Trans. Nonferrous Met. Soc. China 22(2012) s402-s407

Effect of equal channel angular pressing and torsion on SiC-particle distribution of SiCp-Al composites

LI Ping, ZHANG Xiang, XUE Ke-min, LI Xiao

School of Materials Science and Engineering, Hefei University of Technology, Hefei 230009, China

Received 28 August 2012; accepted 25 October 2012

Abstract: Equal channel angular pressing and torsion (ECAPT) was applied to fabricate SiCp-Al composites from the mixture of 35% SiC (volume fraction) particles and 65% Al powder. Based on microstructure observation and the quadrat method, the distributions of SiC particles in different positions of the samples and in different forming stages were studied. And the particle distribution was contrasted with that in the samples fabricated by multi-pass equal channel angular pressing (ECAP). The results show that the shear strain influences the distribution of SiC particles significantly. The distribution homogeneity of SiC particles increases greatly from the compaction stage to the angular pressing stage during ECAPT. The improvement of the particle distribution homogeneity through single pass of ECAPT process is close to that through two passes of ECAP. The relative homogeneous distribution of SiC particles is obtained through ECAPT.

Key words: equal channel angular pressing and torsion; SiCp-Al composites; particle distribution; quadrat method; shear strain

1 Introduction

SiCp-Al composites have the advantages of high strength, high wear resistance, small coefficient of thermal expansion, good dimensional stability, and can be widely used in aerospace, mechanical and manufacturing industry [1,2]. However, the distribution of SiC particles has important effects on properties, such as strength and ductility. Studies have shown that in the regions of particle clusters, defects such as cracks and fractures were found [3,4].

Particle clusters appear when fabricating SiCp-Al composites by traditional methods such as casting and powder metallurgy, which significantly decreases the properties of the composites [5]. As a result, the secondary processing will be applied to decrease the clusters [6]. Therefore, developing a new approach to fabricate SiCp-Al composites without secondary processing is of great significance.

As well known, severe plastic deformation (SPD) can be applied to improve the homogeneity of the particle distribution [7]. As a typical SPD process, equal channel angular processing and torsion (ECAPT) has a high hydrostatic pressure and shear strain, which can make grains refine, holes close and particles distribute homogeneously [8]. Therefore, it is the preferred process for fabricating the metal matrix composites (MMCs) with excellent performances. So far, there are some reports about ECAPT preparation of pure metal and alloys [9,10]. But its applications on particulates reinforced metal matrix composites have not been investigated.

In this work, the mixtures of SiC particles and Al powders were fabricated into metal matrix composites by ECAPT and ECAP, respectively. And the effects of different technologies, positions and deformation stages on the distribution of SiC particles were investigated.

2 Experimental

The materials used in this work were 35% α-SiC particles (volume fraction) and 65% pure Al powders.The average particle sizes were 13.59 μm and 37.28 μm, respectively. Then, the mixed powders were filled into a red copper tube (10 mm×10 mm×60 mm) with the initial relative density of 0.7.

The experiments were conducted using a RZU2000HF pressing and torsion machine. The ECAPT equipment was designed to yield an effective strain of 1-2 by a single pass. The parameters of the die were  =90° and φ=37°, respectively (Fig. 1). The length of the twist channel was 30 mm and the rotation angle of the cross-section was 90°. The dimension of the channels cross-section was 10 mm×10 mm. The deformation temperature was 200 °C and the ram velocity was 1 mm/s. MoS2 and graphite composite lubricant was used.

=90° and φ=37°, respectively (Fig. 1). The length of the twist channel was 30 mm and the rotation angle of the cross-section was 90°. The dimension of the channels cross-section was 10 mm×10 mm. The deformation temperature was 200 °C and the ram velocity was 1 mm/s. MoS2 and graphite composite lubricant was used.

After deformation, the surrounding tube materials were removed by linear cutting and the deformed samples were machined into standard samples vertical to the extrusion direction for microstructure observation and quantitative analysis.

Fig. 1 Schematic of ECAPT

3 Results and discussion

3.1 Effect of shear strain on particle distribution

On the basis of a geometric model of particle distribution, MOSTAFAVI and AGNEW [11] proposed that to obtain a uniform particle distribution, the particle size should not be less than a critical value Dp, which could be expressed by [12]

(1)

(1)

where Dm is the matrix powder size, f is the volume fraction of SiC particles, γ is the shear strain.

For a given matrix material, the homogeneous particle distribution can be obtained when the SiC particle volume fraction is small or the shear strain is large enough.

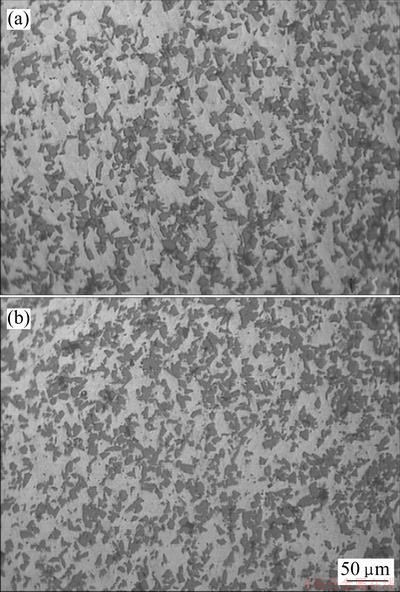

Figure 2 shows the microstructures of the samples processed by one pass of ECAP and ECAPT. It can be seen that most of the SiC particles still keep the initial size after one pass of ECAP, and the particle distribution is inhomogeneous (Fig. 2(a)). Furthermore, many particle clusters with pores and zones without SiC particles are visible. However, zones without SiC particles decrease greatly and relative homogeneous particle distribution are observed after one pass of ECAPT (Fig. 2(b)).

Fig. 2 Microstructures of samples processed by one pass of ECAP (a) and ECAPT (b)

ECAPT induces larger shear strain into sample than ECAP. According to Eq. (1), the particle critical size Dp is smaller and the homogeneity of the particle distribution is improved. With deformation proceeding, the grains are refined and the powder particles are rearranged significantly during ECAPT. Continuous shearing makes the matrix overcome “arch bridge” produced by the clusters and prevents particles from reuniting. The refinement of the matrix microstructure promotes particle redistribution and then makes the SiC particle distribution more homogeneous.

3.2 Quantitative expression of particle distribution

Quadrat method is one of the most simple and effective ways to characterize the uniformity of the particle distribution. In quadrat method, the microstructure image to be studied is divided into a grid of square cells and the number of particles in each cell Nq is counted. In this work, because of the high volume fraction of SiC particles, empty quadrat(matrix without SiC particles), Nq=0, is correlated with particle clusters in other positions. Otherwise, studies found that with the deformation degree increasing, there were more finer SiC particles. It was consistent with the study results of reports about SiC composites [13-15].

Figure 3 shows the mean values of the number of particles per quadrat at different processes. Because the quadrat size is twice of the size of the mean area per particle, the theoretical mean value of the number of particles per quadrat is about 1.5. However, they are about 2 and 2.14 after one and two passes of ECAP, respectively. It is 2.11 after one pass of ECAPT and close to that after two passes of ECAP. Therefore it can be concluded that SiC particles are refined and the total number of the particles increases after ECAPT.

Fig. 3 Average number of SiC particles per quadrat at different processes

3.3 Analysis of particle distribution

The frequency histograms of the number of SiC particles per quadrat, Nq, in different positions of the samples after one pass of ECAP and ECAPT are plotted in Fig. 4. As shown in Fig. 4(a), for ECAP, the frequency of empty quadrat is the lowest in inner corner and the highest in outer corner. It shows that the particle clusters are the least in inner corner and the most in outer corner. Therefore, the uniformity of SiC particle distribution is the best in inner corner and the worst in outer corner of all positions. The frequencies of quadrats containing 1-3 particles are also different in different positions. The different frequencies of quadrats containing 4 particles are caused by the clusters of SiC particles. The results show that the composite materials experience a non-uniform deformation and that an inhomogeneous particle distribution exists in the matrix.

For ECAPT, as shown in Fig. 4(b), the frequencies of empty quadrats in all positions are reduced to less than 5%. The frequencies of empty quadrats and the differences of all positions are less than that of ECAP. The total frequency of quadrats containing 1-3 particles in each position is up to 90%. It shows that improvement of the particle distribution through ECAPT process is better than that through ECAP and relative homogeneous distribution of SiC particles is obtained.

The frequency histogram of the number of SiC particles per quadrat, Nq, in the center of the samples after multi-pass of ECAP and ECAPT are plotted in Fig. 5. The frequencies of empty quadrats decrease with the number of ECAP passes increasing. It shows that the homogeneity of the particle distribution increases with the ECAP passes. The frequency of empty quadrat in the center of the sample processed by ECAPT is lower than that of one pass of ECAP, and as low as two passes of ECAP because the shear strain obtained from ECAPT is larger than that obtained from ECAP for the same pass. That is, the particle clusters can be dissolved during severe shear deformation. The frequencies of quadrats containing four particles discord with the above law. It is attributed to the different effects of grain refinement on the particle distribution during different processes.

Fig. 4 SiC particle distribution in different positions

Fig. 5 SiC particle distribution in different processes

Therefore, the shear strain directly influences the homogeneity of SiC particle distribution. The frequency of empty quadrat is low and the zone without SiC particles is small in the place where the shear strain is large enough. The SiC particles distribute along the grain boundaries. So, when the distribution of SiC particles is homogeneous, the distribution and the size of aluminum grains are also homogeneous.

3.4 Mechanism of SiC particle distribution during ECAPT

SiCp-Al composites have advanced mechanical properties. In order to obtain both high strength and good ductility, high volume fraction of fine particles are preferred. However, SiCp-Al composites with large volume fraction particles show a very inhomogeneous particle distribution, which limits the formability of these materials. So, the distribution of SiC particles is a very significant factor to obtain a material with good properties. And it depends upon the compatibility of SiC particles and matrix, density, process and so on [16].

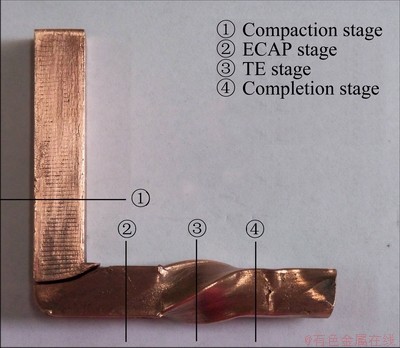

In order to obtain the samples in different deformation stages during ECAPT, the die was disassembled in the half-way of the extrusion and the deforming sample was obtained. According to structural features of the die, the following four deformation stages are chosen, as shown in Fig. 6.

Fig. 6 Schematic of different deformation stages

1) Compaction stage: The materials in the erect channel are going down by the force of punch.

2) ECAP stage: The materials pass the corner to horizontal channel.

3) TE stage [17]: The materials are in the twist channel.

4) Completion stage: The materials complete deformation.

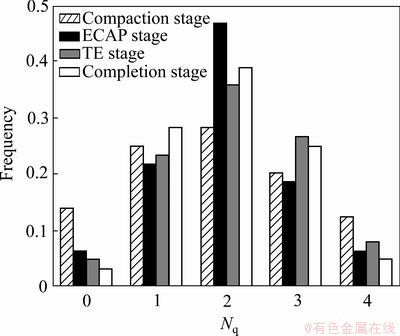

The frequency histogram of the number of SiC particles per quadrat, Nq, in the center of the samples in different stages of ECAPT are plotted in Fig. 7. It can be seen that the frequencies of empty quadrats decrease with deformation proceeding. From the compaction stage to the ECAP stage, the frequency of empty quadrat decreases to 6.3% from 14.1%, the decreasing amplitude is up to 55.3%. It shows that the major decrease of the SiC particle clusters occurs in the ECAP stage. The total frequency of quadrats containing 1-3 particles is above 90% in completion stage. The histogram of the particle distribution for the material after ECAPT resembles the Poisson distribution confirming the near homogeneous SiC particle distribution.

Fig. 7 SiC particle distribution at different stages of ECAPT

Studies have found that, in the compaction stage, the matrix grains still kept the initial size, and most of the particles distributed around the grain boundaries or formed clusters and pores. During ECAPT, numerous shear deformation bands occurred in the materials. With the development of deformation, the grains elongated along the deformation direction. And the surrounding SiC particles realigned as chain-like distribution. The main deformation mechanism of ECAPT was intra- granular dislocation movement. With the deformation proceeding, accumulation of plastic deformation and multiplication of dislocation led to dislocation density and vacancy concentration increase. Because of the obstruction of matrix grain boundaries and SiC particles, dislocation accumulated and tangled. Internal stress increased greatly. With the further proceeding of deformation, the matrix grains were refined and numerous new matrix grain boundaries generated. SiC particles moved and rearranged continuously. When the shear strain was large enough, SiC particles even could overcome the obstruction of the matrix grain boundaries and moved into the grains. It improved the homogeneity of the distribution of SiC particles. Therefore, severe plastic deformation provided by ECAPT, not only promoted the rearrangement of SiC particles, but also supplied driving force and propelled the SiC particles redistribution in the grain boundaries and in the grains. The distribution characteristics of SiC particles during ECAPT are shown in Fig. 8.

Fig. 8 Distribution characteristics of SiC particles during ECAPT

4 Conclusions

1) The homogeneity of the particle distribution is the best in inner corner and the worst in outer corner among all positions after one pass of ECAP and it is improved with the ECAP passes.

2) For ECAPT, with the deformation proceeding, the distribution of the SiC particles is more homogeneous. Especially from the compaction stage to the ECAP stage, the increasing amplitude of homogeneity is the most of all.

3) The improvement of the particles distribution through single pass of ECAPT process is better than that through single pass of ECAP and close to that through two passes of ECAP. The shear strain directly influences the homogeneity of SiC particle distribution. The capability for particle redistribution is enhanced by shear strain.

References

[1] XIU Zi-yang, CHEN Guo-qing, YANG Wen-shu, SONG Mei-hui, WU Gao-hui. Microstructure and thermal properties of recyclable Sip/1199Al composites [J]. Transactions of Nonferrous Metals Society of China, 2009, 19(6): 1440-1443.

[2] LIU Hao-zhe, He Hong-liang WANG Lu-hong, WANG Ai-ming, JIN Chang-qing. Synthesis of SiCp/Al nanocomposites under ultra-high pressure [J]. Chinese Journal of High Pressure Physics, 1999, 13(1): 1-6. (in Chinese)

[3] SONG Ming. Effects of volume fraction of SiC particles on mechanical properties of SiC/Al composites [J]. Transactions of Nonferrous Metals Society of China, 2009, 19(6): 1400-1404.

[4] LLOYD D J. Factors influencing the tensile ductility of melt processed particle reinforced aluminium alloys [C]// Intrinsic and Extrinsic Fracture Mechanisms in Inorganic Composite Systems. Las Vegas, NV, USA: Minerals, Metals & Materials Soc (TMS), 1995: 39-47.

[5] PAGOUNIS E, LINDROOS V K. Processing and properties of particulate reinforced steel matrix composites [J]. Materials Science and Engineering A, 1998, 246(1-2): 221-234.

[6] LLOYD D J, LAGACE H, MCLEOD A, MORRIS P L. Microstructural aspects of aluminum-silicon carbide particulate composites produced by a casting method [J]. Materials Science and Engineering A, 1989, 107(1-2): 73-80

[7] SABIROV I, KOLEDNIK O, PIPPAN R. Homogenization of metal matrix composites by high-pressure torsion [J]. Metallurgical and Materials Transactions A, 2005, 36(10): 2861-2870.

[8] WANG Xiao-xi, XUE Ke-min, LI Ping, WU Zhan-li, LI Qi. Equal channel angular pressing and torsion of pure Al powder in tubes [J]. Advanced Materials Research, 2010, 97(101): 1109-1115.

[9] LI Ping, ZHANG Xiang, XUE Ke-min, WANG Xiao-xi, WU Zhan-li. Research on the new technique of equal channel angular pressing and torsion of pure aluminium [J]. Journal of Plasticity Engineering, 2010, 17(5): 47-52. (in Chinese)

[10] WANG Xiao-xi, XUE Ke-min, LI Ping, ZHANG Xiang, WANG Chen. Deformation behaviour of equal channel angular pressing and torsion with retained sample [J]. China Mechanical Engineering, 2011, 22(8): 976-979. (in Chinese)

[11] MOSTAFAVI M, AGNEW B. The impact of ambient temperature on Lithium-Bromide/water absorption machine [J]. Applied Thermal Engineering, 1996, 16(5): 515-522.

[12] HENRY R C, LEWIS C W, COLLINS J F. Vehicle-related hydrocarbon source compositions from ambient data: The GRACE/SAFER method [J]. Environmental Science and Technology, 1994, 28(5): 823-832.

[13] SUN You-ping, YAN Hong-ge, CHEN Zhen-hua, CHEN Gang. Microstructure and properties of Bc route ECAP of 7090/SiCp composite [J]. The Chinese Journal of Nonferrous Metals, 2008, 18(11): 1964-1970. (in Chinese)

[14] SUN Xu-wei, ZENG Sun-min, CHEN Zhi-qian, CHEN Nan-pu. Research on the Preparation of SiCp/6066Al Composites [J]. Journal of Southwest China Normal University, 2005, 30(5): 888-892. (in Chinese)

[15] SUN You-ping, YAN Hong-ge, HE Jiang-mei, CHEN Gang. Effects of equal channel angular pressing (ECAP) on microstructure and properties of SiCp/Al composites [J]. Special Casting & Nonferrous Alloys, 2010, 30(9): 845-848. (in Chinese)

[16] FAN Jian-zhong, SANG Ji-mei, ZHANG Yong-zhong, ZHANG Kui, ZHANG Shao-ming, SHI Li-kai. The spatial distribution of reinforcements in aluminium matrix composites [J]. Acta Metallrugica Sinica, 1998, 34(11): 1199-1204.

[17] LI Ping, WANG Cheng, XUE Ke-min, WANG Xiao-xi, ZHANG Xiang. Influence of the effective strain on microstructure and property of pure copper in the twist extrusion [J]. Journal of Plasticity Engineering, 2011, 18(3): 30-34. (in Chinese).

等通道转角挤扭工艺对SiCp-Al 复合材料SiC颗粒分布的影响

李 萍,张 翔,薛克敏,李 晓

合肥工业大学 材料科学与工程学院,合肥 230009

摘 要:采用等通道转角挤扭工艺(ECAPT)将体积浓度为35%的SiC颗粒与65%的纯铝混合粉末直接制备SiCp-Al复合材料。基于金相组织观察和样方法分析,研究在同一试样不同的位置和不同的变形阶段的SiC颗粒分布,并与多道次等通道转角挤压工艺(ECAP)下SiC颗粒的分布进行比较。实验结果表明:剪应变对SiC颗粒的分布有重要的影响。在ECAPT过程中,SiC颗粒分布的均匀性从压实阶段到转角阶段得到很大的改善;单道次ECAPT工艺对SiC颗粒分布均匀性的改善效果相当于两道次ECAP,可以获得相对均匀的颗粒分布。

关键词:等通道转角挤扭;SiCp-Al复合材料;颗粒分布;样方法;剪应变

(Edited by DENG  -xiang)

-xiang)

Foundation item: Project (51175138) supported by the National Natural Science Foundation of China; Project (20100111110003) supported by Specialized Research Fund for the Doctoral Program of Higher Education, China; Project (10040606Y21) supported by the Science and Technological Fund of Anhui Province for Outstanding Youth, China

Corresponding author: LI Ping; Tel: +86-0551-2901368; E-mail: cisi_1314@126.com

DOI: 10.1016/S1003-6326(12)61738-5