DOI: 10.11817/j.issn.1672-7207.2017.03.012

弧齿锥齿轮小轮粗切优化及验证

苏进展1,方宗德2

(1. 长安大学 道路施工技术与装备教育部重点实验室,陕西 西安,710064;

2. 西北工业大学 机电学院,陕西 西安,710072)

摘要:为了获得较为均匀的小轮精切余量,提出弧齿锥齿轮小轮粗切参数优化的方法。根据轮坯的中点检查尺寸对小轮两侧精切齿面进行定位;预置精切余量并沿法向方向叠加,得到小轮粗切的目标齿面;建立小轮精切余量的最小二乘法优化模型,采用基于置信域策略的列文伯格-马夸尔特法迭代算法,反求出小轮粗切参数,并对方案进行切齿验证。研究结果表明:将垂直轮位、轴向轮位、床位和刀顶距作为粗切参数,能够获得比格里森粗切更加均匀的精切余量;采用大轮粗切刀盘对小轮进行粗切,则存在明显的齿形角误差。

关键词:弧齿锥齿轮;精切余量;粗切;优化

中图分类号:TH132 文献标志码:A 文章编号:1672-7207(2017)03-0644-06

Optimization and validation of pinion roughing for spiral bevel gears

SU Jinzhan1, FANG Zongde2

(1. Key Laboratory of Road Construction Technology and Equipment, Ministry of Education,

Chang’an University, Xi’an 710064, China;

2. School of Mechanical Engineering, Northwestern Polytechnical University, Xi’an 710072, China)

Abstract: In order to obtain a more uniform finishing allowance, an optimal method for roughing pinion of spiral bevel gears was proposed. The location of both tooth flanks was determined by pinion tooth sizes at the middle of face from gear blank; the objection of roughing surface was achieved according to add the preset finishing allowance to the theoretical finishing surface along the normal direction. The least squares optimization model of the finishing allowance was established, and the parameters of roughing pinion were solved by the Levenberg-Marquardt method with a trust-region strategy, and then an experiment of pinion cutting was conducted to valid the proposed method. The results show that a more uniform finishing allowance can be obtained by the optimal method, compared with Gleason’s rough settings, where the machine settings of work offset, machine center to back sliding base and point width are taken as the optimization parameters, and there exists the profile error of finishing allowance due to the use of roughing head-cutter of wheel gear directly.

Key words: spiral bevel gear; finishing allowance; roughing; optimization

齿轮粗切是在轮坯上开出具有一定深度和厚度的齿槽,若粗切后齿槽两侧余量不均匀或者余量不够,将严重地影响到齿轮精度、刀齿寿命和加工效率。大轮粗切是根据精切余量来调整粗切刀盘的刀顶距,而机床调整参数保持不变;小轮粗切要复杂得多,其原因是小轮精切的两侧齿面是采用单面刀盘在不同的机床调整下加工完成的,而小轮粗切要用双面刀盘加工,在一次装夹中加工出的齿槽是不可能给精切两侧留下相同的余量。目前,国内外学者对弧齿锥齿轮精切或磨齿的加工参数设计及其性能进行了大量的理论研究和试验验证[1-6],而对粗切的研究较少。张金良等[7]提出了准双曲面齿轮粗切方法。LI等[8]提出了螺旋锥齿轮粗切的优化模型,并采用复合形法求解粗切参数。美国Gleason公司推导出一套粗切调整卡,但计算公式繁多、不易掌握,且有些粗切调整卡不全或保密[9]。在实际生产中,采用近似粗切容易出现精切余量不均匀,甚至发生刀齿与齿面干涉的现象[10]。另外,上述方法对粗切刀盘的规格有严格的限制,而对于大多数中小型锥齿轮生产企业而言,需要利用现有粗切刀盘进行粗加工,并且保证两侧余量尽量均匀。本文作者首先获得小轮精切齿面上离散网格点的齿面坐标,通过中点检查尺寸对两侧的精切齿面进行定位;预置小轮精切余量,并沿着网格点的法向方向叠加,获得小轮粗切的目标齿面;建立小轮精切余量的最小二乘法优化模型,采用基于置信域策略的Levenberg- Marquardt优化算法,反求粗切参数;然后比较了格里森粗切、指定刀顶距和优化刀顶距3种粗切方案的精切余量;探讨了采用大轮粗切刀盘对小轮进行粗切的可行性;最后,对采用大轮粗切刀盘且优化刀顶距的粗切方案进行了切齿验证。

1 小轮精切齿面定位

已知小轮的精切参数,根据坐标变换和啮合方程,推导出小轮精切齿面Sf的表达式为

(1)

(1)

式中:uf和qf为小轮切削锥面的坐标参数;ff为加工转角;r1f和n1f分别为小轮齿面的位矢和法矢;f1f为精切的啮合方程。

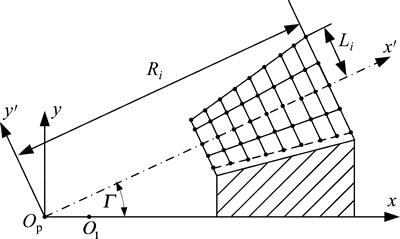

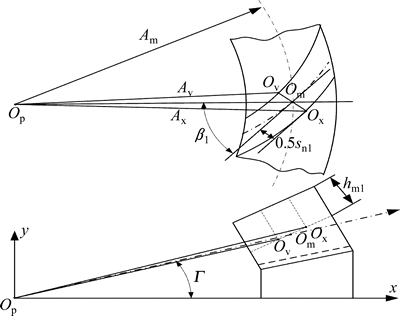

在小轮旋转投影面上取5行×9列共45个网格点,位置参数为(Ri,Li)(i=1, 2, …, 45),如图1所示。

图1 小轮旋转投影面

Fig. 1 Rotating Projection plane of pinion

通过求解非线性方程组(2),获得小轮精切齿面的齿面坐标。

(2)

(2)

式中:x1f,y1f和z1f分别为小轮位矢r1f的3个坐标分量; 为节锥角。

为节锥角。

小轮采用单面法加工,两侧齿面的精切参数不同,则凹、凸齿面不能构成完整的轮齿,需对某个齿面进行旋转,以获得正确的齿形。小轮中点检查尺寸,包括中点弦齿高hm1和中点弦齿厚sn1;测量时,凹、凸面与量具接触点的位置分别为Ov(Rv,Lv),Ox(Rx,Lx)。图2所示为中点检查尺寸在节平面和旋转投影面的表示,则凹面接触点Ov到齿顶线的距离dv等于中点弦齿高hm1,即

(3)

(3)

图2 中点检查尺寸

Fig. 2 Tooth sizes at middle of face

式中:Ai和Ao分别为小轮的内锥距和外锥距;hai和hao分别为小轮的小端齿顶高和大端齿顶高。

在节平面的DOpOmOv中,满足余弦定理

(4)

(4)

式中:b为小轮的中点螺旋角,Am为小轮中点锥距。联立式(3)和(4),求出Ov的位置参数Rv和Lv,再结合式(1)和(2),即可获得Ov的齿面坐标(xv,yv,zv)。

同理,将式(4)中b用p/2+b代替,求出凸面接触点Ox的齿面坐标(xx,yx,zx)。按照小轮中点弦齿厚的定义,有 。则旋转定位角qx应满足如下关系

。则旋转定位角qx应满足如下关系

(5)

(5)

本文以小轮凸面为基准,将小轮凹面旋转 qx后实现小轮精切齿面的定位。

2 小轮粗切目标齿面

通过式(2)求解出小轮精切凸面上45个网格点的位矢 和法矢

和法矢 ,预置小轮单面精切余量d,则小轮凸面的粗切目标齿面

,预置小轮单面精切余量d,则小轮凸面的粗切目标齿面 的位矢为

的位矢为

(6)

(6)

同理,小轮凹面的粗切目标齿面 的位矢为

的位矢为

(7)

(7)

式中: 和

和 分别为小轮的精切凹面经旋转qx定位后得到45个网格点的位矢和法矢。记小轮粗切的目标齿面

分别为小轮的精切凹面经旋转qx定位后得到45个网格点的位矢和法矢。记小轮粗切的目标齿面 的离散点矢量表示为

的离散点矢量表示为

(8)

(8)

3 小轮粗切参数反求

小轮粗切是双面法开槽,不涉及齿面定位的问题。小轮的粗切齿面Sr表示为

(9)

(9)

式中:ur和qr为小轮粗切切削锥面的坐标参数;fr为粗切加工转角;fr为粗切的啮合方程。小轮粗切齿面Sr的单位法矢为

(10)

(10)

式中: 和

和 分别为小轮粗切齿面对坐标参数的偏导。网格点的位矢为pk,其对坐标参数的偏导记为

分别为小轮粗切齿面对坐标参数的偏导。网格点的位矢为pk,其对坐标参数的偏导记为 和

和 。由式(9)得到的小轮凹、凸面组成了一个齿槽,而式(8)得到的是一个轮齿;将粗切齿槽的凸面固定,凹面旋转2p/z1得到粗切后的轮齿,z1为小轮齿数。另外,小轮的粗切轮齿面Sr与粗切目标齿面S*可能相距较远,需将粗切齿面Sr旋转qr角度后,使粗切齿面和目标齿面尽量靠近,以便小轮精切余量的计算,旋转角qr是通过式(11)确定,最终得到粗切齿面

。由式(9)得到的小轮凹、凸面组成了一个齿槽,而式(8)得到的是一个轮齿;将粗切齿槽的凸面固定,凹面旋转2p/z1得到粗切后的轮齿,z1为小轮齿数。另外,小轮的粗切轮齿面Sr与粗切目标齿面S*可能相距较远,需将粗切齿面Sr旋转qr角度后,使粗切齿面和目标齿面尽量靠近,以便小轮精切余量的计算,旋转角qr是通过式(11)确定,最终得到粗切齿面 。

。

(11)

(11)

即小轮粗切轮齿面Sr与小轮粗切目标齿面S*上对应离散点的距离平方和最小,从而求得qr。

定义小轮的目标齿面S*与粗切齿面 对应离散点的偏差:

对应离散点的偏差:

(12)

(12)

式中: ;hk表示第k个网格点的齿面偏差;h为所有网格点的齿面偏差矢量。考虑到pk对坐标参数的偏导均位于小轮粗切齿面的切平面内,则有下列方程组成立

;hk表示第k个网格点的齿面偏差;h为所有网格点的齿面偏差矢量。考虑到pk对坐标参数的偏导均位于小轮粗切齿面的切平面内,则有下列方程组成立

(13)

(13)

齿面偏差向量h可表示为

(14)

(14)

以小轮粗切的刀盘参数和机床调整参数及旋转角作为优化变量,小轮粗切齿面 与目标齿面S*的残余偏差平方和最小为目标函数,建立最小二乘优化模型

与目标齿面S*的残余偏差平方和最小为目标函数,建立最小二乘优化模型

(15)

(15)

采用基于置信域策略的Levenberg-Marquardt迭代算法求解式(15),详细算法可参考相关文献[11-15]。在本文中,以小轮凹面的精切参数为初值,给定优化变量的区间,进行迭代反求。

4 算例

4.1 结果比较

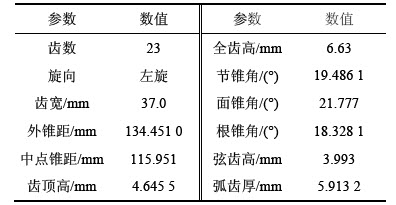

以变性法弧齿锥齿轮小轮为例,预置小轮的单面精切余量为0.2 mm。表1所示为小轮基本参数,其中,弦齿高和弦齿厚均在中点测量;表2所示为小轮的精切切齿参数,包括刀盘参数和机床调整参数,表3所示为小轮的3种粗切参数及中点检查尺寸,其中方案1为格里森粗切参数,方案2为采用Gleason刀盘参数而机床调整参数是采用本文方法得到的,方案3是在方案2的基础上将刀顶距作为优化变量得到的粗切参数。图3所示为3种粗切方案对应的精切余量图。

从图3可知:方案1的精切余量较大,这是由于Gleason粗切的径向刀、角向刀位都与大轮的精切参数相同,且垂直轮位和轴向轮位与大轮的精切参数相同且都为0造成。而本文将这些参数进行优化,因此方案2和方案3的精切余量小且均匀,算例中方案1精切余量的均方根为0.033 9 mm,方案2精切余量的均方根为0.018 7 mm,方案3精切余量的均方根为0.017 1 mm。从表3可见:优化刀顶距的中点全齿高比Gleason和指定刀顶距大,这是由于Gleason粗切刀顶距是由外端槽宽减去精切余量,该方法较为近似。

表1 小轮轮坯参数

Table 1 Tooth blank of pinion

表2 小轮精切参数

Table 2 Machine-tool settings of finishing pinion

表3 小轮粗切参数及中点检查尺寸

Table 3 Roughing parameters of pinion and tooth sizes at middle of face

图3 3种粗切方案的精切余量(单位:μm)

Fig. 3 Finishing allowance of three cases

而本文的优化刀顶距能够使精切余量更均匀、弦齿厚更小、中点全齿高更大,这可减小后续精加工的进给量。

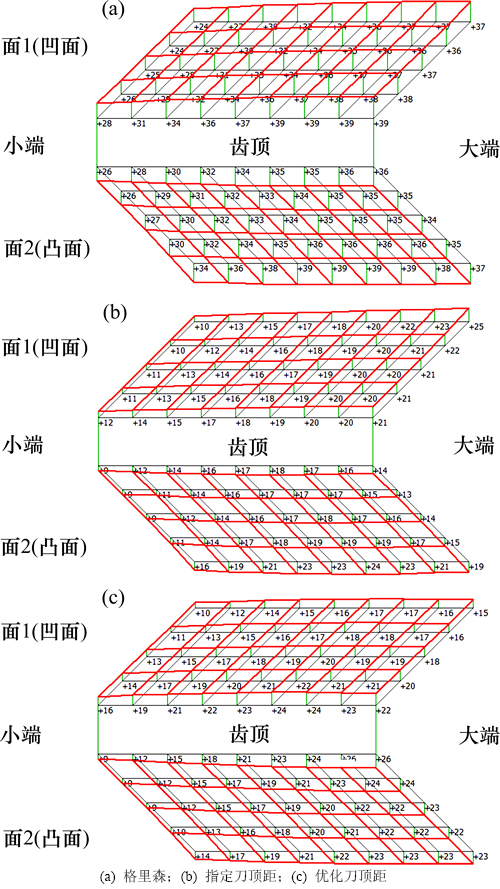

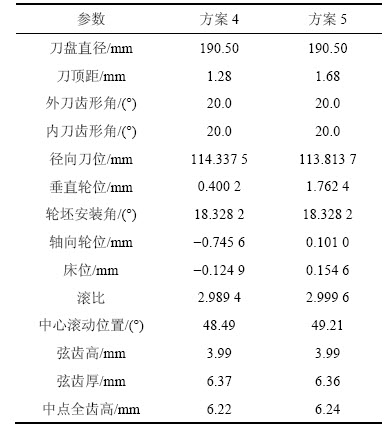

弧齿锥齿轮传统的5刀法中,分别有大轮粗切刀盘和小轮粗切刀盘,而在实际生产中,特别是中小型锥齿轮企业,为了减少刀盘规格直接用大轮粗切刀盘对小轮开槽。一般而言,大、小轮粗切刀盘的齿形角不同,通过调整大轮粗切刀盘的刀顶距和机床调整参数进行一定的补偿。表4所示为采用大轮粗切刀盘的小轮粗切切齿参数及检查尺寸,方案4为直接采用大轮粗切刀盘,方案5为优化大轮粗切刀盘的刀顶距,图4所示为两粗切方案对应的精切余量图。

从表3和图4可知:采用大轮刀盘粗切的中点全齿高较小;图4中,指定刀顶距的精切余量的均方根为0.022 7 mm,而优化刀顶距的精切余量的均方根为0.019 7 mm,两者均存在明显的齿形角误差。

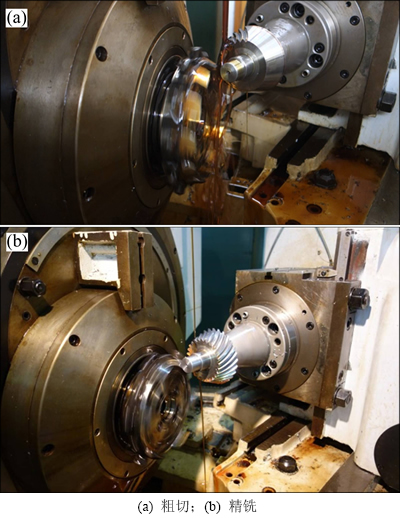

4.2 齿轮试切

小轮粗切、精铣切齿是在YKT2250螺旋锥齿轮铣齿机上进行的。小轮粗切方案是采用大轮粗切刀盘和优化刀顶距。粗切时分2次进给,床位分别为0.300 0 mm和0.154 6 mm,其余参数按表4中的方案5取值,完成粗切开槽,如图5(a)所示。小轮精切时分3次进给,凹面床位分别为1.300 0 mm,1.100 0 mm和0.899 9 mm,凸面床位分别为0.100 0 mm,-0.300 0mm和-0.497 6 mm,其余参数按表2设置,最终完成小轮精铣,如图5(b)所示。最后,对小轮的中点检查尺寸进行测量,中点测量结果:弦齿高3.99 mm,弦齿厚6.368 mm,全齿高6.235 mm,与计算结果基本吻合。

表4 小轮2种粗切参数及中点检查尺寸

Table 4 Two sets roughing parameters of pinion and tooth sizes at middle of face

图4 大轮粗切刀盘的精切余量(单位:μm)

Fig. 4 Finishing allowance with gear head-cutter

图5 小轮粗精加工

Fig. 5 Roughing and finishing of pinion

5 结论

1) 建立了弧齿锥齿轮小轮精切余量的最小二乘法优化模型,采用基于置信域策略的L-M迭代算法,反求出小轮粗切参数。

2) 将垂直轮位、轴向轮位和床位作为粗切参数,能够获得比Gleason粗切方法更均匀的精切余量。

3) 优化刀顶距能够取得较好的粗切效果;若采用大轮粗切刀盘对小轮粗切,则会产形明显的齿形角误差。

参考文献:

[1] ARGYRIS J, FUENTES A, LITVIN F L. Computerized integrated approach for design and stress analysis of spiral bevel gears[J]. Computer methods in applied mechanics and engineering, 2002, 191(11): 1057-1095.

[2] SHIH Y P. A novel ease-off flank modification methodology for spiral bevel and hypoid gears[J]. Mechanism and Machine Theory, 2010, 45(8): 1108-1124.

[3] ARTONI A, GABICCINI M, GUIGGIANI M, et al. Multi- objective ease-off optimization of hypoid gears for their efficiency, noise, and durability performances[J]. Journal of Mechanical Design, 2011, 133(12): 121007.

[4] LIU Guanglei, FAN Hongwei. Pinion tooth surface generation strategy of spiral bevel gears[J]. Chinese Journal of Mechanical Engineering, 2012, 25(4): 753-759.

[5] SU Jinzhan, FANG Zongde, CAI Xiangwei. Design and analysis of spiral bevel gears with seventh-order function of transmission error[J]. Chinese Journal of Aeronautics, 2013, 26(5): 1310-1316.

[6] TANG Jinyuan, HU Zehua, WU Lijuan. et al. Effect of static transmission error on dynamic responses of spiral bevel gears[J]. Journal of Central South University, 2013, 20(3): 640-647.

[7] 张金良, 方宗德, 杨建军, 等. 准双曲面齿轮的小轮粗切过切检验[J]. 机械科学与技术, 2006, 25(7): 781-783.

ZHANG Jinliang, FANG Zongde, YANG Jianjun, et al. Overcutting test of the rough-machining of hypoid gears[J]. Mechanical Science and Technology, 2006, 25(7): 781-783.

[8] LI J G, MAO S M, HE J L, et al. Optimization of pinion roughing of spiral bevel and hypoid gear[J]. Proceedings of the Institution of Mechanical Engineers Part C: Journal of Mechanical Engineering Science, 2006, 220(4): 483-488.

[9] 曾韬. 螺旋锥齿轮设计与加工[M]. 哈尔滨: 哈尔滨工业大学出版社, 1989: 152-155.

ZENG Tao. Spiral bevel gear design and processing[M]. Harbin: Harbin Institute of Technology Press, 1989: 152-155.

[10] 北京齿轮厂. 螺旋锥齿轮[M]. 北京: 科学出版社, 1974: 229-281.

Beijing Gear Factory. Spiral bevel gear[M]. Beijing: Science Press, 1974: 229-281.

[11] ARTONI A, GABICCINI M, GUIGGIANI M. Nonlinear identification of machine settings for flank form modifications in hypoid gears[J]. Journal of Mechanical Design, 2008, 130(11): 1671-1676.

[12] ARTONI A, GABICCINI M, GUIGGIANI M. Synthesis of hypoid gear surface topography by a nonlinear least squares approach[C]// 2007 Proceedings of the ASME International Design Engineering Technical Conference and Computer and Information in Engineering Conference. Las Vegas: American Society of Mechanical Engineers, 2007: 79-88.

[13] GABICCINI M, ARTONI A, GUIGGIANI M. On the identification of machine settings for gear surface topography corrections[J]. Journal of Mechanical Design, 2012, 134(4): 041004.

[14] 苏进展, 贺朝霞. 弧齿锥齿轮齿面的高精度修形方法[J]. 华南理工大学学报(自然科学版), 2014, 42(4): 91-96.

SU Jinzhan, HE Zhaoxia. High-precision modification of tooth surface for spiral bevel gears[J]. Journal of South China University of Technology (Natural Science Edition), 2014, 42(4): 91-96.

[15] 蔡香伟, 方宗德. 弧齿锥齿轮机床加工参数逆向求解的算法研究[J]. 机械传动, 2015, 39(3): 5-8.

CAI Xiangwei, FANG Zongde. Research of inversion algorithm of machine-tool machining parameter for spiral bevel gear[J]. Journal of Mechanical Transmission, 2015, 39(3): 5-8.

(编辑 赵俊)

收稿日期:2016-03-07;修回日期:2016-05-12

基金项目(Foundation item):国家自然科学基金资助项目(51205310,51375384);陕西省自然科学基金资助项目(2015JQ5162);中央高校基本科研业务费专项资金资助项目(310825171003) (Projects(51205310, 51375384) supported by the National Natural Science Foundation of China; Project(2015JQ5162) supported by the Natural Science Foundation of Shannxi Province; Project(310825171003) supported by the Fundamental Research Funds for the Central Universities)

通信作者:苏进展,博士,副教授,从事齿轮传动技术研究;E-mail: sujinzhan@chd.edu.cn