Mg-15Gd-0.6Zr合金的组织与力学性能

肖 阳, 张新明, 陈健美, 蒋 浩

(中南大学 材料科学与工程学院, 长沙 410083)

摘 要: 通过在Mg-Gd二元合金中添加少量的Zr后制备一种新型的Mg-15Gd-0.6Zr合金, 并对合金的微观组织、 时效特性和不同温度下的力学性能及拉伸断裂方式进行研究。 合金在非平衡凝固过程中容易形成MgxGd(x=2, 3, 5)相, 但用热处理的方法几乎不可能消除。 在合金的Cast-T5、 Cast-T6、 Ext-T5和Ext-T6的4种时效状态中, Ext-T5态达到峰值硬度的时间最短, 峰值硬度值最高; 而Cast-T5态的则相反。 合金具有较高的耐热强度和延伸率, 其在不同温度下的抗拉强度与WE54的相当, 而延伸率明显优于WE54及其它耐热镁合金的。 合金在25℃时的断裂方式以准解理断裂为主, 而250℃时的断裂方式以微孔聚集型断裂为主, 300℃和350℃时的断裂方式以典型的微孔聚集型断裂为主。

关键词: Mg-Gd-Zr合金; 耐热镁合金; 微观组织; 力学性能; 时效特性; 断裂方式 中图分类号: TG146.2

文献标识码: A

Microstructures and mechanical properties of Mg-15Gd-0.6Zr alloy

XIAO Yang, ZHANG Xin-ming, CHEN Jian-mei, JIANG Hao

(School of Materials Science and Engineering, Central South University,Changsha 410083, China)

Abstract: A new Mg-15Gd-0.6Zr alloy was developed by adding minor Zr to Mg-Gd binary alloy. The microstructures, aging characteristics, mechanical properties and fracture modes at 25, 250, 300 and 350℃ were investigated. A large number of MgxGd (x=2, 3, 5) phases form due to non-equilbrium solidification which can be hardly eliminated by subsequent heat treatments. Among Cast-T5, Cast-T6, Ext-T5 and Ext-T6, the highest hardness in the shortest time is in the Ext-T5 temper, while the lowest hardness in the longest time is in the Cast-T5. The tensile strengths of the alloy at the studied temperatures are as high as that of WE54 alloy, but the elongations are higher than those of WE54 alloy and some other conventional heat resistant magnesium alloys. The fracture modes of quasi-cleavage and microviod coalescence are dominant at 25 and 250℃, respectively, while at 300 and 350℃, the typical microviod coalescence are observed.

Key words: Mg-Gd-Zr alloy; heat-resistant magnesium alloy; microstructures; mechanical properties; aging characteristics; fracture mode

加入稀土元素合金化能显著提高镁材料的强度和耐热温度[1-2], 国外已将耐热镁稀土合金应用到导弹舱体、 卫星结构件、 飞船框架、 发动机引擎盖、 发动机汽缸体和变速箱壳体等零部件上。 Mg-Y-Nd系中WE54合金已成为目前公认的优秀商业化耐热镁合金, 其耐热温度可达300℃。 我国目前使用较好的耐热镁合金是ZM6, 其耐热温度可达250℃。 由于国内外在耐热镁合金方面存在着巨大的差距, 因此在我国研发出新型的高性能耐热镁合金势在必行。

镁稀土合金的发展历程从Mg-Re系、 Mg-Th系、 Mg-Y系过渡到目前的Mg-Gd系合金。 由于Mg与Gd间的原子间结合力大, Gd与Mg的原子半径差接近固溶上限的15%, 且Gd在Mg中的固溶度可达23.5%(质量分数), 合金的固溶强化和时效强化效果明显。 时效析出的Mg5Gd相的熔点高、 热稳定性好, 致使Mg-Gd系合金具有强度高、 耐热性好的优点[3]。 美国空军部的技术报告中曾指出Mg-Gd系合金在航空航天领域中有着非常好的应用前景[4]。

Drits等[5-7]最早对Mg-Gd二元合金的力学性能进行了研究, 发现Mg-22Gd合金的室温强度可达到400 MPa以上、 耐热温度可达到350℃, 但其室温下的延伸率不到2%, 低的延伸率严重限制了其应用。 日本学者也对Mg-Gd二元合金在不同温度下的力学性能进行了研究[8-10], 认为含Gd量小于10%的Mg-Gd二元合金尽管其延伸率可达到10%, 但含Gd量较少, 引起时效析出的强化相也较少, 导致合金的强度和耐热性能较差; 含Gd量大于20%的Mg-Gd二元合金的强度高, 但延伸率却极低; Mg-15Gd合金的强度、 延伸率及耐热性则介于两者之间, 其综合性能较好。 Zr在镁合金中是一种非常有效的晶粒细化剂[11], 本文作者尝试在Mg-15Gd合金中加入少量的Zr, 分析Mg-15Gd-0.6Zr合金的组织与力学性能, 为今后的耐热镁合金设计提供实验依据。 目前, 国内外还没有关于Mg-Gd-Zr三元合金的相关文献报道。

1 实验

用普通电阻炉进行熔炼, 合金元素以Mg-24%Gd和Mg-30%Zr中间合金的形式添加, 用自制的熔剂进行熔体表面覆盖, 合金的熔炼及浇造温度分别为780和760℃, 熔体浇注到d60mm×150mm的薄壁铁筒中进行水冷成锭, 铸锭的冷却速度保证在1min内冷却到100℃以下。 合金成分在JY38S型等离子体原子光谱仪上进行分析, 分析结果为Gd-13.5%、 Zr-0.4%、 Mg为余量。

铸锭在520℃进行24h的均匀化退火, 用500t的挤压机进行正向挤压, 挤压温度为430℃, 挤压比λ=16, 挤压速率为1m/min。

对合金的铸态、 铸锭固溶态、 挤压态和挤压固溶态在225℃进行不同时间的时效, 其中铸锭固溶工艺为520℃保温24h后水淬, 挤压棒材的固溶工艺为520℃保温2h后水淬。 用HV-10型小负荷维氏硬度计测量合金时效后的硬度, 载荷为98N, 加载时间为30s。 通过硬度测量选择硬度值最高的时效状态, 然后比较这种状态在200、 225和250℃ 3种温度下的力学性能, 分析了温度对时效性能的影响。

拉伸试棒沿挤压棒材的纵向取样、 并按GB6397—86标准统一制成d8mm的短比例试样。 在CSS44100电子万能试验机上进行室温拉伸, 拉伸方法按照GB/T228—2002标准进行; 在Instron 8032试验机上进行高温拉伸, 拉伸方法按照GB/T4338—1995标准进行, 预设的实验温度保证在1h内升到, 试样经15min的保温后开始加载拉伸。 室温和高温的拉伸速率统一为0.5mm/min。 用D/max-rA型转靶X射线衍射仪进行相分析, 用XJP-6A型立式光学显微镜进行金相观察, 用KYKY2800型扫描电镜和Sirion200场发射扫描电镜及附带的Genesis 60S能谱分析仪进行组织分析。

2 结果与分析

2.1 合金的微观组织

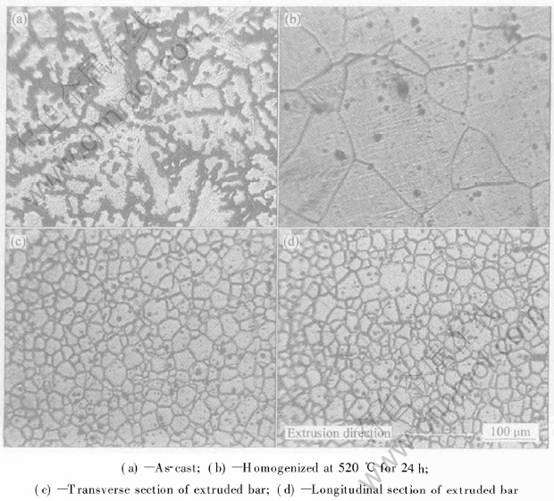

图1所示为合金铸态、 铸锭固溶态和挤压态的纵截面和横截面金相组织。 文中没有给出合金的时效组织, 因为时效析出相的尺寸较小, 用金相显微镜分辨不出时效前后组织的差异。

图1(a)所示为合金的铸态组织。 可看出, 合金在凝固过程中产生大量的枝晶, Gd元素在枝晶臂上富集。 图1(b)所示为合金经过520℃、 24h均匀化退火后的组织。 可看出, 合金的枝晶偏析消除, 晶界清晰, 晶粒大小为50~200μm, 枝晶的消除表明合金的均匀化工艺制定基本合理, 但在晶内还存在未能溶解的黑色相。 图1(c)和(d)所示分别为挤压棒材的横截面和纵截面组织。 由图1(c)和(d)可看出, 挤压棒材的纵截面和横截面的晶粒都呈等轴状, 表明合金在挤压过程中已发生动态再结晶, 这是由于镁合金的层错能较低的缘故[12]。 挤压后晶粒明显细化, 平均晶粒大小约20μm, 未能溶解的黑色相沿挤压方向被拉长或破碎。

为确定金相组织中的黑色相, 对其进行X射线衍射分析, 结果如图2所示。 合金均匀化退火后含有Mg5Gd、 Mg3Gd及Mg2Gd相。 在Mg-Gd-Zr三元合金中, Mg与Zr不形成化合物相。 Gd与Zr也不形成化合物相。 根据二元相图, Mg与Gd在548、 658、 720和756℃分别形成Mg5Gd、 Mg3Gd、 Mg2Gd、 MgGd相, 其中Mg5Gd相的形成温度为548℃, Mg-Gd二元合金的共晶点(熔点)[13]。 而组织中含有Mg5Gd、 Mg3Gd、 Mg2Gd相, 都高于合金均匀化和固溶处理的温度(温度不能高于共晶点), 这是用热处理工艺无法消除的。

图1 Mg-15Gd-0.6Zr合金的金相组织

Fig.1 Optical microstructures of Mg-15Gd-0.6Zr alloy

2 合金均匀退火后的X射线衍射谱

Fig.2 XRD pattern of homogenized alloy

这些MgxGd(x=2, 3, 5)相是合金在非平衡凝固过程中偏析形成的, 其中Mg3Gd和Mg2Gd的形成温度都高于镁的熔点, 因此在合金非平衡凝固的局部区域中, 熔体还没有凝固时, Mg3Gd和Mg2Gd相已经形成, Mg3Gd和Mg2Gd相的形成减少Gd的固溶量。 在随后的时效过程中, 析出强化相Mg5Gd的数量也相应减少, 使Gd元素产生固溶强化和时效强化效果减少, 降低合金的力学性能。

图3所示为对图1(d)中的黑色相进行扫描观察和能谱分析。 图3(a)所示为在金相显微镜下观察到的黑色相用扫描电镜观察则为白色相。 图3(b)所示为对白色相进行放大观察, 白色相都具有规则的立方结构, 在晶界附近分布的数量明显要多于晶内, 其大小多在1~2μm之间。 对白色相的多次能谱的分析表明, 白色相中Gd与Mg的摩尔比多为3∶1(见图中右上角), 因此断定组织中的白色相多为Mg3Gd。 由于Mg2Gd的形成温度为720℃, 且需要33.3%(摩尔分数)的Gd, 因此形成Mg2Gd的数量很少, 且Mg2Gd在随后凝固过程中还会发生包晶反应: L+Mg2Gd→Mg3Gd, Mg2Gd易包裹在Mg3Gd相内, 因此在扫描电镜下不易找到; Mg5Gd相在扫描电镜下没有观察到, 可能是形成的Mg5Gd相尺寸比较小的缘故。

图3 挤压棒材的扫描组织及第二相能谱分析

Fig.3 SEM image of extruded bar(a) and EDS analysis of second phases(b)

2.2 合金的时效特性

Gd在镁中于548℃时的固溶度为23.5%, 当温度降低到200℃时, Gd在镁中的溶解度会急剧下降到3.8%[13], 合金在这一过程中会析出强化相Mg5Gd, 从而使强度和硬度得到提高。 合金经过固溶处理后会增加Gd在镁中的固溶度, 在随后的时效中析出强化相数量会增加, 提高时效温度会减少析出相的数量, 析出相的多少影响合金的性能。

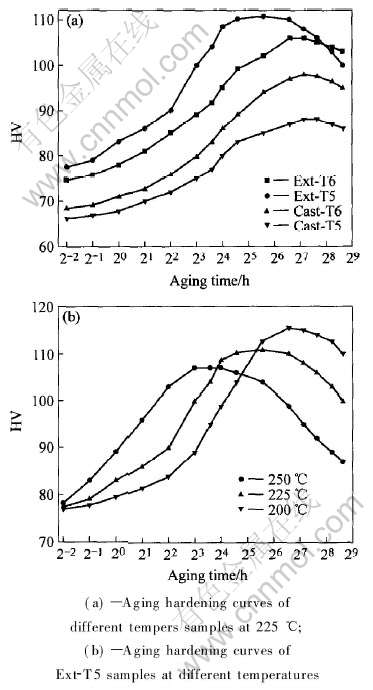

图4所示为用硬度法测量Mg-15Gd-0.6Zr合金不同热处理状态和不同温度下的时效硬化特性。 图4(a)所示为合金的4种不同状态在225℃的时效硬化曲线。 其中铸态直接时效(Cast-T5)到达峰值硬度所需时间最长(140h), 峰值硬度值(HV88)最小。 由于熔铸过程中合金元素的偏析、 产生过饱和固溶体的数量较少, 导致析出强化相的动力小, 析出所需的时间长, 析出强化相的数量也少。

图4 Mg-15Gd-0.6Zr合金的时效硬化曲线

Fig.4 Aging hardening curves of Mg-15Gd-0.6Zr alloy

铸态合金进行520℃, 24h固溶处理后, 时效(Cast-T6)的峰值硬度值(HV98)要高于Cast-T5态。 由于固溶处理消除了铸态中的枝晶偏析, 使合金元素在镁基体中均匀分布并充分固溶, 在随后的时效过程中, 析出强化相的数量要多于铸态时效样品的, Cast-T6态达到峰值的时间与Cast-T5态的相同。

挤压后直接时效(Ext-T5)达到峰值硬度的时间最短(24h), 峰值硬度值最高(HV111)。 由于挤压后晶粒得到明显的细化(见图1), 合金挤压后的硬度值(HV76)比其它状态高, 同时挤压组织中还存在着位错产生的强化效果和加工产生的贮能, 使合金的硬度值最高、 达到峰值的时间最短。 但该状态在峰值阶段持续的时间最短, 在时效时间达到200h后, 硬度开始急剧下降, 说明该状态的热稳定性相对于其它状态要差。

挤压固溶处理后时效(Ext-T6)的峰值硬度值(HV106)要高于Cast-T6态的。 由于挤压使铸态组织被充分破碎, 第二相弥散分布, 强化相析出的数量也要多于Cast-T6态的, 但要低于Ext-T5态的。 由于固溶处理消除加工过程中产生的位错, 且固溶处理会使合金的晶粒长大(加工过程中已经完成了再结晶), 因此该状态的硬度值低于Ext-T5态的, 达到峰值的时间(96h)也较长, 但热稳定性比Ext-T5态的要好。

由于合金的4种状态中Ext-T5态的硬度值最高, 达到峰值时间最短, 因此选择该状态在200、 225和250℃ 3种温度下的时效性能进行比较(见图4(b))。

Ext-T5态在200℃时效的峰值硬度值最高(116), 达到峰值时间最长(96h), 在250℃时效的峰值硬度值最低(HV107), 达到峰值时间最短(8h)。 这是由于时效温度越高, 析出强化相脱溶的驱动能越大, 析出所需的时间就越短, 但析出相的数量相应要少, 时效强化的效果要降低的缘故。 225℃的时效峰值硬度和达到峰值的时间介于200和250℃之间。

2.3 合金的力学性能

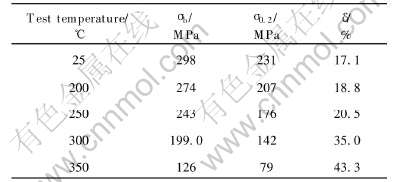

根据图4表现出来的时效特性, 选用合金的挤压棒材在225℃经24h峰值时效后进行室温和高温拉伸, 拉伸结果如表1所列。 合金在温度达到250℃前, 具有非常好的热稳定性; 当温度达到300℃时, 合金的强度开始快速下降; 当温度达到350℃时, 强度急剧下降到126MPa, 这可能达到了合金的耐热极限温度。 经测量合金的密度为1.97g/cm3, 合金具有比铝合金更明显的比强度优势。

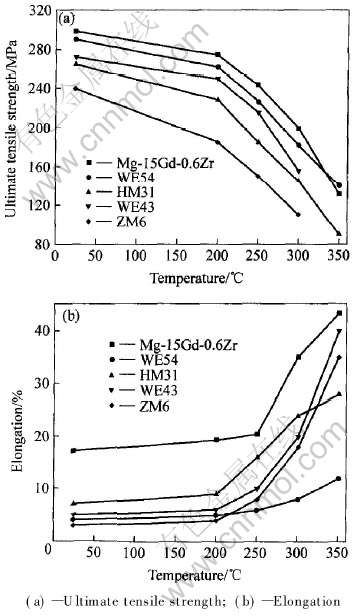

图5所示为耐热镁稀土合金的力学性能比较(其它镁稀土合金的数据来自文献[14])。 从图5(a)中可看出, Mg-15Gd-0.6Zr合金在不同温度下的强

表1 Mg-15Gd-0.6Zr合金Ext-T5态的拉伸性能

Table 1 Tensile properties of Mg-15Gd-0.6Zr alloy in Ext-T5 temper

度明显高于比WE43、 HM31和ZM6合金的, 但合金在350℃时的强度略低于WE54的。 从图5(b)中可看出, Mg-15Gd-0.6Zr合金具有非常高的延伸率, 特别是在室温下, 其延伸达到17.1%, 远远大于其它耐热镁合金的延伸率。 WE54合金正是由于室温的延伸率较低而限制了其应用, 随后开发出WE43合金是通过降低WE54耐热强度的方法来提高延伸率。 因此从综合力学性能方面来比较, Mg-15Gd-0.6Zr合金应该优于WE54合金。

图5 耐热镁稀土合金力学性能的比较

Fig.5 Comparison of tensile properties of heat-resistant Mg-rare earth alloys at different elevated temperatures

2.4 拉伸断口分析

金属在不同温度下的塑性由其变形机制来决定, 变形中滑移系开动的多少及难易程度决定其断裂方式。 由于镁是非对称的密排六方结构, 室温下的塑性变形限于基面{0001} 滑移及锥面

滑移及锥面

孪生, 塑性较差。 当温度达到225℃以上, 镁原子振动的振幅增大, 使得最密排面和次密排面的差别减少, 使角锥滑移面

孪生, 塑性较差。 当温度达到225℃以上, 镁原子振动的振幅增大, 使得最密排面和次密排面的差别减少, 使角锥滑移面 和

和 启动, 塑性得到明显提高。 当温度达到300℃以上时, 基面、 柱面和锥面的滑移系都能开动, 合金进入多系滑移, 因此合金的塑性较好[15]。

启动, 塑性得到明显提高。 当温度达到300℃以上时, 基面、 柱面和锥面的滑移系都能开动, 合金进入多系滑移, 因此合金的塑性较好[15]。

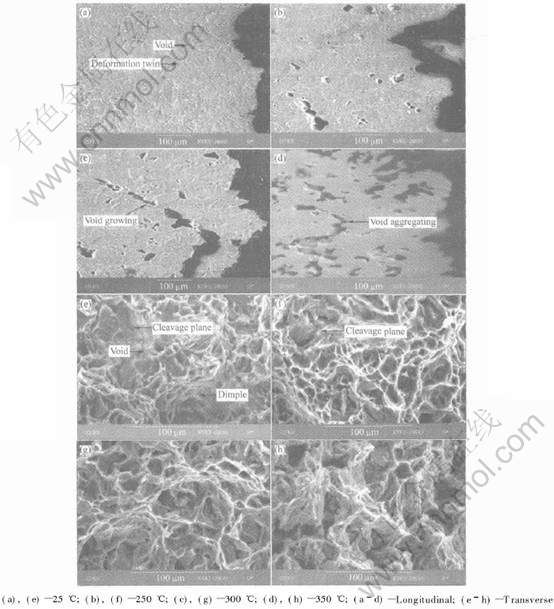

图6所示为Mg-15Gd-0.6Zr合金Ext-T5态在不同温度下拉伸的纵向断口和横向断口的扫描组织。 从中可分析出合金在不同温度下的断裂方式。

图6(a)和(e)所示分别为试样在25℃拉伸的纵向和横向断口。 可看出, 25℃拉伸的纵向断口部分晶粒内有孪晶存在, 在断口的附近有裂纹扩展形成的小空洞; 在横向断口中可看出, 由于滑移系较少形成局部的解理断裂, 解理面上分布着高度不一的解理台阶, 在各个解理面之间的存在着撕裂棱形成的浅平状韧窝和小空洞。 从总体上来看, 该温度下的断裂方式以准解理断裂为主。

图6(b)和(f)所示分别为250℃拉伸的纵向和横向断口。 在纵向断口中可看出, 空洞的尺寸明显比25℃的大, 横向断口可看到由第二相粒子阻碍变形产生的大量韧窝状花样, 部分韧窝随着变形程度的加大演变成空洞, 尽管组织局部还存在着解理断裂, 但该温度下的断裂方式以微孔聚集型断裂为主。

图6 合金Ext-T5态在不同温度下拉伸断口的纵向和横向微观组织

Fig.6 Microstructures of longitudinal and transverse sections of fracture surfaces of Ext-T5 samples at different temperatures

图6(c)、 (g)和(d)、 (h)所示分别为300和350℃的拉伸的纵向和横向断口。 由图6(c)、 (d)、 (g)和(h)可看出, 随着变形温度的升高和变形程度的加大, 晶粒明显被拉长, 进一步增加了韧窝的深度和空洞的尺寸, 空洞沿晶界长大和聚合, 最终导致断裂, 组织中不再出现局部的解理断裂; 350℃的横向断口表面因高温已氧化, 还能看出空洞的聚合使部分晶粒沿晶界开始分离。 总之, 300和350℃的断口特征为典型的微孔聚集型断裂。

综上所述, Mg-15Gd-0.6Zr合金断裂方式在25℃时是以准解理断裂为主, 250℃时是以微孔聚集型断裂为主, 300和350℃时为典型的微孔聚集型断裂。

3 结论

1) 合金在非平衡凝固过程中容易形成大量的MgxGd(x=2, 3, 5)相, 这些相用热处理的方法几乎不可能消除。

2) 在合金的Cast-T5、 Cast-T6、 Ext-T5和Ext-T6的4种时效状态中, Ext-T5态达到峰值硬度的时间最短, 峰值硬度值最高; Cast-T5态的恰好相反。 合金Ext-T5态在200、 225和250℃的3种时效温度中, 其中200℃时效的峰值硬度值最高, 所需时间也最长; 而250℃的时效性能则恰好相反。

3) 合金具有较高的耐热强度和延伸率, 其在不同温度下的抗拉强度与WE54的相当, 而延伸率明显优于WE54及其它的耐热镁合金的。

4) Mg-15Gd-0.6Zr合金在不同温度下拉伸的断裂方式也不一样。 25℃时的断裂方式以准解理断裂为主, 250℃时的断裂方式以微孔聚集型断裂为主, 300和350℃时的为典型微孔聚集型断裂。

REFERENCES

[1]Mordike B L. Creep-resistant magnesium alloys[J]. Mater Sci Eng A, 2002, 324: 103-112.

[2]Maruyama K, Suzuki M, Sato H. Creep strength of magnesium-based alloys[J]. Metallurgical and Materials Transactions A, 2002, 33(3): 875-882.

[3]Drits M E, Sviderskaya Z A, Rokhlin L L, et al. Effect of alloying on the properties of Mg-Gd alloys[J]. Metallovedenie I Termicheskaya Obrabotla Metallov, 1979, 21(11): 62-66.

[4]Department of Air Force. Development of magnesium alloys for aerospace use[R]. 10-147830, Washington, DC: Department of AirForce, 1989.

[5]Drits M E, Rokhlin L L, Oreshkina A A, et al. Principles of alloying heat-resistant alloys based on magnesium[J]. Metally, 1982(5): 98-103.

[6]Rokhlin L L, Nikitina N I. Electron-microscopic investigation of the structure of a precipitated supersaturated Mg-22wt.%Gd solid solution[J]. Fizika Metallov I Metallovedenie, 1986, 62(4): 781-787.

[7]Sukhanov V D, Dobromyslov A V, Rokhlin L L, et al. Decomposition of supersaturated solid solutions Mg-Ho and Mg-Gd[J]. Fizika Metallov I Metallovedenie, 2002, 94(3): 72-81.

[8]Shigeharu K, Shigeru I, Kiyoaki O, et al. Age hardening characteristics and high temperature strength of Mg-Gd and Mg-Tb alloys[J]. Journal of Japan Institute of Light Metals, 1992, 42(12): 727-733.

[9]Shigeru I, Yuji N, Shigeharu K, et al. Age hardening characteristics and high temperature tensile properties of Mg-Gd and Mg-Dy alloys[J]. Journal of Japan Institute of Light Metals, 1994, 44(1): 1-8.

[10]Shigeharu K, Shigeru I, Shigeharu K, et al. Effect of yttrium and neodymium additions on aging characteristics and high temperature tensile properties of Mg-10%Gd and Mg-10%Dy alloys[J]. Journal of Japan Institute of Light Metals, 1994, 44(10): 549-554.

[11]彭卓凯, 张新明, 陈健美, 等. Mn, Zr对Mg-Gd-Y合金组织与力学性能的影响[J]. 中国有色金属学报, 2005, 15(6): 917-922.

PENG Zhuo-kai, ZHANG Xin-ming, CHEN Jian-mei, et al. Effects of Mn, Zr on Microstructure and properties of Mg-Gd-Y alloys[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(6): 917-922.

[12]陈振华. 变形镁合金[M]. 北京: 化学工业出版社, 2005: 149-153.

CHEN Zhen-hua. Wrought Magnesium Alloy[M]. Beijing: Chemical Industry Press, 2005: 149-153.

[13]Manfrinetti P, Gschneidner K A. Phase equilibrium in the La-Mg(0-65at.% Mg) and Gd-Mg systems[J]. Less-Common Metals, 1986, 123: 267-275.

[14]Cahn R W. 非铁合金的结构和性能[M]. 丁道云, 译. 北京: 科学出版社, 1999: 109-142.

Cahn R W. Structure and Properties of Nonferrous Alloys[M]. DING Dao-yun, transl. Beijing: Science Press, 1999: 109-142.

[15]陈振华. 镁合金[M]. 北京: 化学工业出版社, 2004: 202.

CHEN Zhen-hua. Magnesium Alloy[M]. Beijing: Chemical Industry Press, 2004: 202.

(编辑李艳红)

基金项目: 国家重点基础研究发展规划资助项目(5133001E)

收稿日期: 2006-03-14; 修订日期: 2006-07-07

通讯作者: 张新明, 教授; 电话: 0731-8830265; E-mail: xmzhang@mail.csu.edu.cn.