Trans. Nonferrous Met. Soc. China 23(2013) 2141-2146

Fracture mechanism of 2D-C/C composites with pure smooth laminar pyrocarbon matrix under flexural loading

Wei-feng CAO, He-jun LI, Ling-jun GUO, Shou-yang ZHANG, Ke-zhi LI, Hai-liang DENG

State Key Laboratory of Solidification Processing, Northwestern Polytechnical University, Xi’an 710072, China

Received 30 January 2013; accepted 6 May 2013

Abstract: Using natural gas as carbon source, 2D needle felt as preform, 2D-C/C composites were prepared by thermal gradient chemical vapor infiltration. Their microstructures were observed under polarized light microscope (PLM) and scanning electron microscope (SEM), and the flexural behaviors before and after heat-treatment were studied with a universal mechanical testing machine. The fracture mechanism of the composites was discussed in detail. The results show that, carbon matrix exhibits pure smooth laminar (SL) characteristic including numerous wrinkled layered structures and some inter-laminar micro-cracks. With the decreasing density, the strength of the composites decreases and the toughness increases slightly; after 2500 °C heat-treatment, the inter-laminar micro-cracks in matrix increase, the strength decreases, and the toughness obviously increases. The fracture mode of the composites changes from brittle to pseudo-plastic characteristic due to more crack deflections in SL matrix.

Key words: C/C composites; pyrocarbon; fracture; flexural behavior

1 Introduction

Carbon/carbon (C/C) composites are widely used as high temperature structural materials in aeronautics and astronautics due to their excellent properties including low density, high specific strength and modulus, and good strength retention ratio at high temperature [1-3].

As the dominate element, the microstructure of pyrocarbon matrix has great influence on the mechanical behavior of C/C composites and some works on it have been done. GUELLALI et al [4] and LI et al [5] studied the composites with rough laminar (RL) and RL+ smooth laminar (SL) mixed pyrocarbon matrix. The results showed that the composites with RL+SL mixed matrix had higher strength and displayed preferable fracture toughness, which resulted from the crack deflection at the positions of inter-laminar micro-cracks of RL pyrocarbon and the sliding between different pyrocarbon matrixes. ZHANG et al [6] and XIONG et al [7] studied the mechanical property of the isotropic pyrocarbon material and found that the weak interface bonding between the fibers and the matrix resulted in the low mechanical properties. For the composites with SL pyrocarbon matrix, there have been many reports on their mechanical behavior [8-12], and some similar results have been obtained. For example, the strength of the heat-treated sample decreases and the fracture toughness increases compared to the deposited sample. Their emphases mainly lay on explaining the change of the mechanical behavior and the interlayer spacing d002 value of pyrocarbon after heat-treatment at different temperatures, but rarely referred to the influence of the change of SL pyrocarbon microstructure on the mechanical behavior of the composites. Besides, some research also mainly focused on the toughness improvement of the composite by adding nanofibers or other elements [13-15]. The specialized research on the mechanical behavior of the composites with SL pyrocarbon matrix has not been reported. In this work, the flexural behavior of the composite with pure SL pyrocarbon matrix is studied with various densities and pyrocarbon microstructure before and after heat-treatment, and the crack deflection mechanism under flexural loading is discussed in detail.

2 Experimental

2.1 Material preparation

Industrial natural gas (CH4, purity 96%) was used as carbon source. 2D needle porous carbon fiber felts (~0.43 g/cm3), made of long carbon fiber layers and randomly oriented short carbon fiber mats after needle- punching step by step, and the adjacent long fiber layer showing 0°/90°/0°/90° architecture, were used as preforms and then were infiltrated by thermal gradient chemical vapor infiltration to prepare 2D-C/C composites. Some composites were heat-treated at 2500 °C for 2 h in argon atmosphere.

2.2 Test methods

The three-point bending test was carried out using an electronic universal mechanical testing machine (SANS, CMT-5304, Shenzhen, China). The dimensions of the samples were 55 mm×10 mm×4 mm, the span was 40 mm and the loading speed was 0.5 mm/min. The flexural stress was calculated by the following equation:

(1)

(1)

where P is the maximum failure load (N); L is the span (mm); b is the sample width (mm); d is the sample thickness (mm).

The microstructure of the composites was observed using a polarized light microscope (PLM, DMLP, Leica, Germany). The fracture surface morphology of the composite was observed using a scanning electron microscope (SEM, Supra-55, Zeiss, Germany).

The crystal parameters of pyrocarbon were determined using X-ray diffractometer (XRD, PANalytical, Almelo, the Netherlands). The interlayer space d002 and the apparent layer stack height Lc were calculated, respectively, by the following equations [16]:

(2)

(2)

(3)

(3)

The wavelength λ of the used Cu Kα1 ray is 0.154 nm, θ is the Bragg’s diffraction angle (°), B is the full width at half maximum intensity of (002) peak and K is the Scherrer constant (K=0.9).

3 Results and discussion

3.1 Microstructure

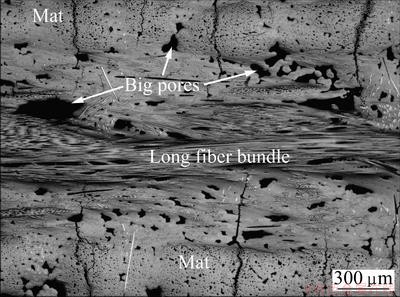

Figure 1 shows the optical image of the composite. It can be found that there are numerous residual pores in mat and some prolate pores in long fiber bundles. At the interface between the long fiber layer and short fiber mat the size of some residual pores can reach several hundreds of microns (big pores in Fig. 1). Generally speaking, pyrocarbon firstly deposits on the fiber surface and grows up gradually surrounding carbon fiber, and the pore filling depends on the gas infiltrating into the deposition zone in the process of chemical vapor infiltration. When a certain zone is filled completely with pyrocarbon, the gas will be very difficult to go on diffusing through it, which results in the formation of the residual pore in the composites. With the progressive densification, the difficulty of the pore filling is increasing. It can be concluded from the filling and distribution of the residual pore that, the pyrocarbon firstly deposits on the fiber surface and grows up gradually, and surrounds the fiber as the micro deposition space decreases. Moreover, compared to the other positions, the gas infiltration at the interface between long fiber bundle and mat is more difficult, so that the big residual pore is easily to be formed at these positions.

Fig. 1 Optical image of 2D-C/C composite

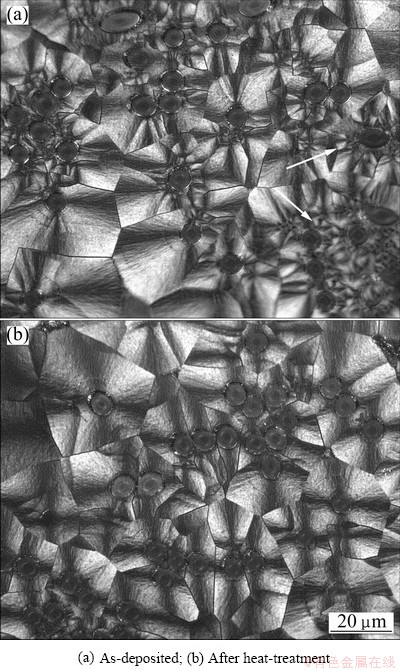

Figure 2 shows the PLM microstructures of the composite. The carbon fiber is surrounded by pyrocarbon matrix, and the matrix exhibits numerous irregular pyrocarbon growth-cones (white arrows) and clear extinction crosses, indicating that it is typical SL texture [17]. After heat-treatment, the optical activity of pyrocarbon slightly increases, and some tiny growth- cones in the deposited sample have not been found in the heat-treated sample (Fig. 2(b)).

3.2 Effect of density on flexural behavior of C/C composites

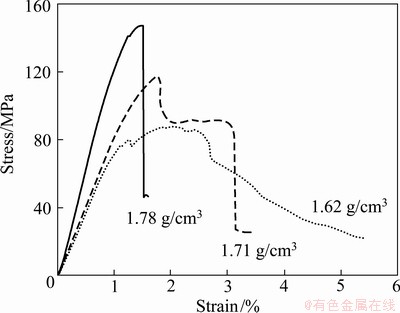

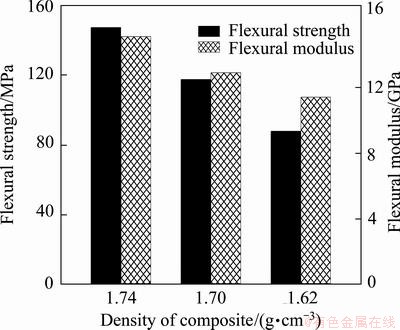

Figure 3 demonstrates the stress—strain curves of the samples with different density at the deposited state. It can be found that, the samples with the density of 1.78 g/cm3 display the typical brittle fracture mode, the samples with a density of 1.71 g/cm3 exhibit a “ladder” type fracture, and the samples with low density of 1.62 g/cm3 present pesudo-plastic fracture characteristic. It is obvious that the toughness of the sample becomes better with the decrease of density, while the flexural strength decreases together with the modulus (Fig. 4).

Fig. 2 PLM microstructures of C/C composite

Fig. 3 Stress—strain curves of 2D-C/C composites with SL pyrocarbon matrix at deposited state

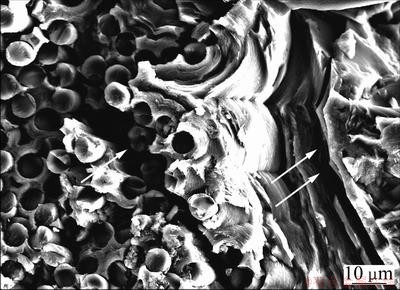

It is well-known that the mechanical behavior of 2D-C/C composites greatly depends on their densities. According to the densification mechanism of the porous performs mentioned in Section 3.1, the pyrocarbon firstly deposits on the fiber surface, and with the progressive deposition of pyrocarbon the gas infiltration becomes more difficult so that some residual pores are formed at the interface between the long fiber layer and mat. Thus, with the density decreasing, at the above mentioned positions the number of pore increases, and the number of big pore in preforms also increases correspondingly, even some larger pores can form in the composites. The increasing residual big pores could make the interface bonding between the long fiber layers and mats decrease due to the formation of more big pores. Moreover, the thickness of pyrocarbon matrix on the fiber surface in long fiber bundles is very thin due to the high fiber volume fraction, making it easy to crack or delaminate as the load rises (white arrows in Fig. 5). Therefore, the reinforcement of the fiber perform is greatly decreased, confirming the decrease of the composite strength with the decreasing density. However, due to the increasing pore, which provides the release route of the fracture energy under flexural loading, the composite toughness is greatly improved with the decreasing density. It similarly accords with the reported results in Ref. [18] on the influence of the distribution of pyrocarbon and fibers on the fracture characteristic of the composites.

Fig. 4 Flexural strength and modulus of composites with different density at deposited state

Fig. 5 SEM morphology of 2D-C/C composite

3.3 Effect of heat treatment on flexural behavior of C/C composites

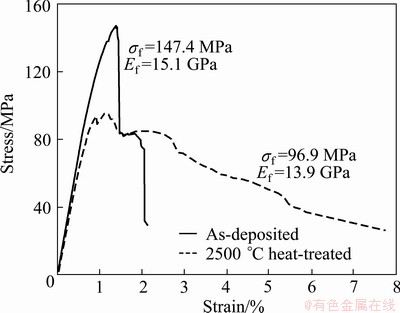

Figure 6 shows the stress—strain curves of the composites with SL pyrocarbon matrix before and after heat-treatment. It can be found that, at the initial loading stage, the stress of the sample shows a linear relationship as a function of the strain. For the as-deposited sample, the stress reaches the maximum value after a little yielding and then presents the abrupt drop showing the “ladder” type fracture characteristic. For the heat-treated sample, the stress undergoes some “zigzag” waves before reaching the maximum value and the stress—strain curve becomes more placid, presenting an ideal pseudo-plastic fracture characteristic. Compared to the deposited sample, the flexural strength of the heat-treated sample decreases by 35%, and the plastic fracture characteristic becomes more distinct. The flexural modulus exhibits a less decrease compared with the stress. It can be concluded that the high temperature treatment can greatly improve the fracture toughness of the composite.

Fig. 6 Stress—strain curves of C/C composites with SL pyrocarbon matrix before and after heat-treatment

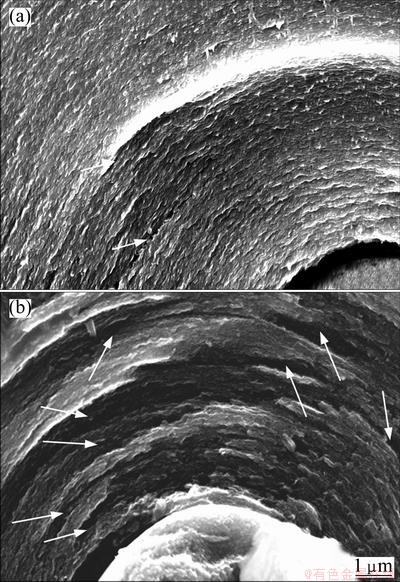

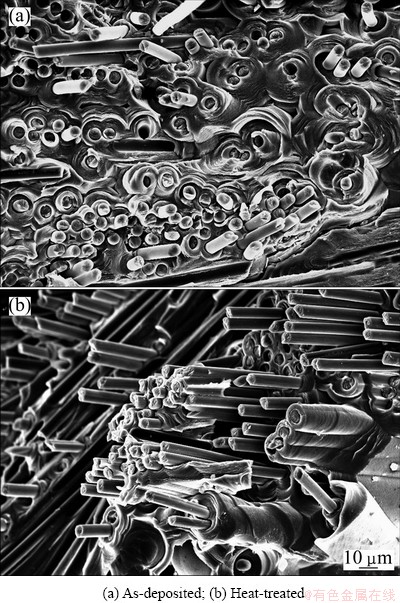

For 2D-C/C composites with the same density, their flexural behavior is mainly determined by the interface bonding between the fiber and matrix and the matrix microstructure. For the deposited sample, the interface bonding between the fiber and matrix is strong (Fig. 7), so the stress can be easily transported to the fiber surface, which favors the high strength. The crack is firstly formed at the outer region of carbon matrix and propagates to the fiber surface in the direction perpendicular to the matrix layer. As the load increases, only the crack reaches the positions of inter layer or inter-laminar micro-cracks in matrix, it will be deflected and the propagation of the stress to the fiber will be slowed down, companied the release of the fracture energy (dash line ellipse in Fig. 7), even if the stress continues to deliver to the fiber surface. Therefore, the deflection of crack can improve the fracture toughness of the composites. It is consistent with the results in Ref. [19]. However, at the deposited state, the SL pyrocarbon layer is thick and only a few of the layers and inter-laminar micro-cracks exist (Fig. 8(a)), only a little fracture energy can be released, which results in the high strength and brittle fracture characteristic of the composites. The nearly flat fracture surface of the sample (Fig. 9(a)) also confirms the fact of the brittle failure.

Fig. 7 Crack deflection in SL pyorcarbon matrix at deposited state under flexural loading

Fig. 8 Microstructures of matrix before (a) and after (b) heat-treatment

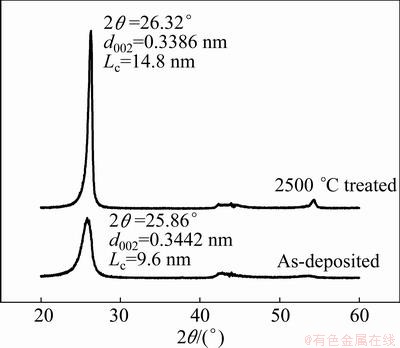

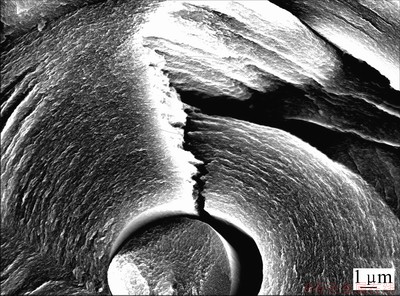

After heat-treatment, the apparent layer stack height Lc increases, the interlayer spacing d002 value decreases, the graphitization degree of pyrocarbon increases (Fig. 10), and the residual stress generated during chemical vapor infiltration can be released [20]. From Fig. 8(b), it can be found that the inter-laminar micro-crack in SL pyrocarbon matrix after heat treatment is more (white arrows) compared to the deposited state, involving numerous tiny wrinkled layered structures. It indicates that more crack deflections can occur and more fracture energy will be released by those interlaminar micro-cracks, which is similar to the fracture mechanism of the deposited sample. Besides, the increasing inter-laminar micro-crack can also make the sliding among layers easier under loading. All of these contribute to the fracture toughness of the composites, although the composite strength decreases. As a result, the uneven surface morphology and a lot of pulled-out fibers on the composite fracture after three-point bending test (Fig. 9(b)) are corresponding to the pseudo-plastic characteristic. Figure 11 shows the SEM morphology of the fiber-matrix in the composites after heat-treatment. It is clear that the crack is firstly formed in the matrix near the fiber, which results from the mismatch of thermal expansion coefficient between the fiber and matrix, and the interface bonding between the fiber and matrix is weakened. As the load rises, the cracks will be deflected layer by layer along these inter-laminar micro-cracks (dashed line ellipse in Fig. 11).

Fig. 9 SEM morphologies of fracture surface of composites

Fig. 10 XRD patterns of pyrocarbon before and after heat- treatment

Fig. 11 Crack deflection of heat-treated sample under flexural loading

4 Conclusions

1) SL pyrocarbon matrix involves numerous wrinkled layered structures with some inter-laminar micro-croaks. After heat-treatment, the number of inter-laminar micro-cracks in the matrix increases.

2) With the decrease of density, the strength of the composite decreases and the toughness increases. The fracture behavior of the composites with SL pyrocarbon matrix is greatly related to the size and distribution of the pore under flexural loading.

3) After heat-treatment at 2500 °C, the strength of composite decreases by 35% and the fracture mode changes from the brittle to pseudo-plastic characteristic due to the more crack deflection in SL pyrocarbon.

References

[1] Savage G. Carbon–carbon composites [M]. Cambridge: Chapman and Hall, 1993: 323-357.

[2] Golecki I. Rapid vapor-phase densification of refractory composites [J]. Materials Science and Engineering, 1997, 20(2): 37-124.

[3] YIN J, XIONG X, ZHANG H B, HUANG B Y. Microstructure and ablation performances of dual-matrix carbon/carbon composites [J]. Carbon, 2006, 44(9): 1690-1694.

[4] Guellali M, Oberacker R, Hoffmann M J. Influence of the matrix microstructure on the mechanical properties of CVI-infiltrated carbon fiber felts [J]. Carbon, 2005, 43(9): 1954-1960.

[5] LI Wei, LI He-jun, ZHANG Shou-yang, WEI Jian-feng, WANG Jie, LI Zhao-qian. Effect of high temperature treatment on the microstructure and mechanical properties of binary layer textured 2D C/C composites [J]. New Carbon Materials, 2011, 26(5): 328-334. (in Chinese)

[6] Zhang J C, Luo R Y, Zhang Y F, NI Y F, LI J S, YANG C L. Effect of isotropic interlayers on the mechanical and thermal properties of carbon/carbon composites [J]. Materials Letters, 2010, 64(13): 1536-1538.

[7] Xiong Xiang, Huang Bo-yun, Li Jiang-hong, WU Feng-qiu. Bending property and fracture mechanism of quasi-3D C/C composites [J]. Journal of Aeronautical Materials, 2006, 26(4): 88-91. (in Chinese).

[8] Guellali M, Oberacker R, Hoffmann M J. Influence of heat treatment on microstructure and mechanical properties of CVI-CFC composites with medium and highly textured pyrocarbon matrices [J]. Composites Science and Technology, 2008, 68(5): 1115-1121.

[9] Reznik B, Guellali M, Gerthsen D, Oberacker R, Hoffmann M J. Microstructure and mechanical properties of carbon–carbon composites with multilayered pyrocarbon matrix [J]. Materials Letters, 2002, 52(1-2): 14-19.

[10] XU G Z, LI H J, BAI R C, WEI J, ZHAI Y Q. Influence of the matrix texture on the fracture behavior of 2D carbon/carbon composites [J]. Materials Science and Engineering A, 2008, 478(1-2): 319-323.

[11] ZHANG Fu-qin, HUANG Qi-zhong, GONG Qian-ming, HUANG Bo-yun, CHEN Teng-fei, XU Hui-juan, JI Dong-ying. Effect of graphitization degree on the mechanical properties of C/C composites [J]. Journal of Central South University of Technology: Natural Science, 2001, 32(3): 289-293. (in Chinese)

[12] YU Shou-quan, ZHANG Wei-gang. Effect of heat-treatment temperature on mechanical properties of pyrocarbon and carbon/ carbon composites [J]. Journal of Inorganic Materials, 2010, 25(3): 315-320. (in Chinese)

[13] LIU H L, JIN Z H, HAO Z B, ZENG X M. Improvement of the mechanical properties of two-dimensional carbon/carbon composites [J]. Materials Science and Engineering A, 2008, 483-484: 316-318.

[14] LI H L, LI H J, LU J H, LI K Z, SUN C, ZHANG D S. Mechanical properties enhancement of carbon/carbon composites by in situ grown carbon nanofibers [J]. Materials Science and Engineering A, 2012, 547: 138-141.

[15] LI X T, LI K Z, LI H J, WEI J, WANG C. Microstructures and mechanical properties of carbon/carbon composites reinforced with carbon nanofibers/nanotubes produced in situ [J]. Carbon, 2007, 45(8): 1662-1668.

[16] Bourrat X, Fillion A, Naslain R, CHOLLON G, BRENDLE M. Regenerative laminar pyrocarbon [J]. Carbon, 2002, 40(15): 2931-2945.

[17] Lieberman M L, Pierson H O. Effect of gas phase conditions on resultant matrix pyrocarbons in carbon/carbon composites [J]. Carbon, 1974, 12(2): 233-241.

[18] Zhang Ming-yu, Su Zhe-an, Li Jian-li, Huang Qi-zhong. Bending properties and fracture mechanism of C/C composites with high density preform [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(8): 1795-1800.

[19] WEI Li-ming, ZHANG Yue, XU Cheng-hai, QI Fei, MENG Song-he. Mechanical properties of 3D carbon/carbon composites by nanoindentation technique [J]. Journal of Central South University, 2012, 19(1): 36-40.

[20] Piat R, Lapusta Y,  T, Guellali M, Reznik B, Gerthsen D, Chen T F, Oberacker R, Hoffmann M J. Microstructure-induced thermal stresses in pyrocarbon matrices at temperatures up to 2900 °C [J]. Journal of the European Ceramic Society, 2007, 27: 4813-4820.

T, Guellali M, Reznik B, Gerthsen D, Chen T F, Oberacker R, Hoffmann M J. Microstructure-induced thermal stresses in pyrocarbon matrices at temperatures up to 2900 °C [J]. Journal of the European Ceramic Society, 2007, 27: 4813-4820.

弯曲载荷下纯净光滑层热解炭基2D-C/C复合材料的断裂机制

曹伟锋,李贺军,郭领军,张守阳, 李克智, 邓海亮

西北工业大学 凝固技术国家重点实验室,西安 710072

摘 要:以天然气作为碳源,以2D针刺碳毡作为预制体,采用热梯度化学气相渗透工艺制备2D-C/C复合材料。采用偏光显微镜(PLM)和扫描电子显微镜(SEM)观察材料的显微组织,采用万用力学试验机测试热处理前后材料的弯曲行为,讨论材料的断裂机制。结果表明,热解炭基体表现为纯净光滑层(SL)特征,包含大量褶皱层片结构和一些层间微裂纹。随着材料密度的降低,材料强度降低,断裂韧性略有提高;经过2500 °C热处理后,基体中层间微裂纹数量大量增加,在加载过程中SL基体中发生了更多的裂纹偏转,材料强度大幅度降低,其断裂韧性明显升高,从沉积态时的脆性断裂转变为理想的假塑性断裂。

关键词:C/C复合材料;热解炭;断裂;弯曲行为

(Edited by Sai-qian YUAN)

Foundation item: Projects (51221001, 51202193) supported by the National Natural Science Foundation of China; Project (B08040) supported by Program of Introducing Talents of Discipline to Universities, China

Corresponding author: He-jun LI; Tel: +86-29-88495004; Fax: +86-29-88492642; E-mail: lihejun@nwpu.edu.cn

DOI: 10.1016/S1003-6326(13)62709-0