文章编号:1004-0609(2011)12-3137-06

红土镍矿还原焙烧-磁选制取镍铁合金原料的新工艺

李光辉,饶明军,姜 涛,黄晴晴,史唐明,张元波

(中南大学 资源加工与生物工程学院,长沙 410083)

摘 要:采用钠盐添加剂强化红土镍矿的还原焙烧-磁选,确定了添加剂存在下适宜的焙烧和磁选技术参数,开发出红土镍矿还原焙烧-磁选制取镍铁合金原料的新工艺。结果表明:钠盐添加剂具有显著降低焙烧温度、大幅提高产品镍、铁品位和回收率的作用;对一种含镍1.58%、铁22.06%的红土镍矿配加添加剂后,在还原温度1 100 ℃、还原时间60 min、磁场强度0.1 T的条件下,磁性产品的镍、铁品位可分别从无添加剂时的2.0%、57.2% 提高到 7.5%、80.5%,镍、铁回收率也相应从19.1%、33.6% 增加到82.7%、62.8%。XRD结果表明:红土镍矿在无添加剂作用下经还原焙烧-磁选所得的磁性产物中仍有部分镁橄榄石及顽火辉石存在;而有添加剂存在时,还原生成的镍铁合金通过磁选可与非磁性脉石成分得到更为有效的分离,产品可作为不锈钢的生产原料。

关键词:红土镍矿;添加剂;还原焙烧;镍铁;不锈钢

中图分类号:TF815 文献标志码:A

Innovative process for preparing ferronickel materials from laterite ore by reduction roasting-magnetic separation

LI Guang-hui, RAO Ming-jun, JIANG Tao, HUANG Qing-qing, SHI Tang-ming, ZHANG Yuan-bo

(School of Minerals Processing and Bioengineering, Central South University, Changsha 410083, China)

Abstract: An innovative process for preparing ferronickel materials from laterite ore by reduction roasting-magnetic separation in the presence of additives was proposed, and the effect of additives on reducing roasting-magnetic separation of laterite ore and the technical parameters of roasting and magnetic separation were investigated. The results show that the sodium salt additives are not only able to dramatically decrease the reducing temperature, but also increase the grades and recoveries of nickel and iron in ferronickel. The grades of nickel and iron are improved from 2.0% and 57.2% to 7.5% and 80.5%, respectively, and also the recoveries of nickel and iron are improved from 19.1% and 33.6% to 82.7% and 62.8%, respectively, as the addition of additives is under the conditions of reduction temperature 1 100 ℃, reduction time 60 min, magnetic field intensity of 0.1 T. The ferronickel materials obtained can be used for the stainless steel production as the XRD results show that the magnetic product is mainly comprised of ferronickel in the presence of additives, while still contains a portion of forsterite and enstatite in the absence of additives.

Key words: laterite; additives; reduction roasting; ferronickel; stainless steel

镍是一种重要的战略金属材料,在现代工业中有着广泛的应用。镍主要消费于不锈钢生产,不锈钢用镍约占全球镍消费总量的65%。2009年,我国不锈钢表观消费量822万t,不锈钢粗钢产量达到880万t,均居世界首位[1-3]。镍原料成本约占奥氏体不锈钢生 产总成本的70%,用占有世界陆基镍资源72%的红土镍矿生产镍铁作为冶炼不锈钢的原料,可以综合回收铁并减少金属镍的消耗,其成本明显低于使用金属镍,是大幅度降低不锈钢生产成本,保障不锈钢工业可持续发展的有效途径之一[4-6]。

回转窑还原红土镍矿并通过磁、重分选生产可直接用于冶炼不锈钢的镍铁合金工艺,具有能耗小、生产成本低的优点。该工艺已在日本大江山冶炼厂(Oyama smelter)获得工业应用,但工艺技术仍不够稳定,且团矿需要在1 350~1 400 ℃的高温条件下(半熔融状态)进行还原焙烧[7-8]。红土镍矿通过还原、物理分选可在一定程度上实现镍、铁富集,但由于镍、铁等金属元素在红土镍矿中的赋存状态复杂,因此,在还原-分选过程中镍、铁富集和回收效果不理想。当处理腐泥土型红土镍矿时,蛇纹石脱羟基生成致密的镁橄榄石,致使赋存于其中的镍难以得到还原,因此,还原温度要求比处理褐铁矿型红土镍矿时更高[9-12]。这也是回转窑还原焙烧需在高温条件下使物料呈熔融(或半熔融)状态的原因。

研究表明,配加适宜的添加剂可以改善红土镍矿的还原分选效果。例如,添加氯化剂进行氯化离析焙烧,在高温下氯化剂与镍氧化物生成氯化镍,氯化镍再被还原成金属镍,通过磁选可得含镍精矿。但是,由于氯化剂在高温反应过程中容易产生HCl和Cl2等有毒、有害气体,污染环境且腐蚀设备,因此,未见工业化应用[13-14]。添加单质S可以降低镍、铁晶粒的表面张力,从而促进镍铁晶粒的聚集、长大,对后续的磁选分离有利。但是,S在镍铁合金表面吸附易造成磁性镍铁合金产品中的S含量超标[15-16]。

因而,开发清洁、高效的添加剂来强化还原,是还原焙烧-分选法处理红土镍矿制备镍铁的研究重点之一。本文作者主要研究钠盐添加剂对红土镍矿还 原-磁选效果的影响,开发添加剂作用下的红土镍矿还原焙烧-磁选制取镍铁合金原料的新工艺及相关 技术。

1 实验

1.1 原料

1.1.1 化学试剂

试验所用的添加剂为无水碳酸钠(Na2CO3)、无水硫酸钠(Na2SO4),均为分析纯试剂。

1.1.2 红土镍矿

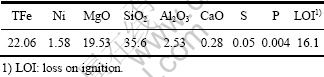

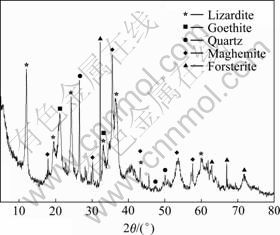

所用的红土镍矿来自印度尼西亚,其主要化学成分和XRD谱分别如表1和图1所示。由表1和图1可知,该红土镍矿镁、硅含量较高,主要矿物组成为利蛇纹石(Mg3Si2(OH)4O5)、镁橄榄石(Mg2SiO4)、针铁矿(FeOOH)、磁赤铁矿(γ-Fe2O3)以及石英(SiO2),属腐泥土型红土镍矿。

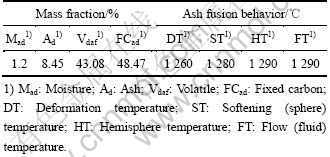

1.1.3 还原剂

试验所用还原剂为褐煤,其工业分析如表2所列。煤中固定碳含量48.47%,挥发份含量43.08%,灰分含量8.45%,试验前破碎至粒度小于5 mm。

表1 红土镍矿的主要化学成分

Table 1 Main chemical composition of laterite sample (mass fraction, %)

图1 红土镍矿的XRD谱

Fig.1 XRD pattern of laterite sample

表2 还原煤的工业分析结果

Table 2 Industrial analysis results of reducing coal

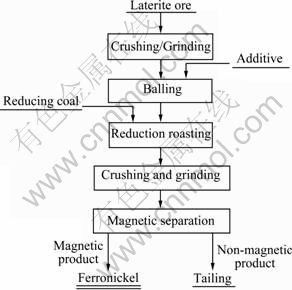

1.2 方法

试验流程如图2所示。红土镍矿经破碎、磨矿至粒径小于74 μm占80%以上后与添加剂按比例(质量比)混匀、造球,球团经干燥后装入预先铺有一定量还原煤的耐高温不锈钢容器(d 60 mm×150 mm)中,再覆盖过量还原煤后置于竖式电阻炉(SK-8-13型)内按设定温度进行还原焙烧。电阻炉管炉内径d 70 mm,用DWK-702精密温控仪控制反应所需温度。待试验达到设定时间之后取出反应罐,惰性气氛下保护冷却至常温。与残煤分离后,将还原球团破碎至小于1 mm,置于球磨机(RK/ZQM液晶智能球磨机)中湿式磨矿后,在XCGS-73型磁选管内进行湿式磁选分离,所得磁性产物即为粉状镍铁合金原料。

图2 红土镍矿还原焙烧-磁选试验流程图

Fig.2 Experimental flowsheet of reduction roasting-magnetic separation of laterite ore

2 结果与分析

2.1 无添加剂作用下红土镍矿的还原焙烧-磁选效果

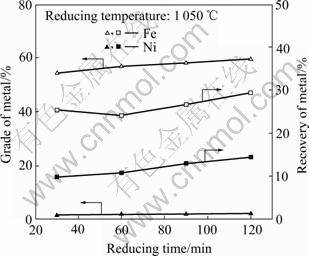

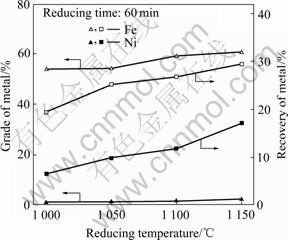

固定还原产物磁选条件为磨矿粒度小于43 μm粒级含量90%左右、磁场强度0.1 T,研究还原焙烧温度、时间对红土镍矿分选效果的影响。由图3和4可以看出,还原时间的延长和温度的提高都有助于改善红土镍矿的还原-磁选效果,但是在试验所选取的温度和时间范围内,红土镍矿还原-磁选效果并不理想。在 1 050 ℃下还原60 min,磁选所得镍铁产品中镍、铁品位仅分别为1.8%、59.2%,镍、铁回收率分别只有11.9%、26.8%。研究表明:在低于1 150 ℃的温度下对红土镍矿进行还原焙烧,镍、铁的分离和富集效果不明显。

2.2 添加剂作用下红土镍矿的还原焙烧-磁选效果

2.2.1 添加剂的影响

固定还原温度1 100 ℃,还原时间60 min,还原产物磨矿粒度小于43 μm粒级含量90%左右,磁场强度0.1 T,研究添加剂种类及用量对红土镍矿还原-磁选效果的影响,添加剂由无水碳酸钠(Na2CO3)和无水硫酸钠(Na2SO4)组成。试验结果如表3所列。

图3 还原时间对红土镍矿还原焙烧-磁选效果的影响

Fig.3 Effects of reducing time on reduction roasting-magnetic separation of laterite ore

图4 还原温度对红土镍矿还原焙烧-磁选效果的影响

Fig.4 Effects of reducing temperature on reduction roasting- magnetic separation of laterite ore

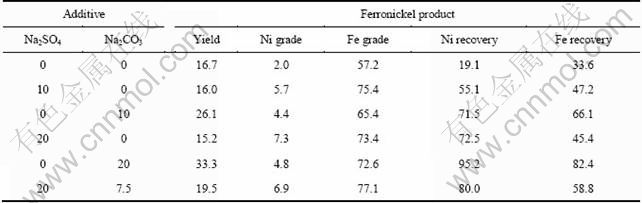

从表3可以看出,在相同的焙烧、磁选制度条件下,无添加剂红土镍矿球团还原-磁选效果不理想,磁性镍铁合金粉中镍、铁品位分别仅为2.0%、57.2%,镍、铁回收率也分别仅为19.1%、33.6%。分别添加硫酸钠或碳酸钠后,分离回收效果均得到一定程度的改善;比较而言,添加剂用量相同时,硫酸钠有利于提高磁性产品中镍、铁品位,而碳酸钠对提高镍、铁磁选回收率有利。增加硫酸钠或碳酸钠的用量到20%,分离回收效果得到进一步改善,同时,不同钠盐对镍、铁的品位和回收率影响的差异也变得更加明显。20%硫酸钠作用下,镍、铁品位分别为7.3%、73.4%,但镍、铁回收率仅为72.5%、45.4%;20%碳酸钠作用下,镍、铁品位仅为4.8%、72.6%,镍、铁回收率则高达95.2%、82.4%。这一结果进一步证实硫酸钠、碳酸钠在红土镍矿的还原分选过程中所起的不同作用。

表3 添加剂对红土镍矿还原焙烧-磁选效果的影响

Table 3 Effects of additives on reduction roasting-magnetic separation of laterite ore (mass fraction, %)

当同时添加硫酸钠(20%)和碳酸钠(7.5%),在两者协同作用下,磁性镍铁合金产品中镍、铁品位达到6.9%、77.1%,同时镍、铁回收率也达到80.0%、58.8%。

2.2.2 焙烧制度的影响

固定还原产物磨矿粒度小于0.043 mm粒级含量90%左右、磁场强度0.1 T,添加剂组分为20%硫酸钠、7.5%碳酸钠。研究还原焙烧温度和时间对红土镍矿还原焙烧-磁选效果的影响,为进一步强化还原分选效果,同时还加入了3%辅助添加剂。

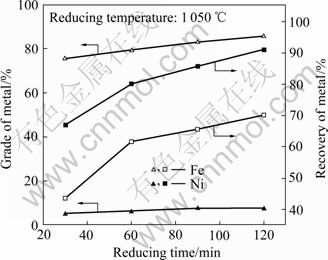

2.2.2.1 还原焙烧时间

在还原温度1 050 ℃的条件下,焙烧时间对红土镍矿还原焙烧-磁选效果的影响如图5所示。当焙烧时间由30 min延长到60 min时,镍、铁品位及回收率得到大幅度提高,但继续延长时间到120 min,镍、铁品位及回收率提高的幅度不大,由此,推荐适宜的还原焙烧时间为60 min左右。此时,磁性产品中镍品位为6.5%、铁品位为79.3%、镍回收率为80.2%、铁回收率为61.7%。

图5 还原时间对添加剂作用下红土镍矿还原焙烧-磁选效果的影响

Fig.5 Effects of reducing time on reduction roasting-magnetic separation of laterite ore with additives

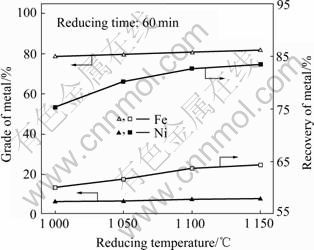

2.2.2.2 还原焙烧温度

图6所示为不同还原温度时红土镍矿还原焙烧-磁选效果。由图6可以看出,在焙烧时间60 min的条件下,当焙烧温度从1 000 ℃上升到1 100 ℃时,磁性镍铁产品中镍、铁品位提高的幅度不大,而镍、铁回收率的提高则较为显著;进一步升高至1 150 ℃,镍、铁回收率也逐渐趋于稳定。综合考虑,推荐适宜的还原焙烧温度为1 050~1 100 ℃。

2.2.3 磁选工艺参数的影响

固定添加剂组成为20%硫酸钠、7.5%碳酸钠和3%辅助添加剂,还原温度1 100 ℃,还原时间60 min。研究还原产物磨矿细度和磁场强度对红土镍矿还原焙烧-磁选效果的影响。

图6 还原温度对添加剂作用下红土镍矿还原焙烧-磁选效果的影响

Fig.6 Effects of reducing temperature on reduction roasting- magnetic separation of laterite ore with additives

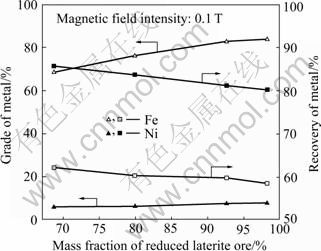

2.2.3.1 磨矿细度

在磁场强度0.1 T条件下,红土镍矿焙烧矿磨矿细度对红土镍矿还原产物-磁选效果的影响如图7所示。当红土镍矿焙烧矿磨矿粒度小于43 μm的含量从69%提高到98%时,镍、铁品位分别从6.2%、68.8%提高到8.1%、83.8%,而镍、铁回收率则分别从85.6%、62.3%降低到80.3%、58.7%。还原产物磨矿粒度小于43 μm的含量90%左右时,磁性产品中镍品位为7.5%,镍回收率为82.7%,铁品位为80.5%,铁回收率为62.8%。

图7 红土镍矿焙烧矿磨矿细度对添加剂作用下红土镍矿还原分选效果的影响

Fig.7 Effects of grinding fineness of reduced laterite ore on reduction roasting-magnetic separation of laterite ore with additives under condition of reducing temperature 1 100 ℃ and reducing time 60 min

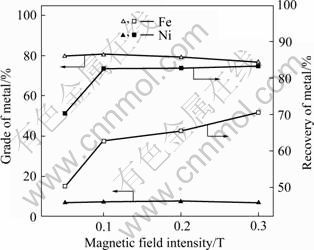

2.2.3.2 磁场强度

在相同的磨矿细度下,磁场强度对红土镍矿还原焙烧-磁选的影响如图8所示。当磁场强度由0.05 T提高到0.1 T时,镍品位和回收率分别由7.2%和70.4%上升到7.5%和82.7%,铁品位和回收率分别从79.7%和50.3%上升到80.5%和62.8%。进一步提高磁场强度,虽然镍、铁回收率得到小幅度提高,但同时因夹杂过高而导致磁性产品中镍、铁品位降低。因而,适宜的磁场强度为0.1 T。

2.3 产品性能分析

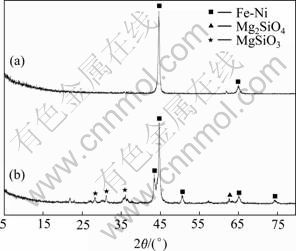

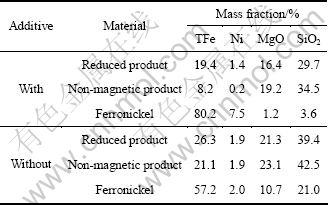

图9所示为红土镍矿还原磁选所得磁性产品的XRD谱。红土镍矿的还原产物、磁选所得的磁性产品以及非磁性产品的主要化学成分如表4所列。

从图9可以看出,红土镍矿在添加剂(硫酸钠:20%;碳酸钠:7.5%;辅助添加剂:3%)作用下于1 100 ℃温度下还原60 min,还原生成的金属镍、铁固溶形成磁性镍铁合金,通过磁选可与非磁性脉石成分得到有效分离(见图9(a))。而无添加剂作用下,磁性产品中仍有部分镁橄榄石及顽火辉石等非磁性物存在(见图9(b)),表明磁选分离效果不佳。结合表3结果进一步表明,添加剂作用下,磁性产品中硅、镁等脉石成分含量显著降低,镍、铁得到了明显的富集,其中Fe的富集比为3.65、Ni的富集比达到4.75,显著高于无添加剂作用下的Fe富集比2.59、Ni富集比1.27。

图8 磁场强度对添加剂作用下红土镍矿还原分选效果的影响

Fig.8 Effects of magnetic field intensity on reduction roasting-magnetic separation of laterite ore with additives under condition of reducing temperature 1 100 ℃ and reducing time 60 min

图9 有、无添加剂作用下磁性产品的XRD谱

Fig.9 XRD patterns of magnetic products obtained with(a) and without(b) additives

表4 红土镍矿还原焙烧产物、非磁性物以及磁性镍铁合金粉的主要化学成分

Table 4 Main chemical composition of reduced product, non-magnetic product and ferronickel

3结论

1) 添加剂硫酸钠、碳酸钠等可显著改善红土镍矿的还原焙烧-磁选效果,获得高镍品位的镍铁合金原料。在还原温度为1 100 ℃和还原时间为60 min的条件下,添加20%硫酸钠、7.5%碳酸钠和3%辅助添加剂后,红土镍矿还原焙烧-磁选所得镍铁产品中的镍、铁品位分别从无添加剂条件下的2.0%、57.2% 提高到 7.5%、80.5%;同时,镍、铁回收率也分别从19.1%、33.6% 增加到82.7%、62.8%。

2) 红土镍矿无添加剂作用下经过还原焙烧-磁选所得的磁性产物中仍有部分镁橄榄石及顽火辉石存在,而添加剂存在下,还原生成的镍铁合金通过磁选可与非磁性脉石成分得到更为有效的分离。

REFERENCES

[1] KIM J, DODBIBA G, TANNO H, OKAYA K, MATSUO S, FUJITA T. Calcination of low-grade laterite for concentration of Ni by magnetic separation[J]. Minerals Engineering, 2010, 23(4): 282-288.

[2] 曾 裕. 中国不锈钢市场现状、发展趋势及对策[J]. 冶金经济与管理, 2006(5): 35-38.

ZENG Yu. Present situation, development trend and countermeasure in the stainless steel market of China[J]. Metallurgical Economics and Management, 2006(5): 35-38.

[3] 中国特钢企业协会不锈钢分会. 2009年中国不锈钢生产、进出口、表观消费情况的统计及其解析[EB/OL]. 2010, http://www.cssc.org.cn/news_show_content.php?news_id=3337.

Stainless steel council of China special steel enterprises association. China stainless steel production, import and export, apparent consumption statistics and analysis in 2009[EB/OL]. 2010, http://www.cssc.org.cn/news_show_content.php?news_id= 3337.

[4] WARNER A E M, D?AZ C M, DALVI A D, MACKEY P J, TARASOV A V. JOM world nonferrous smelter survey, Part Ⅲ: Nickel: Laterite[J]. JOM, 2006, 58(4): 11-20.

[5] 刘 岩, 翟玉春, 张纪谦, 袁 磊. 从镍精矿中提取镍铁合金的还原工艺[J]. 过程工程学报, 2005, 6: 626-630.

LIU Yan, ZHAI Yu-chun, ZHANG Ji-qian, YUAN Lei. Reduction technology of preparation of ferronickel powder from nickel concentrate[J]. The Chinese Journal of Process Engineering, 2005, 6: 626-630.

[6] 张友平, 周渝生, 李肇毅, 李维国. 红土矿资源特点和火法冶金工艺分析[J]. 铁合金, 2007, 38(6): 18-21.

ZHANG You-ping, ZHOU Yu-sheng, LI Zhao-yi, LI Wei-guo. Characteristics of laterite resource and analysis on its pyrometallurgy process[J]. Ferro-Alloys, 2007, 38(6): 18-21.

[7] WATANABE T, ONO S, ARAI H, MATSUMORI T. Direct reduction of garnierite ore for production of ferro-nickel with a rotary kiln at Nippon Yakin Kogyo Co., Ltd., Oheyama Works[J]. International Journal of Mineral Processing, 1987, 19(1/4): 173-187.

[8] 王成彦, 尹 飞, 陈永强, 王 忠, 王 军. 国内外红土镍矿处理技术及进展[J]. 中国有色金属学报, 2008, 18(z1): s1-s8.

WANG Cheng-yan, YIN Fei, CHEN Yong-qiang, WANG Zhong, WANG Jun. Worldwide processing technologies and progress of nickel laterites[J]. The Chinese Journal of Nonferous Metals, 2008, 18(z1): s1-s8.

[9] CRAMA W J, BAAS A H. Process for the preparation of a ferronickel concentrate: United States, 4490174[P]. 1984-12-25.

[10] VALIX M, CHEUNG W H. Study of phase transformation of laterite ores at high temperature[J]. Minerals Engineering, 2002, 15: 607-612.

[11] VALIX M, CHEUNG W H. Effect of sulfur on the mineral phases of laterite ores at high temperature reduction[J]. Minerals Engineering, 2002, 15: 523-530.

[12] Kawahar M, Togur J M, Bergman R A. Reducibility of laterite ores[J]. Metallurgical Transactions B: Process Metallurgy, 1988, 19(2): 181-186.

[13] 汪云华, 范兴祥, 顾华祥. 不同类型红土镍矿的还原-磨选处理方法: 中国, 200610163831.6[P]. 2006-12-22.

WANG Yun-hua, FAN Xin-xiang, GU Hua-xiang. Methods of reduction-grinding-separation for different types of laterites: China, 200610163831.6[P]. 2006-12-22.

[14] 张 军, 张宗华. 铁镁质硅酸镍矿的离析选别试验研究[J]. 矿业工程, 2007, 6: 36-38.

ZHANG Jun, ZHANG Zong-hua. The research of mineral processing on Fe-Mg garnierite[J]. Mining Engineering, 2007, 6: 36-38.

[15] GRAEME G. Nickel recovery from reject laterite[D]. Montreal, Canada: McGill University, 2007.

[16] XIAO F, LIU L X, FANG L, YANG R H, FU Y, ZHAO H K. Measurement and analyses of molten nickel-cobalt alloy surface tension[J]. Rare Metal Materials and Engineering, 2008, 37(2): 255-258.

(编辑 李艳红)

基金项目:国家杰出青年科学基金资助项目(50725416)

收稿日期:2011-11-24;修订日期:2011-03-11

通信作者:姜 涛,教授,博士;电话:0731-88877656;E-mail: Jiangtao@csu.edu.cn