DOI: 10.11817/j.issn.1672-7207.2020.02.008

基于高频电磁阀压力控制的列车制动电液系统仿真

李文静1,龚国芳1,刘建2,张亚坤1,杨华勇1

(1. 浙江大学 机械工程学院,浙江 杭州,310027;

2. 名古屋大学 工学研究科,日本 名古屋,4648603)

摘要:针对列车制动系统的安全性及能量转换、储存和再利用特性,提出一种基于高频电磁阀压力控制的列车制动电液系统。该系统可回收部分列车惯性动能,实现列车制动电液系统的自供能,同时可以通过控制高频电磁阀的开闭实现制动液压缸压力的比例控制。基于高频电磁阀压力控制的列车制动电液系统工作原理,建立制动电液系统的数学模型,采用自适应模糊PID控制器调节PWM控制信号占空比,调控高频电磁阀的开关动作,实现制动电液系统压力的比例控制。利用AMESim/Simulink联合仿真平台,搭建HSV(高速开关阀)型高频电磁阀的机械-电子-液压仿真模型及自适应模糊PID控制器,验证制动系统的有效性。研究结果表明:制动液压缸压力在5~10 MPa的阶跃信号跟踪中,上升时间为0.01~0.02 s,且最大超调量均不超过0.66%,制动电液系统的动态品质优良;制动液压缸压力在5~10 MPa的斜坡信号跟踪中,压力跟踪滞后时间均为0.10 s,且误差波动分别在-0.18~0.15 MPa和-0.20~0.25 MPa,压力波动幅度小,压力跟踪滞后较小,控制精度较高,得到了较优的压力控制结果。

关键词:列车制动;高频电磁阀;模糊PID;占空比;压力控制;联合仿真

中图分类号:TH137 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2020)02-0340-09

Simulation of electro-hydraulic system for train brake based on pressure control of high frequency solenoid valve

LI Wenjing1, GONG Guofang1, LIU Jian2, ZHANG Yakun1, YANG Huayong1

(1. School of Mechanical Engineering, Zhejiang University, Hangzhou 310027, China;

2. Graduate School of Engineering, Nagoya University, Nagoya 4648603, Japan)

Abstract: Aiming at the security of train brake system and energy transformation, storage and recycle, a novel electro-hydraulic system for train brake based on pressure control of high frequency solenoid valve was proposed. The system can recycle part of the train inertial kinetic energy to realize the self-supply energy of the train braking electro-hydraulic system, and the proportional control of the brake hydraulic cylinder pressure by controlling the opening and closing of the high-frequency solenoid valve. According to the working principle of train brake electro-hydraulic system based on pressure control of high-frequency solenoid valve, a mathematical model of the brake electro-hydraulic system was established. An adaptive fuzzy PID controller was employed to adjust the duty cycle of PWM control signal and regulate the switching action of the high-frequency solenoid valve, and thereby pressure proportional control of the brake electro-hydraulic system was achieved. Taking advantage of the AMESim/Simulink joint simulation platform, the mechanical-electronic-hydraulic simulation model of HSV(high-speed switching valve) high-frequency solenoid valve and the adaptive fuzzy PID controller of train brake system were established, and the train brake system was verified.The results show that in the step signal tracking of the brake hydraulic cylinder pressure at 5-10 MPa, the raised time is 0.01-0.02 s, and the maximum overshoot is not more than 0.66%, which proves that the dynamic quality of the brake electro-hydraulic system is excellent. In the slope signal tracking of the brake cylinder pressure at 5-10 MPa, the pressure tracking lag time is both 0.1 s, and the error fluctuations are -0.18-0.15 MPa and -0.20-0.25 MPa, respectively. The pressure fluctuation range and the pressure tracking lag are little, which proves the control accuracy is better, and a better pressure control result is obtained.

Key words: train brake; high frequency solenoid valve; fuzzy PID; duty ratio; pressure control; co-simulation

制动系统对列车的运行安全具有至关重要的作用。制动方式主要包括空气制动、电空制动、再生/电阻制动、磁轨涡流制动、风阻制动和液压制动等[1-2]。空气制动采用空气分配阀、踏面制动器/闸瓦模式或制动缸、轮盘/轴盘的盘形制动与闸片模式,牵引机车与车辆之间存在制动延时[3]等问题。朱长松[4]改造编组列车双管供风,解决列车后连车辆制动延时问题。但在制动过程中,列车的动能通过制动器/制动缸与闸瓦/闸片摩擦全部转换成热量消耗,难以回收能量。再生/电阻制动的电制动模式采用电阻、电容等电器元件,制动时产生电能,反馈至电网[5]。电制动系统虽有优点,但电器元件在大电流异常工况下容易烧毁以致失效[6]。近年来,国内外学者开发了具有能量回收功能的液压制动系统,可有效地将列车部分惯性动能转化为液压能,储存到蓄能器中,如宫崎聪夫等[7]介绍了日本Linimo磁悬浮列车用液压制动器;曹国利等[8]提出了利用比例压力控制阀的低地板轻轨车辆制动液压系统;武氏怀秋等[9]设计了列车液压制动试验台,并利用Simulink分析试验台制动过程;蒋廉华等[10]提出了电液混合制动系统以提高制动的平稳性;张刘杨等[11]提出了用于城市轨道交通的液压混合驱动系统,采用泵/马达作为驱动元件,液压蓄能器存储回收的再生制动能量。但液压制动系统常使用宽频带比例阀控制输出制动力,高频电磁阀同比例阀相比具有价格适中、工作可靠、抗污染能力强、泄漏量少、电控系统简单和易实现与计算机数字系统结合[12-13]的特点。将高频电磁阀作为液压制动系统的压力控制阀,通过控制其高速通断动作实现压力的比例控制,进而代替比例阀;亦可通过多个阀的组合实现制动系统的双向制动功能,提高灵活性。本文针对列车制动中的安全性及能量转换、储存和再利用特性,提出基于高频电磁阀压力控制的列车制动电液系统。可回收列车制动过程中的部分惯性动能。通过控制高频电磁阀的开闭,实现制动液压缸压力的比例控制。大多数的高频电磁阀通常在小流量工况中使用,或作为先导阀使用[14-15]。目前,国内对高频电磁阀的研究主要集中在阀的电磁系统及液压特性上,苏明等[16]在AMESim仿真平台中搭建了HSV型高频电磁阀模型,并对动态和静态特性进行了仿真研究;孟爱红等[17]通过仿真得出拓宽占空比有效工作范围的阀体结构关键参数;高钦和等[18]研究了高频电磁阀控制下的液压缸在起动与到位过程中的速度控制。人们对高频电磁阀的输出压力控制研究大部分针对高频调制,如脉宽调制(pulse width modulation, PWM)[19],通过调节占空比改变阀的平均流量,且频率越高,控制性能越好[20]。王冬良等[21]通过调节PWM电压信号的占空比,实现ESP型高频电磁阀压力精确控制;王伟玮等[22]通过改变PWM电压信号的占空比,实现了高频电磁阀的比例开关功能;高钦和等[23]利用节点容腔法对高频电磁阀控液压缸位置进行建模仿真。高频电磁阀可通过控制PWM电压信号,实现输出压力的精准比例控制。本文聚焦制动电液系统的输出压力控制,建立系统的数学模型,采用自适应模糊PID控制器调节PWM电压信号占空比的控制策略,调控高频电磁阀的开关动作,进而控制制动液压缸输出所需制动压力,采用AMESim/Simulink联合仿真平台,搭建HSV型高频电磁阀的机械-电子-液压仿真模型及自适应模糊PID控制器,验证制动系统的有效性。

1 高频电磁阀及列车制动电液系统原理

1.1 高频电磁阀结构

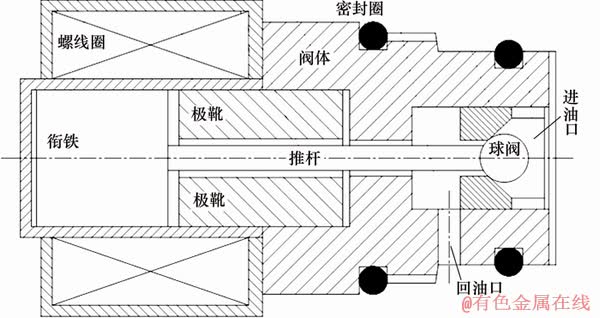

HSV系列开关式高频电磁阀有两通常开、两通常闭、三通常开和三通常闭共4种类型,其中,二通常闭型的结构如图1所示。螺旋线圈得电时,衔铁在电磁力的作用下向右运动,带动推杆推动球阀打开,接通进油口与回油口;当螺旋线圈失电时,衔铁失去电磁力,球阀在油液压差的作用下复位[24]。当施加一定频率及占空比的PWM电压信号时,高频电磁阀以30~50 Hz的开闭频率实现进油-回油路的高速通断。

图1 HSV型高频电磁阀结构图

Fig. 1 Construction of HSV high frequency solenoid valve

1.2 基于高频电磁阀压力控制的列车制动电液系统

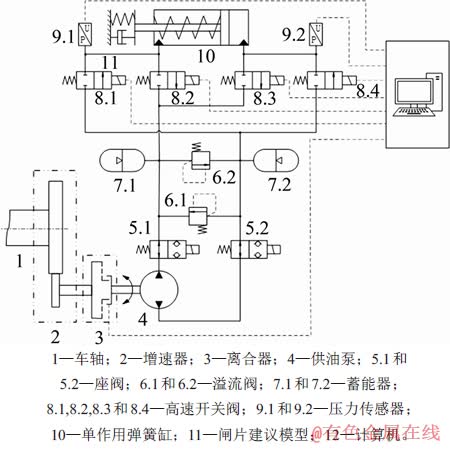

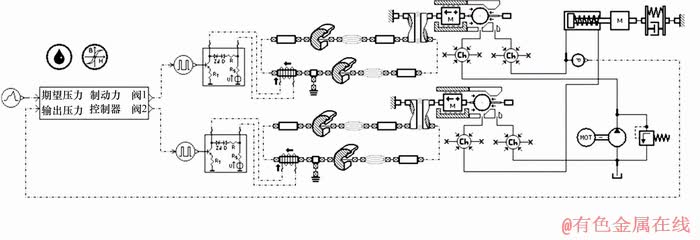

基于高频电磁阀压力控制的列车制动电液系统,采用4个二位二通常闭式HSV电磁阀,分别并联在制动液压缸两油路端,构成进出口独立调节的液压系统,图2所示为列车制动电液系统原理图。

图2 列车制动电液系统原理图

Fig. 2 Electro-hydraulic system for train brake

列车进行制动时,离合器接合,车轴通过增速器和离合器带动供油泵旋转。电控系统采用计算机控制数字指令传输模式,对压力传感器反馈的制动液压缸有杆腔和无杆腔的压力进行闭环处理控制,产生一定占空比的PWM电压信号控制电磁阀的开关动作。若控制高速开关8.3与高速开关8.1打开,则制动液压缸无杆腔与供油泵的输出油路不断通断,同时有杆腔与油箱不断通断,则活塞杆在油压差作用下,克服弹簧力向左行进,闸片夹紧制动盘产生制动力,达到给定制动力后,高速开关8.3关闭,将制动液压缸无杆腔封锁保压,实现列车制动。因此,此系统可回收部分列车惯性动能。

在制动过程中,由于惯性,列车在制动力的作用下继续减速运行,供油泵依旧工作,将油液充入蓄能器7.1作为下次制动或列车启动时的液压能使用。蓄能器充满油液后,离合器分离。

高速开关8.4和8.2、蓄能器7.2、制动液压缸与供油泵构成与上述相同的进出口独立调节液压系统,可在列车反向运行时利用列车惯性制动并回收能量。

2 系统数学模型

根据HSV阀的机械结构及电磁系统,建立高频电磁阀制动系统的动态模型。当螺旋线圈通电时,电压方程为

(1)

(1)

式中: 为螺旋线圈所加电压;

为螺旋线圈所加电压; 为电源内阻;

为电源内阻; 为线圈电阻;

为线圈电阻; 为线圈匝数;

为线圈匝数; 为磁通量;

为磁通量; 为时间;

为时间; 为螺旋线圈产生的电流。

为螺旋线圈产生的电流。

高频电磁阀电磁磁路方程为

(2)

(2)

式中: 为各磁轭长度;

为各磁轭长度; 为磁场强度;

为磁场强度; 为总磁阻;

为总磁阻; 为工作气隙的磁场强度;

为工作气隙的磁场强度; 为初始工作气隙长度;

为初始工作气隙长度; 为阀的开口度。

为阀的开口度。

螺旋线圈电磁铁工作时的电磁铁吸力 为

为

(3)

(3)

式中: 为磁感应强度;

为磁感应强度; 为磁路截面积;

为磁路截面积; 为真空磁导率。

为真空磁导率。

不考虑磁漏及连接部位的气隙影响,以阀芯位移所带来的衔铁行程及衔铁气隙为主气隙,此时,磁感应强度 为

为

(4)

(4)

阀芯的动力学方程为

(5)

(5)

式中: 为阀芯及衔铁顶杆等总质量;

为阀芯及衔铁顶杆等总质量; 为阀芯运动黏性阻尼系数;

为阀芯运动黏性阻尼系数; 为稳态液动力;

为稳态液动力; 为瞬态液动力;

为瞬态液动力; 为液压力。

为液压力。

高频电磁阀在高频的PWM电压信号控制下开关,其阀芯从全闭到全开以及全开到全闭的时间与信号周期比极小,可认为阀只有全开和全闭2种动作状态,近似认为阀的流量与占空比呈线性关系[22-23],在占空比为 ,阀的平均流量

,阀的平均流量 为

为

(6)

(6)

式中: 为阀最大流量,即占空比为1时的流量;其计算公式为

为阀最大流量,即占空比为1时的流量;其计算公式为

(7)

(7)

式中: 为流量系数;

为流量系数; 为球阀开口面积;

为球阀开口面积; 为油液密度。

为油液密度。

制动液压缸的动力学方程为

(8)

(8)

式中: 和

和 分别为制动液压缸无杆腔和有杆腔的压力;

分别为制动液压缸无杆腔和有杆腔的压力; 和

和 分别为制动液压缸无杆腔和有杆腔的面积;

分别为制动液压缸无杆腔和有杆腔的面积; 为运动组件质量;

为运动组件质量; 为活塞杆位移;

为活塞杆位移; 为总黏性系数;

为总黏性系数; 为弹性系数。

为弹性系数。

3 制动压力的自适应模糊PID控制策略

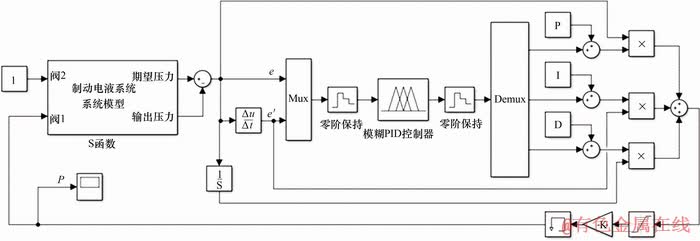

列车在制动过程中,制动压力与制动初速度和线路条件相关。由式(6)~(8)可知:不同制动压力需要对高频电磁阀施加不同占空比的PWM电压信号。普通的PID控制器难以满足列车制动过程中制动压力的大范围、高精度控制特性,图2中计算机控制的电控系统,采用自适应模糊PID控制器调节PWM控制电压信号占空比,可获得列车制动电液系统更好的鲁棒性,且更能有效地抑制超调,减小控制误差。因此,自适应模糊PID控制策略适于本文提出的制动电液系统。

自适应模糊PID控制策略如图3所示,以期望输出压力和实际输出压力的误差及误差变化率为输入,利用模糊规则进行模糊推理,查询模糊矩阵,调整PID的3个参数[25]。与传统PID控制器相比,可以实现在不同的误差和误差变化率下PID控制器参数的自适应矫正[26]。

图3 自适应模糊PID控制策略

Fig. 3 Adaptive fuzzy PID control strategy

4 仿真结果

由于列车正反向运行时,制动电液系统制动机理相同,现取列车单向运行时制动电液系统的关键工作元器件进行仿真。选取额定压力为20 MPa、额定流量为9 L/min、频率为50 Hz的HSV型高频电磁阀及100/70缸径的单作用弹簧缸,以AMESim仿真平台搭建阀的电磁、机械、液压模型及制动电液系统模型,仿真模型如图4所示。由图4可见:供油泵的动力输入拟采用电机元件,制动液压缸进出口各连接1个高频电磁阀模型进行制动过程仿真,闸片使用弹簧阻尼元件进行模拟。左侧的接口模块将期望压力信号及实际输出压力信号传输至Simulink的S-Function模块。

图4 列车制动电液系统仿真模型

Fig. 4 Simulation model of train brake system

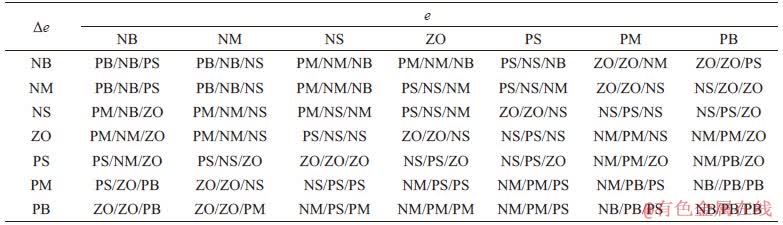

同时,在Simulink中搭建自适应模糊PID控制器,如图5所示。采用Z-N法整定PID控制器的比例系数kp,体分系数ki和微分系数kd分别为8,0.8和0.001。通过MATLAB的脚本文件编写模糊规则并加载到模糊逻辑模块,将压力误差及压力误差变化率输入至模糊逻辑模块,通过模糊规则得到适当的PID矫正参数。压力误差e、压力误差变化率△e、比例系数矫正量△Kp、积分系数矫正量△Ki和微分系数矫正量△Kd的模糊子集均定义为{NB, NM, NS, ZO, PS, PM, PB},其所对应的论域分别设计为{-3, -2, -1, 0, 1, 2, 3},{-30, -20, -10, 0, 10, 20, 30},{-1.2, -0.8, -0.4, 0, 0.4, 0.8, 1.2},{-0.3, -0.2, -0.1, 0, 0.1, 0.2, 0.3}和{-0.003, -0.002,-0.001, 0, 0.001, 0.002, 0.003},采用三角形隶属度函数模糊化处理各变量,模糊规则设计如表1所示,并采用最大隶属度平均法解模糊。产生的占空比控制信号由S-Function传输至AMESim的PWM元件,控制HSV阀的开关,实现图3所示控制策略。

图5 自适应模糊PID控制器仿真模型

Fig. 5 Simulation model of adaptive fuzzy PID controller

表1 △Kp/△Ki和△Kd的模糊控制规则表

Table 1 Table of fuzzy control rules of △Kp, △Ki and △Kd

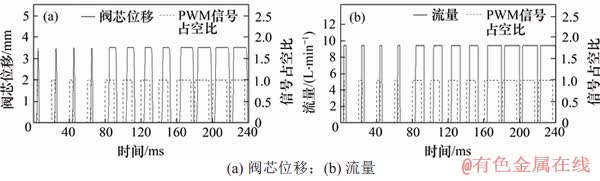

在空载工况下,选取占空比分别为0.2,0.5和0.8,频率为50 Hz的PWM电压信号各4个周期进行仿真,高频电磁阀的阀口开度与流量曲线如图6所示。由图6可见:阀口开始开启的时间与PWM电压信号相比,出现3 ms左右的延迟,此为阀滞后时间特性所致。通过高频电磁阀的流量与阀口开度相对应,基本呈方形波,在1个周期内的平均流量与式(6)描述的相符。

图6 不同占空比PWM信号下阀口开度与流量曲线

Fig. 6 Curves of valve opening and flow versus PWM signal with different duty cycles

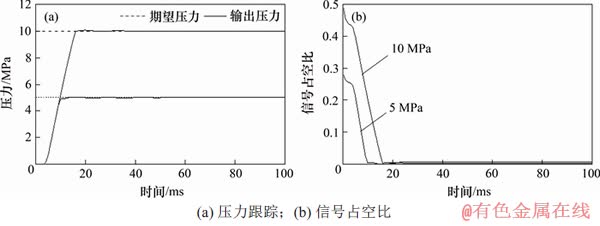

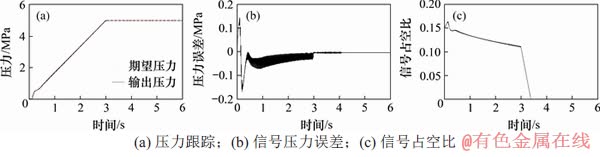

以期望压力分别是阶跃信号和斜坡信号为控制目标,对压力跟踪进行联合仿真,结果如图7~9所示。

由图7可见:5和10 MPa的制动液压缸压力开始提升时间均为3~4 ms,此为HSV阀的开启过程中的滞后时间特性所致。压力开始跟踪时,占空比最大;在压力达到期望压力时,占空比下降至0,导致PWM电压信号为0,阀口呈关闭状态,保持制动液压缸压力。在整个过程中,压力的上升时间分别为0.01和0.02 s,最大超调量均在0.66%以下。结果表明制动电液系统的动态品质优良,在自适应模糊PID控制策略下,制动压力满足列车制动过程中的快速响应要求。

图7 阶跃信号的压力跟踪和占空比曲线

Fig. 7 Tracking trajectory of step input signal of output and duty cycle

由图8(a)可见:期望压力在3 s内从0 MPa升至5 MPa后保持在5 MPa,在压力跟踪曲线中,开始的0.1 s内制动液压缸压力未提升,之后迅速提升超过期望压力,在0.4 s时与期望压力基本贴合。由图8(b)可见:此间段内误差波动为-0.18~ 0.15 MPa。制动液压缸压力在到达3 s时基本接近5 MPa,此时占空比急速下降至0,阀口呈关闭状态。

图8 5 MPa斜坡信号的压力跟踪、误差和占空比曲线

Fig. 8 Tracking trajectory of 5 MPa ramp input signal: output, error, and duty cycle

图9 10 MPa斜坡信号的压力跟踪、误差和占空比曲线

Fig. 9 Tracking trajectory of 10 MPa ramp input signal: output, error and duty cycle

由图9可见:期望误差在3 s内从0 MPa升至10 MPa后保持在10 MPa,压力跟踪曲线与图8所示曲线变化趋势相同,在开始的0.1 s内制动压力未提升,之后迅速提升且在0.5 s时与期望压力基本吻合,在此阶段,跟踪误差在-0.20~0.25 MPa。结果表明制动压力跟踪滞后较小、控制精度较高,满足列车制动过程中的制动压力大范围要求。

5 结论

1) 提出的新型列车制动电液系统对于列车制动是有效的,且采用自适应模糊PID控制器调节PWM电压信号占空比的控制策略,可满足列车制动压力范围大、控制精度高的技术要求。

2) 制动液压缸压力在5~10 MPa的阶跃信号跟踪中,上升时间分别为0.01 s和0.02 s,且最大超调量均不超过0.66%,制动电液系统的动态品质优良。

3) 制动液压缸压力在5~10 MPa的斜坡信号跟踪中,压力跟踪滞后时间均为0.1 s,且误差波动分别-0.18~0.15 MPa和-0.2~0.25 MPa,压力波动幅度小,压力跟踪滞后较小、控制精度较高,得到了较优的压力控制结果。

4) 后续的工作将深入研究所提出的电液制动系统的能量回收特性及在整车中的应用效果。

参考文献:

[1] 张建柏, 彭辉水, 倪大成, 等. 高速列车制动技术综述[J]. 机车电传动, 2011(4): 1-4.

ZHANG Jianbai, PENG Huishui, NI Dacheng, et al. Overviewing braking technology of the high-speed trains[J]. Electric Drive for Locomotives, 2011(4): 1-4.

[2] 刘豫湘, 方长征, 万建兵. 列车制动系统技术现状及发展趋势[J]. 电力机车与城轨车辆, 2014, 37(5): 1-4.

LIU Yuxiang, FANG Changzheng, WAN Jianbing. Technology status and development trend of train braking system[J]. Electric Locomotives & Mass Transit Vehicles, 2014, 37(5): 1-4.

[3] 宋瑞刚, 杨俭, 方宇. 城市轨道车辆牵引动态特性建模与实验系统研究[J]. 铁道学报, 2012, 34(7): 36-42.

SONG Ruigang, YANG Jian, FANG Yu. Research on modeling of dynamic traction characteristics and test system of urban rail vehicles[J]. Journal of the China Railway Society, 2012, 34(7): 36-42.

[4] 朱长松. 工矿编组列车制动气路改造及分析[J]. 隧道建设, 2014, 34(S1): 307-310.

ZHU Changsong. Rehabilitation of and analysis on pneumatic braking of mining marshaling train [J]. Tunnel Construction, 2014, 34(S1): 307-310.

[5] 孙晓霞, 王义春, 邵春鸣, 等. 混合动力车用制动电阻散热性能试验研究[J]. 车辆与动力技术, 2015(3): 25-29.

SUN Xiaoxia, WANG Yichun, SHAO Chunming, et al. Experimental research on braking resistor heat dissipation performance of hybrid electric vehicle[J]. Vehicle & Power Technology, 2015(3): 25-29.

[6] 杨俭, 李发扬, 宋瑞刚, 等. 城市轨道交通车辆制动能量回收技术现状及研究进展[J]. 铁道学报, 2011, 33(2): 26-33.

YANG Jian, LI Fayang, SONG Ruigang, et al. Review of the utilization of vehicular braking energy in urban railway transportation[J]. Journal of the China Railway Society, 2011, 33(2): 26-33.

[7] 宫崎聪夫, 蔡千华. 磁悬浮列车用液压制动器[J]. 国外铁道机车与动车, 2017(3): 34-37.

AOUI Tokio , CAI Qianhua. Hydraulic brake for maglev train [J]. Foreign Railway Locomotive and Motor Car, 2017(3): 34-37.

[8] 曹国利, 曾宪华, 刘睿. 国产低地板轻轨车辆制动系统方案[J]. 城市轨道交通研究, 2012, 15(2): 111-114.

CAO Guoli, ZENG Xianhua, LIU Rui. Braking system for domestic low-floor light rail transit vehicles [J]. Urban Mass Transit, 2012, 15(2): 111-114.

[9] 武氏怀秋, 宋锦春, 范文明. 列车液压制动试验台的设计与研究[J]. 机床与液压, 2016, 44(11): 132-134.

WU Thihoaithu, SONG Jinchun, FAN Wenming. Design and research of train hydraulic brake tester[J]. Machine Tool & Hydraulics, 2016, 44(11): 132-134.

[10] 蒋廉华, 唐亮, 曾春军,等. 中低速磁浮列车制动系统设计与研究[J]. 电力机车与城轨车辆, 2017(3): 18-22.

JIANG Lianhua, TANG Liang, ZENG Chunjun, et al. Design and research on braking system of mid-low speed maglev train [J]. Electric Locomotives & Mass Transit Vehicles, 2017(3): 18-22.

[11] 张刘杨, 吴维. 液压混合驱动在城市轨道交通中的应用研究[C]//第九届全国流体传动与控制学术会议(9th FPTC-2016)论文集. 杭州, 2016: 270-274.

ZHANG Liuyang, WU Wei. An application of hydraulic hybrid system for urban rail transit [C] // 9th FPTC-2016. Hangzhou: 2016: 270-274.

[12] OUYANG Xiaoping, YANG Huayong, JIANG Haoyi, et al. Simulation of the piezoelectric high-speed on/off valve[J]. Science Bulletin, 2008, 53(17): 2706-2711.

[13] LINJAMA M, LAAMANEN A, VILENIUS M. Is it time for digital hydraulics? [C] // The Eighth Scandinavian International Conference on Fluid Power. Tampere: [s. n.], 2003.

[14] 贾文昂, 阮健, 李胜. 2D高速开关阀结构参数优化设计与实验[J]. 农业机械学报, 2016, 47(11): 391-398.

JIA Wenang, RUAN Jian, LI Sheng. Structure parameters optimization and experiments on 2D high-speed on-off valve [J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(11): 391-398.

[15] WANG Feng, GU Linyi, CHEN Ying. A continuously variable hydraulic pressure converter based on high-speed on-off valves[J]. Mechatronics, 2011, 21(8): 1298-1308.

[16] 苏明, 陈伦军. 基于AMESim的电磁高速开关阀动静态特性研究[J]. 液压与气动, 2010(2): 68-72.

SU Ming, CHEN Lunjun. Dynamic characteristic research of high speed on-off solenoid valve based on AMESim[J]. Chinese Hydraulics & Pneumatics, 2010(2): 68-72.

[17] 孟爱红, 王伟玮, 宋健, 等. 高速开关阀高频脉宽调制控制有效占空比工作范围的拓宽[J]. 机械工程学报, 2012, 48(10): 167-172.

MENG Aihong, WANG Weiwei, SONG Jian, et al. Extending of the duty ratio range of pulse width modulation control on high speed on-off valve[J]. Journal of Mechanical Engineering, 2012, 48(10): 167-172.

[18] 高钦和, 宋海洲, 刘志浩, 等. 高速开关阀在液压缸起动与到位过程中的速度控制研究[J]. 中国机械工程, 2013, 24(1): 47-51.

GAO Qinhe, SONG Haizhou, LIU Zhihao, et al. Research on speed control in starting and stopping processes of hydraulic cylinder with HSV[J]. China Mechanical Engineering, 2013, 24(1): 47-51.

[19] 王琼, 吴惠, 夏光, 等. 基于PWM控制模式的高速开关阀开关特性分析及优化[J]. 合肥工业大学学报(自然科学版), 2016, 39(9): 1199-1204.

WANG Qiong, WU Hui, XIA Guang, et al. Analysis and optimization of switching characteristics of high speed on-off solenoid valve based on PWM control mode[J]. Journal of Hefei University of Technology(Natural Science), 2016, 39(9): 1199-1204.

[20] ZHU Kangwu, GU Linyi, CHEN Yuanjie, et al. High speed on/off valve control hydraulic propeller[J]. Chinese Journal of Mechanical Engineering, 2012, 25(3): 463-473.

[21] 王冬良, 陈南, 刘远伟. 基于PWM控制的ESP高速开关阀动力学特性研究与仿真[J]. 机械设计与制造, 2015(12): 87-90.

WANG Dongliang, CHEN Nan, LIU Yuanwei. Dynamics research and simulation of high-speed on-off solenoid value of automotive electronic stability program based on PWM control[J]. Machinery Design & Manufacture, 2015(12): 87-90.

[22] 王伟玮, 宋健, 李亮, 等. 高速开关阀在高频PWM控制下的比例功能[J]. 清华大学学报(自然科学版), 2011, 51(5): 715-719.

WANG Weiwei, SONG Jian, LI Liang, et al. High speed on-off solenoid valve with proportional control based on high frequency PWM control[J]. Journal of Tsinghua University(Science and Technology), 2011, 51(5): 715-719.

[23] 高钦和, 刘志浩, 牛海龙. 参数优化的高速开关阀控液压缸位置控制研究[J]. 机械科学与技术, 2015, 34(6): 903-909.

GAO Qinhe, LIU Zhihao, NIU Hailong. Controlling position of hydraulic cylinder with high-speed on-off valve parameters optimized[J]. Mechanical Science and Technology for Aerospace Engineering, 2015, 34(6): 903-909.

[24] 丁凡, 姚健娣, 笪靖, 等. 高速开关阀的研究现状[J]. 中国工程机械学报, 2011, 9(3): 351-358.

DING Fan, YAO Jiandi, DA Jing, et al. Advances on high-speed on-off valves[J]. Chinese Journal of Construction Machinery, 2011, 9(3): 351-358.

[25] 林小连, 段锁林, 毕友明. 无阀电液位置伺服系统的自适应模糊PID控制器设计[J]. 太原科技大学学报, 2007, 28(6): 457-460.

LIN Xiaolian, DUAN Suolin, BI Youming. Design of a self-adaptive fuzzy PID controller for valveless electro-hydraulic position servo system[J]. Journal of Taiyuan University of Science and Technology, 2007, 28(6): 457-460.

[26] CHEN Jian, SHU Jianping, LI Mian, et al. Research on novel self-spinning high speed on/off valve based on fuzzy-logic parameter self-tuning PID controller[J]. Advanced Materials Research, 2012, 468/469/470/471: 1448-1452.

(编辑 秦明阳)

收稿日期: 2019 -05 -17; 修回日期: 2019 -08 -10

基金项目(Foundation item):国家自然科学基金资助项目(51675472);国家重点基础研究发展计划(973计划)项目(2015CB058100,2015CB058103);国家重点研发计划项目(2017YFB1302600,2017YFB1302602,2017YFB1302604);河南省重大科技专项(161100211100) (Project(51675472) supported by the National Natural Science Foundation of China; Projects(2015CB058100, 2015CB058103) supported by the National Basic Research Development Program (973 Program) of China; Projects(2017YFB1302600, 2017YFB1302602, 2017YFB1302604) supported by the National Key Research and Development Program of China; Project(161100211100) supported by Major Science and Technology Program of Henan Province)

通信作者:龚国芳,博士,教授,从事电液控制系统研究;E-mail:gfgong@zju.edu.cn