深冷轧制与时效处理Al-3.6Cu-1Li合金的显微组织演变和力学性能

来源期刊:中国有色金属学报(英文版)2020年第11期

论文作者:李畅 熊汗青 Laxman BHATTA 王琳 张朝阳 王辉 Charlie KONG 喻海良

文章页码:2904 - 2914

关键词:铝-铜-锂合金;深冷轧制;时效;析出强化;力学性能

Key words:Al-Cu-Li alloy; cryorolling; aging; precipitation strengthening; mechanical property

摘 要:对Al-3.6Cu-1Li合金进行室温轧制和深冷轧制,并研究工艺对材料显微组织演变和力学性能的影响。通过显微组织分析与力学性能测试,研究厚度压下率为70%和90%的室温轧制和深冷轧制样品的显微组织和时效特性。经过90%厚度压下率的深冷轧制样品具有高强度和良好的韧性,这主要是由于深冷轧制样品对动态回复的抑制和高密度位错的积累。人工时效研究结果表明,达到峰值硬度的温度与变形量成反比,与轧制温度成正比。此外,明场透射电子显微镜照片表明,时效处理的深冷轧制样品存在T1(Al2CuLi)相析出。研究表明,高存储的应变能增强合金的时效动力学,进而促进强化相形核。

Abstract: An Al-3.6Cu-1Li alloy was subjected to room temperature rolling and cryorolling to investigate their effects on microstructure evolution and mechanical properties. The microstructure and aging characteristics of the room temperature-rolled and the cryorolled alloys with 70% and 90% of thickness reductions were studied by microstructure analysis and mechanical tests. The samples subjected to cryorolling with 90% of thickness reduction have high strength and good toughness. This is mainly due to the inhibition of dynamic recovery and the accumulation of high-density dislocations in cryorolled samples. In addition, the artificial aging reveals that the temperature at which peak hardness is attained is inversely proportional to the deformation amount and directly proportional to the rolling temperature. Moreover, bright field images of cryorolled samples after aging indicate the existence of T1 (Al2CuLi) precipitates. This suggests that the high stored strain energy enhances the aging kinetics of the alloy, which further promotes the nucleation of T1 phases.

Trans. Nonferrous Met. Soc. China 30(2020) 2904-2914

Chang LI1,2, Han-qing XIONG1,2, Laxman BHATTA1,2, Lin WANG1,2, Zhao-yang ZHANG1,2, Hui WANG3, Charlie KONG4, Hai-liang YU1,2,5

1. State Key Laboratory of High Performance Complex Manufacturing, Central South University, Changsha 410083, China;

2. School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China;

3. Research Center for Advanced Science and Technology, The University of Tokyo, Meguro, Tokyo 1530041, Japan;

4. Electron Microscope Unit, University of New South Wales, Sydney, NSW 2052, Australia;

5. Light Alloys Research Institute, Central South University, Changsha 410083, China

Received 17 February 2020; accepted 19 July 2020

Abstract: An Al-3.6Cu-1Li alloy was subjected to room temperature rolling and cryorolling to investigate their effects on microstructure evolution and mechanical properties. The microstructure and aging characteristics of the room temperature-rolled and the cryorolled alloys with 70% and 90% of thickness reductions were studied by microstructure analysis and mechanical tests. The samples subjected to cryorolling with 90% of thickness reduction have high strength and good toughness. This is mainly due to the inhibition of dynamic recovery and the accumulation of high-density dislocations in cryorolled samples. In addition, the artificial aging reveals that the temperature at which peak hardness is attained is inversely proportional to the deformation amount and directly proportional to the rolling temperature. Moreover, bright field images of cryorolled samples after aging indicate the existence of T1 (Al2CuLi) precipitates. This suggests that the high stored strain energy enhances the aging kinetics of the alloy, which further promotes the nucleation of T1 phases.

Key words: Al-Cu-Li alloy; cryorolling; aging; precipitation strengthening; mechanical property

1 Introduction

Al-Cu-Li alloys are advanced and lightweight structural materials. They possess several interesting characteristics, such as excellent corrosion resistance, high fatigue performance, low density, high strength and superior toughness compared with traditional aluminum alloys [1,2]. These features of aluminum-lithium alloys allow them to replace traditional 2xxx and 7xxx series aluminum alloys in the aerospace field [3,4]. Precipitation strengthening is a predominant strengthening mechanism in aluminum alloys [5]. The second phases include the T1(Al2CuLi) phase, θ′ phase and S′ phase in the Al-Cu-Li alloy in which the equilibrium phase T1 is the main strengthening phase. Hence, extensive interest has been attracted by the investigation of T1 phase [6-8].

Severe plastic deformation technology (SPD) not only accumulates a large number of dislocations but also produces a bimodal grain structure distribution (a microstructure with ultrafine grain (UFG) and nano grain (NG)), which provides better strength and ductility. UFG can store many dislocations, whereas NG can play a role of grain refinement strengthening [9]. The SPD processes, such as equal channel angular press (ECAP) [10], accumulative roll bonding (ARB) [11], high-pressure torsion (HPT) [12] and cryorolling (CR) [13], are effective means to refine the material matrix and uniformly disperse the second phase to improve strength, hardness and ductility [14].

CR is a mature technology in the SPD processes [15]. CR increases the dislocation density by dislocation accumulation and stores great recrystallization power producing fine-grained structures in bulk alloys [16,17]. DENG et al [18] performed a series of room temperature rolling (RTR) and CR experiments of Al-Cu-Li alloys and concluded that CR can precipitate a denser and more dispersed T1 phase with better mechanical properties than RTR. Likewise, SHAHSAVARI et al [19] carried out different approaches to deform AA2024 with high strength and plasticity by combining solid solution treatment, CR and artificial aging to achieve bimodal grains and the nano-precipitated phase. GOPALA KRISHNA et al [20] evaluated the influence of CR followed by annealing through two-step aging on an Al-4Zn-2Mg alloy. They concluded that peak hardness is increased due to the presence of a large number of dislocations caused by CR. SHI et al [21] evaluated the impacts of CR on the microstructure and mechanical properties of AA5052. The results showed that the suppression of the dynamic recovery is expected to preserve the high density of defects, which could act as potential recrystallization sites for producing fine-grain structures.

The aim of this study was to evaluate the fracture behavior, mechanical properties, microstructure (grain size) and precipitation behavior of room temperature rolled and cryorolled Al-Cu-Li alloys. In addition, this study will explore the advantages of CR, probe the best CR parameters and analyze the aging hardened under various processing conditions.

2 Experimental

The high-grade pure aluminum, pure copper and pure lithium were placed into a vacuum heating furnace until all of the metals in the crucible were melted. The melted metal liquid was then poured into the mold and allowed to solidify to form Al-Cu-Li alloy ingots. The chemical composition of the alloy was 3.6% Cu, 1% Li, and balance Al (mass fraction) with inductively coupled plasma optical emission spectrometer (SPECTRO BLUE SOP). The ingot was then solution heat treated (SHT) at 520 °C for 24 h followed by water- quenching, and then hot extrusion to sheets of 3.5 mm. These alloy sheets were further solution heat treated followed by quenching in the water at room temperature. Solution heat-treated sheets were conducted by CR and RTR to 1 mm (70%) and 0.35 mm (90%) at a roller rotational speed of 6 r/min (In the following, they are defined as RTR70, RTR90, CR70 and CR90, respectively). Prior to CR, the sheets were immersed in a liquid nitrogen bath for 30 min. For intermediate passes, the sheets were dipped in liquid nitrogen for 5 min to ensure liquid nitrogen temperature. In order to avoid adiabatic heating, the thickness reduction of each rolling pass was less than 5%.

The samples were mechanically polished by 800, 1000, 1500, and 2000 grit papers for micro- and macro-texture measurements. The crystal structure was observed under an optical microscope (OM, Mshot), which was treated at 20 V working voltage at room temperature in 2.5 vol.% fluoboric acid solution. The X-ray diffraction (XRD, D8 ADVANCE Davinci) analysis was carried out on the parameter with a step size of 0.35 s, a starting angle of 30°, and a termination angle of 100°. The crystallite size, dislocation density and lattice strain were subsequently analyzed by applying the Williamson-Hall (WH) technique through Jade (6.5) software. The relation is expressed as [22]

(1)

(1)

where β is the integral breadth, θ is the diffraction angle, λ is the wavelength, Dv is the volume weighted crystallite size and e is the microstrain. The micro-texture features were characterized using transmission electron microscopy (TEM, FEI Tecnai G20) with an operating voltage of 200 kV. Specimens for TEM were prepared by thinning down the samples to 80 μn by mechanical grinding followed by twin-jet polishing in the solution of 70 vol.% methanol and 30 vol.% perchloric acid at -20 °C using 25 V DC supply for 10-40 s.

The tensile tests were carried out using Shimadzu AGS-X 10kN tensile machine at a strain rate of 1×10-3 s-1. Wire electrical discharge machine was utilized to prepare tensile specimens from the final sheet parallel to the rolling direction as displayed in Fig. 1. Furthermore, a Vickers hardness was measured at a load of 0.05 kg with 10 s dwell time and at least 10 readings were taken on each specimen to obtain the hardness value. The fracture surface morphology after the tensile test was examined by scanning electron microscopy (SEM, Oxford X-Max20). For age hardening, the CR and RTR samples were artificially aged at various temperatures for 0-200 h.

Fig. 1 Dimensions of tensile specimen

3 Results and discussion

3.1 Grain structure of alloys

The optical micrographs (OM) of the transversal surface of SHT and rolled samples are illustrated in Fig. 2. The different colors in the figures indicate that the samples are prepared by anodic coating and observed under the polarized light of an OM. A closer color implies a smallergrain boundary misorientation angle.

Figure 2(a) shows the broken grains and the coarse grains along with the extruding direction because of dynamic recrystallization and grain growth. The grains are elongated along the rolling direction in all rolled samples. With increasing reduction, the grains break and the strip becomes narrower under severer pressure. YUAN et al [23] observed that the elongated nature of the AA2195 grains originates from the RTR process. This elongated process in turn results in grain refinement. Figure 2 implies that the grain size of CR is finer than that of RTR. The decrease in grain size is ascribed to the effective suppression of dislocations associated with dynamic recovery [16], which also facilitates uniform deformation during rolling process. Furthermore, CR90 is more uniform fiber structure than RTR90, as shown in Figs. 2(d) and (e).

3.2 Microstructure parameters of alloys

With elongated grains, lattice strain increases with a further increase in reduction. X-ray diffraction line profile analysis was performed to calculate crystallite size, lattice strain and dislocation density. The XRD peak, peak displacement and peak broadening of SHT, CR and RTR alloys are presented in Fig. 3. The influences of RTR and CR on Al-3.6Cu-1Li alloy are illustrated in Fig. 3(a), and the main reflecting surfaces are (111), (200), (220) and (311). Figure 3(a) shows that the (220) plane has the highest strength compared with other planes, which shows that the (220) crystal plane parallel to the rolling surface takes precedence over the other planes. With an increase in deformation, the intensity of diffraction peak gradually decreases, and moreover the strength of (220) plane is remarkably reduced, which is known as the texture evolution during the rolling deformation. This peak shift is due to the effect of strain accumulation during rolling, while the peak broadening is attributed to the enhancement of microstrain and the decrease of crystal size. Table 1 summarizes the lattice strain, crystalline size and dislocation density from the XRD data obtained through WH method.

Fig. 2 Cross-section optical micrographs of Al-3.6Cu-1Li alloys showing broken grains and coarse grains of extruded growth strips

Fig. 3 XRD patterns of Al-3.6Cu-1Li alloy at different states

Calculations exhibit the crystallite size of the SHT sample to be 4160 nm, the lattice strain 0.35×10–3, and the dislocation density in the order of 1.04×1014. The crystallite size of samples subjected to RTR70 was reduced to 369 nm and the lattice strain was improved by 1.05×10–3 compared with SHT samples. However, the crystallite size of samples subjected to CR70 decreased to 209 nm, and the corresponding lattice strain was increased by 1.15×10–3. The dislocation density of RTR70 (1.84×1014 m-2) was much lower than that of the samples subjected to CR70 (1.91×1014 m-2). Likewise, a similar trend was observed in the samples subjected to RTR90 and CR90. The dislocation density values were intensified to be 2.27×1014 m-2 (RTR90) and 2.79×1014 m-2 (CR90), and the crystallite sizes were reduced to 172 and 97 nm, respectively. This analysis shows that the dislocation density rises in the order of samples subjected to SHT, RTR70, CR70, RTR90 and CR90. Furthermore, the result clearly shows that the CR samples have smaller crystallite sizes. These findings are concurrent with the conclusions of the scholars who studied the CR of aluminum alloys [15], i.e., CR reduces the grain size and improves the dislocation density.

Table 1 Crystallite size, lattice strain and dislocation density of solid solution and rolled Al-3.6Cu-1Li alloy

3.3 Microstructure evolution of alloys

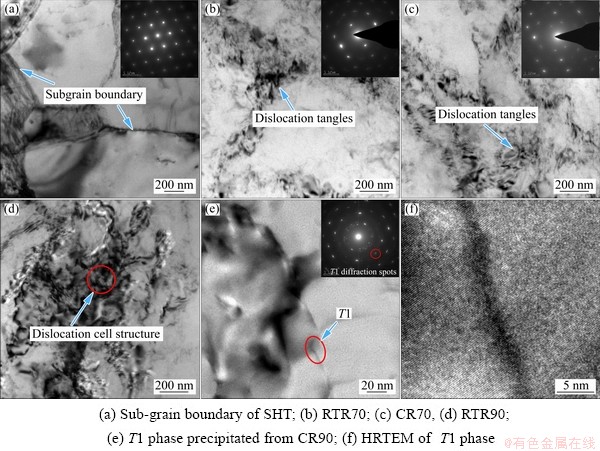

The bright field TEM image of SHT sample shows few of residual dislocation lines (Fig. 4(a)), considering a hot extrusion deformation along with dynamic recovery and recrystallization. Dislocation tangles and dislocation cell structures are observed in all the rolled alloys. Dislocation tangles and dislocation cell structures become denser with an increase in reduction and a decrease in rolling temperature, as demonstrated in Figs. 4(b-e). According to previous TEM studies, cryogenic temperature can restrict the dynamic recovery during large plastic deformation, resulting in high dislocation density in CR samples compared with RTR samples [21]. During the rolling process, a significant amount of strain energy is accumulated in the form of dislocations (Figs. 4(b) and (c)), and the number of dislocations is also increased. In addition, dislocation tangles and dislocation cell structures are ascribed to the FCC structure of aluminum alloys that make the cross-slip process of dislocations easier.

TEM images of SHT, RTR, and CR samples after aging at 80 °C (peak aging of CR90) are displayed in Fig. 5. Compared with samples before aging, dislocation tangles and dislocation cell are also observed in the TEM, which indicates that the reduction of dislocation is due to aging treatment where dislocations are sacrificed to promote precipitation phase nucleation. The microstructure of CR alloys consists of a high density of dislocations and dislocation-tangling zone. The TEM observation on various cryorolled Al alloys exhibits that the dislocation of CR is denser than RTR, which agrees with the results before aging. Likewise, the large number of dislocations retained in the grains during CR is because of the inhibition of dynamic recovery. The microstructure of CR alloys consists of a high density of dislocations and dislocation-tangling zone. The microstructure of SHT (Fig. 5(a)), RTR70 (Fig. 5(b)), CR70 (Fig. 5(c)), and RTR90 (Fig. 5(d)) samples after aging treatment is in line with the microstructure before aging, except a decrease in dislocation density. However, CR90 forms T1-precipitated phase (Al2CuLi) after low-temperature aging (Fig. 5(e)). NAYAN et al [24] found that the plate-shaped precipitates characterized as Al2CuLi (T1) phase have an unusual shape similar to a biconvex lens. These precipitates usually occur as plates on {111} planes. T1 phases observed in this experiment are also similar to a biconvex lens. The volume fraction of T1 phase is lower than that of θ′ phase. And Al-Li alloy is generally strengthened by T1 phase. Figure 5(e) illustrates the interaction between the T1 phase and dislocation, where the T1 phase effectively prevents dislocation slip in order to maintain high strength during tensile ductility. YOSHIMURA et al [25] also observed a T1 phase while investigating the precipitate structure of Al-1.6Li-3.2Cu and Al-2.4Li-3.2Cu alloys after aging at 220 °C, which indicates that the precipitation temperature of T1 phase is high. It concluded that a higher reduction leads to a higher dislocation accumulation and a greater strain energy. This can not only improve the texture of Al-Cu-Li alloy and the aging response but also lower the precipitation temperature of T1 precipitate.

Fig. 4 TEM images of Al-3.6Cu-1Li alloy after solution and rolling treatment

Fig. 5 TEM images with corresponding SAD patterns oriented along (110) axis of CR sample after aging treatment

As a result, the T1 phase is easier to precipitate in the CR samples after aging versus the RTR samples after aging. A small amount of T1 phase is precipitated in CR 90 sample through low- temperature aging. Due to solution strengthening, deformation strengthening and precipitation strengthening, it expects that CR90 exhibits higher mechanical properties after low-temperature aging for 24 h.

High-resolution TEM image (HRTEM) (Fig. 5(f)) shows that the T1 phase gradually grows and nucleates. NAYAN et al [26] also observed a T1 phase in a similar atomic state during HRTEM analysis. In Fig. 5(e) (diffraction pattern of the selected region observed from the direction of [110] crystal axis), the diffraction pattern of T1 phase can be observed in the insert image. This pattern further confirms the existence of T1 phase. The T1 phase is mainly concentrated on the grain boundaries and dislocations. According to Refs. [24-26], T1 phase is in the shape of platelet, about 100 nm in length and several nanometers in thickness, belonging to hexagonal crystal structure. The strengthening effect depends on universality. Furthermore, the SAD diagrams of all selected areas in the upper right corner of Fig. 5 show the diffraction spots of SHT and rolled samples. Diffraction spots of SHT samples are distributed in an array, whereas they are annular after rolling deformation. The number of rings increases with increasing reduction, which confirms that the aluminum matrix metal coexists with a polycrystalline and coarse-grained body.

3.4 Mechanical properties of alloys

Fig. 6 Engineering stress-strain curves of Al-3.6Cu-1Li alloy after solution and rolling treatment

Figure 6 shows the engineering stress-strain curves of the SHT and rolled samples before fracture. Tensile tests were performed to further investigate the influence of rolling temperature on the mechanical properties of Al-3.6Cu-1Li alloys. It is clear that the ultimate tensile strength (UTS) increases, whereas the elongation decreases with an increase in reduction (Fig. 6). The UTS of the SHT is 227 MPa, and the elongation is about 27.5%. UTS and the elongation of CR70 are 345 MPa and 9%, respectively. These are 20 MPa and 1% higher than RTR70. Similarly, the tensile strength of CR90 is 400 MPa, which is about 20 MPa higher than RTR90, whereas elongation to failure of both samples is approximately 4.5%. The toughness of the RTR samples is worse than that of CR samples. The increase in tensile strength and decrease in elongation are attributed to the residual stress in the base metal after deformation where high energy is stored. This phenomenon reveals that the process of large plastic deformation is at the expense of plasticity to improve the strength of materials. YU et al [27] evaluated the impacts of CR and asymmetric CR (ACR) on AA6061 sheets. They concluded that both can result in enhanced strength and ductility of AA6061 sheets. YU et al [28] also showed that CR was superior to cold rolling. Combined with XRD analysis, CR can restrict dynamic recovery, retain high-density dislocation and refine grains ultimately leading to greater tensile strength and elongation.

In general, the CR can maintain better ductility during severe plastic deformation compared with the RTR. Figure 7 shows the fracture surface of specimens at different reduction ratios and rolling temperatures. Figure 7 shows that the samples with a high tensile strength have a slight necking phenomenon on fracture surface, and the fracture is rough and fibrous. The fracture surface is mainly composed of pores and dimples, and these observations suggest a ductile mode of fracture.

Fig. 7 Fracture morphologies of Al-3.6Cu-1Li tensile specimen

NAYAN et al [29] indicated fracture morphology in the form of equiaxed dimples with micro-void coalescence exhibiting an excellent ductility. Interactions between voids and dimples resulted in enhanced ductility. Figure 7 implies that the number of dimples and their size decrease with an increase in reduction. In addition, the number of dimples and toughness of the alloy decrease with an increase in reduction, which is the sign of brittle fracture. Larger holes, larger and deeper dimples, and the size of CR sample imply the enhanced toughness of the CR samples.

In this work, the rolled samples of Al-3.6Cu-1Li alloy were aged at different temperatures by artificial aging, and the hardness was measured in real time to find the peak-aging parameters with the most significant improvement in mechanical properties. Figure 8 shows the optimized age-hardening curves under different deformation temperatures and reductions. Obviously, the mechanical properties of the alloy can be further improved by aging treatment. However, the peak-aging temperature is related to the deformation and rolling temperature. The peak- aging temperature decreases with an increase in reduction, a larger deformation implies a lower peak-aging temperature, and thus the peak-aging temperature of CR is lower than that of RTR samples.

Fig. 8 Peak hardness curves of rolled Al-3.6Cu-1Li alloys during artificial aging with different time (0-196 h)

Figure 8 also shows that the peak-aging time of the rolled samples is around 50 h in which recovery, recrystallization and precipitation occur simultaneously when these heavily deformed samples are subjected to aging treatment. The hardness values suggest an increasing trend during the initial aging due to the grain recrystallization to form ultrafine crystals. During the process, the dislocation density decreases gradually and reduces the effect of strain-strengthening derived from the large rolling deformation. Actually, the precipitation strengthening phases are observed at the peak aging in Fig. 5. T1 phase is evenly dispersed in the matrix and interacts with it to strengthen the alloy. This confirms that the increase in hardness is because of the improvement of precipitation strengthening effect. In addition, an aging treatment even enhances the clustering kinetics leading to an increase in hardness [30]. As the aging time increases, the strain-strengthening decays, and the grains grow and the precipitated phase grows or decomposes, which is the main reason of reduction in hardness. The hardness before aging and peak aging increases with an increase in reduction, and the hardness of CR samples is markedly higher than that of RTR samples as illustrated in Table 2.

Table 2 Hardness of rolled samples before and after aging

The peak temperature of CR90 is only 80 °C and the peak hardness is HV 149. In combination with TEM images after aging (Fig. 5), it can be shown that CR can inhibit recovery, accumulate more dislocations, store more strain energy and provide more aging kinetics, thus promoting strengthening phase precipitation, and improving the mechanical properties of the alloy. And compared with other specimens, T1 phase can be precipitated in CR90 earlier. Figure 8 reveals that the peak-aging temperature of RTR70 (160 °C) is higher than that of RTR90 (140 °C). This once again verifies that increasing reduction provides the great aging kinetics.

4 Conclusions

(1) CR samples can increase dislocation density, enhance lattice strain and reduce grain size. CR90 sample has the smallest grain, the largest lattice strain and the most dislocations in this work.

(2) T1 phase precipitated in the CR90 Al-3.6Cu-1Li alloy during aging at 80 °C. CR samples have higher strength and ductility than RTR samples due to the suppression of dynamic recovery and the accumulation of high-density dislocations.

(3) The aging process is related to rolling temperatures and reduction. The peak hardness of CR90 samples is obtained at 80 °C, which indicates that the storage of large strain energy can reduce the peak-aging temperature.

References

[1] ZHENG Xing-wei, LUO Peng, CHU Zhen-hua, XU Jing-xiang, WANG Feng-hua. Plastic flow behavior and microstructure characteristics of light-weight 2060 Al-Li alloy [J]. Materials Science and Engineering A, 2018, 736: 465-471.

[2] ZHAO Kuo, LIU Jian-hua, YU Mei, LI Song-mei. Through- thickness inhomogeneity of precipitate distribution and pitting corrosion behavior of Al-Li alloy thick plate [J]. Transactions of Nonferrous Metals Society of China, 2019, 29: 1793-1802.

[3] ZHANG Sai-fei, ZENG Wei-dong, YANG Wen-hua, SHI Chun-ling, WANG Hao-jun. Ageing response of a Al-Cu-Li 2198 alloy [J]. Materials and Design, 2014, 63: 368-374.

[4] RIOJA R J, LIU J. The evolution of Al-Li base products for aerospace and space applications [J]. Metallurgical and Materials Transactions A, 2012, 43(9): 3325-3337.

[5] ZOU Xiu-liang, YAN Hong, CHEN Xiao-hui. Evolution of second phases and mechanical properties of 7075 Al alloy processed by solution heat treatment [J]. Transactions of Nonferrous Metals Society of China, 2017, 27: 2146-2155.

[6] GAO Z, LIU J Z, CHEN J H, DUAN S Y, LIU Z R, MING W Q, WU C L. Formation mechanism of precipitate T1 in AlCuLi alloys [J]. Journal of Alloys and Compounds, 2015, 624: 22-26.

[7] EL-ATY A A, XU Yong, GUO Xun-zhong, ZHANG Shi-hong, MA Yan, CHEN Da-yong. Strengthening mechanisms, deformation behavior, and anisotropic mechanical properties of Al-Li alloys: A review [J]. Journal of Advanced Research, 2018, 10: 49-67.

[8] ZHANG Xin-xin, ZHOU Xiao-rong, HASHIMOTO T, LIU Bing, LUO Chen, SUN Zhi-hua, TANG Zhi-hui, LU Feng, MA Yan-long. Corrosion behaviour of 2A97-T6 Al-Cu-Li alloy: The influence of nonuniform precipitation [J]. Corrosion Science, 2018, 132: 1-8.

[9] ZAHID G H, HUANG Y, PRANGNELLP B. Microstructure and texture evolution during annealing a cryogenic-SPD processed Al-alloy with a nanoscale lamellar HAGB grain structure [J]. Acta Materialia, 2009, 57(12): 3509-3521.

[10] DAMAVANDI E, NOUROUZI S, RABIEE S M, JAMAATI R. Effect of ECAP on microstructure and tensile properties of A390 aluminum alloy [J]. Transactions of Nonferrous Metals Society of China, 2019, 29: 931-940.

[11] MASHHADI A, ATRIAN A, GHALANDARI L. Mechanical and microstructural investigation of Zn/Sn multilayered composites fabricated by accumulative roll bonding (ARB) process [J]. Journal of Alloys and Compounds, 2017, 727: 1314-1323.

[12] SEENUVASAPERUMAL P, DOI K, BASSHA D A, SINGH A, ELAYAPERUMAL A, TSUCHIYA K. Wear behavior of HPT processed UFG AZ31B magnesium alloy [J]. Materials Letters, 2018, 227: 194-198.

[13] CHANDRA SEKHAR K, NARAYANASAMY R, VENKATESWARLU K. Formability, fracture and void coalescence analysis of a cryorolled Al-Mg-Si alloy [J]. Materials and Design, 2014, 57: 351-359.

[14] AZUSHIMA A, KOPP R, KORHONEN A, YANG D Y, MICARI F, LAHOTI G D, GROCHE P, YANAGIMOTO J, TSUJI N, ROSOCHOWSKI A, YANAGIDA A. Severe plastic deformation (SPD) processes for metals [J]. CIRP Annals, 2008, 57(2): 716-735.

[15] VIGNESHWARAN S, SIVAPRASAD K, NARAYANASAMY R, VENKATESWARLU K. Microstructure and mechanical properties of Al-3Mg-0.25 Sc alloy sheets produced by cryorolling [J]. Materials Science and Engineering A, 2019, 740-741: 49-62.

[16] VIGNESHWARAN S, SIVAPRASAD K, NARAYANASAMY R, VENKATESWARLU K. Formability and fracture behaviour of cryorolled Al-3Mg-0.25 Sc alloy [J]. Materials Science and Engineering A, 2018, 721: 14-21.

[17] KONKOVA T, MIRONOV S, KORZNIKOV A, KORZNIKOVA G, MYSHLYAEV M M, SEMIATIN S L. Grain structure evolution during cryogenic rolling of alpha brass [J]. Journal of Alloys and Compounds, 2015, 629: 140-147.

[18] DENG Yan-jun, HUANG Guang-jie, CAO Ling-fei, WU Xiao-dong, HUANG Li, XIA Ming-yong, LIU Qing. Improvement of strength and ductility of Al-Cu-Li alloy through cryogenic rolling followed by aging [J]. Transactions of Nonferrous Metals Society of China, 2017, 27(9): 1920-1927.

[19] SHAHSAVARI A, KARIMZADAH F, REZAEIAN A, HEYDARI H. Significant increase in tensile strength and hardness in 2024 aluminum alloy by cryogenic rolling [J]. Procedia Materials Science, 2015, 11: 84-88.

[20] GOPALA KRISHNA K, SIVAPRASAD K, VENKATESWARLU K, HARKUMAR K C. Microstructural evolution and aging behavior of cryorolled Al-4Zn-2Mg alloy [J]. Materials Science and Engineering A, 2012, 535: 129-135.

[21] SHI Jin-tao, HOU Long-gang, ZUO Jin-rong, ZHUANG Lin-zhong, ZHANG Ji-shan. Cryogenic rolling-enhanced mechanical properties and microstructural evolution of 5052 Al-Mg alloy [J]. Materials Science and Engineering A, 2017, 701: 274-284.

[22] SARKAR A, BHAWMIK A, SUWAS S. Microstructural characterization of ultrafine-grain interstitial-free steel by X-ray diffraction line profile analysis [J]. Applied Physics A, 2008, 94(4): 943-948.

[23] YUAN Jian-yu, PANG Jin-cheng, XIE Guo-jun, WANG Ying, HAN Lu. In situ observation of high-temperature microstructure evolution and phase transformation of 2195 Al-Li alloy [J]. Metallurgical and Mayerials Transactions A, 2019, 50(3): 1509-1521.

[24] NAYAN N, NARAYANA M S V S, JHA A K, PANT B, SHARMA S C, GEORGE K M, SASTRY G V S. Mechanical properties of aluminium–copper–lithium alloy AA2195 at cryogenic temperatures [J]. Materials and Design, 2014, 58: 445-450.

[25] YOSHIMURA R, KONNA T J, ABE E, HIRAGA K. Transmission electron microscopy study of the evolution of precipitates in aged Al-Li-Cu alloys: The θ′ and T1 phases [J]. Acta Materialia, 2003, 51(14): 4251-4266.

[26] NAYAN N, NARAYANA M S V S, MUKHOPADHYAY A K, PRASAD K S, JHA A K, PANT B, SHARMA S C, GEORGE K M. Ambient and cryogenic tensile properties of AA2195T87 sheets with pre-aging cold work by a combination of cold rolling and stretching [J]. Materials Science and Engineering A, 2013, 585: 475-479.

[27] YU H L, SU L H, LU C, TIEU K, LI H J, LI J T, GODBOLE A, KONG C. Enhanced mechanical properties of ARB- processed aluminum alloy 6061 sheets by subsequent asymmetric cryorolling and ageing [J]. Materials Science and Engineering A, 2016, 674: 256-261.

[28] YU H L, YAN M, LI J T, GODBOLE A, LU C, TIEU K, LI H J, KONG C. Mechanical properties and microstructure of a Ti-6Al-4V alloy subjected to cold rolling, asymmetric rolling and asymmetric cryorolling [J]. Materials Science and Engineering A, 2018, 710: 10-16.

[29] NAYAN N, MISHRA S, PRAKASH A, MURTY S V S N, PRASAD M J N V, SAMAJDAR I. Effect of cross-rolling on microstructure and texture evolution and tensile behavior of aluminium-copper-lithium (AA2195) alloy [J]. Materials Science and Engineering A, 2019, 740-741: 252-261.

[30] IVANOV R, DESCHAMPS A, de GEUSER F. Clustering kinetics during natural ageing of Al-Cu based alloys with (Mg, Li) additions [J]. Acta Materialia, 2018, 157: 186-195.

李 畅1,2,熊汗青1,2,Laxman BHATTA 1,2,王 琳1,2,张朝阳1,2,王 辉3,Charlie KONG4,喻海良1,2,5

1. 中南大学 高性能复杂制造国家重点实验室,长沙 410083;

2. 中南大学 机电工程学院,长沙 410083;

3. Research Center for Advanced Science and Technology, The University of Tokyo, Meguro, Tokyo 1530041, Japan;

4. Electron Microscope Unit, University of New South Wales, Sydney, NSW 2052, Australia;

5. 中南大学 轻合金研究院,长沙 410083

摘 要:对Al-3.6Cu-1Li合金进行室温轧制和深冷轧制,并研究工艺对材料显微组织演变和力学性能的影响。通过显微组织分析与力学性能测试,研究厚度压下率为70%和90%的室温轧制和深冷轧制样品的显微组织和时效特性。经过90%厚度压下率的深冷轧制样品具有高强度和良好的韧性,这主要是由于深冷轧制样品对动态回复的抑制和高密度位错的积累。人工时效研究结果表明,达到峰值硬度的温度与变形量成反比,与轧制温度成正比。此外,明场透射电子显微镜照片表明,时效处理的深冷轧制样品存在T1(Al2CuLi)相析出。研究表明,高存储的应变能增强合金的时效动力学,进而促进强化相形核。

关键词:铝-铜-锂合金;深冷轧制;时效;析出强化;力学性能

(Edited by Xiang-qun LI)

Foundation item: Project (2019YFB2006500) supported by the National Key Research and Development Program of China; Project (51674303) supported by the National Natural Science Foundation of China; Project (2018RS3015) supported by the Huxiang High-Level Talent Gathering Project of Hunan Province, China; Project (2019CX006) supported by the Innovation Driven Program of Central South University, China; Project supported by the Research Fund of the Key Laboratory of High Performance Complex Manufacturing at Central South University, China

Corresponding author: Hai-liang YU; Tel/Fax: +86-731-88879351; E-mail: yuhailiang1980@tom.com, yuhailiang@csu.edu.cn

DOI: 10.1016/S1003-6326(20)65430-9