DOI:10.19476/j.ysxb.1004.0609.2017.03.018

铁质和镁质红土镍矿直接还原-磁选工艺对比

刘志国,孙体昌,王晓平

(北京科技大学 土木与资源工程学院,北京 100083)

摘 要:主要进行铁质红土镍矿和镁质红土镍矿的直接还原-磁选工艺的对比研究。结果表明:在不使用添加剂的情况下,铁质试样中的镍比较容易还原和回收,镍回收率能达到90%,但镍品位较低。镁质试样中的镍较难回收,镍的品位和回收率都不理想,镍回收率只有45%左右。进一步试验发现,硫酸钠可作为铁质试样的理想添加剂,但对镁质试样作用效果不佳。氟化钙对镁质试样作用效果显著,但对铁质试样作用效果不明显。分析发现,两种试样镍的赋存状态、铁元素含量以及还原所得金属颗粒大小的差异是造成上述差别的主要原因。

关键词:铁质红土镍矿;镁质红土镍矿;直接还原;磁选

文章编号:1004-0609(2017)-03-0594-11 中图分类号:TD925 文献标志码:A

按地质成因,镍资源主要划分为岩浆型硫化镍矿床和风化型红土镍矿床。根据矿层分布和矿石中铁、镁含量的不同,红土镍矿可以简单地分为褐铁矿型和残积型。褐铁矿型的红土镍矿含铁较高,但含镍、镁较低;残积型的红土镍矿含镍、镁、硅较高,但含铁较低。由于红土镍矿的种类和分法太多,没有统一的标准,又可以简单通俗的根据红土镍矿的铁、镁元素含量将其分为铁质红土镍矿、铁镁质红土镍矿和镁质红土镍矿[1-3]。

近年来随着镍的需求不断增加以及世界可供开发的硫化镍资源逐渐短缺,采用直接还原-磁选工艺处理红土镍矿回收镍铁合金得到较多的关注并取得较大的研究进展[4-6]。红土镍矿直接还原-磁选工艺的影响因素众多,比如焙烧温度、焙烧时间、还原气氛、添加剂的种类和用量等[7-11]。但是,由于红土镍矿成矿规律比较复杂,造成红土镍矿种类众多,性质差异大,不同类型的红土镍矿可能需要完全不同的焙烧条件[12-15]。因此,相比于其他影响因素,红土镍矿的原矿种类是尤其重要的一个影响因素。但是,目前的报道大多针对某特定的矿石进行研究,对此系统的研究较少。如LI等[16]研究发现添加硫酸钠能够提高镍的回收率,而JIANG等[17]研究发现添加硫酸钠会使镍的回收率先增高后降低,二者得出的规律具有较大差异。因此,有必要系统地研究原矿性质对红土镍矿直接还原的影响,从而总结出不同种类红土镍矿直接还原的规律,进而为不同种类的红土镍矿选择合适的工艺条件提供可靠的依据。本文作者对铁质和镁质两种红土镍矿的直接还原-磁选工艺进行了对比研究,分析了二者直接还原工艺的差异,可为以后系统地研究原矿性质对该工艺的影响提供参考和借鉴。

1 实验

1.1 试样所含元素和矿物

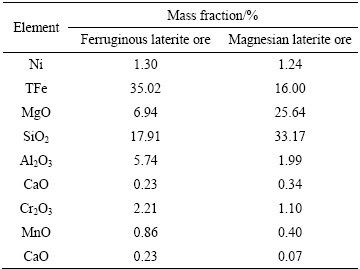

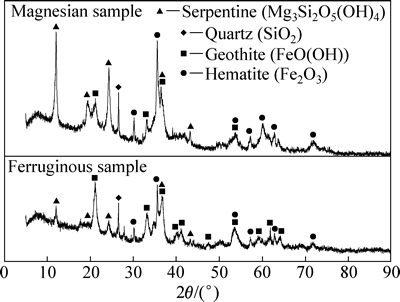

试验选取铁质和镁质两种红土镍矿进行研究,以下称为铁质试样和镁质试样。两种试样主要元素含量见表1,铁质试样铁、铝、铬、锰和钴元素含量较高,镁质试样铁、镁、硅含量较高。为查明两种试样所含主要矿物,对其进行XRD分析(见图1)。可知,两种试样所含矿物种类大致相同,主要含有针铁矿、赤铁矿、蛇纹石和石英,但各矿物在两种试样中的衍射峰强度差异较大。铁质试样中针铁矿的衍射峰较强,镁质试样中蛇纹石和赤铁矿的衍射峰较强。

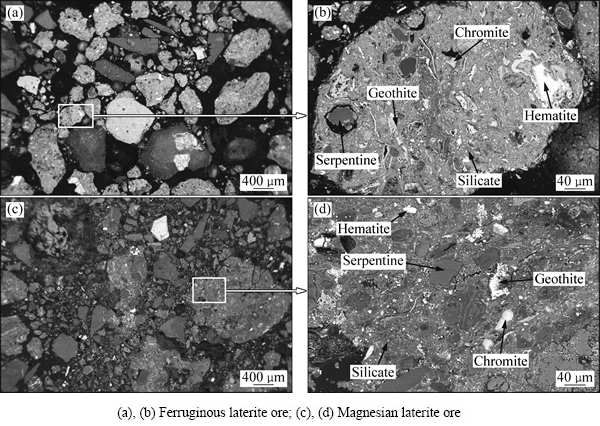

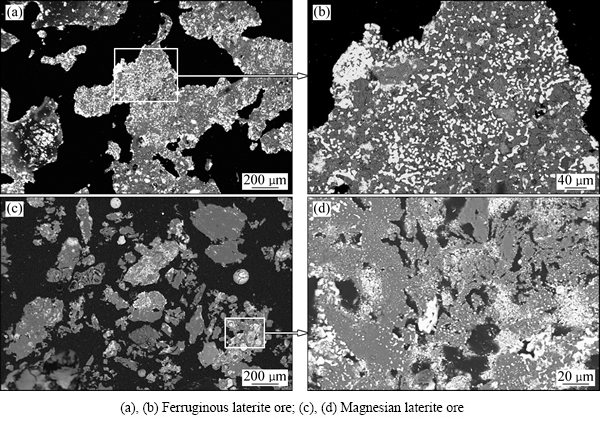

1.2 试样形貌及载镍矿物分析

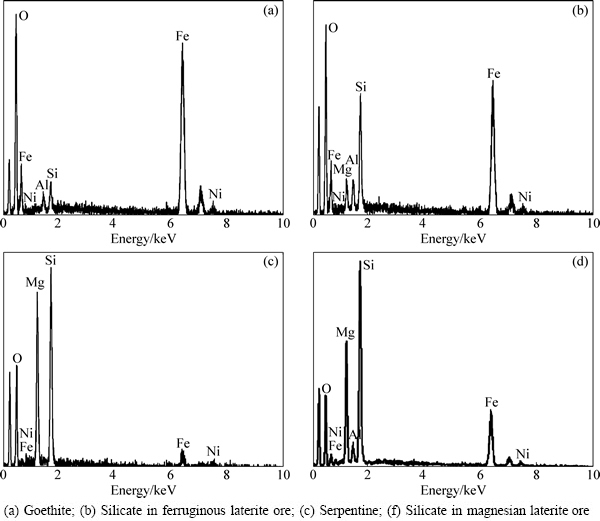

两种试样原矿SEM分析结果如图2所示。图2中最亮且呈颗粒状的为赤铁矿,亮度次之且多呈条状的为针铁矿,灰黑色且有规则形状的为蛇纹石。红土镍矿是风化-次生沉淀形成的矿物,所以试样中除了大颗粒的蛇纹石颗粒含杂质较少,其他矿物颗粒多是多种矿物胶结在一起形成的。铁质试样中针铁矿、赤铁矿和小颗粒的蛇纹石、铬铁矿会通过富含铁的硅酸盐胶结在一起,如图2(a)和(b)所示,其EDS谱如图3(b)所示。镁质试样则是通过富含镁的硅酸盐将上述矿物胶结在一起,如图2(c)和(d)所示,其EDS谱如图3(d)所示。对比图2(a)和(c)可知,铁质试样含有较多的针铁矿颗粒,蛇纹石矿物较少,而镁质试样中蛇纹石矿物颗粒较多,而针铁矿颗粒较少,这与XRD分析一致。但是,红土镍矿中部分矿物结晶较差,在XRD中并没有显示出来,如试样中的一些硅酸盐矿物。

表1 两种试样主要元素含量

Table 1 Content of main elements of two kinds of samples

图1 两种试样XRD谱

Fig. 1 XRD patterns of two samples

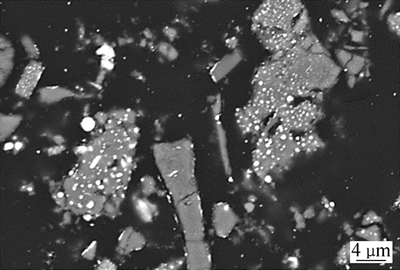

镍是亲铁元素,容易被铁氧化物捕获形成富镍矿物。在成矿过程中针铁矿还会吸附一定的硅、铝元素,其EDS谱如图3(a)所示。在风化-淋滤过程中,硅、镁元素迁移速率较快,容易随淋滤液中往下迁移。在随后的沉积过程中部分残留的淋滤液会与铁氧化物结合形成胶状物,其EDS谱如图3(b)所示,相比于针铁矿,硅含量明显提高,且有镁元素能谱峰。

在风化-淋滤过程中,形成的富含硅、镁的淋滤液会形成SiO2-MgO凝胶并捕获镍元素。当成矿条件比较充分的时候就会形成结晶比较好的蛇纹石,其EDS谱如图3(c)所示。当成矿条件不充分时就会形成一些结晶较差的硅酸盐,其EDS谱如图3(d)所示。

由以上分析可知,铁质试样的镍主要赋存在针铁矿和富含铁的硅酸盐矿物中,镁质试样的镍主要赋存在蛇纹石和非晶态硅酸盐中。

图2 两种试样的SEM像

Fig. 2 SEM images of two samples

图3 两种试样的EDS谱

Fig. 3 EDS spectra of two samples

1.3 试验方法

直接还原-磁选试验是将试样与煤、添加剂按一定质量比混匀后装入石墨坩埚,然后放入指定温度的马弗炉中进行还原焙烧,焙烧产物经自然冷却后进行磨矿、磁选得到镍铁产品。试验所用煤成分分析见表2。焙烧采用SX-10-13马弗炉,磨矿使用RK/BK三辊四筒智能棒磨机,磨矿时间为15 min,磁选采用CXG-99磁选管,磁场强度为144 kA/m。

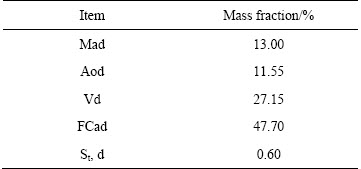

表2 试验所用煤的成分分析(空气干燥基)

Table 2 Composition analysis of coal used in test (dry air base)

试验SEM-EDS分析设备为德国卡尔蔡司EVO18扫描电子显微镜及Bruke XFlash Detector 5010能谱分析仪。

2 两种试样直接还原-磁选效果的差异

试验主要考察煤用量、焙烧温度、焙烧时间和添加剂对两种试样作用规律的差异,添加剂选择硫酸钠和氟化钙进行对比研究。

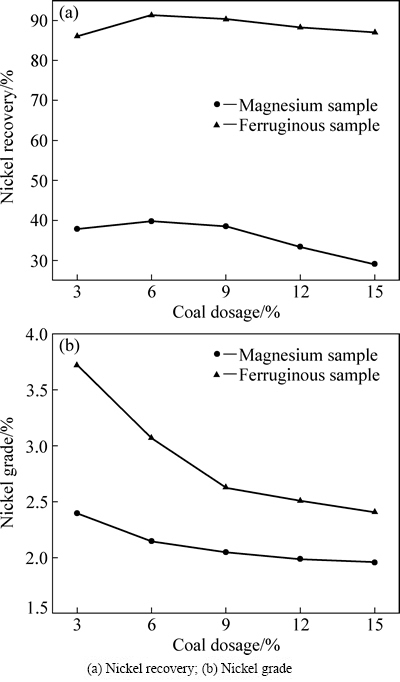

2.1 煤用量作用效果的差异

煤用量试验主要研究还原气氛的变化对两种矿样影响规律的异同,并确定试验最佳煤用量。在焙烧温度1200 ℃、焙烧时间50 min的条件下进行煤用量试验,结果见图4。随着煤用量的增加,两种试样的镍回收率规律变化相同,都是先增加然后下降,在煤用量为6%时达到最佳值。但铁质试样镍回收率下降趋势较缓,镁质试样的镍回收率下降趋势明显;两种试样的镍铁产品的镍品位均呈下降趋势,铁质试样下降明显。

分析可知,铁质试样中的镍较易回收,镁质试样中的镍较难回收。随着煤用量的增加,还原气氛的增强,铁质试样的镍回收率受影响较小,但镍品位受影响较大,镁质试样的镍回收率受影响较大,镍品位受影响相对较小。

图4 煤用量对两种试样镍回收率和品位的影响

Fig. 4 Effects of coal consumption on two samples of nickel recovery and grade

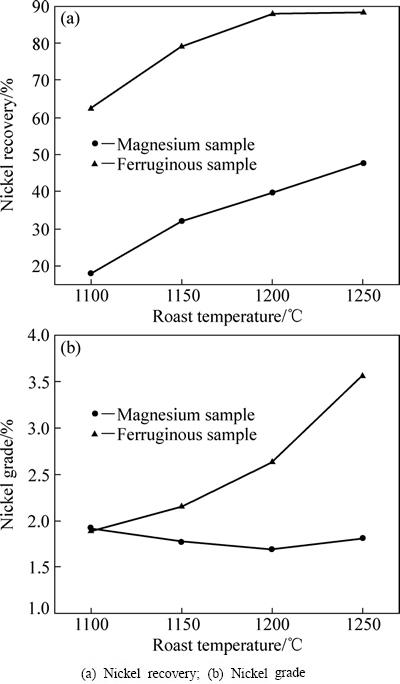

2.2 焙烧温度作用效果的差异

在焙烧时间为50 min、煤用量为6%的基础上进行焙烧温度试验,试验结果见图5。由图5可看出,随着焙烧温度的升高,两种试样的镍回收率都呈上升趋势。铁质试样的镍较易回收,当焙烧温度提高到1200 ℃时已获得较高的回收率,继续升高温度效果不大。镁质试样的镍回收率受温度影响较大,随着焙烧温度的提高镍回收率一直呈现上升的趋势,超过1200 ℃之后增速也没有出现变缓的趋势。铁质试样镍铁产品的镍品位明显提高,镁质试样的镍品位没有明显变化。综合考虑,能耗和镍回收率以及两种试样后续的对比试验研究,将焙烧温度定为1200 ℃。

图5 焙烧温度对两种试样镍回收率和品位的影响

Fig. 5 Effects of roasting temperature on two samples of nickel recovery and grade

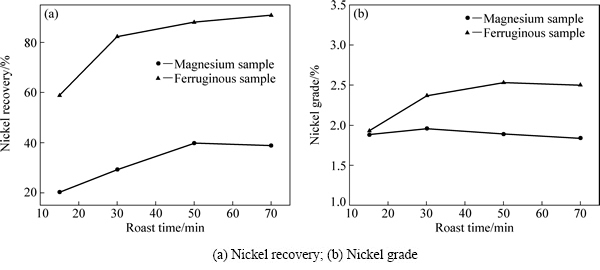

2.3 焙烧时间作用效果的差异

在焙烧温度为1200 ℃、煤用量为6%的条件下进行焙烧时间试验,结果见图6。由图6可看出,随着焙烧时间的延长,两种试样的镍回收率都呈现上升的趋势,且都在50 min左右达到较佳值。值得注意的是,铁质试样的镍较好回收,在焙烧30 min时回收率就达到较大值,而镁质试样是在焙烧50 min后镍回收率才达到较大值。焙烧时间对铁质试样的镍品位有一定影响,对镁质试样影响不大。综合考虑,焙烧时间选取50 min为宜。

图6 焙烧时间对两种试样镍回收率和品位的影响

Fig. 6 Effects of roasting time on two samples of nickel recovery and grade

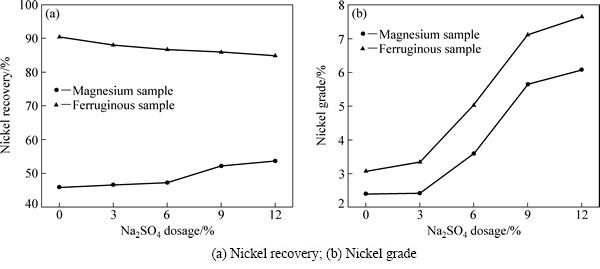

图7 硫酸钠用量对两种试样镍回收率和品位的影响

Fig. 7 Effects of sodium sulfate dosage on two samples of nickel recovery and grade

2.4 硫酸钠作用效果的差异

在焙烧温度为1200 ℃、焙烧时间为50 min、煤用量为6%的条件下,进行硫酸钠用量试验,结果见图7。由图7可看出,随着硫酸钠用量的增加,两种试样的镍品位变化规律都十分相似,呈现明显的上升趋势,铁质试样更为明显,镍品位从3%增长到8%左右。但是,镍回收率的变化规律有较大差异。随着硫酸钠用量的增加,铁质试样镍回收率呈略微下降的趋势,镁质试样的镍回收率反而呈现略微上升的趋势。

对于铁质试样而言,添加硫酸钠能够在保证镍的回收率的前提下,明显提高镍品位,解决了铁质试样镍铁产品镍品位低的问题,是其理想的添加剂。对于镁质试样而言,添加硫酸钠虽能提高镁质试样的镍品位,但不能有效提高镍回收率,镍回收率只有53%左右。因此,硫酸钠不能作为镁质试样的添加剂,考虑到其提高镍品位的作用,可以探索和其他添加剂组成组合添加剂。

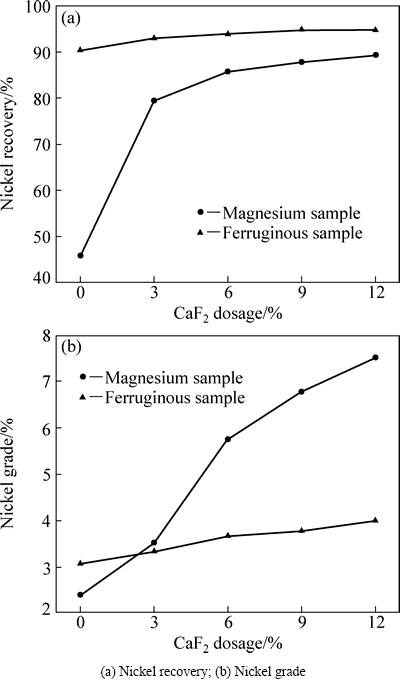

2.5 氟化钙作用效果的差异

在焙烧温度为1200 ℃、焙烧时间为50 min、煤用量为6%的条件下,进行氟化钙用量试验,试验结果见图8。随着氟化钙用量的增加,铁质试样的镍品位和回收率略微提高。镁质试样的镍回收率和品位得到明显提高,镍回收率从45%提高到85%左右,品位从2.5%提高到7.5%左右。

氟化钙对铁质试样作用不明显,各指标只有略微的变化。对镁质试样作用效果显著,能明显提高镍回收率和品位,是镁质试样比较理想的添加剂。

3 机理分析

以上试验研究发现两种试样直接还原工艺存在较大的差异,两种试样随焙烧条件变化出现了不同的变化规律。研究将着重从试样的镍赋存状态、铁元素含量以及还原所得金属颗粒大小几个方面进行分析,阐述矿石种类对红土镍矿直接还原-磁选工艺的影响机理。

3.1 镍赋存状态造成的影响

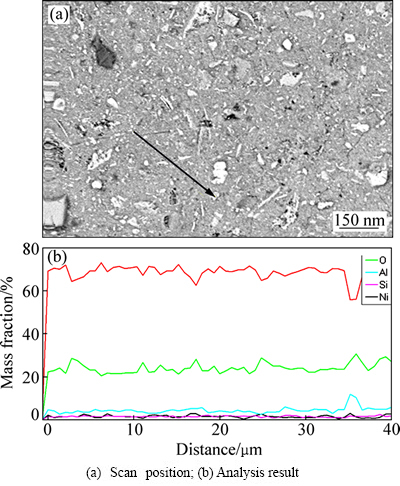

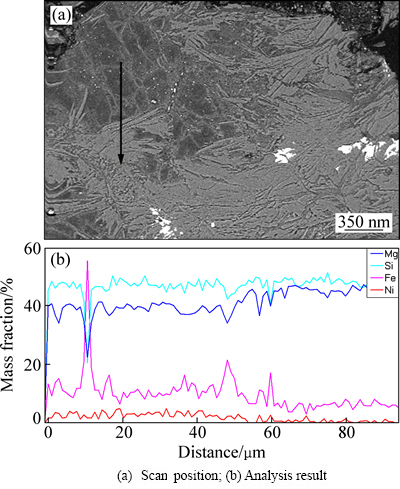

上述分析可知铁质试样中的镍主要是以针铁矿等铁氧化物为载镍矿物,镁质试样中的镍主要是赋存于蛇纹石等硅酸盐矿中。分别对这两种形式的矿物颗粒进行电镜线扫描分析,结果见图9和10。

图8 氟化钙用量对两种试样镍回收率和品位的影响

Fig. 8 Effects of calcium fluoride dosage on two samples of nickel recovery and grade

图9显示镍元素含量随扫描距离的变化不大,没有出现明显的波动,没有特别富集的地方。镍是亲铁元素,针铁矿会通过吸附作用将氧化镍吸附在针铁矿颗粒上,镍含量的变化与其他元素含量的变化没有明显的相关性。图9分析结果与之相符,说明针铁矿中的镍是以吸附态的氧化镍存在的。

图10显示镍、铁元素含量和镁元素含量随着扫描距离的增加呈现一定的相关性。在0~60 μm的范围内,镍和铁元素的含量较高;超过60 μm后,镍、铁含量下降,镁元素含量上升。镍、铁元素会通过离子交换作用替换掉蛇纹石矿物中的镁元素,从而以类质同像的形式存在于蛇纹石矿物中。图10分析结果与之相符,说明硅酸盐的镍处在蛇纹石矿物的晶格中。

吸附态的氧化镍很容易被还原,而处在硅酸盐矿物晶格中的镍反应活性较低,较难还原。从铁质红土镍矿到镁质红土镍矿,吸附态的氧化镍减少,硅酸镍的含量增多,镍的还原难度增加,这势必会影响镍的回收率。

3.2 直接还原所得金属颗粒大小差异造成的影响

直接还原-磁选工艺的镍铁产品是通过磁选得到的。金属颗粒的大小以及其与脉石矿物的嵌布关系是影响磁选效果的关键。不同种类的红土镍矿直接还原后形成镍铁颗粒的形态和大小会有差异,因此会对后续的磁选过程产生不同的影响。

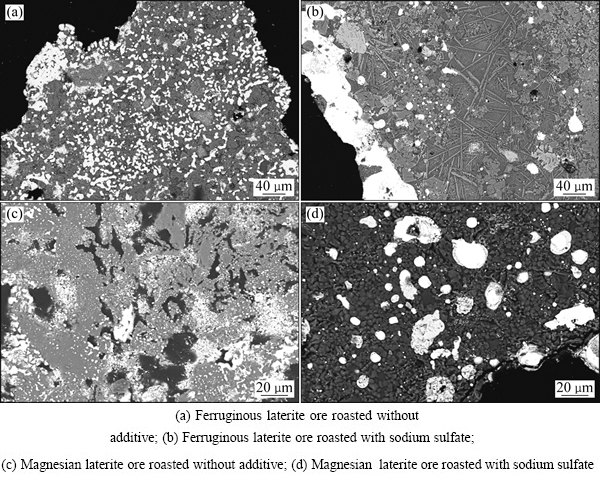

两种试样在只添加还原剂的情况下焙烧50 min,将得到的焙烧产物进行扫描电镜分析,结果见图11。

图9 针铁矿颗粒线扫描分析结果

Fig. 9 Line scan results of goethite particles

图10 蛇纹石颗粒线扫描分析结果

Fig. 10 Line scan results of serpentine particles

图11 两种试样只添加煤焙烧所得产物的SEM像

Fig. 11 SEM images of two roasted samples only with coal added

可知,铁质试样直接还原后得到的焙烧产物出现熔融现象,镍铁颗粒粒度较大。镁质试样的焙烧产物没有出现熔融现象,焙烧产物颗粒还保留着原矿颗粒的形貌,所得的镍铁颗粒粒度很小,多呈星状。对其磁选尾矿进行扫描电镜分析,结果见图12。结果显示如此小的金属颗粒显然不能与脉石矿物充分解离,在磁选过程中进入尾矿,造成镍的回收率偏低。可见,镁质试样直接还原所得的镍铁合金粒度太小是其镍回收率低的重要原因。

煤用量的多少会影响焙烧产物的中金属颗粒的大小,过多的煤用量会使金属颗粒变小,从而降低镍的回收率。这也是图3中显示的随煤用量的增加两种试样的镍回收率降低的原因。由于镁质试样的金属颗粒较小,所以其镍回收率受煤用量的影响更大。

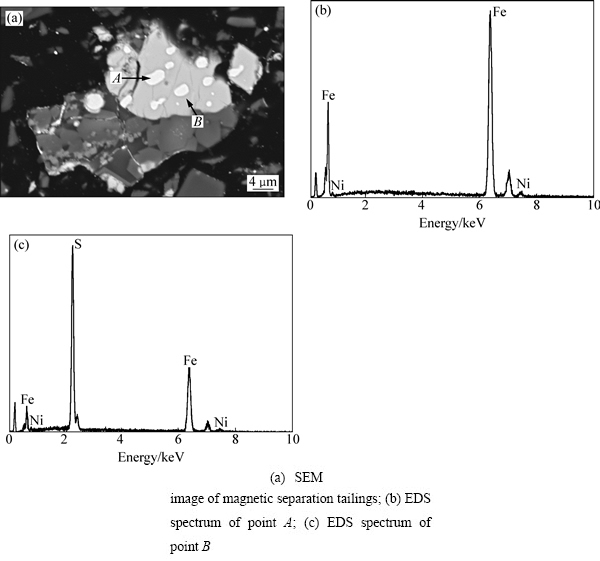

图12 镁质试样磁选尾矿SEM像

Fig. 12 SEM image of magnesia sample magnetic separation tailings

3.3 铁含量不同造成的影响

3.3.1 对硫酸钠作用的影响

众多研究[11, 16-19]发现,在红土镍矿的直接还原过程中添加硫酸钠能够生成FeS从而显著提高镍铁合金中镍的品位,在此方面不再赘述。研究的重点在于添加硫酸钠对提高镁质试样镍回收率效果不佳的原因。对两种试样添加硫酸钠所得的焙烧产物进行扫描电镜分析,结果见图13。可以发现,添加硫酸钠后两种试样的金属颗粒都明显聚集长大。长大的金属颗粒易与脉石矿物解离,而且在磁选过程中受到的磁力作用较强,避免了微小金属颗粒的损失,能够提高镍的回收率。按理,镁质试样的镍回收率应该呈明显上升的趋势,但硫酸钠对镁质试样的作用效果并不理想,镍回收率仅从45%提高到53%,因此还有其他影响因素需要研究。

图13 两种试样添加硫酸钠前后焙烧产物SEM像

Fig. 13 SEM images of two roasted samples before and after adding sodium sulfate

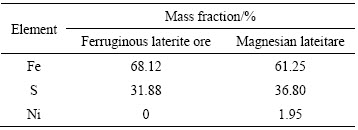

针对前面镍回收率的问题,对镁质试样的尾矿进行扫描电镜分析,结果见图14。可以看出,尾矿中除了部分细小的金属颗粒外,FeS的EDS能谱中也出现了镍的衍射峰。添加硫酸钠后焙烧产物中会形成大量的FeS,而没有磁性的FeS会进入尾矿中。因此,FeS中含有镍,对镍的回收极为不利。对两种试样添加硫酸钠后形成的FeS进行EDS能谱定量分析,结果见表3。表3的结果是对多个FeS颗粒进行分析后取得的平均值。铁质试样中的FeS中没有检测到镍,镁质试样中的FeS中含有1.9%左右的镍,这部分镍会损失在尾矿中造成镍回收率的下降。由反应(Fe+NiS=FeS+Ni)可知,硫更容易和铁结合。当体系中存在大量的Fe时,更容易形成Fe-FeS,所以表3中铁质试样所得FeS的Fe与S的摩尔比大于1:1。而镁质试样还原形成的Fe含量较少,所以才会形成Fe-Ni-S,而且镍含量较高,达到1.9%。

随着硫酸钠用量的增加,铁质试样的镍回收率有略微下降,因此,该试样形成的FeS中也应该含有镍,但由于含量太低,未能够在EDS能谱中显示。对于镁质试样来说,最终的镍回收率变化是由金属颗粒长大提高镍回收率和形成Fe-Ni-S降低镍回收率共同作用的结果。镁质试样原来金属颗粒太小,金属颗粒长大的作用较为明显,所以其镍回收率呈上升趋势。但由于其形成Fe-Ni-S共熔体使得很大一部分镍损失在尾矿中,使得镍的回收率只有53%左右。所以,硫酸钠不是镁质试样理想的添加剂。

3.3.2 对氟化钙作用的影响

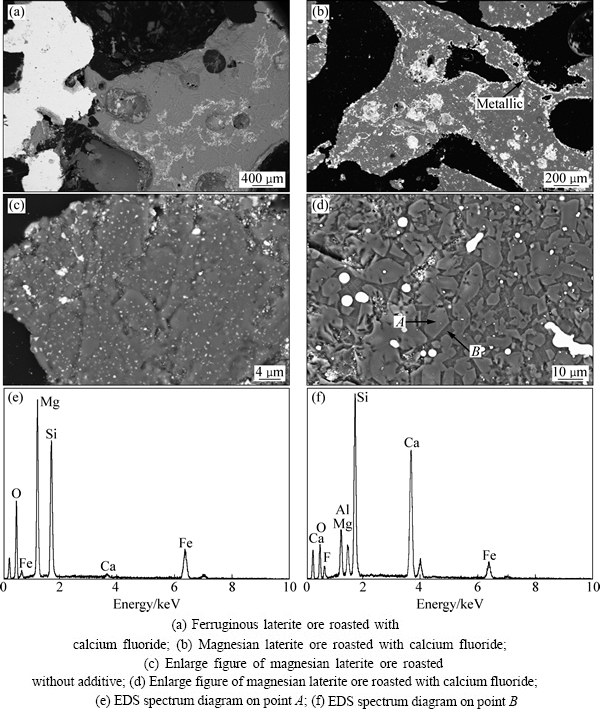

将两种试样添加氟化钙所得的焙烧产物进行扫描电镜分析,结果见图15。由图15(a)和(b)可以看出,添加氟化钙后两种试样的焙烧产物中的金属颗粒聚集长大,并出现了金属壳。图15(c)和(d)对比了镁质试样添加氟化钙前后焙烧产物的变化,发现没有添加氟化钙时原矿中的硅酸盐矿物结构没有被破坏,金属颗粒在硅酸盐中的迁移阻力很大,基本没有聚集长大。当添加氟化钙后,硅酸盐的结构受到破坏,形成了图15(d)中点A所示的熔点较高在冷却过程中结晶较好的橄榄石,和点B所示的熔点较低的钙铝硅酸盐。金属颗粒通过低熔点的钙铝硅酸盐形成的渣相聚集长大。

表3 两种试样添加硫酸钠后所得FeS的元素含量

Table 3 FeS element content of two samples with sodium sulfate

图14 镁质试验添加硫酸钠后磁选尾矿SEM像和EDS谱

Fig. 14 SEM image and EDS spectra of magnetic separation tailings of magnesia laterite ore with sodium sulfate

图15 试样添加氟化钙前后焙烧产物SEM像和EDS谱

Fig. 15 SEM images and EDS spectra of roasted ore without or with calcium fluoride

添加氟化钙后,铁质试样的金属颗粒长大十分明显,所以镍的品位和回收率都有略微提高。但由于铁质试样中的铁含量太高,而氟化钙对铁还原的抑制作用不明显,镍铁产品中含有大量的铁导致镍铁产品中镍的品位不高。处理铁质试样最主要的问题抑制铁的还原以得到高镍品位的镍铁产品,所以,氟化钙不能作为铁质试样理想的添加剂。对于镁质试样而言,添加氟化钙能够明显促进金属颗粒的聚集长大,有利于镍铁合金的磁选回收,使镍的回收率从45%提高到85%左右,大大提高了镍的回收率。同时,镁质试样本身铁含量不高,对镍品位的稀释作用不明显,使得镁质试样能够在获得高镍回收率的情况下保持较高的镍品位,因此,氟化钙是镁质试样理想的添加剂。

4 结论

1) 铁质红土镍矿的主要载镍矿物是针铁矿以及铁氧化物与硅酸盐形成的胶结物,该类型的镍比较容易还原,且容易形成较大的金属颗粒,易于后续的磁选回收;镁质红土镍矿的载镍矿物是蛇纹石和非晶态的硅酸盐,其中的镍较难还原,而且还原所得的金属颗粒很小,不利于后续的磁选回收。

2) 硫酸钠只能作为铁质红土镍矿理想的添加剂,镍的品位能从3%提高到8.5%左右。由于镁质红土镍矿中的铁含量较低,添加硫酸钠会生成含镍约1.9%的Fe-Ni-S使镍损失在磁选尾矿中,不宜作为镁质红土镍矿的添加剂。

3) 氟化钙通过破坏硅酸盐结构,形成低熔点物质,促进金属颗粒聚集长大,对镁质红土镍矿作用效果明显。能够显著提高镁质红土镍矿镍铁产品的镍品位和回收率,镍的品位从3%左右提高到7.5%左右,镍的回收率能从45%左右提高到85%左右。但对铁质红土镍矿作用效果不明显,选别指标没有太大变化。

REFERENCES

[1] BUTT C, CLUZEL D. Nickel laterite ore deposits: weathered serpentinites[J]. Elements, 2013, 9(2): 123-128.

[2] 何 灿, 肖述刚, 谭木昌. 印度尼西亚红土型镍矿[J]. 云南地质, 2008, 27(1): 20-26.

HE Can, XIAO Shu-gang, TAN Mu-chang. The nideposits of laterite type in indonesia[J]. Yun Nan Geology, 2008, 27(1): 20-26.

[3] 蒋 曼. 低镍高铁红土镍矿选择性还原焙烧分离镍铁及机理研究[D]. 北京: 北京科技大学, 2013.

JIANG Man. Mechanism of separating nickel and iron from nickel laterite ore by selective reduction roasting process[D]. Beijing: University of Science & Technology Beijing, 2013.

[4] RAO M, LI G, JIANG T, LUO J, ZHANG Y B, FAN X H. Carbothermic reduction of nickeliferous laterite ores for nickel pig iron production in china: a review[J]. JOM, 2013, 65(11): 1573-1583.

[5] 及亚娜, 孙体昌, 蒋 曼. 红土镍矿提镍工艺进展[J]. 矿产保护与利用, 2011(2): 43-49.

JI Ya-na, SUN Ti-chang, JIANG Man. Advance in extraction of nickel from laterite nickel ore[J]. Conservation and Utilization of Mineral Resources, 2011(2): 43-49.

[6] 李艳军, 于海臣, 王德全, 尹文新, 白元生. 红土镍矿资源现状及加工工艺综述[J]. 金属矿山, 2010(11): 5-9.

LI Yan-jun, YU Han-chen, WANG De-quan, YI Wen-xin, BAI Yuan-sheng. The current status of laterite nickel ore resources and its processing technology[J]. Metals Mine, 2010(11): 5-9.

[7] 梁 威, 王 晖, 符剑刚, 何章兴. 从低品位红土镍矿中高效回收镍铁[J]. 中南大学学报(自然科学版), 2011, 42(8): 2173-2177.

LIANG Wei, WANG Hui, FU Jian-gang, HE Zhang-xing. High recovery of ferro-nickel from low grade nickel laterite ore[J]. Journal of Central South University (Science and Technology), 2011, 42(8): 2173-2177.

[8] 蒋 曼, 孙体昌, 刘志国, 张士元, 刘 娜, 曹允业. 红土镍矿选择性还原焙烧过程中的相变转化[J]. 北京科技大学学报, 2013, 35(1): 27-34.

JIANG Man, SUN Ti-chang, LIU Zhi-guo, ZHANG Shi-yuan, LIU Na, CAO Yun-ye. Phase transformation of nickel laterite ores in the selective reduction roasting process[J]. Journal of University of Science and Technology Beijing, 2013, 35(1): 27-34.

[9] 曹志成, 孙体昌, 杨慧芬, 王静静, 仵晓丹. 红土镍矿直接还原焙烧磁选回收铁镍[J]. 北京科技大学学报, 2010, 32(6): 708-712.

CAO Zhi-cheng, SUN Ti-chang, YANG Hui-fen, WANG Jing-jing, WU Xiao-dan. Recovery of iron and nickel from nickel laterite ore by direct reduction roasting and magnetic separation[J]. Journal of University of Science and Technology Beijing, 2010, 32(6): 708-712.

[10] 孙体昌, 及亚娜, 蒋 曼. 煤种对红土镍矿中镍选择性还原的影响机理[J]. 北京科技大学学报, 2011, 33(10): 1197-1203.

SUN Ti-chang, JI Ya-na, JIANG Man. Influence mechanism of different types of coal on selective nickle reduction in nickel laterite reduction roasting[J]. Journal of University of Science and Technology Beijing, 2011, 33(10): 1197-1203.

[11] 孙体昌, 蒋 曼, 刘志国, 刘 娜, 张士元, 寇 珏, 徐承焱. 添加剂对低镍高铁红土镍矿选择性还原的影响[J]. 中国矿业大学学报, 2013, 42(5): 838-844.

SUN Ti-chang, JIANG Man, LIU Zhi-guo, LIU Na, ZHANG Shi-yuan, KOU Jue, XU Cheng-yan. Research on the effect of additive on selective reduction of the laterite ores with low nickel and high iron content[J]. Journal of China University of Mining & Technology, 2013, 42(5): 838-844.

[12] YOSHINORI S, SHIGEMI N, SETSUO S, IICHI N. Activity measurements in the oxide solid solutions of NiO-MgO and NiO-MgO-SiO2 systems in the temperature range between 1073 and 1273 K[J]. International Journal of Mineral Processing, 1987, 19(s1/4): 237-251.

[13] BUNJAKU A, KEKKONEN M,  K, TASKINEN P. Effect of mineralogy and reducing agent on reduction of saprolitic nickel ores[J]. Mineral Processing and Extractive Metallurgy, 2012, 121(3): 156-165.

K, TASKINEN P. Effect of mineralogy and reducing agent on reduction of saprolitic nickel ores[J]. Mineral Processing and Extractive Metallurgy, 2012, 121(3): 156-165.

[14] BUNJAKU A, KEKKONEN M, TASKINEN P. Effect of mineralogy on reducibility of calcined nickel saprolite ore by hydrogen[J]. Mineral Processing and Extractive Metallurgy, 2012, 121(1): 16-22.

[15] KAWAHARA M, TOGURI J M, BERGMAN R A. Reducibility of laterite ores[J]. Metallurgical Transactions B, 1988, 19(2): 181-186.

[16] LI G, SHI T, RAO M, JIANG T, ZHANG Y B. Beneficiation of nickeliferous laterite by reduction roasting in the presence of sodium sulfate[J]. Minerals Engineering, 2012, 32(3): 19-26.

[17] JIANG M, SUN T, LIU Z, KOU J, LIU N, ZHANG S Y. Mechanism of sodium sulfate in promoting selective reduction of nickel laterite ore during reduction roasting process[J]. International Journal of Mineral Processing, 2013, 123(9): 32-38.

[18] LU J, LIU S, SHANGGUAN J, DU W G, PAN F, YANG S. The effect of sodium sulphate on the hydrogen reduction process of nickel laterite ore[J]. Minerals Engineering, 2013, 49(8): 154-164.

[19] 李光辉, 饶明军, 姜 涛, 史唐明, 黄晴晴. 红土镍矿钠盐还原焙烧-磁选的机理[J]. 中国有色金属学报, 2012, 22(1): 274-280.

LI Guang-hui, RAO Ming-jun, JIANG Tao, SHI Tang-ming, HUANG Qing-qing. Reduction rosting-magnetic separation mechanisms of nickelferous laterite ore in presence of sodium salts[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(1): 274-280.

Comparison of direct reduction-magnetic separation process on ferruginous and magnesian laterite ore

LIU Zhi-guo, SUN Ti-chang, WANG Xiao-ping

(School of Civil and Resource Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: A contrast study was carried out on the direct reduction-magnetic separation process between ferruginous laterite ore and magnesian laterite ore. The result shows that nickel in ferruginous laterite ore is easier to be reduced and recovered without adding additives. The nickel recovery rate can reach 90%, but nickel grade is low. The nickel in magnesian laterite ore is harder to be reduced and recovered without adding additives. Both nickel grade and recovery rate are not ideal. The nickel recovery rate just can reach 45%. Sodium sulfate can be used as an ideal additive for ferruginous laterite ore sample, while which is not suitable for magnesian laterite ore. The effect of calcium fluoride on magnesian laterite ore is remarkable, but it is not obvious for ferruginous laterite ore. It is found that nickel existing state, the iron content as well as the metal particle size obtained by reduction are the main reasons for above differences between the two kinds of ores.

Key words: ferruginous laterite ore; magnesian laterite ore; direct reduction; magnetic separation

Foundation item: Project (20130006110017) supported by Specialized Research Fund for the Doctoral Program of Higher Education, China

Received date: 2016-01-25; Accepted date: 2016-10-24

Corresponding author: SUN Ti-chang; Tel: +86-10-62314078; E-mail: suntc@ces.ustb.edu.cn

(编辑 王 超)

基金项目:高等学校博士学科点专项科研基金(20130006110017)

收稿日期:2016-01-25;修订日期:2016-10-24

通信作者:孙体昌,教授,博士;电话:010-62314078;E-mail:suntc@ces.ustb.edu.cn