Cu/Mg比对AA7085显微组织与性能影响

来源期刊:中国有色金属学报(英文版)2014年第7期

论文作者:吴先哲 肖代红 朱哲民 李秀秀 陈康华

文章页码:2054 - 2060

关键词:AA7085铝合金;Cu/Mg比;力学性能;腐蚀性能

Key words:AA7085 aluminum alloy; Cu/Mg ratio; mechanical properties; corrosion performance

摘 要:采用熔铸法制备具有不同Cu/Mg比(0.67, 1.0, 1.06, 1.6)的AA7085铝合金。采用金相显微镜、扫描电镜、力学性能测试和腐蚀测试研究Cu/Mg比对基体合金显微组织、力学性能和腐蚀行为的影响。结果表明,当Cu/Mg比为1.6时,AA7085铝合金具有更好的抑制再结晶能力和抗腐蚀性能。当Cu/Mg比为0.67时,铝合金具有更为优越的力学性能,其抗拉强度与屈服强度分别达到586和550 MPa。而当Cu/Mg比为1.0时,合金的力学性能和耐腐蚀性能均下降。

Abstract: AA7085 aluminum alloys with different Cu/Mg ratios (0.67, 1.0, 1.06, 1.6) were prepared by ingot metallurgy method. The effects of Cu/Mg ratio on the microstructure, mechanical properties and corrosion behavior of the AA7085 alloys were investigated by optical microscope, scanning electron microscope (SEM), mechanical properties and corrosion testing. The results indicate that a better recrystallization inhibition and corrosion resistance can be achieved when Cu/Mg ratio is 1.6. When Cu/Mg ratio is 0.67, the alloy reveals better mechanical properties, and the tensile strength and yield strength of AA7085 alloys are 586 and 550 MPa, respectively. Moreover, both the mechanical properties and corrosion resistance of the alloy are reduced when Cu/Mg ratio is equal to 1.0.

Trans. Nonferrous Met. Soc. China 24(2014) 2054-2060

Xian-zhe WU, Dai-hong XIAO, Zhe-min ZHU, Xiu-xiu LI, Kang-hua CHEN

State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China

Received 17 October 2013; accepted 11 April 2014

Abstract: AA7085 aluminum alloys with different Cu/Mg ratios (0.67, 1.0, 1.06, 1.6) were prepared by ingot metallurgy method. The effects of Cu/Mg ratio on the microstructure, mechanical properties and corrosion behavior of the AA7085 alloys were investigated by optical microscope, scanning electron microscope (SEM), mechanical properties and corrosion testing. The results indicate that a better recrystallization inhibition and corrosion resistance can be achieved when Cu/Mg ratio is 1.6. When Cu/Mg ratio is 0.67, the alloy reveals better mechanical properties, and the tensile strength and yield strength of AA7085 alloys are 586 and 550 MPa, respectively. Moreover, both the mechanical properties and corrosion resistance of the alloy are reduced when Cu/Mg ratio is equal to 1.0.

Key words: AA7085 aluminum alloy; Cu/Mg ratio; mechanical properties; corrosion performance

1 Introduction

7xxx (Al-Zn-Mg-Cu) alloys with ultra-high strength are very important light-mass structure materials and widely used in military and aerospace technology because of the unique combination of high strength-to-density ratio and excellent mechanical properties [1-3]. However, Al-Zn-Mg-Cu alloys are susceptible to the localized corrosion. And sometimes the increase in yield strength of Al-Zn-Mg-Cu alloy is accompanied by the decrease in fracture toughness and corrosion resistance [4-6]. This limits the application of ultra-high strength Al-Zn-Mg-Cu alloys in many areas. Thereby, many studies on the improvement in corrosion resistance and fracture toughness of Al-Zn-Mg-Cu alloys have been made by controlling the heat treatment or composition.

It is well known that the addition of Cu as one of alloying elements in Al-Zn-Mg alloys greatly improves the mechanical strength of Al-Zn-Mg-Cu series alloys by precipitation hardening. Cu distributes in the microstructure of Al-Zn-Mg-Cu alloy in different forms. In the Al matrix, fine hardening precipitates on the order of nanometers in size, such as Guinier-Preston (GP) zones or θ′ (Al2Cu) phase, contain most of Cu in the alloy. Cu also exists in coarse intermetallic compounds such as S (Al2CuMg) phase, θ (Al2Cu) phase or Al7Cu2Fe particles, and in the grain boundary precipitates with 50-100 nm in size, such as Mg(ZnCuAl)2 [7-10]. The Cu distribution in the microstructure affects the susceptibility to the localized corrosion [11]. MENG and FRANKEL [12] found that Cu plays a beneficial role in improving the resistance of Al-Zn-Mg-Cu alloys to stress corrosion cracking, but the corrosion resistance of the alloys at open circuit in aerated solution decreases with increasing Cu content. These contradictory effects of Cu content must be rationalized.

At the same time, the Mg content plays an important role in the mechanical strength and corrosion resistance of Al-Zn-Mg-Cu series alloys by forming intermetallic compounds such as S (Al2CuMg), T (Al2Mg3Zn3) and η (MgZn2) phases [13]. These intermetallic compounds have great effect on the mechanical strength and corrosion resistance of the alloys.

AA7085 alloy is a new generation of high strength thick plate alloy developed by ALCOA. The unique properties are given by the higher zinc content along with the lower content of copper than other 7xxx aluminum alloy, i.e., high fracture toughness and slow quench sensitivity [14]. Generally, high strength and good corrosion resistance have a contradictory relationship, which are significantly affected by the composition and heat treatment [15-18].

The intermetallic compounds will largely change with the Cu/Mg ratio. The quantity of copper atoms that harden the alloys by precipitation will be changed synchronously. There will be a competitive reaction among the generation of different intermetallic compounds and precipitate, which enormously affects the microstructure and properties of the alloys. Thereby, the research on the relationship between alloy properties and Cu/Mg ratio is significant and necessary. There are little reports about the effect of Cu/Mg ratio on microstructure and properties of AA7085 alloys. In this work, the effect of Cu/Mg ratio on the microstructure and properties of AA7085 aluminum alloys was investigated.

2 Experimental

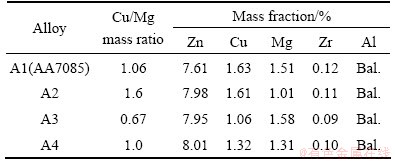

Four alloys with the nominal compositions are given in Table 1. The alloys were melted by induction heating. The temperature of the alloy melt was kept between 720 and 750 °C. The melt was degassed by adding C6Cl6 for 10-15 min, and then cast into iron moulds to produce billets with 80 mm in length and 45 mm in diameter. The billets were homogenized at 450 °C for 24 h, followed by air cooling to room temperature, and then hot extruded to bars of 13.5 mm×10.2 mm at 420 °C. Subsequently, the bars were solution treated at 475 °C for 2 h, followed by water quenching, and finally aged at 120 °C for 24 h (T6 tempter).

Table 1 Chemical compositions of alloys

The tensile properties were tested at room temperature and a strain rate of about 1×10-4 s-1 on an Instron-8082 testing machine. The exfoliation corrosion testing (EXCO-testing) was carried out at room temperature for 72 h, according to the Chinese HB5455-90 specification. The corrosive liquid was standard EXCO solution which contained 4.0 mol/L NaCl, 0.5 mol/L KNO3 and 0.5 mol/L HNO3 in hydrosolvent. The rates of exfoliation corrosion were calculated by mass loss method in the EXCO-testing solution. The microstructural characterization was performed by optical microscope (OM) and scanning electron microscope (SEM).

3 Results

3.1 Mechanical properties

The tensile properties of the specimens are shown in Table 2. Compared with AA7085 A1 alloy, whose tensile strength and yield strength are 494 and 454 MPa, respectively, alloy A3 with the Cu/Mg ratio of 0.67 exhibits the highest tensile strength, which at least increases by 18.6%. This means that a higher strength exhibits when the Cu/Mg ratio is less than 1.0. And compared with alloy A4, alloy A2 has better mechanical properties, which are 4.98% higher in tensile strength and 9.40% in yield strength.

Table 2 Tensile properties of specimens

3.2 Corrosion properties

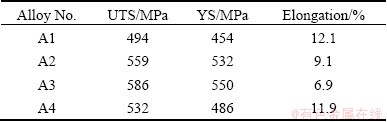

The EXCO corrosion rates of the four alloys at different times are shown in Fig. 1. At the first 24 h, alloy A4 has the highest EXCO resistance, of which the corrosion rate is 0.8 mg/(h·cm2). However, at the next 24 h corrosion and the finally 72 h corrosion, alloy A2 shows higher EXCO resistance, whose corrosion rate is down to 0.54 and 0.37 mg/(h·cm2), respectively. The corrosion rate of alloy A3 is 11.56% faster than that of alloy A2, and the corrosion rate of alloy A1 is 27.69% faster than that of alloy A2 after 72 h. Moreover, alloy A4 shows the worst EXCO resistance among the four alloys after 48 and 72 h.

Fig. 1 EXCO corrosion rates of four alloys

3.3 Microstructures

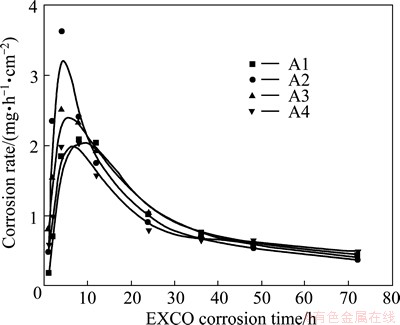

Typical optical microstructures of T6-tempered Al-Zn-Mg-Cu alloys are shown in Fig. 2. From Fig. 2, it can be seen that alloy A1 is fully recrystallized and many coarse recrystallized grains are found. Alloys A2, A3 and A4 are partially recrystallized. Some of the subgrains in the alloy grow up into large recrystallized grains, and other subgrain boundaries disappear. Compared with alloy A3, alloy A2 with higher Cu content has a lower recrystallization. The recrystallization degree of alloy A4 is the largest among the four alloys. It is clear that the recrystallization resistance of T6-tempered Al-Zn-Mg-Cu alloy can be improved by changing Cu/Mg ratio. Moreover, it can be observed that the grain size of the recrystallization region decreases with the increase of the recrystallization degree. Alloy A2 has the largest grain size of the recrystallization region, while alloy A4 has the smallest one.

Fig. 2 Optical micrographs of different T6-tempered alloys

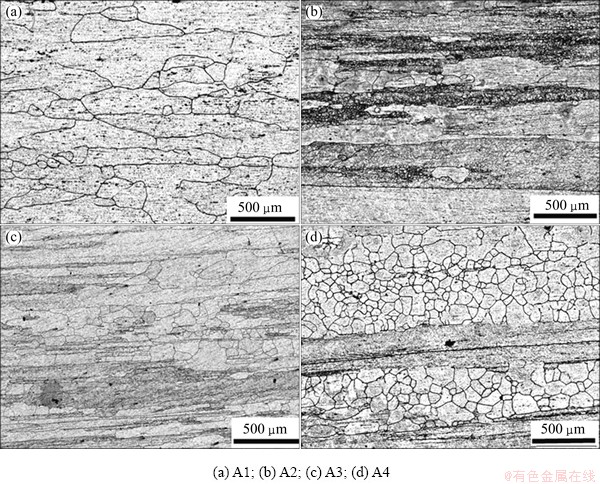

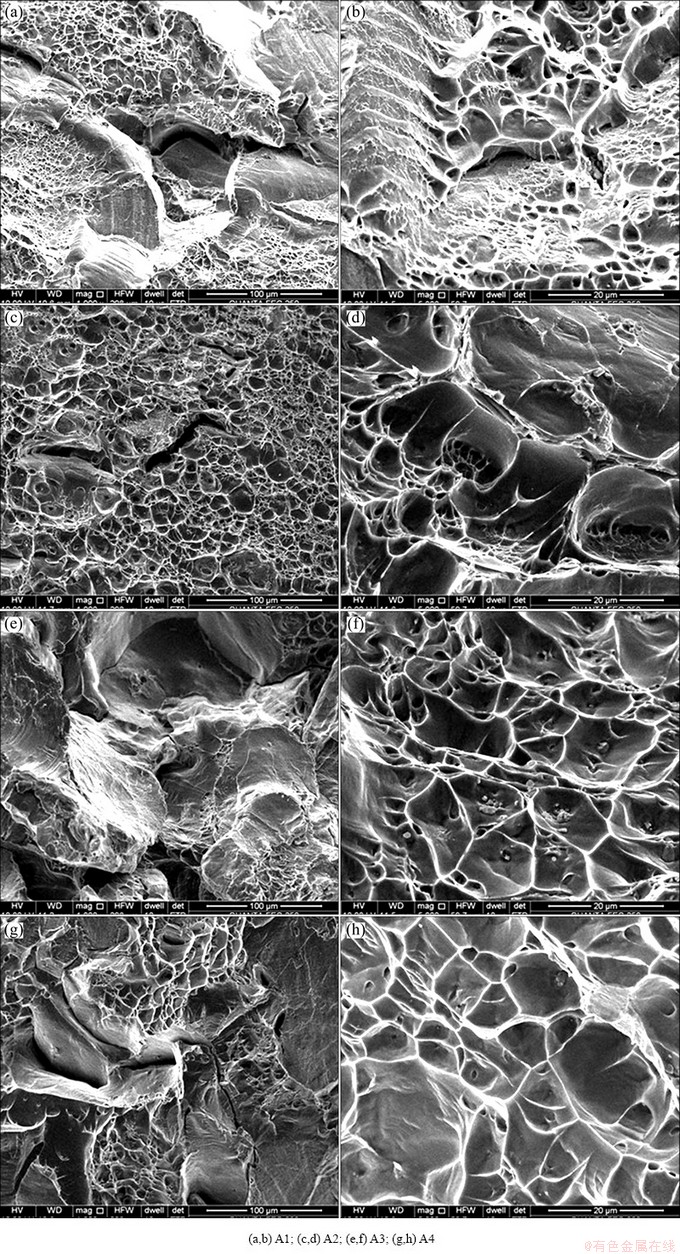

The SEM images of fracture surfaces of the experimental alloys after tensile testing are shown in Fig. 3. A mixed fracture mode consisting of dominant intergranular fracture is observed in the four alloys. The serious cracks which are both wide and deep are found in alloy A1, and the SEM observation at a higher magnification reveals that the crack propagates along the grain boundaries. Shallow dimples adjacent to grain boundary regions are also observed. Several short but wide cracks are found on the fracture surfaces of alloy A2. There are some tiny cracks on the fracture surfaces of alloy A3 and the cracks propagate along the recrystallized grain boundaries. The narrow but long cracks are observed on the fracture surfaces of alloy A4. Among alloys A2, A3 and A4, fine dimples and some white phases can be found at the bottom of dimples.

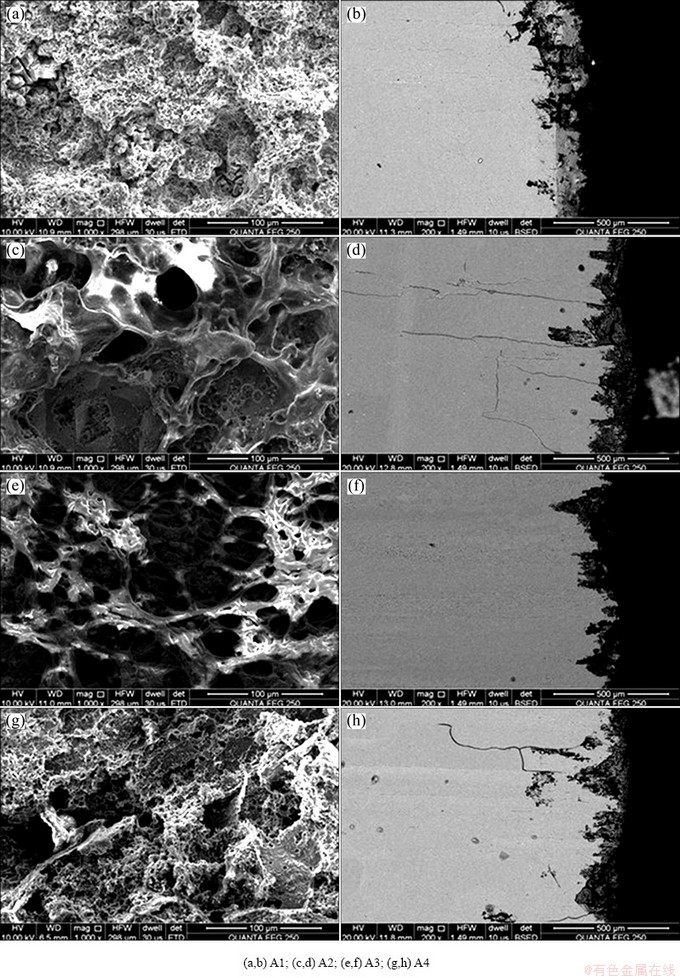

The surface SEM images and cross-section SEM images of the T6-tempered specimens after 72 h EXCO-testing are shown in Fig. 4. Large and deep etch pits and many microcracks form on the surface of alloy A1. Obvious intergranular corrosion can be found. Wide and uniform etch pits form on the surface of alloy A2. Intergranular corrosion is found at the beginning of exfoliation corrosion. Large and deep etch pits form and penetrate deeply into the surface of alloy A3. Uniform corrosion can be considered. Besides, reticular fibers are found to leave on the surface of alloys A2 and A3. And the fibrous structure of alloy A3 is slender. Many tiny etch pits and piece of layered structure form on the surface of alloy A4.

4 Discussion

In general, the corrosion resistance of ultra-high strength Al-Zn-Mg-Cu alloys decreases as the yield strength increases, which has heavy involvement with higher density of anodic precipitates on grain boundaries [4-6,18]. Preferential precipitation and aggregation tend to happen at the recrystallized grain boundaries. Precipitates with low density have discrete distribution at the subgrain boundaries. The recrystallized grain boundaries with higher density precipitates are susceptive to anodic dissolution and provide relatively easy path for the crack propagation. Thus, the corrosion resistance and fracture toughness of Al-Zn-Mg-Cu alloys are affected by the degree of recrystallization [16]. It is well accepted that the recrystallized grain boundaries have higher energy than the subgrain boundaries, and thus precipitates with higher density tend to be aggregated at the recrystallized grain boundaries in full recrystallized alloy A1. Fine and scattered precipitates distribute at the subgrain boundaries in the fibrous unrecrystallized part of alloys A2, A3 and A4. The proportion of fine scattered precipitates has a deep relationship with the degree of recrystallization. Furthermore, the Cu/Mg ratio may be also strongly related to the types of precipitated phases, which determines the electrochemistry system. Thereby, the changes of Cu/Mg ratio will result in the transformation of corrosion behavior as well.

Fig. 3 SEM images of fracture surfaces of alloys after tensile testing

Fig. 4 SEM images of corrosion surfaces and cross-section of T6-tempered specimens after 72 h EXCO testing

From Table 2, it can be seen that Cu/Mg ratio has some effects on the mechanical properties of the T6-tempered Al-Zn-Mg-Cu alloys. The main reasons are the synthetic action of three factors: the changes of wild phase types, the inhibition of recrystallization and the stabilization of deformation reversion structure occurring during the extrusion and solution treatment. There is no doubt that the type and quantity as well as the distribution of phases will change with the Cu/Mg ratio. When the Cu/Mg ratio is equal to 1, the trend of forming Al-Cu-Zn phases will be strong [5]. At the same time, when the Mg content increases and Cu/Mg ratio is less than 1, the trend of forming intermetallic compounds, such as S (Al2CuMg), T ( Al2Mg3Zn3) and η (MgZn2) phases, increases for the alloy abundant in Mg [9]. But the amount of S phase will be less than that of the alloys with Cu/Mg ratio of 1. Moreover, the effect of fine precipitation hardening of Cu on the order of nanometers in size, such as GP zones or θ′ (Al2Cu) phase, is easier to happen when the Cu/Mg ratio is more than 1.

Figure 2 shows that Cu/Mg ratio affects the recrystallization of the alloys. Dispersoids prevent the motion of subgrain boundaries during annealing [10]. The effect of dispersoid distribution on inhibiting recrystallization can be quantified by calculating the average pinning pressure pz of the dispersoids, according to the Zener pinning equation [19]:

(1)

(1)

where r is the radius, φ is the volume fraction of dispersoids, γGB is the energy of the boundary that the dispersoids are pinning. Eq. (1) shows that a high φ/r ratio, namely, a high volume fraction of tiny and stable dispersoids, should be necessary in order to overcome the driving force for boundary migration and achieve high recrystallization resistance. According to Fig. 2, alloy A3 does better in inhibiting recrystallization than alloy A4, while alloy A2 has the highest recrystallization resistance. Compared with alloy A4 that has a strong trend of forming coarse intermetallic compounds, alloy A2 with fine precipitation hardening on the order of nanometers in size is necessary in order to pin the grain boundary. Moreover, alloy A3 has a smaller volume fraction of S phases than alloy A4, which means that the volume fraction of other tiny phases will be more than that of alloy A4. Thereby, alloy A3 achieves higher recrystallization resistance than alloy A4 that is lower than alloy A2.

The intergranular fracture is found to preferentially occur along the recrystallized grain boundaries with dense density grain boundary precipitates rather than at subgrain boundaries with discrete precipitates. The precipitates with low density are beneficial to improving grain boundary fracture resistance and fracture toughness of Al-Zn-Mg-Cu alloy compared with precipitates with higher density [17]. The mechanical properties of the alloy have a close relationship with the degree of recrystallization. Thus, according to Table 2, full recrystallized alloy A1 containing a higher density of grain boundary precipitates shows low fracture toughness and dominant intergranular fracture. Fibrous partly recrystallized alloys A2, A3 and A4 that contain discrete grain boundary precipitates exhibit higher fracture toughness and ductile transgranular fracture with the distribution of fine dimples. Thereby, it can be achieved that the increase of Cu content or Mg content results in the decrease of intergranular fracture and the improvement of fracture toughness and ductility of Al-Zn-Mg-Cu alloy. Moreover, alloy A3, whose Cu content is more than Mg content, has better mechanical properties than alloy 2, in which the relationship of Cu and Mg is opposite. The differences among the three alloys are the degree of recrystallization and the volume fraction of different wild phases. And it can be inferred that the volume fraction of different wild phases plays a more influential role than the degree of recrystallization. Different phases make different levels of contributions to mechanical properties, and Al-Mg-Zn phases or Mg-Zn phases play better roles in improving mechanical properties than Cu precipitate.

Figure 1 shows that the T6-tempered Al-Zn-Mg-Cu alloys are susceptible to intergranular corrosion and exfoliation corrosion, which may be highly related to the grain boundary η precipitates. The η phase is anodic to aluminum matrix and dissolves preferentially when the alloys are exposed to the corrosion environment. In Al-Zn-Mg-Cu alloys, precipitates with higher density distribute at the high angle recrystallized grain boundaries and will be preferentially attacked at the beginning of intergranular corrosion. Once the cracks form, they propagate along the recrystallized grain boundaries very quickly. Thus, the recrystallized grain boundaries are more vulnerable to corrosion than the subgrain boundaries [6]. According to Fig. 2, four alloys have different proportions of recrystallized grain boundaries. The fibrous parts without the recrystallization of alloys A2, A3 and A4 with numerous fine subgrain boundaries have fine and scattered precipitates at the grain boundary. Thus, the progress of anode corrosion is cut off to some extent and the corrosion rate decreases, and the resistance to intergranular corrosion and exfoliation corrosion of the alloy is improved. At the same time, the corrosion process is determined by the electrochemical system, which is deeply affected by the potential difference between the phases and the matrix. The electrochemical system keeps on changing by collapsing and rebuilding. Thereby, the relationship of corrosion rate among the four alloys is changeable during the corrosion process. However, the stable period comes after corrosion for a period of time. The potential difference between the phases and the matrix affect more on corrosion rates during the stable period. And compared with alloy A2, alloy A3 has worse corrosion resistance because of the increase of η phase in alloy A3. Cu atoms can dissolve in η′ and η phases, which reduce the potential difference in the grain boundary and matrix. And a higher corrosion resistance of alloy A3 is achieved.

5 Conclusions

1) The degree of recrystallization is related to Cu/Mg ratio. The alloy with Cu/Mg ratio larger than 1 achieves higher recrystallization inhibition.

2) The mechanical properties and corrosion resistance of AA7085 alloys can be improved by changing the Cu/Mg ratio. Al-Zn-Mg-Cu alloy shows better complex properties when Cu/Mg ratio is not equal to 1.

3) AA7085 alloys have better mechanical properties when Mg content is higher than Cu content.

4) Excellent corrosion resistance can be achieved when Cu content is higher than Mg content in the alloys.

References

[1] LI Jin-feng, PENG Zhuo-wei, LI Chao-xing. Mechanical properties, corrosion behaviors and microstructures of 7075 aluminum alloy with various aging treatments [J]. Transactions of Nonferrous Metals Society of China, 2008, 18(4): 755-762.

[2] HEINZ A, HASZLER A, KEIDEL C. Recent development in aluminum alloys for aerospace applications [J]. Materials Science and Engineering A, 2000, 280(1): 102-107.

[3] WILLIAMS J C, JAMES C, EDGAR A, STARKER E A Jr. Progress in structural materials for aerospace systems [J]. Acta Materialia, 2003, 51(19): 5775-5799.

[4] DUMONT D, DESCHAMPS A, BRECHET Y. On the relationship between microstructure, strength and toughness in AA7050 aluminum alloy [J]. Materials Science and Engineering A, 2003, 356: 326-336.

[5] XIONG Bai-qing, LI Xi-wu, ZHANG Yong-an, LI Zhi-hui, ZHU Bao-hong, WANG Feng, LIU Hong-wei. Quench sensitivity of Al-Zn-Mg-Cu alloys [J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2631-2638. (in Chinese)

[6] PUIGGALI M, ZIELINSHI A, OLIVE J M, RENAULD E. Effect of microstructure on stress corrosion cracking of an Al-Zn-Mg-Cu alloy [J]. Corrosion Science, 1998, 40: 805-819.

[7] SHUEY R T, BARLAT F, KARABIN M E, CHAKRABARTI D J. Experimental and analytical investigations on plane strain toughness for 7085 aluminum alloy [J]. Metallurgical and Materials Transactions A, 2009, 40: 365-376.

[8] XIAO Dai-hong, HUANG Bai-yun. Effect of Yb addition on precipitation and microstructure of Al-Cu-Mg-Ag alloys [J]. Transactions of Nonferrous Metals Society of China, 2007, 17(6): 1181-1185.

[9] GAO M, FENG C R, WEI R P. An analytical electron microscopy study of constituent particles in commercial 7075-T6 and 2024-T3 alloys [J]. Metallurgical and Materials Transactions A, 1998, 29(4): 1145-1151.

[10] PUIGGALI M, ZIELINSHI A, OLIVE J M, RENAULD E. Effect of microstructure on stress corrosion cracking of an Al-Zn-Mg-Cu alloy [J]. Corrosion Science, 1998, 40(4): 805-819.

[11] LUNARSKA E, SZKLARSKA Z. Surface degradation of powder metallurgy AlZnMg alloys in NaCl solutions at different applied potentials [J]. Corrosion, 1987, 43(6): 353-359.

[12] MENG Q J, FRANKEL G S. Effect of Cu content on corrosion behavior of 7xxx series aluminum alloys [J]. Journal of the Electrochemical Society B, 2004, 151(5): 271-283.

[13] WOLVERTON C. Crystal structure and stability of complex precipitate phases in Al-Cu-Mg-(Si) and Al-Zn-Mg alloys [J]. Acta Materialia, 2001, 49(16): 3129-3142.

[14] CHAKRABARTI D J, LIU J, SAWTELL R R, VENEMA G B. New generation high strength high damage tolerance 7085 thick alloy product with low quench sensitivity [J]. Materials Forum, 2004, 28: 969-974.

[15] DHRUBA J C, JONH L, JAY H G, GREGORY B V. Aluminum alloy products having improved property combinations and method for artificially aging same: US Patent, 6972110B2 [P]. 2005-12-06.

[16] XIAO D H, CHEN K H, LUO W H. Effect of solution heat treatment on microstructure and properties of AA7085 aluminum alloys [J]. Rare Metal Materials and Engineering, 2010, 39(3): 494-497. (in Chinese)

[17] CHEN Song-yi, CHEN Kong-hua, JIA Le, PENG Guo-sheng. Effect of hot deformation conditions on grain structure and properties of 7085 aluminum alloy [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(2): 329-334.

[18] KARABIN M E, BARLAT F, SHUEY R T. Finite element modeling of plane strain toughness for 7085 aluminum alloy [J]. Metallurgical and Materials Transactions A, 2009, 40: 354-364.

[19] SARGENT P M, ASHBY M F. Deformation maps for titanium and zirconium [J]. Scripta Metallurgica, 1982, 16(12): 1415-1422.

吴先哲,肖代红,朱哲民,李秀秀,陈康华

中南大学 粉末冶金国家重点实验室,长沙 410083

摘 要:采用熔铸法制备具有不同Cu/Mg比(0.67, 1.0, 1.06, 1.6)的AA7085铝合金。采用金相显微镜、扫描电镜、力学性能测试和腐蚀测试研究Cu/Mg比对基体合金显微组织、力学性能和腐蚀行为的影响。结果表明,当Cu/Mg比为1.6时,AA7085铝合金具有更好的抑制再结晶能力和抗腐蚀性能。当Cu/Mg比为0.67时,铝合金具有更为优越的力学性能,其抗拉强度与屈服强度分别达到586和550 MPa。而当Cu/Mg比为1.0时,合金的力学性能和耐腐蚀性能均下降。

关键词:AA7085铝合金;Cu/Mg比;力学性能;腐蚀性能

(Edited by Wei-ping CHEN)

Foundation item: Projects (51271152, 51021063) supported by the National Natural Science Foundation of China; Project (13JJ6006) supported by Hunan Provincial Natural Science Foundation, China; Project (2012CB619502) supported by National Basic Research Program of China

Corresponding author: Dai-hong XIAO;Tel: +86-731-88877880;E-mail: daihongx@csu.edu.cn

DOI: 10.1016/S1003-6326(14)63311-2