Trans. Nonferrous Met. Soc. China 22(2012) 456-460

Red-mud treatment using oxalic acid by UV irradiation assistance

YU Zhang-long1, SHI Zhi-xia2, CHEN Yong-mei1, NIU Yin-jian1, 3, WANG Yong-xia1, WAN Ping-yu1

1. School of Science, Beijing University of Chemical and Technology, Beijing 100029, China;

2. Department of Mineral Resource and Metallurgical Materials,

Beijing General Research Institute for Nonferrous Metals, Beijing 100088, China;

3. The Nonferrous Metal Society of China, Beijing 100814, China

Received 21 February 2011; accepted 2 April 2011

Abstract: Red-mud is the residue from the Bayer process, in which the iron minerals should be removed before red-mud is used to produce refractory materials. The iron minerals in red-mud were extracted by oxalic acid solution. The content of Fe (calculated in Fe2O3) in red-mud was reduced from 17.6% to less than 1% after being treated by 1 mol/L oxalic acid solution at 75 °C for 2 h. The Fe(III) oxalate solution obtained was then irradiated by UV light, resulting in the precipitation of Fe(II) oxalate. Under UV photocatalysis, more than 90% of Fe(III) oxalate in the extracted solution was transformed into the precipitation of Fe(II) oxalate crystallite (β-FeC2O4·2H2O). The filtrate from the Fe(II) oxalate precipitate filtration could be reused in the next cycle. The mechanism of UV photocatalysis precipitation was also discussed.

Key words: red-mud; iron minerals; oxalic acid; UV irradiation

1 Introduction

The annual output of alumina is about 80 million tons in the world, while 100 million tons of residues (red-mud) are simultaneously produced per year [1, 2]. Therefore, the storage of red-mud becomes a serious problem for many alumina refineries [3, 4]. Moreover, red-mud causes pollution to soil and harm to the living organism due to its strong caustic nature [3-5]. Transforming red-mud into an useful stuff is thought to be an important way to solve these problems.

The main components of red-mud are SiO2 and Al2O3, which are similar to the raw materials to produce cement and brick [6-8]. However, low fire resistance due to high content of Fe2O3 in red-mud is the fatal weakness to produce refractory materials [9]. Many researchers tried to remove iron from red-mud or other ores [9, 10]. ALLEN [11] disclosed a method to remove iron minerals from clay as follows: sintering clay in a reductive atmosphere of CO or C, and then adding Cl2 to transfer ferric oxide into evaporable ferrous chloride. AMBIKADEVI and LALITHAMBIKA [12] tried many organic acids to extract iron minerals from red-mud, and found oxalic acid was better than other organic acids (such as acetic acid, formic acid and citric acid) because oxalate group has a strong acidity and the chelating ability to iron ions.

Nowadays, oxalic acid can be produced through biofermentation of glucose, which makes oxalic acid cheap enough for large-scale production. This study focuses on how to leach iron minerals in red-mud with oxalic acid and how to treat the leachate to make oxalic acid recyclable. It is concluded that ferric oxalate could be precipitated as ferrous oxalate by UV-irradiation assistance and then it is possible to recycle the remaining oxalic acid for further reducing the cost.

2 Experimental

2.1 Iron removing by oxalic acid solution

The red-mud sample was collected from Henan Branch of CHALCO and was air-dried without washing. 1 mol/L oxalic acid solution was prepared with analytical grade reagent of oxalic acid and deionized water. 10 g of the crushed red-mud (about 74 μm) and 150 mL of 1 mol/L oxalic acid solution were added to a 250 mL three-neck flask. The reaction mixture was stirred continuously for 0.5-2 h in a water bath at the certain temperatures.

Fe content in the filtrate was analyzed by the spectrophotometric method using phenanthroline. The leaching rate was calculated as the fraction of iron content in leachate to that in red-mud, and the change of oxalate group content in the leachate was also measured through titration by standard potassium permanganate solution. The oxalate decomposition ratio was defined as the fraction of decreased oxalate content to the initial content. Every experiment was repeated 3 times.

2.2 UV-irradiation for leachate treatment

The filtrate was irradiated by using a UV light source (355 nm, 150 W, GGY400-125, Guangdong, China) at room temperature, and yellow-orange crystal powder was precipitated gradually from the solution. 20 mL of the supernatant was sampled every 10 min for detecting the content of iron and oxalate groups. The irradiation was stopped when the iron content was not further decreased. The precipitated powder was filtered, washed and dried at 50 °C for further XRD, FT-IR, SEM tests.

3 Result and discussion

3.1 Red-mud components analysis

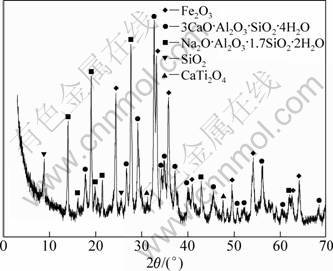

XRD pattern of the dried red-mud is shown in Fig. 1. Red-mud is the residue of bauxite after being digested by alkali in the Bayer process. The main components are calcium aluminosilicate hydrate, sodium aluminosilicate, iron oxide, calcium titanate and other silica minerals.

Fig. 1 XRD pattern of red-mud

The contents of these components measured by chemical analysis are shown in Table 1. The Fe2O3 content is as high as 17.6%. According to GB/T 3995—1983, the Fe2O3 content in the refractory material should be less than 2%, so most of iron has to be removed before red-mud is reused to produce refractory materials.

Table 1 Chemical analyses of red-mud (mass fraction, %)

3.2 Optimization of acid leaching conditions

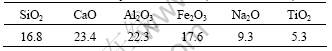

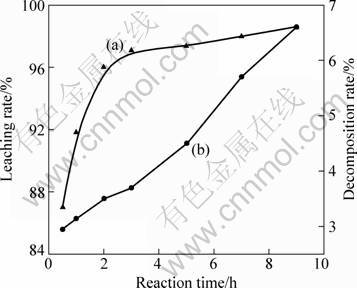

The removal efficiency of iron minerals from red-mud by oxalic acid solution depends on its acidity and the chelating ability to iron ions. The leaching rate increases with increasing temperature and reaction time, but oxalate can be decomposed into CO2 at too high temperature. Therefore, the leaching conditions should be optimized on the basis of both the iron leaching rate and oxalate decomposition rate. The results are shown in Fig. 2 and Fig. 3.

Fig. 2 Effect of temperature on leaching rate of iron in red mud (a) and decomposition rate of C2O42- (b)

Fig. 3 Effect of reaction time on leaching rate of iron in red- mud (a) and decomposition rate of C2O42- (b)

As shown in Fig. 2, the leaching rate of iron rises as reaction temperature increases. The leaching rate reaches 95% at 90 °C. On the other hand, it could be found that some oxalate groups decompose at the temperature above 60 °C. The decomposition becomes more severe at higher temperature and the decomposition rate reaches 4.5% at 95 °C. Therefore, the optimum temperature should be chosen as 75 °C.

The extraction process involves a solid-liquid heterogeneous system, in which the reaction rate is controlled by mass transferring and diffusion. Therefore, extending reaction time is beneficial to improving the iron leaching rate. It is shown in Fig. 3 that the iron leaching rate is 85% for the first 0.5 h at 75 °C, and it increases to 96% after 2 h. However, with further extending time, the leaching rate is only a little increased, e.g. only about 98% after 9 h. On the contrary, the decomposition rate of oxalate groups increases almost linearly with the time increasing. The decomposition rate is 3.5% after 2 h, while up to 6.5% after 9 h. Therefore, the optimized leaching time is selected as 2 h in consideration of both the economic benefit and the leaching efficiency. After leaching, the Fe2O3 content in the leached red-mud is reduced to 0.7%, which meets the criteria for producing refractory materials.

3.3 Reductive reaction of ferric oxalate under UV irradiation

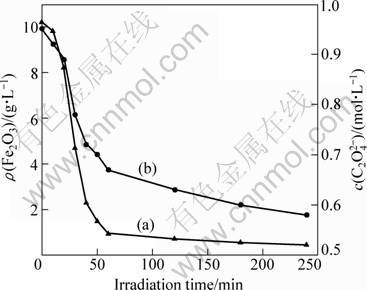

When the obtained leachate is settled in the indoor environment, some yellow-orange precipitation starts to form after 10 h, while the precipitate will form much more rapidly if the leachate is irradiated by UV light or sunlight. Figure 4 shows the concentration change of Fe (calculated in Fe2O3, the same below) and oxalate groups in the leachate during UV irradiation.

Fig. 4 Concentration change of Fe (a) and C2O42- (b) in leachate solution during UV irradiation

The initial concentration of Fe and oxalate groups was 10.2 g/L and 0.95 mol/L, respectively. As shown in Fig. 4, the concentration of Fe in the leachate reduces from 10 g/L to 1 g/L in the first 60 min, which indicates that almost 90% of Fe in the leachate is precipitated in only 1 h. Meanwhile, the concentration of oxalate groups also decreases from 0.95 mol/L to 0.65 mol/L during 1 h irradiation. The mole ratio of the lost oxalate groups to the removed iron is about 3:1. After being irradiated for longer time, the Fe content hardly changes while the oxalate group content still decreases slowly.

3.4 Characterization of precipitation

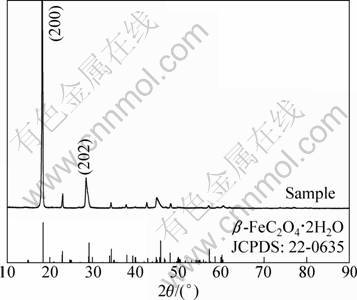

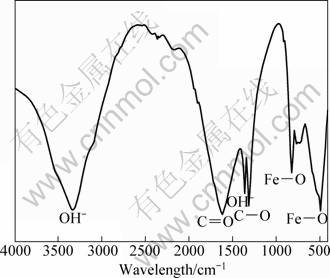

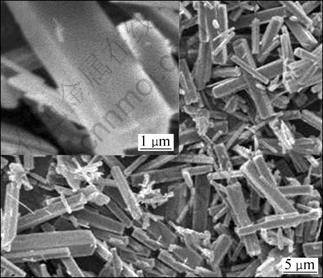

The precipitate formed during the irradiation was collected for characterization by XRD, SEM and IR. Figure 5 shows the XRD pattern of the precipitate. The 2θ angle and intensities of the peaks well match with those of the standard pattern (JCPDS 22-0635) of β-FeC2O4·2H2O. For the FT-IR spectrum in Fig. 6, the strong peak at 1700 cm-1 could be assigned to the vibration of carboxylic group C=O. The two medium strong peaks in the range of 1500-1000 cm-1 are attributed to the vibrations of C—O and O—H groups in the oxalic acid. The two strong sharp peaks below 1000 cm-1 are attributed to the presence of Fe(II)—O group [13]. The SEM image of ferrous oxalate crystallite (Fig. 7) shows that it has regular rod-shape with the length of 5-10 μm and width of 1 μm.

Fig. 5 XRD pattern of UV-irradiated precipitation

3.5 Mechanism of UV-photocatalysis reductive reaction of ferric oxalate to ferrous oxalate

Several researchers were interested in the dissolution of Fe2O3 by oxalic acid solution and some of them observed the precipitation process with or without irradiation [14-17]. One kind of mechanism was described as that the reduction reaction from Fe(III) to Fe(II) due to oxalate groups occurred during the leaching process. So the predominant species was Fe(II) oxalate in the leachate and the precipitation of Fe(II) oxalate occurred when the pH value of the solution changed into lower value because the solubility was limited [17]. The another mechanism considered that Fe(III) oxalate was transformed into Fe(II) oxalate under irradiation, in which it underwent the charge transfer from ligand (ox2-) to metal (Fe3+) (LMCT) [13-15, 18].

It was found in the present study that the precipitate of Fe(II) oxalate could form in indoor environment but it spent more than 10 h, while about 90% of Fe could be precipitated in only 1 h with UV-irradiation. Since the standard redox potential of Fe(C2O4)33-/Fe(C2O4)22- is -0.158 V (comparing with 0.77 V of Fe3+/Fe2+), it is difficult for Fe(C2O4)33- to reduce into Fe(C2O4)22- by oxalate even if in the concentrated oxalic acid solution like that in the present study (about 1 mol/L). However, UV-assisted LMCT leads the reduction reaction to be accelerated greatly. Once Fe(II) oxalate is formed and getting more and more concentrated, the precipitate of β-FeC2O4·2H2O would form due to the equilibrium existing between Fe(C2O4)22- and FeC2O4. The main reaction equations can be described as follows:

Fe2O3+6H++6C2O42-=2Fe(C2O4)33-+3H2O (1)

2Fe(C2O4)33-=2Fe(C2O4)22-+C2O42-+2CO2 (slow) (2)

2Fe(C2O4)33-+hn=2Fe2++5C2O42-+2CO2 (fast) (3)

Fe2++2C2O42- Fe(C2O4)22-

Fe(C2O4)22- FeC2O4(s) (4)

FeC2O4(s) (4)

Fig. 6 FT-IR spectrum of UV- irradiated precipitation

Fig. 7 SEM image of UV-irradiated precipitation

The remaining Fe in the solution after UV-irradiation was about 1 g/L, which accords with the solubility of β-FeC2O4·2H2O in water (0.97 g/L calculated in Fe2O3). It should be considered as indirect evidence to support the above mechanism.

In the case of this study, about 35% of oxalate groups in the original solution are lost in the whole process, in which about 4% of oxalate groups decompose into CO2 during leaching process. And the other 31% are lost during irradiation, in which 11.3% of oxalate groups are precipitated together with Fe(II), while another 5.7% are stoichiometrically oxidized to CO2 in accordance with reaction (3), and the other 14% are probably oxidized by O2 in the air during UV-irradiation. The filtrate after ferrous oxalate being filtrated could be reused as the extractant in the next cycle with replenishing certain amount of oxalic acid.

4 Conclusions

1) By using 1 mol/L oxalic acid solution as leachant, about 96% of Fe in the red-mud can be leached out at 75 °C for 2 h. The Fe2O3 content in the residue is reduced to below 1%, which is suitable to be used for producing refractory materials.

2) Being photocatalyzed by UV irradiation, most of Fe(III) oxalate in the leachate can be precipitated as ferrous oxalate in a short time. The remaining Fe content in the filtrate depends on the solubility of ferrous oxalate, which is about 1 g/L.

3) The filtrate from the precipitates filtration can be reused in the next cycle. About 35% of oxalate groups are lost in the whole process.

4) It is confirmed that the precipitate of ferrous oxalate is β-FeC2O4·2H2O, which has a good crystallite shape with the length of 5-10 μm and width of 1 μm.

References

[1] International Aluminium Institute. Alumina Production [EB/OL]. [2010-11-26]. https://stats.world-aluminium.org/iai/stats_new/ formServer.asp?form=5

[2] LIU Y, LIN C, WU Y. Characterization of red mud derived from a combined Bayer process and bauxite calcination method [J]. J Hazard Mater, 2007, 146(1-2): 255-261.

[3] LI Xiao-bin, XIAO Wei, LIU Wei, LIU Gui-hua, PENG Zhi-hong, ZHOU Qiu-sheng, QI Tian-gui. Recovery of alumina and ferric oxide from Bayer red mud rich in iron by reduction sintering [J]. Transactions of Nonferrous Metals Society of China, 2009, 19(5): 1342-1347.

[4] ZHANG Kun-yu, HU Hui-ping, ZHANG Li-juan, CHEN Qi-yuan. Surface charge properties of red mud particles generated from Chinese diaspore bauxite [J]. Transactions of Nonferrous Metals Society of China, 2008, 18(5): 1285-1289.

[5] BONENFANT D, KHAROUNE L, SAUVE? S B, HAUSLER R, NIQUETTE P, MIMEAULT M, KHAROUNE M. CO2 sequestration by aqueous red mud carbonation at ambient pressure and temperature [J]. Industrial & Engineering Chemistry Research, 2008, 47(20): 7617-7622.

[6] GUPTA V K, SHARMA S. Removal of cadmium and zinc from aqueous solutions using red mud [J]. Environmental Science & Technology, 2002, 36(16): 3612-3617.

[7] GUPTA V K, ALI I, SAINI V K. Removal of chlorophenols from wastewater using red mud: An aluminum industry waste [J]. Environmental Science & Technology, 2004, 38(14): 4012-4018.

[8] JU Dong-ying, BIAN Pei. Low-temperature sintering method for NiCuZn ferrite and effect of Mn addition on electromagnetic properties [J]. Transactions of Nonferrous Metals Society of China, 2006, 16(S1): s67-s70.

[9] LIU Wan-chao, YANG Jia-kuan, XIAO Bo. Recovering iron and preparing building material with residues from Bayer red mud [J]. The Chinese Journal of Nonferrous Metals, 2008, 18(1): 187-192. (in Chinese)

[10] LIU Zi-gao, YANG Chang-shi, CHENG Zong-hao, AI Meng-jing. Treatment and utilization of red mud derived from Bayer process [J]. The Chinese Journal of Nonferrous Metals, 1997, 7(1): 40-44. (in Chinese)

[11] ALLEN S. Production of aluminium chloride: United states, US3842163 [P]. 1974-10-15.

[12] AMBIKADEVI V R, LALITHAMBIKA M. Effect of organic acids on ferric iron removal from iron-stained kaolinite [J]. Applied Clay Science, 2000, 16(3-4): 133-145.

[13] LAHIRI A. Influence of ascorbate and oxalic acid for the removal of iron and alkali from alkali roasted ilmenite to produce synthetic rutile [J]. Industrial & Engineering Chemistry Research, 2010, 49(18): 8847-8851.

[14] POZDNYAKOV I P, KEL O V, PLYUSNIN V F, GRIVIN V P, BAZHIN N M. New insight into photochemistry of ferrioxalate [J]. The Journal of Physical Chemistry A, 2008, 112(36): 8316-8322.

[15] MONTEAGUDO J M, DUR N A, AGUIRRE M, SAN M I. Optimization of the mineralization of a mixture of phenolic pollutants under a ferrioxalate-induced solar photo-Fenton process [J]. Journal of Hazardous Materials, 2011, 185(1): 131-139.

[16] PRATO-GARCIA D, VASQUEZ-MEDRANO R, HERNANDEZ- ESPARZA M. Solar photoassisted advanced oxidation of synthetic phenolic wastewaters using ferrioxalate complexes [J]. Solar Energy, 2009, 83(3): 306-315.

[17] LEE S O, TRAN T, JUNG B H, KIM S J, KIM M J. Dissolution of iron oxide using oxalic acid [J]. Hydrometallurgy, 2007, 87(3-4): 91-99.

[18] KATSUMATA H, OKADA T, KANECO S, SYZUKU T, OHTA K. Degradation of fenitrothion by ultrasound/ferrioxalate/UV system [J]. Ultrasonics Sonochemistry, 2010, 17(1): 200-206.

采用草酸和紫外光催化法处理赤泥

余章龙1,石志霞2,陈咏梅1,钮因健1, 3,王永霞1,万平玉1

1. 北京化工大学 理学院,北京 100029;

2. 北京有色金属研究总院 矿物资源与冶金材料研究所,北京100088;

3. 中国有色金属学会,北京 100814

摘 要:利用草酸作为浸出剂以除去拜耳法残渣赤泥中的氧化铁,从而提高赤泥的工业应用价值,同时对草酸浸出液进行紫外光照射,将草酸铁还原成草酸亚铁沉淀,实现草酸溶液循环再利用。实验结果表明,在75 °C下,赤泥在1 mol/L草酸溶液中浸出2 h,氧化铁的浸出率可达到96%,浸出后赤泥中氧化铁的含量由17.6%降低至小于1%。在紫外光照催化作用下,1 h内浸出液中90%以上的草酸铁转变成草酸亚铁沉淀,剩余草酸可循环再利用。该草酸亚铁为β-FeC2O4·2H2O。对UV催化沉淀的机理进行讨论分析。

关键词:赤泥;氧化铁;草酸;紫外光

(Edited by YUAN Sai-qian)

Foundation item: Project (2010AA101703) supported by the National Hi-tech Research and Development Program of China

Corresponding author: CHEN Yong-mei; Tel/Fax: +86-10-64435452; E-mail: chenym@mail.buct.edu.cn; WAN Ping-yu; pywan@mail.buct.edu.cn

DOI: 10.1016/S1003-6326(11)61198-9