DOI: 10.11817/j.issn.1672-7207.2021.02.006

Zener-Hollomon参数对Cr4Mo4Ni4V高合金钢热变形行为的影响

马少伟1, 3,张艳1, 3,杨明1, 2, 3,李波2

(1. 贵州大学 材料与冶金学院,贵州 贵阳,550025;

2. 贵州电力科学研究院,贵州 贵阳,550025;

3. 贵州大学 高性能金属结构材料与制造技术国家地方联合工程实验室,贵州 贵阳,550025)

摘要:依据热模拟压缩实验结果,研究Cr4Mo4Ni4V高合金钢在变形温度为950~1 100 ℃、应变速率为0.001~1 s-1条件下的热变形行为。基于Zener-Hollomon参数(Z参数)建立Arrhenius本构方程,并表征不同应变条件下材料常数(α,n,Q和lnA)的变化规律,证实所建立的本构模型具有较高的预测精度。此外,利用Z参数建立动态再结晶的临界模型,并结合微观组织在热变形中的演化规律,获得Z参数影响微观组织变形机制和软化行为的基本规律。研究结果表明:在高温低应变速率下,材料的流变应力较低,且呈现出明显的动态再结晶特征;在高lnZ(≥45.11)条件下,绝热剪切带和混晶是主要的微观组织形态;而在38.80≤lnZ≤43.40时,微观组织是以动态再结晶的形式发生软化和细化,且随着Z参数的减小,动态再结晶体积分数相应增加;而较小的lnZ(36.49)会导致再结晶晶粒粗化,不利于热加工。据此,获得的相关结论能够为Cr4Mo4Ni4V高合金钢热加工工艺的制定提供参考。

关键词:Cr4Mo4Ni4V高合金钢;本构方程;Zener-Hollomon参数;临界应变;微观组织演变

中图分类号:TG142.1 文献标志码:A

文章编号:1672-7207(2021)02-0376-13

Effect of Zener-Hollomon parameters on hot deformation behavior of Cr4Mo4Ni4V high alloy steel

MA Shaowei1, 3, ZHANG Yan1, 3, YANG Ming1, 2, 3, LI Bo2

(1. School of Materials and Metallurgy, Guizhou University, Guiyang 550025, China;

2. Guizhou Electric Power Research Institute, Guiyang 550025, China;

3. National & Local Joint Engineering Laboratory for High-performance Metal Structure Material and Advanced Manufacturing Technology, Guizhou University, Guiyang 550025, China)

Abstract: Based on the results of the thermal simulation compression test, the hot deformation behavior of Cr4Mo4Ni4V high alloy steel was investigated in terms of deformation temperature (950-1 100 °C) and strain rate (0.001-1 s-1). Meanwhile, the Arrhenius constitutive equation was established and the variation law of the material constants (α, n, Q and lnA) under different strain conditions was characterized based on the Zener-Hollomon parameter (Z), which confirms that the constitutive equation has high prediction accuracy. In addition, the critical model of dynamic recrystallization assisted by using Z-parameter and microstructure evolution characterization in hot deformation was performed to acquire the basic law, which reflects the effect of Z parameter on the deformation mechanism and softening behavior of microstructure. The results show that the flow stress of the material is low and shows obvious dynamic recrystallization characteristics at high temperature and low strain rate. When lnZ is high (≥45.11), the adiabatic shear band and mischcrystal structure are the main microstructure features, when 38.80≤lnZ≤43.40, the microstructure presents softening and refining characterization in the form of dynamic recrystallization, and the volume fraction of dynamic recrystallization increases with the decrease of Z parameter. However, the low lnZ(36.49) will lead to the coarsening of recrystallized grains and have detrimental effect on hot processing. So the relevant conclusions can provide a reference for the regulation of the hot processing technology of Cr4Mo4Ni4V high alloy steel.

Key words: Cr4Mo4Ni4V high alloy steel; constitutive equation; Zener-Hollomon parameter; critical strain; microstructure evolution

近年来,航空工业的快速发展对航空发动机轴承的力学性能和服役寿命提出了更高的要求,而控制轴承部件的热加工组织将是提高其力学性能的重要方法[1]。Cr4Mo4Ni4V高合金钢是我国依据美国M50NiL钢自主研发的新一代航空轴承材料,具有优越的强韧性匹配、较高的疲劳强度以及良好的耐高温、耐腐蚀性能[2-3],主要用于制造航空航天领域精密齿轮轴承部件,如C919大飞机发动机的轴承。轴承部件在热加工过程中,其力学性能依赖于热变形后的微观组织。然而,工艺参数(应变速率 、变形温度T和应变ε)对材料热变形后微观组织有影响显著[4-5],因此,研究Cr4Mo4Ni4V高合金钢的热变形行为并控制其热变形后的微观组织对获得优异性能的轴承部件具有重要意义。热变形中工艺参数对变形的交互作用复杂,而Zener-Hollomon参数是表征变形温度和应变速率的函数[6],利用Zener-Hollomon参数建立精度较高的流变应力本构模型,不仅能够准确描述不同工艺参数之间的非线性关系,而且可以对高温流变行为进行有效预测,对研究金属材料的热变形行为极为重要[7-8]。此外,在热变形过程中,动态再结晶是一种能够细化组织、改善材料力学性能的微观组织演变机制。然而,Cr4Mo4Ni4V钢中合金元素含量较高,这些元素通常以固溶体形式存在,或者在热变形中以合金化合物的形式析出[9],固溶强化和第二相强化提高了材料的变形抗力,导致微观组织变形不均匀,因此,确定动态再结晶发生的临界条件并获得微观组织演变的规律具有重要意义。为了表征再结晶临界条件,有学者提出,流变曲线的单峰特征预示着动态再结晶的发生[10]。但大量研究表明,动态再结晶在峰值应力之前就已经发生[11]。HU等[12]利用Zener-Hollomon参数建立了动态再结晶临界模型,并证实了贝氏体钢的动态再结晶临界应变发生在峰值应力之前。由此可见,通过Zener-Hollomon参数来构建本构方程和动态再结晶临界模型对研究材料的热变形行为意义重大。目前,对高合金钢热变形的研究主要集中在2方面:一方面为工艺参数对表观激活能的影响[13],另一方面为变形参量对微观组织演化的影响[14]。然而,很少有学者系统探究加工工艺参数对热变形各个物理参量和微观组织演化的影响,并建立三者之间的内在联系。为此,本文作者以Cr4Mo4Ni4V高合金钢为研究对象,通过等温热压缩实验数据获得Cr4Mo4Ni4V高合金钢在不同变形条件下的流变曲线,分析工艺参数对流变曲线和软化机制的影响。同时,利用Z参数建立含有应变补偿的本构方程,求解获得动态再结晶临界条件。通过观察微观组织演化规律,分析Z参数变化对组织演变及微观变形机制的影响,获得的相关结论为Cr4Mo4Ni4V高合金钢热加工工艺的优化以及动态再结晶行为的数值模拟提供参考。

、变形温度T和应变ε)对材料热变形后微观组织有影响显著[4-5],因此,研究Cr4Mo4Ni4V高合金钢的热变形行为并控制其热变形后的微观组织对获得优异性能的轴承部件具有重要意义。热变形中工艺参数对变形的交互作用复杂,而Zener-Hollomon参数是表征变形温度和应变速率的函数[6],利用Zener-Hollomon参数建立精度较高的流变应力本构模型,不仅能够准确描述不同工艺参数之间的非线性关系,而且可以对高温流变行为进行有效预测,对研究金属材料的热变形行为极为重要[7-8]。此外,在热变形过程中,动态再结晶是一种能够细化组织、改善材料力学性能的微观组织演变机制。然而,Cr4Mo4Ni4V钢中合金元素含量较高,这些元素通常以固溶体形式存在,或者在热变形中以合金化合物的形式析出[9],固溶强化和第二相强化提高了材料的变形抗力,导致微观组织变形不均匀,因此,确定动态再结晶发生的临界条件并获得微观组织演变的规律具有重要意义。为了表征再结晶临界条件,有学者提出,流变曲线的单峰特征预示着动态再结晶的发生[10]。但大量研究表明,动态再结晶在峰值应力之前就已经发生[11]。HU等[12]利用Zener-Hollomon参数建立了动态再结晶临界模型,并证实了贝氏体钢的动态再结晶临界应变发生在峰值应力之前。由此可见,通过Zener-Hollomon参数来构建本构方程和动态再结晶临界模型对研究材料的热变形行为意义重大。目前,对高合金钢热变形的研究主要集中在2方面:一方面为工艺参数对表观激活能的影响[13],另一方面为变形参量对微观组织演化的影响[14]。然而,很少有学者系统探究加工工艺参数对热变形各个物理参量和微观组织演化的影响,并建立三者之间的内在联系。为此,本文作者以Cr4Mo4Ni4V高合金钢为研究对象,通过等温热压缩实验数据获得Cr4Mo4Ni4V高合金钢在不同变形条件下的流变曲线,分析工艺参数对流变曲线和软化机制的影响。同时,利用Z参数建立含有应变补偿的本构方程,求解获得动态再结晶临界条件。通过观察微观组织演化规律,分析Z参数变化对组织演变及微观变形机制的影响,获得的相关结论为Cr4Mo4Ni4V高合金钢热加工工艺的优化以及动态再结晶行为的数值模拟提供参考。

1 实验材料与方法

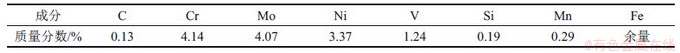

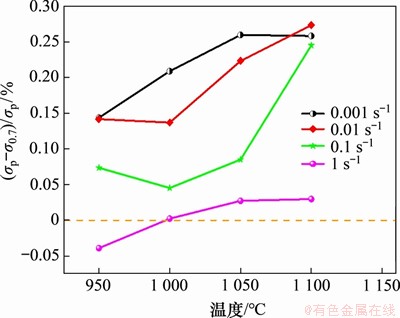

实验所采用的材料为Cr4Mo4Ni4V高合金钢棒材,其化学成分如表1所示。材料初始晶粒尺寸约为75 μm,如图1(a)所示。考虑到FCC结构具有很强的塑性变形能力,通常将Cr4Mo4Ni4V高合金钢加热到单相奥氏区进行热变形。借助相变仪,测得Cr4Mo4Ni4V高合金钢的Ac1和Ac3温度分别为711 ℃ 和943 ℃,故选择热变形温度在950~1 100 ℃区间,应变速率在0.001~1 s-1区间。

表1 Cr4Mo4Ni4V高合金钢的化学成分

Table 1 Chemical compositions of Cr4Mo4Ni4V high alloy steel

本实验采用Gleeble-3500热模拟试验机进行等温热压缩试验,试样为直径8 mm、高度12 mm的圆柱,热变形工艺如图1(b)所示。为减少压头对试样的摩擦阻力,可在试样两端分别涂上石墨润滑剂,贴上钽片。将试样以20 ℃/s的速度加热至1 100 ℃,保温5 min,然后以10 ℃/s的速度冷却至变形温度,保温30 s以消除变形前试样的温度梯度。然后,分别以0.001,0.01,0.1和1 s-1的变形速度进行等温压缩,所有试样的真应变都为1。在热变形后,将所有试样立即淬火至室温,以保留高温变形后的微观组织。随后,沿压缩轴方向切开,经抛光、腐蚀后,在光学显微镜下观察变形后的组织。

图1 Cr4Mo4Ni4V高合金钢初始试样处理图

Fig. 1 Initial sample treatment maps of Cr4Mo4Ni4V high alloy steel

2 实验结果

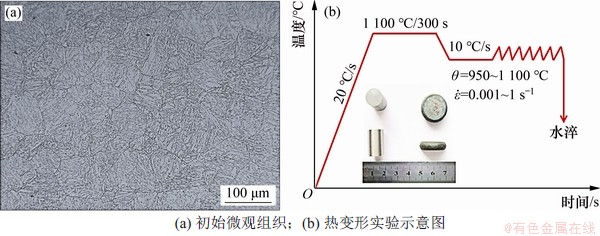

流变曲线是变形过程中微观组织演变及力学性能变化的宏观表现。图2所示为Cr4Mo4Ni4V高合金钢在等温热压缩过程中的流变曲线。由图2可知:在同一变形温度下,随着应变速率的增加,曲线中峰值应力逐渐增大,如当温度为950 ℃时,应变速率0.01 s-1对应的峰值应力为150 MPa,而当应变速率增大到1 s-1时,峰值应力为250 MPa,两者相差100 MPa;此外,在相同应变速率下,随着变形温度的升高,峰值应力逐渐降低,如在应变速率为0.1 s-1时,1 100 ℃工艺下对应的峰值应力较950 ℃对应的峰值应力降低了约100 MPa;显然,应变速率和变形温度对流变软化机制有显著影响。进一步比较Cr4Mo4Ni4V钢和其他轴承钢(AISI52100,GCr15)的流变曲线[15-16]可以发现,在相同的变形条件下,Cr4Mo4Ni4V钢的峰值应力范围为130~250 MPa,而AISI52100和GCr15的峰值应力分别为75~130 MPa和80~150 MPa,这可能与Cr4Mo4Ni4V钢合金元素含量高相关,质量分数较高的合金元素造成了较大的变形抗力。

图2 Cr4Mo4Ni4V高合金钢不同变形条件下流变曲线

Fig. 2 Flow curves of Cr4Mo4Ni4V high alloy steel under different deformation conditions

此外,在变形初期,流变应力随应变的增加急剧上升,在应变约为0.2时达到峰值应力,这是位错滑移并不断增殖所致,在这个过程中,材料的加工硬化起主导作用。流变应力达到峰值意味着加工硬化和流变软化达到平衡。随着应变继续增加,流变应力逐渐减小,表明在此阶段材料的软化起主导作用。值得注意的是,到达峰值应力后,随应变增加,流变应力逐渐降低,最终保持稳定。在这一变化过程中,峰值应力和稳态应力并不相同,两者存在一定的差值,这个差值实质上反映了动态再结晶程度的差异。峰值应力和稳态应力之间的差距越大,说明动态再结晶程度越高,流变软化效果越明显,热变形中软化抵消加工硬化的影响显著,从而使流变应力降低到更低的水平。

3 讨论

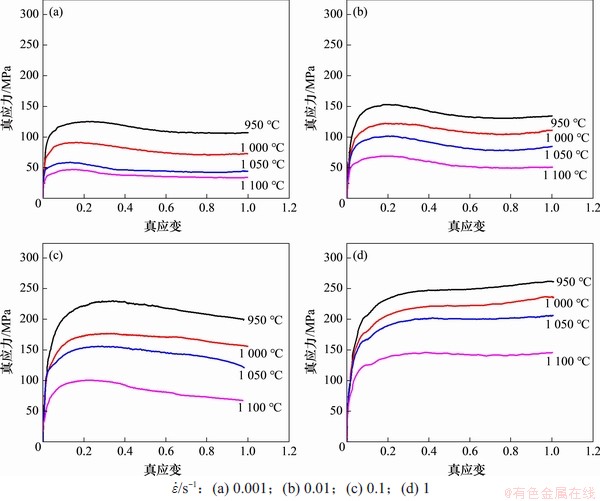

3.1 流变软化机制

为了定量分析Cr4Mo4Ni4V高合金钢在热变形过程中的流变软化机制,采用流变软化因子(△σ/σp,(△σ=σp-σ0.7))进行表征[17],如图3所示(其中,σp为峰值应力,σ0.7为真应变为0.7时的流变应力)。通常认为流变软化因子大于0时材料的软化机制主要是动态再结晶,流度软化因子小于0时材料的软化机制主要是动态回复。由图3可知:除变形温度为950 ℃,应变速率为1 s-1时,曲线呈现出动态回复型特征外,材料在其他变形条件下均表现出明显的动态再结晶型软化特征,且流变软化程度随变形温度的升高和应变速率的降低而增大,因此,可以判断高温、低应变速率有利于再结晶发生,并促进流变软化。而在高应变速率下(1 s-1),流变软化程度随温度的变化并不大,可见高应变速率会导致加工硬化率削弱动态再结晶的软化效果[18],使加工硬化和流变软化保持动态平衡。

图3 流变软化因子(△σ/σp,△σ=σp-σ0.7)

Fig. 3 Factor of flow softening(△σ/σp,△σ=σp-σ0.7)

3.2 Z参数对峰值应力的影响

热变形是一个由热激活控制的过程,材料的流变应力对变形温度和应变速率非常敏感。通常采用SELLARS等[19]提出的Arrhenius本构方程来揭示变形温度和应变速率对流变应力的影响。故本文选取峰值应力为流变曲线的特征应力,采用双曲正弦Arrhenius方程来描述:

式中:式(1),(2)和(3)分别适用于低应力水平、高应力水平和所有应力水平; 为应变速率,s-1;Q为变形激活能,kJ/mol;R为气体常数,8.314 J/(mol·K);A1,A2,A,n1,β和α为材料常数,且α=β/n1;θ为变形温度,℃;n为材料应力指数;σ为峰值应力,MPa。

为应变速率,s-1;Q为变形激活能,kJ/mol;R为气体常数,8.314 J/(mol·K);A1,A2,A,n1,β和α为材料常数,且α=β/n1;θ为变形温度,℃;n为材料应力指数;σ为峰值应力,MPa。

为了探究变形温度和应变速率对热变形行为的影响,引入Zener-Hollomon参数[20]即Z参数来表征热变形过程中材料变形的难易程度:

(4)

(4)

将式(1),(2)和(3)两边取对数,将峰值应力与相对应的应变速率代入式(4)中,通过线性回归方程得到ln -ln

-ln ,ln

,ln -

- 和ln

和ln -ln[sin

-ln[sin (

( )]三者的关系曲线,拟合后可以得到

)]三者的关系曲线,拟合后可以得到 1和

1和 分别为6.746和0.051 27 MPa-1,从而得到材料常数

分别为6.746和0.051 27 MPa-1,从而得到材料常数 =

= /

/ 1=0.007 6 MPa-1。将计算得到的

1=0.007 6 MPa-1。将计算得到的 代入式(3),并对两边取对数可得ln

代入式(3),并对两边取对数可得ln -ln[sinh(ασ)]关系曲线,由曲线斜率求得应力指数

-ln[sinh(ασ)]关系曲线,由曲线斜率求得应力指数 ={

={ }T=4.932。在相同应变速率下,由式(3)可以获得ln[sinh(ασ)]-1/θ的关系曲线,因此,求得Q=R{

}T=4.932。在相同应变速率下,由式(3)可以获得ln[sinh(ασ)]-1/θ的关系曲线,因此,求得Q=R{ }T{

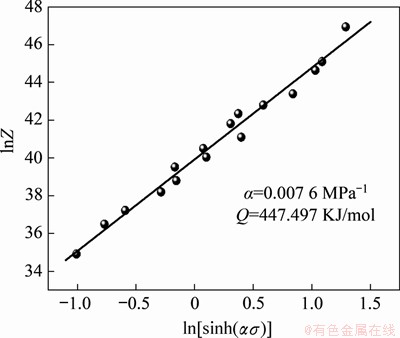

}T{ =477.497 kJ/mol。根据式(4)可以获得lnZ-ln[sinh(ασ)]之间的关系曲线,如图4所示,经线性回归分析后可得方程lnZ=39.93+4.897ln[sinh(ασ)],故lnA=39.93,得A=2.195×1017。

=477.497 kJ/mol。根据式(4)可以获得lnZ-ln[sinh(ασ)]之间的关系曲线,如图4所示,经线性回归分析后可得方程lnZ=39.93+4.897ln[sinh(ασ)],故lnA=39.93,得A=2.195×1017。

图4 线性拟合曲线ln[sinh(ασ)]-ln Z

Fig. 4 Linear relationship between ln[sinh(ασ)] and ln Z

将α,n,Q和A代入式(3),即可得到Cr4Mo4Ni4V高合金钢的本构方程为

(5)

(5)

当材料常数和变形激活能被确定后,可以用Z参数来预测特定应变下的峰值应力:

(6)

(6)

故峰值应力与Z参数函数关系的本构方程为

(7)

(7)

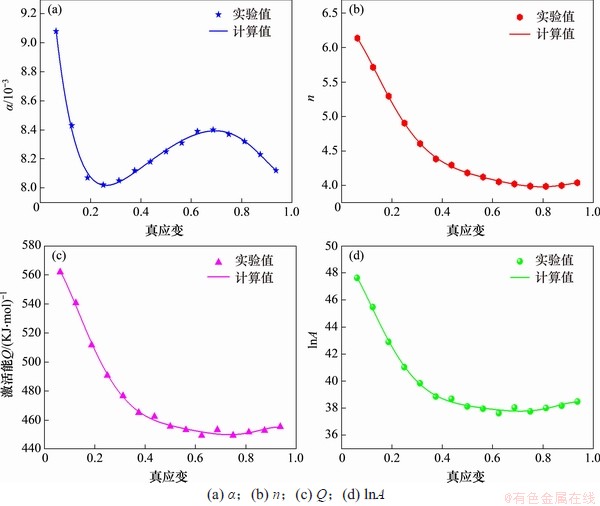

通常认为应变对高温流变行为影响甚小,因此,多数研究忽略了应变对材料流变应力的影响。事实上,在整个热变形过程中,应变对流变应力(σ)、激活能(Q)及其他材料参数(α,β,lnA和n)的影响显著[21]。为了更准确地预测高温流变行为,利用数学回归方法的原理[22],进行六阶多项式拟合,如图5所示,其拟合方程如下:

(8)

(8)

图5 材料参数与应变的多项式拟合

Fig. 5 Polynomial fittings of material constants with true strain

将α,n,Q和A代入式(8),即可得到含有Z参数的应变补偿本构方程,如

(9)

(9)

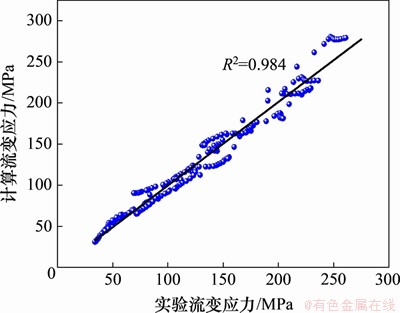

为了验证本构方程的准确性,将相同间隔为0.062 5的应变代入式(9),计算得到各应变量对应的流变应力,与实验得到的流变应力进行比较,如图6所示,结果表明,流变应力实验值与计算值具有较高的吻合度。为了进一步验证本构模型,采用相关系数(R2)和平均绝对相对误差进行精确评估[23-24],如图7所示。从图7可以看出:流变应力实验值和计算值之间具有较高的相关性(R2=0.984),这表明所提出的本构方程与实验值之间拟合程度较高。同时,对比流变应力计算可得平均绝对相对误差为6.91%,由此证实所建立的本构模型具有较强的预测能力。因此,含有Z参数的本构模型可准确描述Cr4Mo4Ni4V高合金钢的高温流变行为。

图6 实验值与计算值之间的比较

Fig. 6 Comparisons between experimental values and calculated values of Cr4Mo4Ni4V high alloy steel

图7 本构方程实验和计算流变应力相关性

Fig. 7 Correlation between experimental and calculated flow stressform constitutive equation

3.3 基于Z参数建立的动态再结晶临界模型

动态再结晶的临界应变是表征动态再结晶开始及演变过程的重要参数,通常在流变曲线中无法直观地获得临界应变(εc)的大小。POLIAK等[10]指出,通过对流变曲线中获得的加工硬化率(θH)进行适当处理,可以建立加工硬化速率θH与流变应力σ的关系,从而获得临界应变。其中,加工硬化率反映了流变应力随应变量增加的快慢程度,其大小与变形过程中材料内部错位密度的变化有关[25]。

POLIAK等[10-11]认为材料发生动态再结晶时,θH-σ曲线会出现拐点,拐点即为发生动态再结晶的临界点。为了研究Cr4Mo4Ni4V高合金钢在热变形中动态再结晶行为,获得不同条件下再结晶临界应变,本文采用相同的方法,建立加工硬化速率与流变应力的关系曲线,如图8所示。从图8(a)和8(b)可以看出,当应变速率为1 s-1时,加工硬化曲线可以分为2个阶段:第1阶段,加工硬化速率随着应力的增大而迅速减小,之后在曲线上存在1个明显的拐点;拐点之后进入第2阶段,加工硬化速率随应力的增大又迅速减小,拐点的位置即为发生动态再结晶的临界应变位置。为了更加精确地确定曲线中拐点的位置,本研究采用P-J法[11]对θH-σ曲线求偏导:

(10)

(10)

由图8(c)和8(d)可以发现: θH/

θH/ σ随着流变应力的增大出现极大值,随后又减小,而极大值点对应的位置即为发生动态再结晶的临界值。此外,在所有变形条件下,

σ随着流变应力的增大出现极大值,随后又减小,而极大值点对应的位置即为发生动态再结晶的临界值。此外,在所有变形条件下, θH/

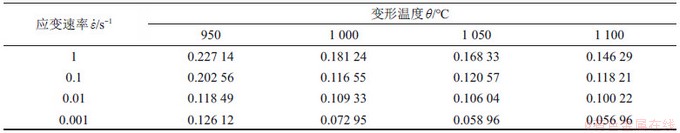

θH/ σ-σ曲线的极大值都十分明显;随着应变速率的减小,流变应力减小,这是由于当应变速率减小时,变形时间充裕,使塑性变形时位错攀移及位错反应等引起的软化作用相对增加,促进位错的运动,削弱了加工硬化的作用,使材料的临界切应力减小,流变应力减小[26]。另一方面,当变形温度升高时,流变应力也减小,这是因为当变形温度升高时,原子的热运动即扩散速率增加,位错的交滑移、攀移以及亚晶的形成较易进行,加快了动态再结晶的形核速率,使软化效果增强,从而使流变应力减小。根据上述方法,可求得不同工艺参数下所对应的动态再结晶的临界应变值,如表2所示。

σ-σ曲线的极大值都十分明显;随着应变速率的减小,流变应力减小,这是由于当应变速率减小时,变形时间充裕,使塑性变形时位错攀移及位错反应等引起的软化作用相对增加,促进位错的运动,削弱了加工硬化的作用,使材料的临界切应力减小,流变应力减小[26]。另一方面,当变形温度升高时,流变应力也减小,这是因为当变形温度升高时,原子的热运动即扩散速率增加,位错的交滑移、攀移以及亚晶的形成较易进行,加快了动态再结晶的形核速率,使软化效果增强,从而使流变应力减小。根据上述方法,可求得不同工艺参数下所对应的动态再结晶的临界应变值,如表2所示。

表2 不同变形条件下Cr4Mo4Ni4V高合金钢的临界应变

Table 2 Critical strains of Cr4Mo4Ni4V high alloy steel under different deformation conditions

由表2可知:Cr4Mo4Ni4V钢在较高的变形温度和较低的应变速率下,发生动态再结晶所需临界应变较小,即在较高的温度和较低的应变速率下易于发生动态再结晶。

为了定量描述工艺参数对临界再结晶条件的影响,可以借助Z参数建立动态再结晶临界模型,即

图8 Cr4Mo4Ni4V高合金钢在不同变形条件下的加工硬化速率与流变应力的关系曲线

Fig. 8 Relationship curves between hardening rate and flow stress of Cr4Mo4Ni4V high alloy steel under different deformation conditions

(11)

(11)

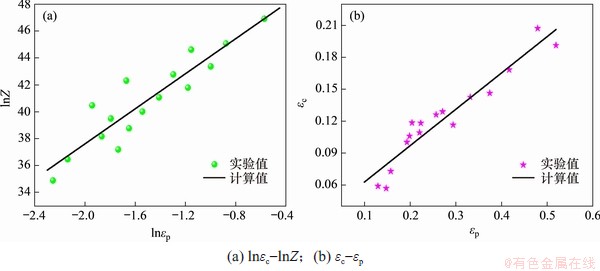

依据所获得的临界应变(εc)和峰值应变(εp),建立临界值与工艺参数(lnZ)之间的关系,如图9所示。Cr4Mo4Ni4V高合金钢发生动态再结晶的临界应变模型为

(12)

(12)

图9 Cr4Mo4Ni4V高合金钢Z参数与再结晶临界发生条件之间的关系

Fig. 9 Relationship between Z parameter and DRX critical conditions of Cr4Mo4Ni4V high alloy steel

由图9可以看出:动态再结晶的临界应变(εc)与Z参数呈现正相关性,表明动态再结晶的发生与Z参数和临界应变都存在关系,即当Z参数达到某一临界值,应变达到临界应变时,才能发生动态再结晶。

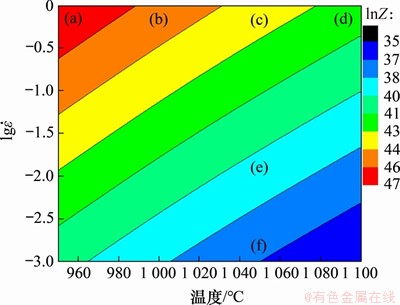

图10 不同变形条件下lnZ的分布特征

Fig. 10 Distribution characteristics of lnZ value under different deformation conditions

3.4 Z参数对热变形行为的影响

Zerner-Hollomon参数表示变形温度和应变速率之间的函数关系,同时也能反映热变形过程中材料组织演变的特征,即lnZ较大的区域对应的变形区域组织特征为动态回复型特征,lnZ较小的区域组织特征为动态再结晶型特征,且随着lnZ从大到小,微观组织由动态回复型转变为动态再结晶型[27-28]。因此,微观组织演变特征中的动态再结晶型区域才是材料合适的热加工区域。

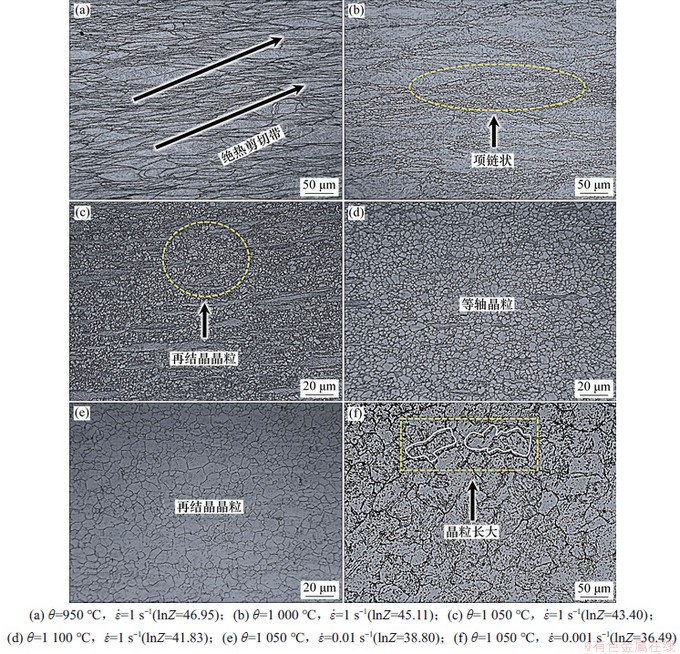

图10所示为不同工艺参数下lnZ的变化趋势图。从图10可以看出:随着变形温度升高或应变速率减小,lnZ逐渐减小。对应lnZ的变化趋势图,以lnZ从大到小,分别讨论Z参数对热变形过程中的微观组织演变规律的影响,如图11所示。由图11可知:在相同的应变速率下,随着变形温度升高,lnZ逐渐减小;当lnZ=46.95时,微观组织有与径向成45°形成的绝热剪切带,YUAN等[29]在研究奥氏体-铁素体双相钢中,发现绝热剪切带与剪切应变和绝热温度的非均匀分布相关,通常出现在低温高应变速率的位置。绝热剪切带的出现表明材料在加工过程中出现了塑性失稳,这是一种微观组织缺陷,在其他的钢中也能被观察到,如9Cr-1Mo钢[30]、马氏体不锈钢[31]等。其原因是在低温高应变速率下,塑性变形产生的热量由于时间不足而未能及时释放,从而使局部区域内温度升高,导致沿最大剪应力面出现局部剪切带,促使晶界附近晶粒不均匀,这种现象会造成应力集中,导致裂纹、孔洞等缺陷的萌生,不利于材料加工。从图11(b)可以看出:当lnZ=45.11时,细小的再结晶晶粒沿晶界和变形带分布,且晶粒尺寸比拉长的晶粒小得多。这是因为绝热变形使局部温度升高,晶界和变形带的位错密度高于晶内的位错密度,促使沿着晶内再结晶形核,导致再结晶晶粒沿晶界和变形带出现[32],形成“项链状”结构,呈现出混晶特征。混晶组织会削弱材料的力学性能,因此,在加工过程中应避免。从图11(c)和(d)可以看出:当lnZ从43.40减小到41.83时,原始变形晶粒已经基本消失,其显微组织呈现出细小均匀的再结晶晶粒。造成这种现象的原因是:随着温度升高,位错发生攀移和交滑移比低温时更容易[27],同时,由于温度的升高,原子热运动加剧及扩散速率增大,晶界迁移能力增强,导致晶粒生长速率增大,促进了动态再结晶的形核,从而产生大量细小的动态再结晶晶粒。众所周知,细化晶粒可以有效地改善材料的力学性能。因此,考虑到工艺的安全性,应避免绝热剪切带和混晶区域,选择在晶粒细化的区域进行加工。

另一方面,当变形温度一定时,随着应变速率减小,lnZ也逐渐减小。对比图11(c)和图11(e)发现:在相同的变形温度下,当lnZ由43.40减小到38.80时,细长的晶粒已经消失,取而代之的是细小的动态再结晶晶粒。这表明在该工艺条件下,变形组织已经发生了动态再结晶,且晶粒尺寸更均匀,但晶粒的尺寸较lnZ=43.4时稍粗大,这是由于在低应变速率下,材料易于发生变形,且变形时间相对较长,变形所产生的位错有充足的时间被抵消,使变形更加均匀,从而呈现出均匀的再结晶晶粒,此区域适合加工。然而,当lnZ=36.49即应变速率减小到0.001 s-1时(如图11(f)所示),再结晶晶粒尺寸明显增大且晶粒表现出不均匀性。这是由于过低的应变速率会促使新生成的再结晶晶粒继续长大,导致晶粒粗化,粗化的晶粒会影响材料的力学性能,应避免在此区域内进行加工。

图11 Cr4Mo4Ni4V高合金钢不同ln 下的微观组织

下的微观组织

Fig. 11 Microstructures of Cr4Mo4Ni4V high alloy steel under different ln

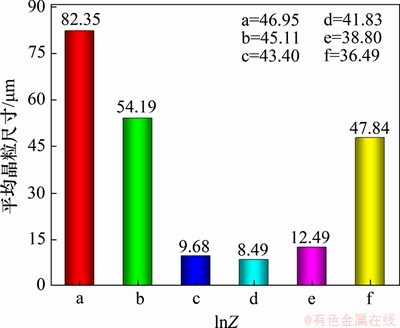

为了定量描述工艺参数对晶粒尺寸和均匀性的影响,对不同lnZ下的晶粒尺寸进行统计,发现其变化规律如图12所示。由图12可知:随着lnZ从46.95减小到41.83,应变速率保持不变;当温度由950 ℃增加到1 100 ℃时,平均晶粒尺寸逐渐减小,从82.35 μm减小到8.49 μm,呈现出随lnZ的减小而不断细化的规律。这是因为当应变速率一定时,随着温度升高,有助于促进动态再结晶的发生,且在较高温度下,表现出更好的动态再结晶组织。当lnZ从43.40减小到36.49,温度保持不变,应变速率从1 s-1减小到0.001 s-1时,平均晶粒尺寸从9.68 μm先缓慢增加到12.49 μm,然后又急剧增加到47.84 μm。值得注意的是,平均晶粒尺寸在lnZ=36.49时出现异常增大的现象,而造成晶粒长大的主要原因是随着应变速率的减小,变形时间延长,并且在较高温度下,抑制晶界长大的碳化物溶解到奥氏体中,导致晶界钉扎效应减弱,使再结晶晶粒长大失去抑制作用,造成再结晶晶粒迅速长大。因此,过小的lnZ对应粗化的再结晶晶粒,这不利于材料的热加工性,在加工过程中应避免。

图12 不同lnZ下的晶粒尺寸

Fig. 12 Grain sizes at different lnZ values

综合以上分析可知:当lnZ≥45.11即变形条件为950~1 000 ℃/1 s-1时,组织会出现绝热剪切带和混晶组织特征,不利于材料进行热加工;当38.80≤lnZ≤43.40即变形条件为1 050~1 100 ℃/1 s-1和1 050 ℃/0.01 s-1时,组织呈现典型的动态再结晶型组织,再结晶晶粒细小且均匀分布,该区域有利于热加工;此外,过小的lnZ=36.49 (1 050 ℃/0.001 s-1)对应粗化的再结晶晶粒,在加工过程中应避免。

4 结论

1) 在低温高应变速率下,动态回复型软化特征显著;在高温低应变速率下表现出较低的流变应力,且呈现出明显的动态再结晶型特征。

2) 基于Zener-Hollomon参数建立了峰值应力与Z参数关系函数的本构方程,并引入不同应变下的相关参数(α,n,Q和lnA),证实其具有较高的预测精度。同时,通过临界应变拐点判据,确定了发生动态再结晶临界应力(σc)和临界应变(εc),并建立了动态再结晶临界模型。

3) Cr4Mo4Ni4V高合金钢的Z参数随着变形温度的升高或应变速率的减小而减小。当lnZ≥45.11时,组织呈现出绝热剪切带和混晶特征,是主要的微观组织形态;而当38.80≤lnZ≤43.40时,动态再结晶是主要的微观组织形态,动态再结晶程度较高,且组织均匀细小,有利于提高材料的热加工性及力学性能。此外,过小的lnZ(=36.49)会导致再结晶晶粒的粗化,最终影响材料的力学性能。

4) 材料热变形最佳的热加工工艺参数为:1 050~1 100 ℃/1 s-1和1 050 ℃/0.01 s-1。

参考文献:

[1] YANG Zhinan, ZHANG Fucheng, ZHENG Chunlei, et al. Study on hot deformation behaviour and processing maps of low carbon bainitic steel[J]. Materials & Design, 2015, 66: 258-266.

[2] JIN Jie, CHEN Yunbo, GAO Kewei, et al. The effect of ion implantation on tribology and hot rolling contact fatigue of Cr4Mo4Ni4V bearing steel[J]. Applied Surface Science, 2014, 305: 93-100.

[3] WANG Xing′an, YAN Mufu, LIU Ruiliang, et al. Effect of rare earth addition on microstructure and corrosion behavior of plasma nitrocarburized M50NiL steel[J]. Journal of Rare Earths, 2016, 34(11): 1148-1155.

[4] JAFARI M, NAJAFIZADEH A. Correlation between Zener-Hollomon parameter and necklace DRX during hot deformation of 316 stainless steel[J]. Materials Science and Engineering: A, 2009, 501(1/2): 16-25.

[5] RAJPUT S K, CHAUDHARI G P, NATH S K. Characterization of hot deformation behavior of a low carbon steel using processing maps, constitutive equations and Zener-Hollomon parameter[J]. Journal of Materials Processing Technology, 2016, 237: 113-125.

[6] WANG Yitao, LI Jianbo, XIN Yunchang, et al. Effect of Zener-Hollomon parameter on hot deformation behavior of CoCrFeMnNiC0.5 high entropy alloy[J]. Materials Science and Engineering: A, 2019, 768: 138483.

[7] 章晓婷, 黄亮, 李建军, 等. 300 M高强钢高温流变行为及本构方程[J]. 中南大学学报(自然科学版), 2017, 48(6): 1439-1447.

ZHANG Xiaoting, HUANG Liang, LI Jianjun, et al. Flow behaviors and constitutive model of 300 M high strength steel at elevated temperature[J]. Journal of Central South University(Science and Technology), 2017, 48(6): 1439-1447.

[8] 王梦寒, 王瑞, 王根田, 等. 超临界马氏体不锈钢热变形行为[J]. 中南大学学报(自然科学版), 2017, 48(6): 1448-1457.

WANG Menghan, WANG Rui, WANG Gentian, et al. Hot behavior of supercritical martensitic stainless steel at elevated temperature[J]. Journal of Central South University(Science and Technology), 2017, 48(6): 1448-1457.

[9] DECAUDIN B, DJEGA-MARIADASSOU C, CIZERON G. Structural study of M50 steel carbides[J]. Journal of Alloys and Compounds, 1995, 226(1/2): 208-212.

[10] POLIAK E I, JONAS J J. A one-parameter approach to determining the critical conditions for the initiation of dynamic recrystallization[J]. Acta Materialia, 1996, 44(1): 127-136.

[11] POLIAK E I, JONAS J J. Initiation of dynamic recrystallization in constant strain rate hot deformation[J]. ISIJ International, 2003, 43(5): 684-691.

[12] HU Maoliang, WEI Shuaihu, SHI Qian, et al. Dynamic recrystallization behavior and mechanical properties of bimodal scale Al2O3 reinforced AZ31 composites by soild state synthesis[J]. Journal of Magnesium and Alloys, 2020, 8(3): 841-848.

[13] MATHUR V, ARYA P K, DIXIT M. Analysis of apparent activation energy of shear viscosity of PVC/ZnO nanocomposite, at its phase transition temperature[J]. Materials Today: Proceedings, 2020, 30: 84-87.

[14] 丁开勇, 李雷, 冀国良, 等. 热压缩参数对M50NiL轴承钢动态再结晶行为的影响[J]. 机械工程材料, 2017, 41(3): 63-66.

DING Kaiyong, LI Lei, JI Guoliang, et al. Effects of thermal compression parameters on dynamic recrystallization behavior of M50NiL bearing steel[J]. Materials for Mechanical Engineering, 2017, 41(3): 63-66.

[15] LIAO Shulun, ZHANG Liwen, YUE Chongxiang, et al. Hot deformation behaviors and flow stress model of GCr15 bearing steel[J]. Journal of Central South University of Technology, 2008, 15(5): 575-580.

[16] EL MEHTEDI M, GABRIELLI F, SPIGARELLI S. Hot workability in process modeling of a bearing steel by using combined constitutive equations and dynamic material model[J]. Materials & Design, 2014, 53: 398-404.

[17] TAN Y B, MA Y H, ZHAO F. Hot deformation behavior and constitutive modeling of fine grained Inconel 718 superalloy[J]. Journal of Alloys and Compounds, 2018, 741: 85-96.

[18] DEHGHAN-MANSHADI A, BARNETT M R, HODGSON P D. Hot deformation and recrystallization of austenitic stainless steel: part I. dynamic recrystallization[J]. Metallurgical and Materials Transactions A, 2008, 39(6): 1359-1370.

[19] SELLARS C M, MCTEGART W J. On the mechanism of hot deformation[J]. Acta Metallurgica, 1966, 14(9): 1136-1138.

[20] ZENER C, HOLLOMON J H. Effect of strain rate upon plastic flow of steel[J]. Journal of Applied Physics, 1944, 15(1): 22-32.

[21] HAGHDADI N, ZAREI-HANZAKI A, ABEDI H R. The flow behavior modeling of cast A356 aluminum alloy at elevated temperatures considering the effect of strain[J]. Materials Science and Engineering: A, 2012, 535: 252-257.

[22] SHAMSOLHODAEI A, ZAREI-HANZAKI A, GHAMBARI M, et al. The high temperature flow behavior modeling of NiTi shape memory alloy employing phenomenological and physical based constitutive models: a comparative study[J]. Intermetallics, 2014, 53: 140-149.

[23] CAI Jun, LI Fuguo, LIU Taiying, et al. Constitutive equations for elevated temperature flow stress of Ti-6Al-4V alloy considering the effect of strain[J]. Materials & Design, 2011, 32(3): 1144-1151.

[24] MARANDI A, ZAREI-HANZAKI A, HAGHDADI N, et al. The prediction of hot deformation behavior in Fe-21Mn-2.5Si-1.5Al transformation-twinning induced plasticity steel[J]. Materials Science and Engineering: A, 2012, 554: 72-78.

[25] 马琳, 李伟, 白娇娇, 等. 粉末冶金Ti-14Mo-2.1Ta-0.9Nb-7Zr合金热变形行为[J]. 材料工程, 2018, 46(10): 47-54.

MA Lin, LI Wei, BAI Jiaojiao, et al. Hot deformation behavior of powder metallurgy Ti-14Mo-2.1Ta-0.9Nb-7Zr alloy[J]. Journal of Materials Engineering, 2018, 46(10): 47-54.

[26] KUNDU A, FIELD D P. Influence of microstructural heterogeneity and plastic strain on geometrically necessary dislocation structure evolution in single-phase and two-phase alloys[J]. Materials Characterization, 2020, 170: 110690.

[27] NIE Xi, DONG Shuai, WANG Fenghua, et al. Effects of holding time and Zener-Hollomon parameters on deformation behavior of cast Mg-8Gd-3Y alloy during double-pass hot compression[J]. Journal of Materials Science & Technology, 2018, 34(11): 2035-2041.

[28] HU H E, ZHEN L, YANG L, et al. Deformation behavior and microstructure evolution of 7050 aluminum alloy during high temperature deformation[J]. Materials Science and Engineering: A, 2008, 488(1/2): 64-71.

[29] YUAN Fuping, XIAN De bian, JIANG Ping, et al. Dynamic shear response and evolution mechanisms of adiabatic shear band in an ultrafine-grained austenite-ferrite duplex steel[J]. Mechanics of Materials, 2015, 89: 47-58.

[30] SAMANTARAY D, MANDAL S, BHADURI A K. Characterization of deformation instability in modified 9Cr-1Mo steel during thermo-mechanical processing[J]. Materials & Design, 2011, 32(2): 716-722.

[31] ZOU Dening, HAN Ying, YAN Dongna, et al. Hot workability of 00Cr13Ni5Mo2 supermartensitic stainless steel[J]. Materials & Design, 2011, 32(8/9): 4443-4448.

[32] PU Enxiang, ZHENG Wenjie, XIANG Jinzhong, et al. Hot deformation characteristic and processing map of superaustenitic stainless steel S32654[J]. Materials Science and Engineering: A, 2014, 598: 174-182.

(编辑 刘锦伟)

收稿日期: 2020 -04 -20; 修回日期: 2020 -06 -24

基金项目(Foundation item):贵州省教育厅工程研究中心项目([2017]016); 贵州省自然科学基金重点资助项目([2020]1Z046) (Project([2017]016) supported by the Engineering Research Center Program of Education Department of Guizhou Province; Project([2020]1Z046) supported by the Key Program of Natural Science Foundation of Guizhou Province)

通信作者:杨明,博士,副教授,从事金属材料加工及力学行为研究;E-mail:myang5@gzu.edu.cn

引用格式: 马少伟, 张艳, 杨明, 等. Zener-Hollomon参数对Cr4Mo4Ni4V高合金钢热变形行为的影响[J]. 中南大学学报(自然科学版), 2021, 52(2): 376-388.

Citation: MA Shaowei, ZHANG Yan, YANG Ming, et al. Effect of Zener-Hollomon parameters on hot deformation behavior of Cr4Mo4Ni4V high alloy steel[J]. Journal of Central South University(Science and Technology), 2021, 52(2): 376-388.