作者采用烧结后冷等静压处理,提高致密度,再进行冷加工成形来取代热挤压等热加工工艺,避免热加工工艺所带来的不利影响,并探索烧结后冷加工成形的工艺方法,及制品的组织、性能情况。

1 实验

本实验中试样的制备工艺流程如下:雾化制备Cu-Al合金粉末→添加氧化剂→内氧化→还原→压制→烧结→致密化处理→冷加工成形。具体步骤如下。

1) 采用水雾化制得粒径小于47 μm的Cu-0.15%Al合金粉末。该合金粉末的理论Al2O3粒子生成量与ASTM-C15715(市场化商标为GlidCop? AL-15)相当。将Cu-Al合金粉与分析纯的Cu2O粉末混合均匀,Cu2O的量由3种不同的氧源因数k(1.0, 1.15, 1.30)决定。其中,氧源因数k的表达式如下:

(1)

(1)

式中: 是混合粉末中加入的Cu2O的实际质量;

是混合粉末中加入的Cu2O的实际质量; 是按化学方程式(2)计算的Cu2O的质量(假设反应完全进行且无多余的氧)。

是按化学方程式(2)计算的Cu2O的质量(假设反应完全进行且无多余的氧)。

(2)

(2)

由此计算出Cu-0.15%Al合金粉末与Cu2O粉末的质量比分别为84:1,73:1,64.6:1;k分别为1.00,1.15和1.30。

2) 将混合均匀的粉末经内氧化(950 ℃,1 h ,N2气氛)、还原(900 ℃,1 h,H2气氛)后,在600 MPa压力下压制成形并烧结(1 000 ℃,1 h,H2气氛),得到烧结态弥散强化铜样品,样品尺寸约为50 mm×10 mm×5 mm。

3) 将烧结态样品经200 MPa冷等静压致密化处理后,再冷轧成带状样品。2次退火间冷轧压下量依次为30%、40%和50%,即通过多道次轧制后试样厚度分别为3.5和2.1 mm时采取中间退火,中间退火工艺为800 ℃、保温1 h,H2气氛保护[9]。终轧后厚度约为1.0 mm。

终轧后沿轧制方向电火花线切割成条状样。用排水法测量烧结态及冷轧态样品的密度,在TH2512B型智能直流低电阻测试仪上测量烧结态和冷轧态样品的电阻。冷轧态样品在电阻炉中不同温度下退火60 min。采用HVS-1000显微维氏硬度计测量冷轧态和退火态样品的硬度,载荷为9.8 N,保压时间为30 s。在CTM4000三思电子万能试验机上进行拉伸试验,拉伸速率为1 mm/min,用10 mm引伸计测量应变大小。用MeF3A金相显微镜观察显微组织,金相样品侵蚀液为(10 g)重铬酸钾+(5 mL)浓硫酸+(80 mL)蒸馏水。用JSM-6360LV扫描电子显微镜观察拉伸试样的断口形貌。

2 结果与分析

2.1 合金的密度及电导率

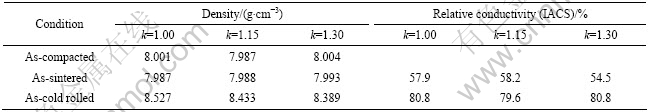

表1所列为不同状态下弥散强化铜合金的密度及相对电导率。

由表1可知,与压坯密度相比,烧结后样品的密度略有降低。这说明烧结过程中样品发生了膨胀。文献[10]的研究表明,当铜粉压坯孔隙度低于14%时,

表1 弥散强化铜合金的密度及相对电导率

Table 1 Densities and relative conductivities of dispersion strengthened copper alloys

烧结后样品根本不收缩,反而膨胀,且粉末越细,膨胀越显著。升温烧结时,由于铜的热膨胀系数较大而迅速膨胀,压坯内的残余内应力在烧结时急剧消除,压坯中的孔隙中残存有高压气体,导致烧结坯密度反而降低。本实验中3个合金的压坯密度约为8.0 g/cm3,致密度为90.5%(以C15715合金的标准密度8.84 g/cm3为参照),孔隙度低于10%,所以在烧结后样品发生轻微膨胀。

经过轧制变形后,样品的密度都有较大提高。k=1.00时,冷轧合金的密度达到8.527 g/cm3,即达到96.5%的致密度。但随着k值的增大,冷轧态合金的密度下降。k=1.15和1.30时,相应的致密度分别为 95.4%和94.9%。

烧结态样品的电导率并不高。这主要是因为烧结态样品中还有较多的孔洞,从而使材料的有效导电横截面降低。在3种不同Cu2O配比的烧结态合 金中,k为1.00和1.15时合金的电导率较高,都约为58%(IACS);而k=1.30时较低,只有54.5%IACS,这可能是由于添加的氧化剂含量较高,超过了Cu-0.15%Al合金粉末完全氧化的需求量,因此,有过量的[O]扩散粉末颗粒中。这些[O]在后续还原和烧结过程未能与氢充分反应,因而导电性下降。研究表明,对于不同的Cu-Al合金粉末,加入Cu2O的量有一个最佳的范围。如:对于Cu-0.2%Al,Cu2O过量10%~20%;对于Cu- 0.6%Al,Cu2O过量40%~60%[11-12]。

经过冷轧处理后,合金的电导率都有较大幅度提高,其中k为1.00和1.30时合金的电导率相当,达到了80.8%(IACS),虽然低于C15715合金的标准(92%(IACS)),但与高强高导铜合金(如铬青铜、铬锆青铜)的导电性相当,因此,也不失为一种好的高导电性合金。与烧结态合金不同,k为1.15的冷轧态合金的电导率略低 (79.6%(IACS))。由于3个合金都没有达到全致密状态,电导率没有达到C15715合金的标准也是可以理解的。

合金经过致密化处理和冷轧工艺后,在三向压应力的作用下,大量的孔隙闭合而使致密度提高,合金的导电性也大幅度提高。但是3个合金的电导率与致密度的关系并不完全对应,k为1.30的低致密度 (94.9%(IACS))合金与k为1.00的高致密度(96.5%(IACS))合金的电导率相当,而k=1.15的中间致密度(95.3%(IACS))合金的电导率略低,说明电导率的影响因素除了致密度外,还存在其他因素,如原始粉末颗粒间的结合界面状态、夹杂和残余的固溶Al元素等。经过轧制后合金的电导率似乎与Cu2O加入量的关系也不大。这可能是因为经过致密化处理和冷加工处理后,冷加工引起的亚结构强化效果有差异,合金中残存的[O]经冷轧-退火处理后会发生变化,Al2O3粒子的尺寸及其与基体的结合等也会有差别,这些因素都会造成导电性的变化。因此,合金的导电性不再是单纯随Cu2O的配比而发生变化了。

2.2 合金的力学性能

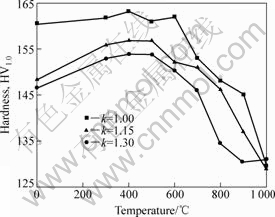

图1所示为冷轧态合金的硬度与退火温度的关系。在低于500 ℃退火时,退火后合金的硬度不仅没有降低,反而升高了。这种现象称为低温退火的硬化效应,即某些金属及合金在回复退火的温度下,硬度、强度,特别是屈服极限和弹性极限不仅不会降低,反而升高。大多数铜基及镍基合金存在这种硬化效应。目前认为,这种硬化效应最普遍的原因是,变形材料中的可动位错和退火时由多边化产生的位错壁中的可动位错发生闭锁[13]。

图1 不同Cu2O配比时退火温度对冷轧态合金硬度的影响

Fig.1 Influence of anneal temperature on hardness of cold rolled alloys with different Cu2O addition

在高于600 ℃退火时,合金的硬度开始降低,但3个合金硬度降低的程度与退火温度的关系并不相同。比如下降到140HV1.0,对应于k=1.00、1.15和1.30的3个合金的退火温度分别为930、870和750 ℃。可见,过量Cu2O有降低再结晶温度的趋势。

从图1还可以看出,当退火温度低于900℃时,随着k值的增大,合金的硬度下降。这可能与合金的密度有关系。从表1可知,合金的密度随着k值的增大而降低。但也可能与其它因素有关。比如说由于某种原因,添加的氧化剂流失,使Cu基体中的Al未完全氧化而从Cu基体的晶格中脱离出来,固溶在Cu基体中的Al会导致材料的硬度提高,那么随着k值的增加,Al的残余量降低,合金的硬度也是会降低的。

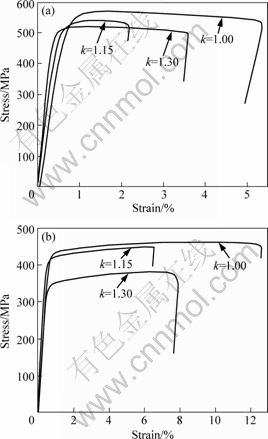

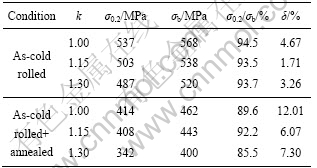

从不同退火态合金的硬度可以看出,退火温度高于900 ℃后,3种Cu2O配比的合金几乎都发生了完全再结晶软化。因此,选取在950 ℃温度下退火,考查3种Cu2O配比合金退火前、后拉伸性能的变化。图2所示为冷轧态及退火态合金的拉伸曲线,相应的拉伸性能数据示于表2中。

图2 冷轧态及退火态弥散强化铜合金的拉伸曲线

Fig.2 Tensile curves of cold-rolled and cold-rolled plus annealed alloys: (a) As-cold rolled; (b) As-cold rolled plus annealed

表2 冷轧态及退火态弥散强化铜合金的拉伸性能

Table 2 Tensile properties of cold-rolled and annealed alloys

由图2(a)及表2可见,经过冷轧加工后,k=1.00,1.15和1.30的3种成分配比合金的屈服强度(σ0.2)分别为537、503和487 MPa;抗拉强度σb分别为568、538和520 MPa;合金的屈强比σ0.2/σb分别为94.5%、93.5%和93.7%。与硬度的变化情况相似,屈服强度和抗拉强度都随着k的增加而降低,其原因同样可能与密度、残余Al固溶量等因素相关。

经950 ℃退火后,3种成分配比合金的强度有所下降,合金的屈服强度σ0.2分别为414、408和342 MPa;抗拉强度σb分别为462、443和400 MPa;合金的屈强比σ0.2/σb分别为89.6%、92.2%、85.5%。退火态合金的屈服强度和抗拉强度也随k的增加而降低。总的来说,3种合金退火态和冷轧态的强度和硬度都比较高,达到了C15715合金的强度指标。

很多铜合金都具有高的屈强比,但经过高温退火一段时间后这一比值会迅速降低。由表2中数据可 知,冷轧态弥散强化铜合金具有很高的屈强比 (>90%),且经过950℃退火1 h后,合金的屈强比还保持很高的数值(>85%)。这说明内氧化-冷轧法制备的弥散强化铜合金具有优良的抗高温软化性能[14-15]。

由图2(a)还可以看出,3种合金的应力—应变曲线上加工硬化段很短,即达到最大工程应力所需要的应变很小,而后出现了应力随着应变的增加而下降的现象。这说明3个冷轧合金在拉伸实验前已经承受了大的变形(40%),因此拉伸时硬化后迅速开始出现缩颈,缩颈变形造成局部横截面积减少而使得工程应力开始下降,断裂伸长率也比较小。而对应于退火态合金(见图2(b)),除了弹性变形外,应力-应变曲线上有一段比较长的加工硬化阶段,即应力随着应变的增加而增加阶段,使得3个合金的断裂伸长率也比较高。

另外,从图2还可以看出,无论是冷轧态还是退火态,k=1.00时合金的断裂伸长率最高,k=1.30时合金的断裂伸长率次之,而k=1.15时最小。k=1.00和1.30的2个合金的伸长率的差别可能与密度有关。但无论是冷轧态,还是退火态,k=1.15合金的断裂伸长率都是最小的。从表2可知,在冷轧态,k=1.15合金的电导率也比较小。如果这个合金存在类似原始颗粒界面结合不良的问题,那么其导电性差和伸长率低都是可以理解的。正是由于k=1.15合金的断裂伸长率小,使得退火态合金在屈服后迅速断裂,因此,其退火态的屈强比出现了异常(见表2)。

2.3 合金的显微组织

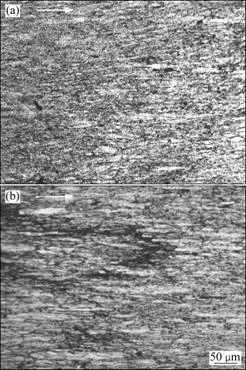

采用致密化处理后冷轧的方法代替传统的热挤压工艺,所获得的弥散强化铜合金具有较高的强度和抗高温软化能力,达到一般弥散强化铜的力学性能要求。通过分析合金的金相组织和断口形貌,讨论合金强度高和抗高温软化性能好的微观机制。由于3种合金的金相组织和断口形貌几乎相似,因此,只讨论k=1.15合金的金相组织和断口形貌。图3所示为k=1.15时,弥散强化铜合金轧向纵截面的金相组织,图中箭头所指方向为轧制方向。

图3 k=1.15时弥散强化铜合金的显微组织

Fig.3 Microstructures of dispersion strengthened copper alloys at k=1.15: (a) As-cold rolled; (b) Annealed at 950 ℃ for 1 h

由图3(a)可见,冷轧态弥散强化铜合金的轧制纵截面组织呈非常细小的纤维状,沿轧制方向晶粒被拉长变形,且颗粒界面已难以辨认。合金是从5 mm厚,经2次800 ℃中间退火轧制到约1 mm厚,由于800 ℃不足以引起完全再结晶(从图1的硬度结果可以得出这样的结论),也就是说终轧合金的实际变形量要大于50%(第二次中间退火后的总变形量),轧制后合金中形成了非常细密的纤维组织。合金在接近熔点的温度(950 ℃)退火后,仍然没有出现等轴再结晶晶粒组织,而是形成宽化的纤维组织(见图3(b)),表明该合金的再结晶阻力非常大。由于合金的强度和抗高温软化性能都与传统内氧化法制备的弥散强化铜的性能相近,并且具有较高的抗高温软化能力,可以判断合金中形成了具有弥散效果的Al2O3颗粒。从图3还可以看出,无论是冷轧组织还是退火组织,都有少量的孔洞存在,这些孔洞必然降低合金的密度、电导率,但似乎对力学性能影响不大。

图4所示为k=1.15时弥散强化铜合金的拉伸断口形貌。

图4 k=1.15时弥散强化铜合金的拉伸断口形貌

Fig.4 Fractographs of dispersion strengthened copper alloys at k=1.15: (a) As-cold rolled; (b) Annealed at 950 ℃ for 1 h

由图4(a)可见:冷轧态合金的拉伸断口出现长条状晶粒撕裂形貌,这种长条状组织可能由原始粉末压扁形成;韧窝较少,有沿颗粒间薄弱部位裂开的迹象,因此,冷轧合金的伸长率较低。与冷轧合金相比,950 ℃退火态合金的断口形貌上(见图4(b))出现了大量细小韧窝,因此,合金的伸长率较高。

3 结论

1) 由内氧化-冷轧法制备的弥散强化铜合金抗拉强度(σb)>520 MPa、屈强比(σ0.2/σb)>90%、相对电导率也保持在80%(IACS)以上。即使在950 ℃退火后,合金也保持着很高的强度(σb>400 MPa)和屈强比(σ0.2/σb>85%)。因此,该合金具有高强高导和优良的抗高温软化性能。

2) 冷轧态弥散强化铜合金的硬度随退火温度的升高先增加后降低,并在高于700 ℃的温度下退火后有不同程度的软化。

3) 冷轧态弥散强化铜合金的组织呈现出非常细小的、高度拉长变形的纤维状,且拉伸断口表面分布一定数量的韧窝;经950 ℃退火后,合金的纤维组织宽化,且拉伸断口表面的韧窝增多变深,塑性提高。

REFERENCES

[1] GUO Ming-xing, WANG Ming-pu, SHEN Kun, CAO Ling-lei, LEI Ruo-shan, LI Shu-mei. Effect of cold rolling on properties and microstructures of dispersion strengthened copper alloys[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(2): 333-339.

[2] GUO M X, WANG M P, CAO L F, LEI R S. Work softening characterization of alumina dispersion strengthened copper alloys[J]. Materials Characterization, 2007, 58(10): 928-935.

[3] 李美霞, 郭志猛, 赵奇特. 氧化铝弥散强化铜的研究进展及其应用[J]. 粉末冶金工业, 2008, 18(1): 36-40.

LI Mei-xia, GUO Zhi-meng, ZHAO Qi-te. Progress in and applications of copper-base alloys[J]. Powder Metallurgy Industry, 2008, 18(1): 36-40.

[4] KIM S H, LEE D N. Recrystallization of alumina dispersion strengthened copper strips[J]. Materials Science and Engineering A, 2001, 313(1/2): 24-33.

[5] 武建军, 雷廷权, 张 运, 姜延飞, 李国彬. 弥散强化铜基复合材料制备工艺[J]. 粉末冶金技术, 1999, 17(3): 195-200.

WU Jian-jun, LEI Ting-quan, ZHANG Yun, JIANG Yan-fei, LI Guo-bin. A new method to prepare dispersive strengthened copper matrix composites[J]. Powder Metallurgy Technology, 1999, 17(3): 195-200.

[6] 温宏权, 毛协民, 徐匡迪, 叶文博. 铜电车线材料的研究进展[J]. 材料导报, 1998, 12(1): 25-28.

WEN Hong-quan, MAO Xie-min, XU Kuang-di, YE Wen-bo. Progress of researches on copper cable materials[J]. Materials Review, 1998, 12(1): 25-28.

[7] LI Guo-bin, SUN Ji-bing, GUO Quan-mei, WANG Ru. Fabrication of the nanometer Al2O3/Cu composite by internal oxidation[J]. Journal of Materials Processing Technology, 2005, 170(1/2): 336-340.

[8] 曹先杰, 李娜娜. 内氧化工艺对弥散强化铜粉末强化质点特性和显微硬度的影响[J]. 矿冶工程, 2002, 22(3): 101-103.

CAO Xian-jie, LI Na-na. The effects of internal oxidation on the characteristics of reinforcing particles and the microhardness of the dispersion-strengthened copper powder[J]. Mining and Metallurgical Engineering, 2002, 22(3): 101-103.

[9] 罗丰华, 高 翔. 一种高强度高导电性氧化铝弥散强化铜的制备工艺: 中国. 2009103036998[P]. 2009-06-25.

LUO Feng-hua, GAO Xiang. Fabrication process of an alumina dispersion-strengthened copper with high strength and high electrical conductivity: CN. 2009103036998[P]. 2009-06-25.

[10] 黄培云. 粉末冶金原理[M]. 第2版. 北京: 冶金工业出版社, 1997: 296-297.

HUANG Pei-yun. Principles of powder metallurgy [M]. 2nd ed. Beijing: Metallurgical Industry Press, 1997: 296-297.

[11] SONG Ke-xing, XING Jian-dong, DONG Qi-ming, LIU Ping, TIAN Bao-hong, CAO Xian-jie. Internal oxidation of dilute Cu-Al alloy powders with oxidant of Cu2O[J]. Materials Science and Engineering A, 2004, 380(1/2): 117-122.

[12] KLAR E, NADKARNI A V, SAMAL P K. Oxygen-free dispersion-strengthened copper and process for making same: US. 4462845[P]. 1984-07-31.

[13] 李才巨, 黄素贞, 张代明, 朱心昆, 杨凤丽, 唐海林, 李 钢. 冷轧及退火工艺对纯铜力学性能的影响[J]. 金属热处理, 2007, 32(10): 66-68.

LI Cai-ju, HUANG Su-zhen, ZHANG Dai-ming, ZHU Xin-kun, YANG Feng-li, TANG Hai-lin, LI Gang. Effects of cold rolling and annealing on mechanical properties of pure copper[J]. Heat Treatment of Metals, 2007, 32(10): 66-68.

[14] AL-HAJRI M, MELENDEZ A, WOODS R, SRIVATSAN T S. Influence of heat treatment on tensile response of an oxide dispersion strengthened copper[J]. Journal of Alloys and Compounds, 1999, 290(1/2): 290-297.

[15] SRIVATSAN T S, NARENDRA N, TROXELL J D. Tensile deformation and fracture behavior of an oxide dispersion strengthened copper alloy[J]. Materials & Design, 2000, 21(3): 191-198.

(编辑 龙怀中)

基金项目:湖南省博士后科学基金资助项目(2009RS3027)

收稿日期:2009-10-09;修订日期:2010-03-01

通信作者:罗丰华,教授,博士;电话:0731-88830614;E-mail:fenghualuo@mail.csu.edu.cn