文章编号:1004-0609(2012)02-0401-07

高压扭转压力对SiCp-Al复合材料组织性能的影响

李 晓,李 萍,薛克敏,王 成

(合肥工业大学 材料科学与工程学院,合肥 230009)

摘 要:采用高压扭转工艺将SiC和Al的混合粉末直接制备金属基复合材料。用金相显微镜、显微维氏硬度计、万能试验机和扫描电镜分析压力对SiCp-Al复合材料的显微组织和力学性能的影响。结果表明:压力越高,对SiCp-Al复合材料粉末成形的应变积累越有利;压力越高,扭转前粉末的致密程度越高,对SiCp-Al复合材料粉末成形的应变积累越有利,SiC颗粒在Al基体内的分布越均匀,显微硬度有所提高,但增幅不大;当压力从0.5 GPa增大至0.62 GPa,材料的屈服强度增加32.6%,但抗拉强度和伸长率均分别减小4%和25.5%。拉伸断口以大小不一的脱粘韧窝为主要特征。

关键词:SiCp-Al复合材料;高压扭转;显微组织;力学性能

中图分类号:TB331 文献标志码:A

Effects of high-pressure torsion pressure on microstructure and mechanical property of SiCp-Al composites

LI Xiao, LI Ping, XUE Ke-min, WANG Cheng

(School of Materials Science and Engineering, Hefei University of Technology, Hefei 230009, China)

Abstract: SiC particles and Al powder mixtures (SiCp-Al composites) were successfully fabricated into the metal matrix composites by high-pressure torsion (HPT). The effects of pressure on the microstructure and mechanical properties of the composites were investigated by optical telescope, microhardness-testing device, universal testing machine and scanning electronic telescope. The results show that higher pressure is more helpful to the strain accumulation during the power forming of SiCp-Al composites. In the HPT process, the higher the pressure is, the better the powerful densification is, the higher the accumulated strain is, and the more homogeneous of the SiC particles are, while the increase of microhardness is not so high. When the pressure increases from 0.5 GPa to 0.62 GPa, the yield strength increases by 32.6%, while the tensile strength and elongation decrease by 4% and 25.5%, respectively. The fracture surface of the dimples shows various sizes as the main feature.

Key words:SiCp-Al composites; high-pressure torsion; microstructure; mechanical property

SiCp/Al复合材料具有密度小,比强度、比刚度高,热膨胀系数低,导热、导电性能良好以及耐磨性能优良等一系列优点[1-4],在航空航天、汽车发动机、电子封装等方面有着广泛的应用前景[5]。传统方法(如铸造、粉末冶金)制得的复合材料存在孔隙率高、SiC颗粒分布不均匀等问题,常需要通过二次加工以增大压力和变形量进行改善[4, 6-10]。

研究表明,大塑性变形工艺可获得很大的剪切变形量,其中高压扭转法(High pressure torsion,HPT)的剪切变形能力最强,其原理示意图如图1所示[11],即在试样的轴向施加压力的同时使之受到周向的扭矩作 用[12-13]。这种工艺能获得较高的剪切变形量和较高的静水压力,不仅可以细化基体晶粒,使颗粒分布更均匀,同时能较大程度地提高粉体材料的致密程度,减少裂纹的产生,是制备综合性能优良的颗粒增强金属基复合材料的首选工艺。压力是高压扭转工艺的最主要因素,对材料的组织和性能有着极其重要的影响。迄今,国内仍未见高压扭转法制备颗粒增强金属基复合材料的相关报道。国外对复合材料的高压扭转研究主要集中于剪切应变对材料组织性能的影响[11, 14-16],而对压力的研究较少。

图1 高压扭转工艺原理示意图

Fig. 1 Schematic illustration of HPT processing

本文作者采用高压扭转法成功将SiC与Al的混合粉末直接制备成复合材料,并研究高压扭转过程压力对材料组织性能的影响。

1 实验

实验选用平均颗粒尺寸为13.59 μm的绿色多角形α-SiC颗粒(纯度99%以上)为增强体,以平均颗粒尺寸37.28 μm的工业铝粉(纯度大于98.7%)为基体。在室温下采用高压扭转技术直接将经过高温氧化处理的SiC颗粒与纯铝的混合粉末制成体积分数为8.75%的SiCp-Al复合材料。扭转角速度约为1 r/min,获得的试样尺寸约为d 30 mm×2 mm。

用4XB-TV倒置显微镜对试样横截面的显微组织进行分析。分别采用MH-3型显微维氏硬度计、CMT 4104万能试验机和JSM6490/LV扫描电镜进行显微硬度、拉伸性能、拉伸断口扫描等测试(采用排水法对试样的密度进行测量)。

2 结果与讨论

该高压扭转实验过程是压制+扭转的组合,将SiC颗粒、Al的混合粉放置型腔内,上模下压,压力达到设定值后开始扭转。为确定扭转前压力对粉末致密的影响,故对粉末进行扭转前的压制,并测量压制后试样的致密度。结果表明,压力从0.3 GPa增加至0.62 GPa,试样致密度从95.1%提高至98.2%。

2.1 显微组织分析

2.1.1 扭转变形初期的显微组织

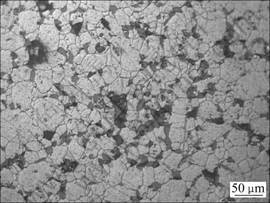

图2所示为扭转前压力为0.3 GPa室温压制后试样中心处的金相组织。由于各个扭转半径处的金相组织基本相同,在此只选了中心处的金相照片。图2基体晶粒大小不一,呈近似等轴状,较多的SiC颗粒簇分布在晶界,存在较多明显孔隙,致密效果较差。为分析粉末在扭转变形初期压力对粉末变形的影响,因此对室温、较低压力下扭转较多圈数的试样1(p=0.3 GPa,N=0.5)和在较高压力扭转较少圈数的试样2 (p=0.5 GPa,N=1/3)进行金相组织分析。

图2 0.3 GPa压力压制后试样的显微组织

Fig. 2 microstructure of sample after pressing at 0.3 GPa

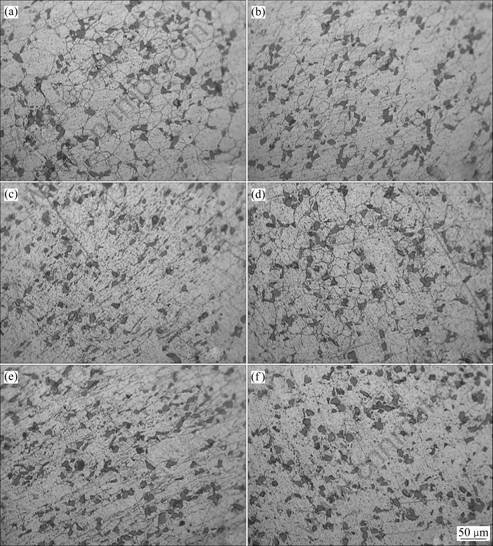

图3所示为试样1和2在不同扭转半径处的金相组织。从图3可以看出,中心处(r=0 mm)的基体晶粒 (见图3(a)和(d)),呈近似等轴状,几乎无扭转变形特征,形态基本与图2相似。随着扭转半径的增大,等轴状的基体晶粒逐渐被拉长,晶界最后模糊不清。但是压力越大,晶粒呈现明显形变特征的位置越靠近中心。表1所列为试样1和2在不同扭转半径处的显微组织特征。压力比较大的试样2的理论剪切变形 量[11]γ=1.17π时呈现明显的形变特征,而压力较小的试样1在γ=5.1π时才出现。从图3也发现,形变特征比较明显的组织内部均无明显孔隙。这是因为粉末在变形初期,主要以致密为主。在剪切变形和压力的共同作用下,粉末致密程度逐渐提高。当致密到一定程度,粉末变形则以剪切变形为主。压力越大则粉末起始致密度越高,剪切变形则越快占主导地位,实际积累的剪切应变量越大。

图3 试样不同扭转半径处基体组织

Fig. 3 Matrix microstructures of samples at different distances from center: (a) Sample 1, r=0; (b) Sample 1, r=7 mm; (c) Sample 1, r=10.5 mm; (d) Sample 2, r=0; (e) Sample 2, r=3.5 mm; (f) Sample 2, r=7 mm

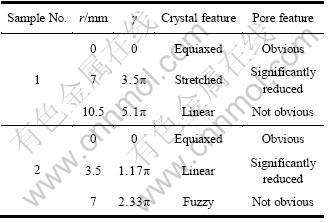

表1 试样1和2在不同扭转半径处的显微组织特征

Table 1 Microstructure features of samples 1 and 2 at different distances from center

2.1.2 压力对显微组织的影响

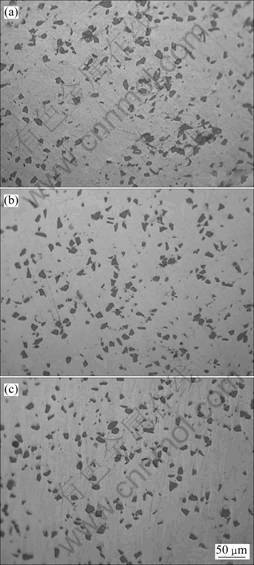

图4所示为室温(RT)下扭转2圈、r=3.5 mm处不同压力下试样的金相照片。压力较小时,存在大量SiC颗粒集聚簇,且集聚簇间有少量空隙。且随着压力的增加,SiC颗粒集聚簇及空隙均发生明显减少,单个游离的SiC颗粒成链状排列,大尺寸的SiC颗粒数量稍微减少,SiC颗粒尖角发生明显钝化,大片“贫SiC”铝基体区域有所减小,颗粒分布逐渐均匀。这是由于在高压扭转过程中,一方面随着变形的进行,位错密度不断提高,在SiC颗粒和基体晶界的阻碍作用下,堆积缠结。逐渐增大的压力使得粉末致密程度得到提高,实际积累的剪切变形量增大,位错缠结加剧,内应力增大,最终使基体晶粒得到细化,晶界增多,SiC颗粒发生移动和重新排列的空间变大。另一方面,增大压力可以更好地传递扭矩[17],使材料受到更有效的剪切作用。逐渐增大的剪应力克服团聚SiC颗粒簇间的吸附力,使之分散成细小的团聚簇甚至游离的SiC颗粒,离散分布在晶界间,颗粒分布的均匀性得到改善。同时,较大的SiC颗粒通常存在一定的微裂纹,在逐渐增大的剪应力作用下容易发生断裂、破碎;而SiC颗粒尖角处引起的应力集中一般较大,尖角在剪应力作用下易发生断落,并随着压力的增大而逐渐圆化。

图4 不同压力条件下试样的金相照片

Fig. 4 Microstructures processed by HPT at different pressures: (a) 0.3 GPa; (b) 0.5 GPa; (c) 0.62 GPa

2.2 力学性能分析

2.2.1 显微硬度

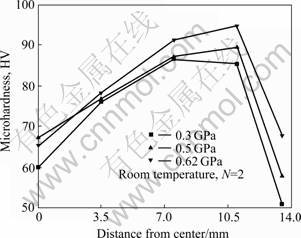

图5所示为不同压力下扭转2圈所获得的试样沿扭转半径的显微硬度曲线。从图5可以看到,显微硬度沿着扭转半径先增大后减小。随着压力的增大,试样整体的显微硬度逐渐提高,但幅度不大。这是由于一方面压力的增大使粉末材料得到有效的致密化,并改善SiC颗粒的团聚程度,提高对基体的增强效果;另一方面,增大压力,材料的起始致密度增大,使得试样积累的有效剪切变形量增加,基体组织的细化效果得到提高,单位体积内的晶界面积增多,导致硬度增大。但由于压力的提高对剪切变形量的影响程度有限,故增大幅度不大。此外,由于试样边缘附近位于高压扭转工艺凸凹模间隙的影响区,材料不受三向压应力作用,导致接近边缘处的硬度降低。

图5 不同压力下高压扭转试样的显微硬度曲线

Fig. 5 Microhardness curves of samples processed by HPT at different pressures

2.2.2 拉伸性能及断口分析

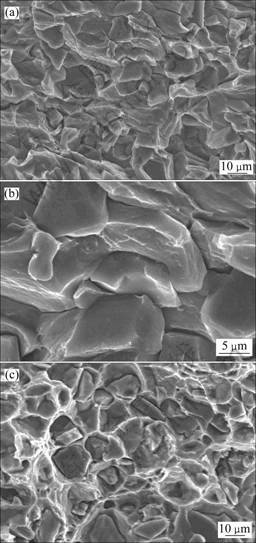

图6(a)所示为试样1和2的拉伸真实应力—应变曲线。可见,试样1的强度、伸长率均远小于试样2的。试样1和试样2的拉伸断口SEM形貌如图7所示。试样1的断口组织内部存在明显的裂纹,颗粒之间的固结效果非常差。裂纹一方面从铝颗粒间结合较弱处萌生,沿着结合边界扩展;另一方面在SiC颗粒与铝基体的弱结合面处形成,沿着界面向基体扩展。随着拉伸应力的增加,裂纹迅速形核生长,材料断裂。而试样2的拉伸断口上存在大大小小的坑, 较大尺寸的坑与SiC颗粒相当,内部比较光滑,是SiC从基体脱落留下的,外形与韧窝相似,在此简称为脱粘韧窝。有少量脱粘韧窝内仍镶嵌着断裂的SiC颗粒。从脱粘韧窝的分布可看出SiC颗粒有少量团聚。而少量尺寸很小的坑分布在铝基体上,是在拉伸变形过程形成的,属于典型的韧窝。由于SiC的阻碍作用使得微孔或者微裂纹不会继续长大,当发生宏观失效时,韧窝被破坏,基体发生撕裂。从以上分析可知,在扭转变形的初始阶段,压力是影响材料力学性能的最主要因素。

图6 室温下试样的拉伸真应力—应变曲线

Fig. 6 Tensile true stress—strain curves of samples at room temperature

图6(b)所示为室温下扭转2圈、压力分别0.5 GPa、0.62 GPa时试样的真实应力—应变曲线。由图6(b)可知:随着压力的增加,材料的屈服强度增加32.6%,但抗拉强度和断后伸长率分别减小4%和25.5%。由2.2.1节的分析知,压力越大,材料起始的致密度越高,而从试样2的显微组织也发现,0.5 GPa压力引起的致密程度达到一个较高的水平,故扭转过程中试样以剪切变形为主。因此,随着压力的继续增加尤其是增幅不大的情况下,材料受到的剪切应变相差不太大;随着压力的增加,材料的屈服强度提高但抗拉强度和塑性却稍有降低。

图7 拉伸试样断口的SEM形貌

Fig. 7 SEM fractographs of fracture of tensile samples: (a), (b) Sample 1, p=0.3 GPa, N=0.5; (c) Sample 2, p=0.5 GPa, N=1/3

图8所示为室温扭转2圈、不同压力下试样的拉伸断口SEM形貌。由图8可以看出,断口上分布着尺寸不一的脱粘韧窝,部分仍镶嵌着断裂的SiC颗粒。裂纹主要是从SiC颗粒的界面结合较弱的区域产生,沿着SiC与基体的结合面向基体扩展,遇到微孔,裂纹则急剧长大。随着拉伸应力的增加,材料失效,最后发生断裂。相比压力低的试样断口(见图8(a))),压力稍高的试样断口的脱粘韧窝尺寸明显增大,深度变浅,数量减少,且基体上分布着数量不少的细小深孔,这导致压力高的试样性能反而比压力低的差。因为脱粘韧窝数量越少,尺寸越大,深度越浅,则裂纹扩展和长大的阻力越小,材料越容易断裂。同时基体微孔的增多,使得基体的裂纹源增多,宏观上则表现为材料的强度和塑性下降。

图8 不同压力下拉伸试样的断口SEM形貌

Fig. 8 SEM fractographs of fracture of tensile samples by HPT at different pressures: (a) 0.5 GPa; (b) 0.62 GPa

3 结论

1) 压力越大,则扭转前粉末的致密程度越高,试样在扭转过程中积累的剪切应变量越多;SiC颗粒在Al基体内的分布越均匀。

2) 硬度沿着扭转半径先增大后减小。随着压力的增大,积累的有效剪切应变量有所增加,基体组织得到一定程度的细化,单位体积内晶界面积增多,硬度得到提高但幅度不大。

3) 高压扭转过程压力从0.5 GPa增大至0.62 GPa,材料的屈服强度增加32.6%,但抗拉强度和断后伸长率均分别减小4%和25.5%。从断口分析可知,基体中的微孔对材料性能有重要影响。

4) 高压扭转后,SiCp-Al复合材料拉伸断口均以大小不一的脱粘韧窝为主要特征。在拉伸应力的作用下,裂纹首先在基体与 SiC之间结合较弱的局部区域萌生;随着拉伸应力的增大,裂纹不同程度的向各个方向扩展、长大。

REFERENCES

[1] Contreras A, Angeles-Chávez C, Flores O, PEREZ R. Structural, morphological and interfacial characterization of Al2Mg/TiC composites[J]. Mater Character, 2007, 58: 685-693.

[2] zamtzis T S, Barekar N S, Hari Babu N, Patel J, Dhindaw B K, Fan Z. Processing of Advanced Al/SiC particulate metal matrix composites[J]. Composites A, 2009, 40: 144-151.

[3] Miracle D B. Metal matrix composites—From science to technological signi?cance[J]. Compos Sci Technol, 2005, 65: 2526-2540.

[4] 郝 斌, 段先进, 崔 华, 杨 滨, 张济山. 金属基复合材料的发展现状及展望[J]. 材料导报, 2005, 19(7): 64-68.

HAO Bin, DUAN Xian-jin, CUI Hua, YANG Bin, ZHANG Ji-shan. Present status and expectation of metal matrix composites[J]. Materials Review, 2005, 19(7): 64-68.

[5] 胡耀波, 王敬丰, 潘复生, 左汝林, 王文明, 宋文远, 曾苏民. 包套热挤压SiCp/6066铝基复合材料断裂机制和强化机制的研究[J]. 材料导报, 2007, 21(2): 151-153.

HU Yao-bo, WANG Jing-feng, PAN Fu-sheng, ZUO Ru-lin, WANG Wen-ming, SONG Wen-yuan, ZENG Su-min. Research on fracture and strengthening mechanisms of SiCp/6066 aluminum matrix composites with canned hot extrusion[J]. Materials Review, 2007, 21(2): 151-153.

[6] 武 涛, 柴东朗, 宋余九. 粉末冶金制备颗粒增强5052铝基复合材料的压力加工工艺研究[J]. 热加工工艺, 2005(6): 65-67.

WU Tao, CHAI Dong-lang, SONG Yu-jiu. Study on pressing and extruding processes of particulate reinforced 5052Al alloy matrix composite made by P/M method[J]. Hot Working Technology, 2005(6): 65-67.

[7] 栾佰峰, 姜龙涛, 孙海宽, 武高辉. 热挤压变形对亚微米Al2O3p/A复合材料组织性能的影响[J]. 中国有色金属学报, 2002, 13(2): 374-376.

LUAN Bai-feng, JIANG Long-tao, KONG Hai-kuan, WU Gao-hui. Effect of hot extrusion deformation on microstructure and mechanical properties of sub-micro Al2O3p/Al composite[J]. The Chinese Journal of Nonferrous Metals, 2002, 13(2): 374-376.

[8] ZHANG Fan, SUN Peng-fei, LI Xiao-cui, ZHANG Guo-ding. A comparative study on microplastic deformation behavior in a SiCp/2024Al composite and its unreinforced matrix alloy[J]. Materials Letters, 2001, 49: 69-74.

[9] Xu H, Palmiere E J. Particulate refinement and redistribution during the axisym metric compression of an Al/SiCp metal matrix composite[J]. Composites A, 1999, 30: 203-211.

[10] 魏少华, 樊建中, 张 琪, 左 涛,邹利华. 等温锻造对SiCp/Al复合材料颗粒分布的影响[J]. 宇航材料工艺, 2009, 4: 52-57.

WEI Shao-hua, FAN Jian-zhong, ZHANG Qi, ZUO Tao, ZOU Li-hua. Effect of isothermal forging on distribution of particles of SiCp/Al composites[J]. Aerospace Materials & Technology, 2009, 4: 52-57.

[11] Alexander P, Zhilyaev, Langdon T G. Using high-pressure torsion for metal processing: Fundamentals and applications[J]. Progress in Materials Science, 2008, 53: 893-979.

[12] 陈勇军, 王渠东, 彭建国, 翟春泉, 丁文江. 大塑性变形制备细晶材料的研究、开发与展望[J]. 材料导报, 2005, 19(4): 77-80.

CHEN Yong-jun, WANG Qu-dong, PENG Jian-guo, ZHAI Chun-quan, DING Wen-jiang. Research and development prospects of ultrafine-grained materials fabricated by severe plastic deformation[J]. Materials Review, 2005, 19(4): 77-80.

[13] 上官丰收, 谢季佳, 洪友士. 高压扭转致纯铜晶粒细化及与应变的关系[J]. 材料研究学报, 2007, 21(1): 72-76.

SHANGGUAN Feng-shou, XIE Ji-jia, HONG You-shi. Grain refinement and its correlation with strain for pure copper subjected to high pressure torsion[J]. Chinese Journal of Materials Research, 2007, 21(1): 72-76.

[14] Sabirov I, Kolednik O, Pippan R. Homogenization of metal matrix composites by high pressure torsion[J]. Metallurgical and Materials Transactions A, 2005, 36: 2005-2863.

[15] Alexandrov I V, Zhu Y T, Lowe T C, ISLAMGALIEV R K, VALIEV R Z. Microstructures and prosperities of nanocomposites obtained through SPTS consolidation of powders[J]. Metal Mat Trans A, 1998, 29A: 2253-2260.

[16] Edalati K, Horita Z. Application of high-pressure torsion for consolidation of ceramic powders[J]. Scripta Materialia, 2010, 63(2): 174-177.

[17] WETSCHER F, VORHAUER A, PIPPAN R. Strain hardening during high pressure torsion deformation[J]. Materials Science and Engineering A, 2005, 410/411: 213-216.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51175138);高等学校博士学科点专项基金资助项目(20100111110003);安徽省优秀青年科技基金项目资助(10040606Y21)

收稿日期:2011-01-24;修订日期:2011-06-10

通信作者:李 萍,教授,博士;电话:0551-2901368;传真:0551-2904758;E-mail: cisi_1314@126.com