文章编号:1004-0609(2016)-08-1774-08

电解锰生产流程中物流对理想能耗的影响

王洪才1, 2,时章明1, 3,刘 波1,陈 波1,杨钦皓1,叶 铮1

(1. 中南大学 能源科学与工程学院,长沙 410083;

2. 中南大学 流程工业节能湖南省重点实验室,长沙 410083;

3. 湖南节能评价技术研究中心,长沙 410083)

摘 要:为定量分析电解锰生产流程的能源利用情况,以钢铁生产流程的“基准物流图”概念为基础,建立电解锰生产流程的理想物流图,提出理想能耗的计算方法。以某电解锰企业生产数据为依据,绘制该电解锰生产流程的实际物流图和理想物流图,计算出电解锰单位产品理想能耗为22.32 GJ/t,并定量分析各类物流变化对电解锰理想能耗的影响。结果表明:在电解锰生产流程中,当出现α物流时,将使能耗降低,有利于节能;当出现β和γ物流时,将使能耗增加,而且越是后部工序出现这两种物流,能耗增加的越多。为降低电解锰能耗,应降低外排矿渣和阳极泥中Mn元素的含量,使各道工序中的含Mn物流尽量多地输入到下一道工序。

关键词:电解锰;物流;理想物流图;理想能耗

中图分类号:TF792 文献标志码:A

电解金属锰生产是典型的高能耗、高污染、资源性的“两高一资”行业。我国电解锰产能和产量的全球占比均超过98%,是世界最大的电解锰生产国、消费国和出口国[1],提高电解锰能效水平已引起社会的广泛重视。目前,国内外学者主要从电解锰清洁生产技术[2-5]、电解槽应用技术[6-8]、电解锰阳极渣还原[9-10]以及电解锰污染防治[11-12]等方面对电解锰生产工艺进行研究,但对电解锰生产过程中各工序能源利用效率和生产流程中各工序能耗状况及其影响因素没有进行具体分析。

电解金属锰的生产过程具有工序多、物流复杂、能耗高等特点,其中复杂的物流对电解锰产品的能耗、成本等技术经济指标都有很重要的影响。HYMAN等[13]针对流程工业开发了物流和能流的校对模型,并将其应用到造纸[14-15]和钢铁[16-17]等行业;国内部分学者采用物流分析法研究了工业部门[18]和城市间的能流状况[19-20],从宏观层面分析物流与能流的相互关系。陆钟武等[21]提出了基准物流图研究方法,并将其应用到钢铁行业,定量分析了钢铁生产流程中物流变化对能耗的影响关系[22-23]。此后,该研究方法被拓展应用到氧化铝[24-28]、铅冶炼[29-30]、镍铁冶炼[31]和铝电解[32]等行业,定量分析各自生产流程中物流对能耗的影响因素,为推动流程工业节能减排和提高产品能效水平做出重要贡献。由于电解金属锰生产过程与钢铁、氧化铝等行业生产过程都属于流程工业,本文作者借鉴钢铁[21]和氧化铝[25]生产流程中的“基础物流图”概念,研究提出电解锰生产流程的“理想物流图”分析方法,计算电解锰单位产品理想能耗,并应用该方法定量分析某电解锰企业生产流程中各类物流变化对能耗的影响,为电解锰行业开展节能降耗提供定量分析的依据。

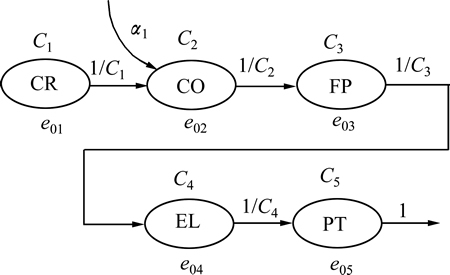

1 电解锰生产流程的理想物流图

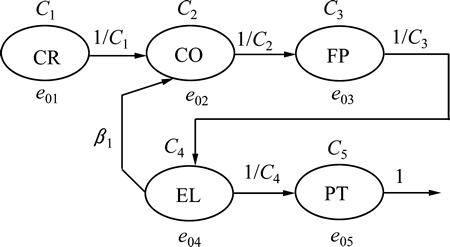

金属锰是由锰矿石、硫酸、液氨等原料经过多个物理化学变化从天然资源到最终金属锰产品的生产过程,其生产流程主要有破碎(Crushing, CR)、化合(Combination, CO)、压滤(Filter-press, FP)、电解(Electrolysis, EL)、后处理(Post-treatment, PT)等5道工序组成。基于钢铁和氧化铝生产流程中基准物流图的概念[21, 26],采用e-p分析方法[27],结合电解锰生产工艺,建立一种 “全封闭单行道”式的电解锰生产流程物流图:1) 全流程中含Mn物流的唯一流向是从上游工序流向下游工序;2) 在流程中途,没有含Mn物流的输入、输出。能够同时满足以上两个条件,并以1 t Mn为最终产品的物流图,定义为电解锰生产流程的理想物流图,如图1所示。

图1 电解锰生产流程的理想物流图

Fig. 1 Optimal material flows diagram for EMM process

图中每个圆圈代表一道工序,圆圈上方所标的C1、C2、C3、C4、C5是各工序物流中含Mn元素的质量分数(吨Mn元素在吨物流中所占比例),在理想物流图中,只在最后一道工序产出Mn成品,即C5=1;圆圈下方所标的e01、e02、e03、e04、e05是各工序的理想工序能耗(GJ/t合格工序产品);图中箭头表示含Mn物流的流向,在每个箭头旁边的1/C1、1/ C2、1/C3、1/C4是各工序的实物产量与Mn产量之比,称其为理想折合比,并记作p01、p、p03、p04,其中1/C5=p05=1。

本研究中所称的“理想能耗”,是指在不改变现有生产工艺和生产设备条件下,所能获得的最佳能耗。它是一个可望而不可及的能耗水平,不包括因为技术进步和设备更新等生产条件变化而提高的能耗。根据理想物流图的定义,可得电解锰生产流程中1 t Mn的理想能耗E0如式(1)所示:

(1)

(1)

式(1)是同各种物流变化状况下电解锰单位产品能耗值进行比较的基准。

2 电解锰生产理想能耗计算分析

本研究以某电解锰生产流程为例,计算分析该企业电解锰单位产品的理想能耗。

2.1 电解锰生产流程的物流类型

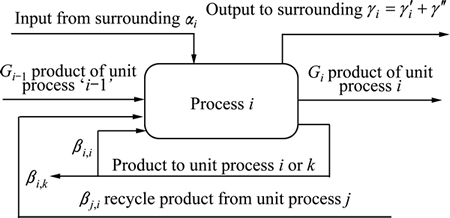

实际上电解锰生产流程中物流不可能完全满足理想物流图中提到的两个假设条件,对任何一道生产工序(i)来说,都可能发生图2所示的物流状况。

图2 生产工序的物流图

Fig. 2 Material flows diagram of unit process

1) 输入物流,第i-1道工序的产品作为原料输入到第i道工序,其锰素流量为Gi-1;

2) 外加物流,从流程外界加入第i道工序的含锰物流,其锰素流量为 ;

;

3) 排放物流,第i道工序向外界输出的含锰物流,其锰素流量为 ;(

;( ,其中

,其中 为外输的第i道工序合格产品所含锰元素质量,

为外输的第i道工序合格产品所含锰元素质量, 是向外界输出的不合格产品、生产损失等所含锰元素质量)

是向外界输出的不合格产品、生产损失等所含锰元素质量)

4) 循环物流,第i道及其下游各工序生产的不合格产品或废品,作为原料重新返回到本道工序或其他上游工序循环使用,其锰素流量为 ;(其中,

;(其中, 为返回本工序的物流所含锰元素质量,

为返回本工序的物流所含锰元素质量, 为由本工序返回到其上游第k道工序的物流所含锰元素的质量(k=1, 2, …, i-1),

为由本工序返回到其上游第k道工序的物流所含锰元素的质量(k=1, 2, …, i-1), 为下游第j道工序生产的不合格产品或废品,作为原料返回到第i道工序所含锰元素的质量(j=i+1, i+2, …, n),即满足

为下游第j道工序生产的不合格产品或废品,作为原料返回到第i道工序所含锰元素的质量(j=i+1, i+2, …, n),即满足 )

)

5) 输出物流,第i道工序输出给第i+1道工序的合格产品,其锰素流量为Gi。

上述5类物流满足锰元素质量守恒关系,如式(2)所示:

(2)

(2)

由图2可知,在电解锰生产流程中,有一股从第一道工序一直贯穿到最后一道工序的主物流Gi。除主物流外,还有3种不同类型的物流:第一类物流( 物流),是指从流程以外输入到各道工序的含Mn物流;第二类物流(

物流),是指从流程以外输入到各道工序的含Mn物流;第二类物流( 物流),包括从各道工序输出后又返回本工序重新处理的物流、由各道工序输出后返回它们上游工序重新处理的物流以及由下游工序返回到各工序去的物流;第三类物流(

物流),包括从各道工序输出后又返回本工序重新处理的物流、由各道工序输出后返回它们上游工序重新处理的物流以及由下游工序返回到各工序去的物流;第三类物流( 物流),是指各道工序向外界输出后不再返回到生产流程中的各股物流。

物流),是指各道工序向外界输出后不再返回到生产流程中的各股物流。

2.2 理想能耗计算及验证分析

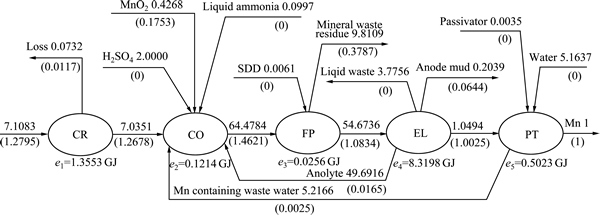

以最终产品为1 t Mn为基准,结合文献[21-23]中相关计算方法,根据某电解锰企业年度平均生产和能耗数据,可绘制出其实际物流图,如图3所示。

图3 电解锰生产流程的实际物流图

Fig. 3 Real material flows diagram for EMM process

图3中每个圆圈下方标明了各道工序的工序能耗,在每个箭头上方标明了各股物流折合比(吨Mn元素在吨物流中的比例),并在括号中注明了与之相当的Mn元素质量(t)。由式(1)可得电解锰产品实际能耗为Es=27.99 GJ/t。

同时,根据该企业的年度公告,同年度电解锰成品年平均能耗是27.95 GJ/t(成品电解锰品位为99.70%),折合100%品位的电解锰能耗为28.03 GJ/t。与本研究计算得出的电解锰单位产品能耗相对误差仅为ε=0.14%。考虑到生产过程中如原料、环境、温度等不稳定因素的影响,此相对误差在允许范围内,由此可验证式(1)的可靠性。

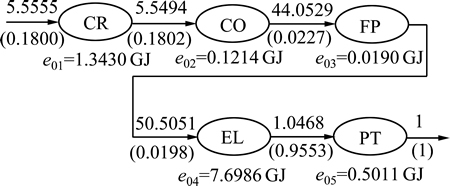

根据理想物流图的概念,在图3的基础上,可绘制电解锰生产流程的理想物流图,如图4所示。

图4 电解锰生产流程的理想物流图

Fig. 4 Optimal material flows diagram for EMM

图4中圆圈下方标明的是各工序的理想工序能耗,箭头上方注明的是各股物流的折合比,箭头下方注明的是各工序产品Mn元素含量。

根据理想物流图数据,由式(1)计算可得:

E0=1.3430×5.5494+0.1214×44.0529+0.0190×50.5051+7.6986×1.0468+0.5011×1=22.32 GJ/t

即电解锰生产流程的单位产品理想能耗为22.32 GJ/t,该企业实际能耗Es与理想能耗E0相比,当年存在25.40%的节能潜力。

3 各类物流变化对理想能耗影响

根据图2生产工序的物流图分析可知,在电解锰实际生产过程中有3类物流偏离理想物流图的情况,分别是含锰物流(二氧化锰矿粉 )从外界输入流程的中间工序;下游工序的废品(电解工序阳极液

)从外界输入流程的中间工序;下游工序的废品(电解工序阳极液 ,后处理工序含锰废水

,后处理工序含锰废水 )返回上游工序重新处理;含锰物流从中间工序向外界输出,不回收(压滤工序输出矿渣

)返回上游工序重新处理;含锰物流从中间工序向外界输出,不回收(压滤工序输出矿渣 ,破碎工序输出粉尘及矿粉运输损失

,破碎工序输出粉尘及矿粉运输损失 ,电解工序输出阳极泥

,电解工序输出阳极泥 )。以图1为例,结合文献[21]中的计算方法,分别举例分析各类物流偏离理想物流图时对电解锰单位产品理想能耗的影响。

)。以图1为例,结合文献[21]中的计算方法,分别举例分析各类物流偏离理想物流图时对电解锰单位产品理想能耗的影响。

3.1 含Mn物流从外界输入到流程工序

二氧化锰矿粉从流程外界输入到化合工序属于这种情况,如图5所示。

化合工序的实物产量仍为1 t,但此时,有 t(

t( <1)二氧化锰矿粉从外界输入,按含Mn量计算,它相当于

<1)二氧化锰矿粉从外界输入,按含Mn量计算,它相当于 /C1 t化合工序所用的原料。因此,从破碎工序进入化合工序的物流量可由1/C1减至为(1/C1-

/C1 t化合工序所用的原料。因此,从破碎工序进入化合工序的物流量可由1/C1减至为(1/C1- /C1) t。

/C1) t。

图5 含Mn物流从外界输入到流程工序的物流图

Fig. 5 Material flows diagram for materials flow containing Mn input to process from surrounding

此种情况下电解锰单位产品能耗E1如式(3)所示:

(3)

(3)

与电解锰单位产品理想能耗相比,其能耗增量如式(4)所示:

(4)

(4)

由图3可知,从外界输入到化合工序的二氧化锰矿粉 =0.1753 t,它对理想能耗的影响为

=0.1753 t,它对理想能耗的影响为

GJ/t

GJ/t

同理分析可知,假设当有含Mn物流从外界输入到电解工序时,电解锰单位产品能耗 如式(5)所示:

如式(5)所示:

(5)

(5)

与电解锰单位产品理想能耗相比,其能耗增量如式(6)所示:

(6)

(6)

由此可见,当有含Mn物流从外界输入到流程的中间工序时,可以降低其上游工序的折合比,从而降低电解锰单位产品能耗,而且物流输入的工序越靠后,能耗降低的越大,越能够接近理想能耗水平。因此,在电解锰生产流程中加入含Mn物流是降低电解锰能耗的一项重要的节能措施。

3.2 含Mn物流返回上游工序重新处理

电解工序中的阳极液返回到化合工序重新处理属于这种情况,如图6所示。电解工序有含Mn物流返回到化合工序重新处理,电解工序的合格产品仍然保持原来的数量,即1 t,同时也会有 t(

t( <1)含Mn物流产生,电解工序总实物产量增至(1+

<1)含Mn物流产生,电解工序总实物产量增至(1+ ) t,相应的化合、压滤工序实物产量也增至(1+

) t,相应的化合、压滤工序实物产量也增至(1+ ) t。

) t。

图6 含Mn物流返回上游工序重新处理的物流图

Fig. 6 Material flows diagram for materials flow containing Mn returning to upstream process maching

此种情况下电解锰单位产品能耗E2如式(7)所示:

(7)

(7)

与电解锰单位产品理想能耗相比,其能耗增量如式(8)所示:

(8)

(8)

由图3可知,从电解工序返回到化合工序重新处理的阳极液 =0.0165 t,它对理想能耗的影响为

=0.0165 t,它对理想能耗的影响为

=0.24 GJ/t

=0.24 GJ/t

同理,可得从后处理工序返回到化合工序重新处理含Mn废水 =0.0025 t对理想能耗的影响为

=0.0025 t对理想能耗的影响为

=0.04 GJ/t

=0.04 GJ/t

分析可知,从任何工序回收含Mn物流到其上游工序进行再处理,增加该工序的工序能耗和上游接受物流工序的折合比,从而增加电解锰单位产品能耗。且在其他条件相同的情况下,含Mn物流返回的距离(按进出两工序的序号差值计)越长,对电解锰单位产品能耗的影响越大,离理想能耗的目标越远。因此,在流程中间工序减少含Mn物流废品或副产品的产生和降低返料量,是降低电解锰能耗的主要的节能措施。

3.3 含Mn物流从中间工序向外输出

压滤工序向外界输出矿渣属于此种情况,如图7所示。压滤工序有 t(

t( <1)矿渣向外界输出(不回收),此时,压滤工序的实物产量仍为1 t,而总的产物有(1+

<1)矿渣向外界输出(不回收),此时,压滤工序的实物产量仍为1 t,而总的产物有(1+ ) t,相应地上游各道工序的实物产量都将增至(1+

) t,相应地上游各道工序的实物产量都将增至(1+ ) t。

) t。

图7 含Mn物流从中间工序向外输出的物流图

Fig. 7 Material flows diagram for materials flow containing Mn output from middle of process

此种情况下电解锰单位产品能耗E3如式(9)所示:

(9)

(9)

与电解锰单位产品理想能耗相比,其能耗增量如式(10)所示:

(10)

(10)

由图3可知,压滤工序向外界输出的矿渣 =0.3787 t,它对理想能耗的影响为

=0.3787 t,它对理想能耗的影响为

=5.21 GJ/t

=5.21 GJ/t

同理,破碎工序向外界输出粉尘及矿粉运输损失 =0.0117 t对理想能耗的影响为

=0.0117 t对理想能耗的影响为

=0.09 GJ/t

=0.09 GJ/t

电解工序向外界输出阳极泥 =0.0644 t对理想能耗的影响为

=0.0644 t对理想能耗的影响为

=1.41 GJ/t

=1.41 GJ/t

结果表明,从任何工序向外界输出含Mn物流,增加该工序的工序能耗和上游各道工序的折合比,从而增加电解锰单位产品能耗。而且在其他条件不变的情况下,向外界输出含Mn物流的工序越靠后,对电解锰单位产品能耗的影响越大,离理想能耗的目标越远。为降低电解锰产品能耗,必须努力降低各道工序直接向外界输出的不合格产品、废品或其他含Mn物流。

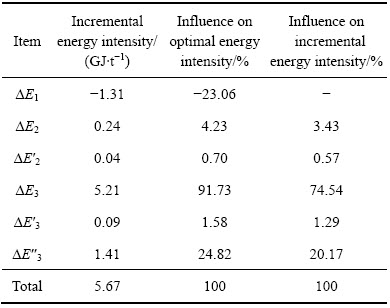

综合以上分析可知,电解锰生产流程中,各股物流对理想能耗的影响如表1所列。

表1 电解锰生产流程物流对理想能耗的影响

Table 1 Influence of material flows in EMM process on its optimal energy intensity

由此可知,电解锰生产流程中各类物流对理想能耗的总影响 为

为

=5.67 GJ/t

=5.67 GJ/t

从物流角度分析,压滤工序向外界输出矿渣和电解工序向外界输出阳极泥对电解锰单位产品能耗增量的影响分别是5.21和1.41 GJ/t,合计占到所有物流对能耗增量影响的94.71%;二氧化锰矿粉被从流程外界输入到化合工序会使电解锰单位产品能耗降低,影响量为-23.06%。为降低电解锰单位产品能耗,应尽量减少外排矿渣和阳极泥中Mn元素的含量。

4 结论

1) 借鉴钢铁生产流程基准物流图的概念,建立电解锰生产流程的理想物流图;提出理想能耗的概念,并以某电解锰生产数据为基础进行计算分析,验证理想能耗计算方法的可靠性。

2) 定量分析了电解锰生产流程中各类物流变化对理想能耗的影响,结果表明:在影响电解锰单位产品理想能耗的6股物流中,压滤工序向外界输出矿渣时对能耗增量的影响最大,占比达74.54%;其次,从电解工序向外界输出阳极泥对能耗增量的影响也较高,占比为21.17%;二氧化锰矿粉从流程外界加入化合工序时,会促使能耗降低。

3) 在电解锰生产流程中,凡由外界向某中间工序加入含Mn物流( 物流),必有利于节能,且越是发生在靠后的工序,节能效果越显著;凡是由流程中间工序向外界输出(

物流),必有利于节能,且越是发生在靠后的工序,节能效果越显著;凡是由流程中间工序向外界输出( 物流)或返回本工序及上游工序重新处理(

物流)或返回本工序及上游工序重新处理( 物流)的含Mn物流,必将增大该工序及其上游工序的实物产量和折合比,从而增大电解锰产品能耗,而且越是靠后的工序发生上述情况(

物流)的含Mn物流,必将增大该工序及其上游工序的实物产量和折合比,从而增大电解锰产品能耗,而且越是靠后的工序发生上述情况( 和

和 物流),耗能越多。

物流),耗能越多。

REFERENCES

[1] 段 宁, 但智钢, 王志增. 污染预防是传统产业绿色发展必由之路[N]. 中国环境报, 2013-06-25(2).

DUAN Ning, DAN Zhi-gang, WANG Zhi-zeng. The pollution prevention is the only way of green development in the traditional industry[N]. China Environmental News, 2013-06-25(2).

[2] BISWAL A, MAHAKUD S, BHUYAN S, DASH B, SARANGI C K, SANJAY K, TRIPATHY B C, SUBBAIAH T, BHATTACHARYA I N, JOO S H, SHUN M S, PARK K H. Recovery of Co metal and electrolytic manganese dioxide (EMD) from Co-Mn sludge[J]. Hydrometallurgy, 2015, 152: 159-168.

[3] DUAN Ning, DAN Zhi-gang, WANG Fan, PAN Cen-xuan, ZHOU Chang-bo, JIANG Lin-hua. Electrolytic manganese metal industry experience based China's new model for cleaner production promotion[J]. Journal of Cleaner Production, 2011, 19(17/18): 2082-2087.

[4] 汪启年, 王 璠, 高小娟, 于宏兵. 电解锰行业清洁生产审核[J]. 环境工程, 2013, 31(S1): 700-702.

WANG Qi-nian, WANG Fan, GAO Xiao-juan, YU Hong-bing. Cleaner production audit in electrolytic manganese industry[J]. Environmental Engineering, 2013, 31(S1): 700-702.

[5] 裴倩倩, 周长波, 李旭华, 沈 忱, 赵志远, 苑喜男. 电解锰企业实施清洁生产审核实例[J]. 环境保护科学, 2015(5): 95-98.

PEI Qian-qian, ZHOU Chang-bo, LI Xu-hua, SHEN Chen, ZHAO Zhi-yuan, YUAN Xi-nan. A case study of cleaner production audit of an electrolytic manganese enterprise[J]. Environmental Protection Science, 2015(5): 95-98.

[6] 詹锡松. 电解金属锰电解槽节能技术的探讨[J]. 中国锰业, 2008, 26(4): 48-50.

ZHAN Xi-song. A technical research of thrifty of energy of EMM channel[J]. China's Manganese Industry, 2008, 26(4): 48-50.

[7] 林 韬, 卢立祥, 魏建民, 王吉刚. 电解锰生产工艺及设计[J]. 天津化工, 2013, 27(3): 26-28, 32.

LIN Tao, LU Li-xiang, WEI Jian-min, WANG Ji-gang. Process and design of electrolytic manganese production[J]. Tianjin Chemical Industry, 2013, 27(3): 26-28, 32.

[8] 冯雅丽, 杜云龙, 李辉, 周宇照, 王维大. 用离子膜电解槽无硒电沉积金属锰[J]. 湿法冶金, 2014, 33(3): 203-207.

FENG Ya-li, DU Yun-long, LI Hui, ZHOU Yu-zhao, WANG Wei-da. Non-selenium electrodeposition of metal manganese using ion membrane electrolyzer[J]. Hydrometallurgy of China, 2014, 33(3): 203-207.

[9] 牛莎莎, 王志兴, 郭华军, 李新海, 彭文杰, 胡启阳, 张云河. 电解锰阳极渣还原浸出锰[J]. 中国有色金属学报, 2012, 22(9): 2662-2666.

NIU Sha-sha, WANG Zhi-xing, GUO Hua-jun, LI Xin-hai, PENG Wen-jie, HU Qi-yang, ZHANG Yun-he. Reductive leaching of manganese from manganese anode slag[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(9): 2662-2666.

[10] 严 浩, 彭文杰, 王志兴, 李新海, 郭华军, 胡启阳. 响应曲面法优化电解锰阳极渣还原浸出工艺[J]. 中国有色金属学报, 2013, 23(2): 528-534.

YAN Hao, PENG Wen-jie, WANG Zhi-xing, LI Xin-hai, GUO Hua-jun, HU Qi-yang. Reductive leaching technology of manganese anode slag optimized by response surface methodology[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(2): 528-534.

[11] 周兆安, 甘红祥, 李家元, 杨天足, 楚 广. 含锰废水深度净化的热力学分析[J]. 中国有色金属学报, 2012, 22(9): 2676-2681.

ZHOU Zhao-an, GAN Hong-xiang, LI Jia-yuan, YANG Tian-zu, CHU Guang. Thermodynamic analysis of deep purification in manganiferous wastewater[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(9): 2676-2681.

[12] 刘静静. 电解金属锰生产污染防治措施分析[J]. 环境科学导刊, 2015, 34(4): 62-64.

LIU Jing-jing. Analysis of the pollution prevention and control measures on electrolytic manganese metal production[J]. Environmental Science Survey, 2015, 34(4): 62-64.

[13] HYMAN B, REED T. Energy intensity of manufacturing process[J]. Energy, 1995, 20(7): 593-606.

[14] GIRALDO L, HYMAN B. Energy end-use models for pulp, paper, and paperboard mills[J]. Energy, 1995, 20(10): 1005-1019.

[15] GIRALDO L, HYMAN B. An energy process-step model for manufacturing paper and paper board[J]. Energy, 1996, 21(7/8): 667-681.

[16] ANDERSEN J P, HYMAN B. Energy and material flow models for the U.S. steel industry[J]. Energy, 2001, 26(2): 137-159.

[17] COSTA M M, SCHAEFFE R, WORRELL L. Energy accounting of energy and materials flows in steel production system[J]. Energy, 2001, 26(5): 363-3845.

[18] SUN X Q, AN H Z, GAO X Y, JIA X L, LIU X J. Indirect energy flow between industrial sectors in China: A complex network approach[J]. Energy, 2016, 94(1): 195-205.

[19] SONG T, YANG Z S, CHAHINE T. Efficiency evaluation of material and energy flows, a case study of Chinese cities[J]. Journal of Cleaner Production, 2016, 112(5): 3557-3675.

[20] CHEN S Q, CHEN B. Urban energy consumption: Different insights from energy flow analysis, input-output analysis and ecological network analysis[J]. Applied Energy, 2015, 138(1): 99-107.

[21] 陆钟武, 蔡九菊, 于庆波, 谢安国. 钢铁生产流程的物流对能耗的影响[J]. 金属学报, 2000, 36(4): 370-378.

LU Zhong-wu, CAI Jiu-ju, YU Qing-bo, XIE An-guo. The influences of materials flows in steel manufacturing process on its energy intensity[J]. Acta Metallurgica Sinica, 2000, 36(4): 370-378.

[22] 于庆波, 陆钟武, 蔡九菊. 钢铁生产流程中物流对能耗影响的计算方法[J]. 金属学报, 2000, 36(4): 379-382.

YU Qing-bo, LU Zhong-wu, CAI Jiu-ju. Study on the method for calculating influence of mass flow on energy consumption in steel manufacturing process[J]. Acta Metallurgica Sinica, 2000, 36(4): 379-382.

[23] 蔡九菊, 王建军, 陆钟武, 殷瑞钰. 钢铁企业物质流与能量流及其相互关系[J]. 东北大学学报(自然科学版), 2006, 27(9): 979-982.

CAI Jiu-ju, WANG Jian-jun, LU Zhong-wu, YIN Rui-yu. Material flow and energy flow in iron & steel industry and correlation between them[J]. Journal of Northeastern University (Natural Science), 2006, 27(9): 979-982.

[24] LIU L R, AYE L, LU Z W, ZHANG P H. Analysis of the overall energy intensity of alumina refinery process using unit process energy intensity and product ratio method[J]. Energy, 2006, 31(8/9): 1167-1176.

[25] LIU L R, AYE L, LU Z W, ZHANG P H. Effect of material flows on energy intensity in process industries[J]. Energy, 2006, 31(12): 1870-1882.

[26] 刘丽孺, 陆钟武, 张红福. 复合流程工业中物流对能耗影响的分析模型[J]. 中国有色金属学报, 2009, 19(11): 2050-2055.

LIU Li-ru, LU Zhong-wu, ZHANG Hong-fu. Model for analyzing effect of material flows on energy intensity in complex process industries[J]. The Chinese Journal of Nonferrous Metals, 2009, 19 (11): 2050-2055.

[27] 刘丽孺, 陆钟武, 于庆波, 闫书明, 姜玉敬, 吕子剑. 氧化铝生产综合能耗的e-p分析 [J]. 中国有色金属学报, 2002, 12(6): 1294-1299.

LIU Li-ru, LU Zhong-wu, YU Qing-bo, YAN Shu-ming, JIANG Yu-jing, L Zhi-jian. Analysis of comprehensive energy consumption for producing alumina[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(6): 1294-1299.

Zhi-jian. Analysis of comprehensive energy consumption for producing alumina[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(6): 1294-1299.

[28] 刘丽孺, 陆钟武, 于庆波, 闫书明, 姜玉敬, 吕子剑. 拜耳法生产氧化铝流程的物流对能耗的影响[J]. 中国有色金属学报, 2003, 13(1): 265-270.

LIU Li-ru, LU Zhong-wu, YU Qing-bo, YAN Shu-ming, JIANG Yu-jing, L Zhi-jian. Influence of material flow in alumina manufacturing process with Bayer method on its energy intensity[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(1): 265-270.

Zhi-jian. Influence of material flow in alumina manufacturing process with Bayer method on its energy intensity[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(1): 265-270.

[29] WANG H C, SHI Z M, LIN L F, CHEN B. Coupling model of energy flow and material flow in SKS lead smelting[J]. The Open Materials Science Journal, 2014, 8: 131-135.

[30] 王洪才, 时章明, 沈 浩, 陈 通, 姜信杰. SKS炼铅物质流变化对能耗的影响[J]. 中南大学学报(自然科学版), 2012, 43(7): 2850-2854.

WANG Hong-cai, SHI Zhang-ming, SHEN Hao, CHEN Tong, JIANG Xin-jie. Influences of materials flows in SKS lead smelting process on its energy consumption[J]. Journal of Central South University (Science and Technology), 2012, 43(7): 2850-2854.

[31] 刘 鹏, 李宝宽, 吴文远. 基于镍铁冶炼工艺流程中物质流和能量流的模型与软件[J]. 工程科学学报, 2015(7): 857-866.

LIU Peng, LI Bao-kuan, WU Wen-yuan. Model and software of materials flow and energy flow in ferronickel smelting[J]. Chinese Journal of Engineering, 2015(7): 857-866.

[32] 李春丽, 马子敬, 祁卫玺, 鲁 佳, 许新乐, 成春春. 铝电解生产过程物质流和能量流分析[J]. 有色金属(冶炼部分), 2014(2): 21-24.

LI Chun-li, MA Zhi-jing, QI Wei-xi, LU Jia, XU Xin-le, CHENG Chun-chun. Analysis of material and energy flow in aluminum electrolysis process[J]. Nonferrous Metals (Extractive Metallurgy), 2014(2): 21-24.

Influence of material flows in electrolytic manganese metal process on its optimal energy intensity

WANG Hong-cai1, 2, SHI Zhang-ming1, 3, LIU Bo1, CHEN Bo1, YANG Qin-hao1, YE Zheng1

(1. School of Energy Science and Engineering, Central South University, Changsha 410083, China;

2. Hunan Key Laboratory of Energy Conservation in Process Industry,

Central South University, Changsha 410083, China;

3. Hunan Research Center of Energy-saving Evaluation Technology, Changsha 410083, China)

Abstract: In order to quantitatively analyze the energy utilization in the electrolytic manganese metal (EMM) process, based on the concept of standard material flows diagram of steel manufacturing process, the concept of optimal material flows diagram of the EMM process was defined and the calculation method of optimal energy intensity was put forward. Based on the EMM plant data, the real material flows diagram of this plant was figured out, and the optimal material flows diagram was established accordingly. The unit optimal energy intensity for the EMM products was calculated as 22.32 GJ/t. The influences of material flows in EMM process on its optimal energy intensity were analyzed quantitatively as examples. The results show that, when the material flows of α are happened in the EMM process, the energy intensity of final product decreases, and it is beneficial for energy-saving. Nevertheless, when the material flows of β and γ happen in the EMM process, the energy intensity of final product increases significantly. In order to decrease the energy intensity of EMM product, the manganese containing materials of mineral waste residue and anode mud should be reduced, and the manganese containing materials should be impelled input to the next unit process as many as possible.

Key words: electrolytic manganese metal; material flow; optimal material flow diagram; optimal energy intensity

Foundation item: Project(51376198) supported by the National Natural Science Foundation of China; Project (2013SK3290) supported by the Science and Technology Funds of Hunan, China; Project (20150533218) supported by the Fundamental Research Funds for the Central Universities of Central South University, China

Received date: 2015-12-28; Accepted date: 2016-04-11

Corresponding author: WANG Hong-cai; Tel: +86-731-88836930; E-mail: hongcai_001@163.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51376198);湖南省科技计划资助项目(2013SK3290);中南大学中央高校基本科研业务专项资金资助项目(20150533218)

收稿日期:2015-12-28;修订日期:2016-04-11

通信作者:王洪才,讲师,博士研究生;电话:0731-88836930;E-mail: hongcai_001@163.com