文章编号:1004-0609(2012)07-1969-07

添加BN对光滑层热解炭结构的C/C复合材料摩擦性能的影响

张本固,肖 鹏,李 专

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:通过粉末层铺法向全网胎炭纤维预制体中添加六方氮化硼粉末和化学气相沉积热解炭增密制备C/C-BN复合材料。在MM-1000摩擦试验机上对其摩擦磨损性能进行测试,并对摩擦表面进行光学形貌观察以及对材料的组织结构和磨屑进行SEM形貌观察。结果表明:与C/C复合材料相比,C/C-BN复合材料的线性磨损率降低了40%,质量磨损率降低了70%;摩擦表面中的六方BN在摩擦过程中始终保持稳定,BN的存在使光滑层热解炭结构的C/C复合材料的摩擦因数曲线变得平稳、波动小并且对刹车压力响应迅速,摩擦表面上形成了一层薄的摩擦膜。

关键词:C/C复合材料;BN;摩擦磨损;摩擦表面;磨屑

中图分类号:TB332 文献标志码:A

Effect of BN on tribological properties of C/C composites with SL pyrolytic carbon texture

ZHANG Ben-gu, XIAO Peng, LI Zhuan

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The carbon fiber reinforced/carbon-boron nitride (C/C-BN) hybrid matrix composites were prepared by adding hexagonal boron nitride (h-BN) powders in preform and subsequent chemical vapor infiltration (CVI) process. Friction and wear properties of C/C-BN were investigated on an MM-1000 testing machine. The morphologies of wear surfaces were observed by optical microscope. The morphologies of wear debris and the microstructures of samples were analyzed by scanning electron microscope. The results show that the C/C-BN composites display linear wear rate 40% lower and mass wear loss 70% lower than those of C/C composites. The h-BN in the matrix always keeps stable. The addition of BN in the matrix can effectively improve the stability of friction curves of C/C composites with a SL pyrolytic carbon texture, and cause the formation of a thin wear film on the wear surface.

Key words: C/C composites; BN; friction and wear; wear surface; wear debris

C/C复合材料是一种综合性能优良的高温摩擦材料,其比强度、比模量和断裂韧性高,密度低,热性能、摩擦磨损性能及承载能力优良,使用寿命长。自1973年C/C复合材料第一次用于飞机刹车以来,目前绝大多数民航客机和军用飞机均采用C/C复合材料作为刹车片,具有广阔的市场前景[1-4]。

C/C复合材料的摩擦磨损性能是其作为飞机刹车材料的关键特性。国外生产炭刹车盘的公司大多采用热解炭作为基体炭[5-6],根据化学气相沉积工艺条件的不同可得到粗糙层(RL)、光滑层(SL)和各向同性(ISO) 3种不同结构的热解炭[7-8]。据研究表明[9],热解基体炭为粗糙层结构的C/C复合材料可以获得优良的制动摩擦磨损性能,摩擦因数高而稳定、耐磨性好,适用于高性能的航空刹车材料。然而在实际生产当中,粗糙层结构的热解炭是一种很难获得的结构,其制备工艺参数范围窄、要求高而且精确。另外,C/C复合材料存在易氧化、对环境要求较高等缺点,从C/C复合材料基体改性研究的文献报道来看,在C/C复合材料基体中添加BN、SiC等的方法被看好[10]。C/C-SiC复合材料(即炭纤维增强炭和碳化硅基体复合材料)最早在20世纪80年代作为热结构材料出现,在90年代中期已经成功应用于高级轿车、重载卡车和高速列车等摩擦领域,国内外对C/C-SiC复合材料的制备技术、性能以及理论和应用等方面的研究已经很系统、成熟和深入[11]。但关于C/C-BN复合材料作为摩擦材料的研究报道比较少,还没有文献报道其应用于工业领域。对于C/C-BN复合材料的研究将丰富陶瓷基摩擦材料体系。

BN有类似于石墨的层状结构,与C之间具有许多相似性,包括密度、导热系数、热容和晶体结构。BN的抗氧化性远优于C/C,在空气中的明显氧化温度在800 ℃,而C仅为450 ℃[12]。目前,在C/C-BN复合材料的研究中,SEGHI等[13-14]的结果引人注目,他们采用先驱体浸渍裂解法制备出C/C-BN复合材料,并进行了小样制动摩擦试验,发现与同类型炭基体的1.75 g/cm3的C/C相比,密度为1.55 g/cm3的C/C-BN复合材料的磨损率降低了50%,并认为BN的引入提高了材料在不同能载下摩擦膜的稳定性,降低了氧化磨损率和颗粒状磨屑的产生。张晓明等[15]采用在炭布叠层预制体中添加六方氮化硼固体润滑组元以及等温化学气相渗透和超高压沥青浸渍/炭化混合工艺制备了炭/炭复合材料,表明预制体中添加h-BN可以明显降低材料的摩擦因数,稳定材料的摩擦磨损性能。制备BN基体的工艺主要有化学气相渗透法(CVI)和先驱体浸渍裂解法(PIP)。CVI工艺具有可实现近净成形、制备温度低、基体纯度高、对炭纤维增强体的损伤小等优点,但是CVI工艺的成本高、制备周期长、工艺参数复杂、所生成的BN结构多变[16]。先驱体浸渍裂解法中,先驱体在热解过程中的体积收缩、有机物的分解和挥发会使基体内部出项大量的裂纹和孔隙,而且所制备的BN具有较大的晶面间距会降低BN的抗氧化性能。

本文作者通过粉末层铺法向全网胎结构的纤维预制体中直接添加六方氮化硼粉末和化学气相沉积热解炭增密制备了C/C-BN复合材料[17]。该方法操作简单快捷,没有CVI那样复杂且要求精确的工艺,所以是一种低成本快速制备C/C-BN复合材料的方法,具有一定的新意和科学依据,将丰富陶瓷基摩擦材料体系。利用化学气相沉积热解炭增密制备了相同全网胎针刺结构C/C复合材料作为对比。在MM-1000摩擦试验机上对两种复合材料的摩擦磨损性能进行了测试,初步研究了添加BN对C/C复合材料摩擦性能的影响。

1 实验

1.1 试样制备

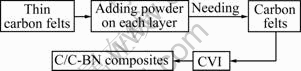

首先按配比选取国产的长度为40~60 mm的短切炭纤维,通过纺织技术制备成密度为0.11 g/cm3的全网胎炭纤维薄层。通过粉末层铺法把六方氮化硼粉末均匀地铺撒在网胎薄层上面,然后采用带下倒钩刺的针对网胎叠层进行往返针刺,得到含有BN粉末的全网胎预制体。随后采用化学气相沉积法沉积热解炭增密制得最终密度为1.70 g/cm3的C/C-BN复合材料,其中BN的质量分数为6.3%。试样制备工艺流程如图1所示。在化学气相沉积工艺中,以丙烯作为碳源气,氮气作为载气,沉积温度为1 000 ℃,丙烯流量为25 L/min,氮气流量为25 L/min。六方氮化硼粉末为山东省潍坊邦德特种材料有限公司生产,其颗粒平均粒径为1 μm。按相同工艺制备了全网胎结构的C/C复合材料作为对比。

图1 试样制备工艺流程图

Fig. 1 Flow chart for manufacturing C/C-BN composites

1.2 性能测试

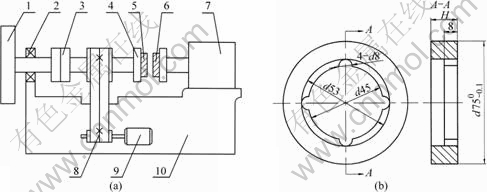

1.2.1 摩擦磨损性能测试

将C/C-BN复合材料和C/C复合材料机加工成外径为75 mm,内径为53 mm,厚度为14~16 mm的圆环形摩擦试环。在MM-1000型摩擦磨损试验机上采用环-环自对偶接触形式模拟飞机在正常着陆条件下的刹停试验(见图2)。动环通过键槽与驱动主轴相连,并随着驱动主轴和惯性飞轮一同加速到规定的制动速度之后,机器会施加一定的压力使静环与旋转的动环相摩擦形成制动力矩,吸收动能而完成制动过程。试验条件:转速为7 500 r/min,转动惯量为0.3 kg/m2,摩擦面上压力为0.6 MPa。摩擦试验的环境为空气气氛、温度为室温25 ℃、湿度为50%。在正式试验前进行磨合试验,当两个摩擦试环的接触面积大于80%以上时才可以进入正式的摩擦性能试验。试验次数为10次,整个试验过程中记录相应的力矩、摩擦因数曲线。用精度为0.01 mm的千分尺测量试环在摩擦磨损试验前后的尺寸变化,在摩擦试环上标记6个等距离的点以便于测量线性磨损,线性磨损率为6处标记点每次每面测量值的平均值;用分度值为0.1 mg的电子读数分析天平测量试环在摩擦磨损试验前后的质量变化,计算出平均每次每面的质量磨损。由于BN在空气中的氧化温度为800 ℃,而炭在空气中氧化产生挥发性的CO和CO2,所以可以忽略氧化增重现象,用总的质量磨损减去由于厚度减少而引起的质量磨损,即根据下式来计算试样的氧化磨损。

mo=mm-rl×22.12×ρ/10 (1)

式中:mo为氧化磨损;mm为质量磨损;rl线性磨损;ρ为复合材料的密度。

图2 MM-1000摩擦磨损试验机和摩擦试环示意图

Fig. 2 Schematic diagrams of home-made laboratory scale inertia type of dynamometer (a) and testing specimen (b): 1—Inertial wheel; 2—Bearing; 3—Clutch; 4—Specimen holder; 5—Rotor; 6—Stator; 7—Pressing cylinder; 8—Strap; 9—Electric motor; 10—Lathe bed

1.2.2 形貌观察

采用JSM-6360LV型扫描电子显微镜观察材料的组织结构和磨屑的形貌。用MeF3A型金相显微镜(偏光)观察热解炭的结构。用KH-7700型三维数字视频显微镜观察C/C与C/C-BN摩擦试环的摩擦表面形貌。用日本Rigaku-3014型X射线衍射仪分析摩擦表面 成分。

2 结果与讨论

2.1 试样的显微结构

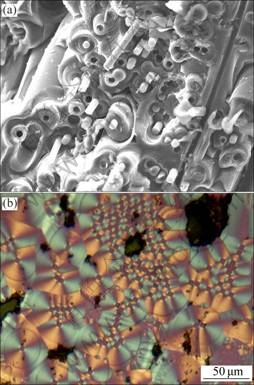

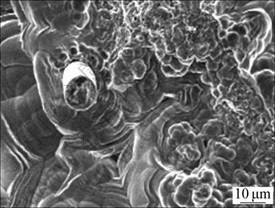

图3(a)所示为C/C试样的组织结构,可以看到热解炭围绕炭纤维呈环状圆周生长,热解炭与炭纤维的组织界面清晰分明。图3(b)所示为C/C试样的偏光金相显微结构,可以看出C/C的基体炭为光滑层结构,具有规则的十字消光轮廓,环向裂纹清晰可见。图4所示为C/C-BN试样的组织结构,可以看到小区域范围内热解炭呈圆周生长纹路,在大部分区域热解炭以颗粒状堆积生长。在CVI过程中,热解炭沉积在预制体里面吸附在炭纤维上面的六方氮化硼颗粒表面而成球状或颗粒状形貌。

图3 C/C试样的显微结构

Fig. 3 Microstructures of C/C composites: (a) SEM image; (b) Polarized optical micrograph

图4 C/C-BN试样的SEM像

Fig. 4 SEM image of C/C-BN composites

2.2 摩擦磨损性能分析

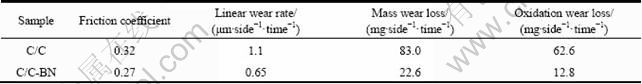

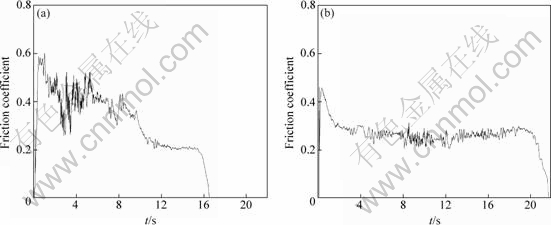

表1列出了C/C和C/C-BN复合材料的摩擦磨损性能测试结果,而图5所示为两种试样的摩擦因数曲线。从表1的结果可知,添加了BN之后C/C复合材料的摩擦因数略有下降,从0.32降到0.27;而其线性磨损率降低了40%,质量磨损率降低了70%,氧化磨损率更是降低了80%。因此添加BN可以显著降低C/C复合材料的线性磨损和质量磨损。图5(a)所示为C/C复合材料的摩擦因数曲线,其曲线稳定性差,在整个制动过程中摩擦因数波动大。摩擦因数曲线一开始有0.5 s左右对刹车压力的响应滞后(见图5(a)中曲线的左端);在制动中期摩擦因数波动很大,出现了波峰和波谷;在制动后期曲线明显下滑并出现拖尾。在本实验中所用的C/C复合材料为光滑层热解炭结构的C/C复合材料(见图3),其摩擦因数曲线的大概趋势和先前的研究相一致[9]。图5(b)所示为C/C-BN复合材料的摩擦因数曲线,该曲线对刹车压力响应迅速,在整个制动过程中曲线波动小且摩擦因数保持在稳定值0.27。比较图5中两种试样的摩擦因数曲线可知,添加BN可以有效改善光滑层热解炭结构的C/C复合材料的摩擦特性,使摩擦因数曲线变得平稳且消除了对刹车压力响应滞后的现象。

2.3 摩擦磨损机制

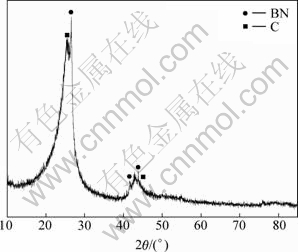

图6所示为C/C-BN复合材料摩擦表面的XRD谱。由图6可知,材料的组分主要由炭和六方BN构成,由于炭纤维属于非晶材料,所以并未显示出明显的衍射峰;C/C-BN复合材料经过MM-1000摩擦试 验后,摩擦表面中的BN仍然稳定保持六方晶型,并没有发生明显的氧化现象。

C/C复合材料的摩擦表面光学形貌如图7所示。从图7可知,C/C复合材料的摩擦表面在低倍下呈光滑平整的镜面形貌,在光学显微镜下明亮反光;在高倍下可以看到杂乱交错的磨损犁沟和材料的微观组织。先前的研究表明[18],C/C复合材料在摩擦过程中存在磨粒磨损,在硬质颗粒的犁削作用下,摩擦表面会产生磨损犁沟。由于C/C复合材料的基体炭为光滑层结构,是一种难石墨化的硬炭,在摩擦过程中主要产生硬相的磨屑,磨屑硬度大难以剪切变形。这些磨屑在剪切应力作用下难以形成连续的磨屑层。另外,光滑层结构的热解炭中活性微区的数量很多,容易与氧发生反应,从表1的氧化磨损数据可知,C/C复合材料发生了严重的氧化磨损。因此,摩擦表面上的一部分磨屑在离心力作用下被抛离摩擦面,另一部分磨屑主要以氧化的形式被烧蚀掉。由图7可知,无论显微镜在低倍或高倍下,C/C复合材料的摩擦表面都观察不到磨屑层的存在。由于没有磨屑层,在制动过程开始加压的瞬间,摩擦表面很难马上贴合得很好,因此出现了摩擦因数曲线对刹车压力响应滞后的现象。同时,在整个制动过程中摩擦因数曲线稳定性差、波动大。

表1 摩擦试验结果

Table 1 Results of friction experiment

图5 C/C和C/C-BN复合材料的摩擦因数曲线

Fig. 5 Typical friction curves of two composites: (a) C/C composites; (b) C/C-BN composites

图6 C/C-BN摩擦表面的XRD谱

Fig. 6 XRD pattern of friction surface of C/C-BN composites

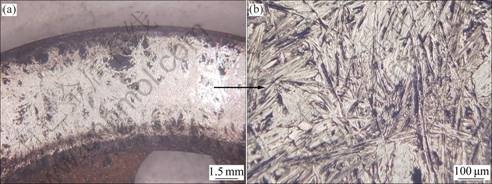

图8所示为C/C-BN复合材料摩擦表面的光学形貌照片。与C/C复合材料相比,C/C-BN复合材料的摩擦表面在光学显微镜下没有反光的现象,在高倍下可以观察到其表面涂敷了一层薄的磨屑层,即摩擦膜。由于BN的抗氧化性远优于C/C的[12],C/C-BN复合材料的磨屑中因含有BN而提高了其抗氧化性能。从表1的摩擦试验结果可知,添加BN后C/C复合材料的氧化磨损下降了80%。因此,除了小部分的磨屑在离心力作用下被抛离摩擦面(只有在摩擦试验前期可以收集到从摩擦表面掉下来磨屑,摩擦试验后期几乎没有收集到磨屑),大部分的磨屑在强烈挤压剪切应力作用下破碎变形,填充了摩擦表面的一些孔洞和纤维间的低凹处,涂敷在摩擦表面上形成了一层薄的磨屑层,即摩擦膜。从图8(b)可知,在C/C-BN复合材料的摩擦表面上已经观察不到杂乱交错的磨损犁沟和材料的微观组织。由于摩擦表面有摩擦膜的存在以及BN具有更高的抗氧化性,因此,在整个制动过程中,C/C-BN复合材料的摩擦因数曲线变得平稳且对刹车压力的响应迅速,同时,与C/C复合材料相比,其线性磨损率降低了40%,氧化磨损率更是降低了80%。

图7 C/C复合材料摩擦表面的光学形貌照片

Fig. 7 Optical micrographs of friction surfaces of C/C composites: (a) Lower magnification; (b) Higher magnification

图8 C/C-BN复合材料摩擦表面的光学形貌照片

Fig. 8 Optical micrographs of friction surfaces of C/C-BN composites: (a) Lower magnification; (b) Higher magnification

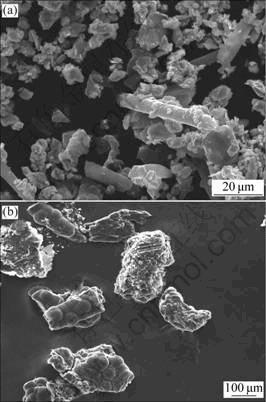

图9所示为C/C与C/C-BN复合材料磨屑的SEM像。在摩擦磨损试验过程中,可以收集到大量的C/C复合材料的磨屑,而C/C-BN复合材料的磨屑很少。C/C复合材料的磨屑中可见大量尺寸约为3~6 μm的CVI热解炭颗粒以及大量的短纤维(见图9(a))。C/C复合材料的基体炭为光滑层结构,是一种难石墨化的硬炭,在高阻摩擦应力作用下易发生脆性开裂形成大量均匀的硬质无定形热解炭颗粒,而炭纤维的氧化温度比热解炭的高,因而在磨屑中会裸露大量的短炭纤 维。由图9(b)可知,与C/C复合材料细小的颗粒状磨屑不同,C/C-BN复合材料的磨屑为尺寸较大(大于 200 μm)的块状磨屑。这说明两者的摩擦磨损机制不同,BN的添加显著地抑制了光滑层热解炭结构C/C复合材料的氧化磨损和磨粒磨损,但C/C-BN复合材料的摩擦磨损机制还有待于进一步的研究来揭示。

图9 C/C与C/C-BN复合材料磨屑的SEM像

Fig. 9 SEM images of wear debris of two composites: (a) C/C composites; (b) C/C-BN composites

由于BN的抗氧化性远优于C/C复合材料的,因此C/C-BN复合材料的磨屑因含有BN而提高了其抗氧化性能,因而在摩擦过程中,大部分磨屑在挤压剪切应力作用下破碎变形,涂敷在摩擦表面上形成了一层薄的摩擦膜。由于摩擦膜的存在,在整个制动过程中C/C-BN复合材料的摩擦因数曲线变得平稳并且对刹车压力响应迅速,同时显著降低了线性磨损和氧化磨损。

3 结论

1)添加BN可以有效改善光滑层热解炭结构的C/C复合材料的摩擦特性,使摩擦因数曲线变得平稳并且消除了对刹车压力响应滞后的现象。

2) 摩擦表面中的BN在摩擦过程中始终保持稳定,BN的存在使复合材料的摩擦表面形成了一层薄的摩擦膜,显著降低了氧化磨损和磨粒磨损。与C/C复合材料相比,C/C-BN复合材料的线性磨损率降低了40%,质量磨损率降低了70%,氧化磨损率更是降低了80%。

3) C/C-BN复合材料的摩擦磨损机制有待于进一步的研究来揭示。

REFERENCES

[1] SAVAGE G. Carbon/carbon composites [M]. Chapman & Hall, 1993.

[2] SCHMIDT D L, DAVIDSON K E, THEIBES L S. Unique application of carbon/carbon composites materials [J]. SAMPE, 1999, 35(3): 27-39.

[3] 李翠云, 李辅安. 碳/碳复合材料的应用研究进展[J]. 化工新型材料, 2006, 34(3): 18-20.

LI Cui-yun, LI Fu-an. Study on application of carbon/carbon composites [J]. New Chemical Materials, 2006, 34(3): 18-20.

[4] 胡志彪, 李贺军, 陈 强, 李克智, 黄荔海. 碳/碳复合材料摩擦学性能及摩擦机制研究进展[J]. 材料工程, 2004(12): 59-62.

HU Zhi-biao, LI He-jun, CHEN Qiang, LI Ke-zhi, HUANG Li-hai. Advance in research on tribological behavior and mechanism of carbon/carbon composites [J]. Materials Engineering, 2004(12): 59-62.

[5] 罗瑞盈. C/C复合飞机刹车材料的研究和应用现状[J]. 宇航材料工艺, 1997(5): 7-10.

LUO Rui-ying. Present research and application of carbon/ carbon aeroplane brake material [J]. Aerospace Materials Technology, 1997(5): 7-10.

[6] 程永宏, 罗瑞盈, 王天民. 化学气相沉积(CVD)炭/炭复合材料(C/C)研究现状[J]. 炭素材料, 2002(5): 26-32.

CHENG Yong-hong, LUO Rui-ying, WANG Tian-min. Summary of chemical vapor deposition (CVD) in preparation of carbon/ carbon composites [J]. Carbon Techniques, 2002(5): 26-32.

[7] LIEBERMAN M L, PIERSON H O. Effect of gas phase conditions on resultant matrix pyrocarbons in carbon/carbon composites [J]. Carbon, 1974, 12(2): 233-241.

[8] XAVIER B, BEATRICE T. Pyrocarbon anisotropy as measured by electron diffraction and polarzed light [J]. J Mater Res, 2000, 15(1): 92-101.

[9] XIONG X, HUANG B Y, LI J H, XU H J. Friction behaviors of carbon/carbon composites with different pyrolytic carbon textures [J]. Carbon, 2006, 44(4): 463-467.

[10] KRENKEL W, HEIDENREICH B, RENZ R. C/C-SiC Composites for advanced friction systems [J]. Advanced Engineering Materials, 2002, 4(7): 427-436.

[11] 肖 鹏, 熊 翔, 张红波, 黄伯云. C/C-SiC陶瓷制动材料的研究现状和应用[J]. 中国有色金属学报, 2005, 15(5): 667-674.

XIAO Peng, XIONG Xiang, ZHANG Hong-bo, HUANG Bai-yun. Progress and application of C/C-SiC ceramic braking materials [J]. The Chinese Journal of Nonferrous Metals, 2005, 15(5): 667-674.

[12] COFER C G, ECONOMY J. Oxidative and hydrolytic stability of boron nitride—A new approach to improving the oxidation resistance of carbonaceous structures [J]. Carbon, 1995, 33(4): 389-395.

[13] SEGHI S, LEE J, ECONOMY J. Carbon/carbon-boron nitride composites with improved wear resistance compared to carbon/ carbon [J]. Carbon, 2004, 42(15): 3043-3048.

[14] SEGHI S, LEE J, ECONOMY J. High density carbon fiber/ boron nitride matrix composites: Fabrication of composites with exceptional wear resistance [J]. Carbon, 2005, 43(10): 2035- 2043.

[15] 张晓明, 李克智, 李贺军, 张守阳, 颜夏峰. 预制体添加BN对炭/炭复合材料性能的影响[J]. 机械科学与技术, 2010, 20(1): 36-39.

ZHANG Xiao-ming, LI Ke-zhi, LI He-jun, ZHANG Shou-yang, YAN Xia-feng. Influence of BN on the properties of the carbon/ carbon composites [J]. Mechanical Science and Technology for Aerospace Engineering, 2010, 20(1): 36-39.

[16] LIN FH, HSU CK, TANG TP, YANG FF. Thermal-heating CVD synthesis of BN nanotubes from trimethyl borate and nitrogen gas [J]. Material Chemistry and Physics, 2008, 107: 115-121.

[17] 肖 鹏, 李 专, 张本固, 李鹏涛. 一种炭纤维增强炭和氮化硼双基体摩擦材料的制备方法: 中国, 2010500033[P]. 2010- 01-29.

XIAO Peng, LI Zhuan, ZHANG Ben-gu, LI Peng-tao. A method of the fabrication of a carbon fiber reinforced carbon and boron nitride hybrid matrix composites: CN2010500033 [P]. 2010- 01-29.

[18] AWASTHI S, WOOD J. C/C composite materials for

air-craft brakes [J]. Adv Ceram Mater, 1988, 3(5): 449-451.

(编辑 何学锋)

基金项目:湖南省科技重大专项资助项目(2009FJ1011-3);国家自然科学基金资助项目(51072231)

收稿日期:2011-06-02;修订日期:2012-01-14

通信作者:肖 鹏,教授,博士;电话:0731-88830131;E-mail: xiaopeng@mail.csu.edu.cn