热处理制度对7039铝合金抗腐蚀性能的影响

蔡一鸣1,梁霄鹏2,李慧中2,汤国建1

(1. 国防科技大学 航天与材料工程学院,湖南 长沙,410073;

2. 中南大学 材料科学与工程学院,湖南 长沙,410083)

摘 要:采用拉伸力学性能测试、金相显微观察、扫描电镜及透射电镜等分析手段,研究不同热处理制度下7039铝合金的力学性能及其在腐蚀液中浸泡后的腐蚀形貌。结合不同热处理制度后合金的腐蚀形貌与晶界析出相形貌,建立该系列合金晶界析出相形貌与腐蚀形貌的关系的示意模型。结果表明:在保持与T6处理的合金强度相当的基础上,经RRA处理可使抗腐蚀性能明显提高;在腐蚀液中浸泡腐蚀后,T6和RRA处理的合金表面呈成块状剥落腐蚀的现象,T73处理的合金呈点状腐蚀现象;T6处理后合金的纵向和横向最大腐蚀深度分别为378.53 μm和31.91 μm;T73处理的合金纵向和横向腐蚀深度分别为19.21 μm和8.07 μm;RRA处理的合金纵向和横向腐蚀深度分别为178.15 μm和15.38 μm。

关键词:7039铝合金;热处理;抗腐蚀性能;显微组织

中图分类号:TG146.2 文献标志码:A 文章编号:1672-7207(2009)06-1540-06

Effect of heat treatment on corrosion resistance of 7039 aluminum alloy

CAI Yi-ming1, LIANG Xiao-peng2, LI Hui-zhong2, TANG Guo-jian1

(1. College of Aerospace and Material Engineering, National University of Defense Technology, Changsha 410073, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The mechanical properties and microstructures after soak corrosion of 7039 aluminum alloy were investigated by means of tensile test, optical microscopy (OM), scanning electron microscopy (SEM) and transmission electron microscopy (TEM). Combining with the microstructure of corrosion and grain boundary precipitate after different heat treatments, the model of relationship between precipitate microstructure and that of corrosion was established. The results show that the RRA treatment can remarkably increase the corrosion resistance while maintain tensile performance is as the same as that of T6 treatment. After eroded in the corrosion solution, the surface microstructures of the T6 treatment alloy and RRA treatment alloy show block exfoliation erosion and that of T73 treatment alloy shows pit corrosion. The greatest longitudinal and crosswise depth of corrosion are 378.53 μm and 31.91 μm after T6 treatment, 19.21 μm and 8.07 μm after T73 treatment, and 178.15 μm and 15.38 μm after RRA treatment, respectively.

Key words: 7039 aluminum alloy; heat treatment; corrosion resistance; microstructures

7039铝合金是一种中高强Al-Zn-Mg系铝合 金,该合金具有优良的焊接性能、抗弹性能以及较好的加工成型性,作为炮架和装甲结构件被广泛应 用[1-3]。Al-Zn-Mg系合金与其他铝合金相比,虽然强度较高,但是其抗腐蚀性能较差,在一定程度上制约了其应用。近年来,人们就提高该系列合金的抗腐蚀性能进行了大量的研究,如:李松等[4]对LC52铝合金和仿7039铝合金进行了研究,发现高温近固溶温度下的晶界预析出,可提高合金时效状态的综合性能,特别是抗应力腐蚀性能,而强度降低不大;李松等[4]还研究了高温预析出对自然时效状态铝合金的应力腐蚀抗力的影响,进一步探讨了高温预析出处理的适用范围[5];林高用等[6]研究了不同热处理制度对LC52铝合金组织和抗腐蚀性能的影响,并对其影响机理进行解释,认为合金的极化电阻越大,合金的抗剥落腐蚀性能越好。大量的研究结果表明:回归再时效(Retrogression and re-ageing treatment,RRA)可以在保持Al-Zn-Mg系铝合金强度不降低的前提下提高其抗应力腐蚀性能[7-9]。在此,本文作者以7039铝合金为基础,研究了不同热处理制度(T6,T73和RRA)对合金在腐蚀液中浸泡时的腐蚀性能,分析不同热处理制度与合金抗腐蚀性能之间的关系,并建立晶界析出相的形貌与腐蚀机理的关系模型。

1 实 验

1.1 材料制备

试验合金的化学成分为(质量分数):0.30% Si,0.40% Fe,4.50% Zn,3.30% Mg,0.15% Cu,0.25% Mn,0.20% Zr,0.10% Ti,余量为Al。将厚度为3 mm的热轧板于箱式电阻炉中进行490 ℃/1 h固溶处理,随后淬于25 ℃的水中,淬火转移时间小于3 s,然后,分别进行以下3种时效处理:T6处理,即120 ℃/24 h;T73处理,即120 ℃/4 h+160 ℃/20 h;RRA处理,即120 ℃/24 h+180 ℃/45 min+120 ℃/24 h。

1.2 实验方法

拉伸试验在CSS-44100电子拉伸机上进行。沿板材的轧向平行选取5个试样,各测试结果均取平均值。晶间腐蚀按照GB 7998—87标准对不同热处理制度的合金取样,其长×宽×高为25 mm×20 mm×2 mm。先用金相砂纸打磨各面,并机械抛光,计算各试样的表面积,按照面容比为100 cm2/L的比例垂直悬挂于0.5 mol/L NaCl+0.1 mol/L HCl的腐蚀溶液中24 h,溶液温度保持在(35±1) ℃,腐蚀产物用5%稀硝酸和清水清洗。将试样沿轧制的纵向和横向分别距各自的边缘5 mm处取样进行水磨和抛光,在Sirion200场发射扫描电镜上观察腐蚀深度与腐蚀试样表面形貌。

在XJP-6A金相显微镜上观察金相试样。将透射试样先用机械方法减薄成厚度为0.1 mm的薄片,然后,在MIT-Ⅱ型双喷电解仪上用30% HNO3+ 70% CH3OH(体积比)溶液双喷减薄,采用液氮冷却,双喷温度为-25 ℃,电压为10~20 V,电流为80~100 mA,在TecnaiG220型透射电镜上对合金组织进行分析。

2 实验结果

2.1 拉伸力学性能

不同热处理制度下合金的拉伸力学性能如表1所示。由表1可以看出:经T6处理的合金具有较高的强度与伸长率,其抗拉强度σb,屈服强度σ0.2,伸长率δ分别为485 MPa,416 MPa和14.6%;经T73处理后的合金其抗拉强度较T6处理的合金低23 MPa,伸长率低2.8%;经RRA处理后的合金的抗拉强度较T6处理其合金略降低(3 MPa),但远高于经T73处理的合金的抗拉强度,伸长率为11.0%,与经T73处理的合金的伸长率相当(0.8%)。

表1 合金的拉伸力学性能

Table 1 Machanical properties of alloys

2.2 金相组织

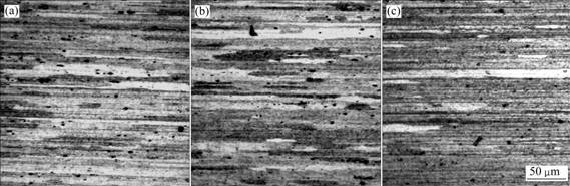

图1所示为不同热处理状态的各合金的金相组织。由图1可以看出,经时效处理后各合金的组织依然呈现加工态的纤维状组织,晶粒沿着变形方向被拉长。

(a) T6;(b) T73;(c) RRA

图1 合金的金相组织

Fig.1 Optical microstructures of alloys

2.3 表面腐蚀形貌

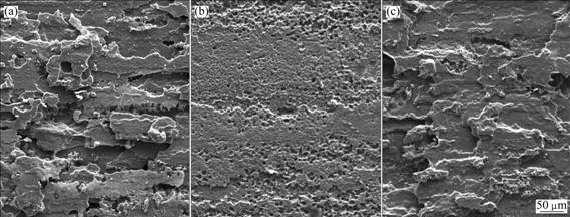

在不同热处理制度下,合金在腐蚀液中浸泡24 h后的表面腐蚀形貌如图2所示。由图2可以看出:经T6和RRA处理后的合金腐蚀后表面金属呈成块剥落的迹象(图2(a)和图2(c)),同时,经T6处理的合金腐蚀深度和剥落面积均比经RRA处理的合金大;经T73处理的合金表面呈现腐蚀坑的现象而非剥落迹象(图2(b)),这些腐蚀坑是由于第二相粒子经腐蚀剥落后留下的。说明经T6和RRA处理的合金表面出现基体的腐蚀剥落,而经T73处理的合金出现第二相的腐蚀剥落。

(a) T6;(b) T73;(c) RRA

图2 合金的表面腐蚀形貌

Fig.2 Surface microstructures of alloys after corrosion

2.4 晶间腐蚀

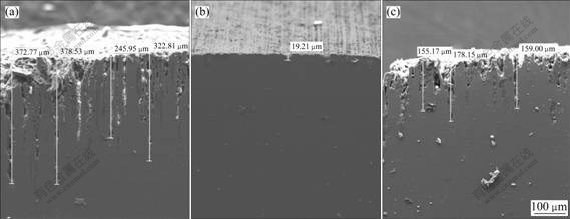

图3所示为不同热处理制度的合金在腐蚀液中浸泡后的纵向腐蚀形貌。由图3可以看出:经T6处理后的合金最大腐蚀深度为378.53 μm,平均腐蚀深度为245.95~378.53 μm(图3(a)),表现出比较严重的晶间腐蚀形貌;经T73处理的合金只在合金的边缘产生深度为19.21 μm的腐蚀坑(图3(b)),表现出良好的抗晶间腐蚀能力;经RRA处理的合金其最大腐蚀深度为178.15 μm,平均腐蚀深度为155.17~178.15 μm(图3(c)),其抗晶间腐蚀能力与经T6处理的合金相比有较大提高。

(a) T6;(b) T73;(c) RRA

图3 合金的纵向晶间腐蚀形貌

Fig.3 Longitudinal microstructures of alloys after intergranular corrosion

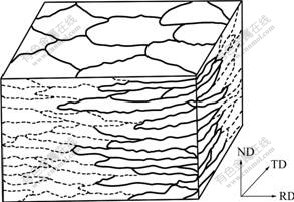

图4所示为不同热处理制度的合金在腐蚀液中浸泡后的横向腐蚀形貌。由图4可见:各种热处理制度的合金其横向腐蚀深度的规律与纵向腐蚀深度的规律相同,均为由T6处理制度的腐蚀深度最大,经RRA处理的腐蚀深度次之,经T73处理的腐蚀深度最小。其中,经T6处理的合金的横向腐蚀深度为31.91 μm (图4(a)),经T73处理的合金横向腐蚀深度为8.07 μm (图4(b)),经RRA处理的合金横向腐蚀深度为15.38 μm(图4(c))。同时,各热处理状态的合金其纵向腐蚀深度较横向腐蚀深度深,这主要是由于各合金的组织为纤维组织(图1),在腐蚀液中浸泡时,腐蚀是沿着晶界进行的,变形时纵向变形量远大于横向变形量,使得合金的晶粒纵向的变形程度大,晶粒被拉得更长,从而导致纵向腐蚀深度大。合金在腐蚀液中浸泡时的腐蚀情况如图5所示,其中,实线部分表示已被腐蚀的晶界,虚线部分表示未被腐蚀的晶界。当合金在腐蚀液中浸泡时,腐蚀沿着晶界进行,合金表面呈扁平的组织,腐蚀时将沿着晶界成块剥落,沿轧制方向的晶粒长度较宽展方向的长,腐蚀深度较大。

(a) T6;(b) T73;(c) RRA

图4 合金的横向晶间腐蚀形貌

Fig.4 Crosswise microstructures of alloys after intergranular corrosion

图5 合金腐蚀示意图

Fig.5 Sketch of alloy corrosion

2.5 透射电镜观察

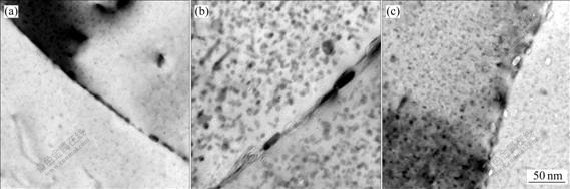

图6所示为不同热处理制度的合金的TEM形貌。

(a) T6;(b) T73;(c) RRA

图6 合金的TEM形貌

Fig.6 TEM images analysis of alloys

由图6可以看出:经T6处理的合金晶界析出相呈链状分布,晶内的析出相呈均匀、细密分布(图6(a));经T73处理后,合金的组织与T6处理的组织有明显不同,晶内析出的η′相尺寸明显增大,数量减少,晶界析出物长大、球化,呈不连续分布,同时,有明显的无沉淀析出带(PFZ)(图6(b));经RRA处理的合金,晶内的析出相比T73处理的析出相小,呈细小弥散分布,与T6处理时的晶内组织相似;晶界析出的η相与T73处理的η相相似,呈不连续的球化分布,无沉淀析出带不明显。

3 分析与讨论

Al-Zn-Mg-Cu系合金时效过程通常为:α固溶体→GP区→η′过渡相→η稳定相(Zn2Mg)[13],这一沉淀过程是呈连续变化的。通常,经T6处理后,晶内析出相以与基体共格的GP区为主,并含有少量与基体部分共格的η′。而晶界上析出连续分布的η相,无沉淀析出带(PFZ)很窄(如图6(a)),经T73处理后,合金实际上处于过时效状态,晶界析出的平衡相η相粗大且不连续分布,PFZ较宽。晶内的析出相也以与基体不共格的η相为主,由于析出相粗大,使得析出相之间的距离增大,对位错运动时的钉扎作用减弱,因而导致合金强度降低。对于RRA处理的合金,当进行回归处理时,由于回归温度较低(180 ℃),大部分GP区并不发生溶解,而是向η′相转变,只有少部分尺寸小于临界值的GP区发生回溶,晶界析出的η′相一部分继续长大,一部分向η相转变。再进行时效处理时,回归形成的溶质原子在GP区以η′相重新析出,回归后形成的η′相大部分保留,少部分向η相转变,最终晶内形成以η′为主,少量GP区和η相共存的组织,但析出相的尺寸比T6处理的合金的析出相粗大,晶界的η相一直长大导致其呈不连续球状分布,形成与T73处理的合金相似的晶界析出相形貌(见图6(c))。尽管经RRA处理的合金中析出η相,且GP区和η′相的尺寸也较大,但是其强度仅比经T6处理的合金低3 MPa,这主要是由于合金中η′相数量增多,而η′相具有比GP区更明显的强化作用[11-13],从而弥补了由于η相的形成及η′相的粗化造成的强度损失。

高强铝合金腐蚀一般是沿晶界扩展的,晶界性质以及晶界析出相的尺寸和分布的连续性对合金抗腐蚀性能有重要影响。由于晶界处的析出相,PFZ以及基体之间存在电极电位差,根据文献[14],高强铝合金中晶界析出相η相的电极电位为-0.86 V,PFZ的电极电位为-0.57 V,基体晶粒的电极电位为-0.68 V,三者之间的电位差导致合金在腐蚀液中浸泡时,在局部形成为电池。由于析出相的电位最负,使之成为阳极,阳极逐渐溶解使腐蚀沿着析出相向周围扩展。当晶界的析出物不连续分布时,在一定程度上阻断了腐蚀通路,腐蚀只能在析出相周围进行,直到将析出物腐蚀脱落为止,使材料表现为一个个腐蚀坑(如图2(b)所示);当晶界析出物连续分布时,会使整个晶粒的晶界成为一个腐蚀通路,使材料表现为沿着整个晶粒的晶界剥落。

合金晶界析出物的形态与沿晶界腐蚀的过程如图7所示,图中箭头方向表示腐蚀方向。晶界析出物不连续分布时,可以认为每一个析出相与周围基体形成一个单独的腐蚀单元,当析出相腐蚀脱落后,该腐蚀单元的腐蚀完成,可以近似认为是点腐蚀;当晶界析出物连续分布时,多个析出相与其周围的基体形成一个大的腐蚀单元,使得腐蚀进程延长,更容易使其与相邻的腐蚀单元连通;当整个晶界上的腐蚀单元连通后,晶粒就会整块脱落,可以认为这种腐蚀是面腐蚀。

(a) 晶界析出物不连续分布;(b) 晶界析出物连续分布

图7 晶界析出物形态与腐蚀过程的关系模型

Fig.7 Models of relationship between precipitation and corrosion process

4 结 论

a. 7039铝合金经RRA处理后的抗拉强度和T6处理的抗拉强度接近,比T73处理的抗拉强度高 20 MPa,在3种热处理状态下,合金的抗拉强度关系为σb(T6)≈σb(RRA)>σb(T73)。

b. 不同热处理的7039铝合金在腐蚀液中浸泡腐蚀后,T6和RRA处理的合金表面呈成块腐蚀剥落的形貌,T73处理的合金呈点状腐蚀形貌。

c. T6处理后合金在腐蚀液中浸泡后的纵向和横向最大腐蚀深度分别为378.53 μm和31.91 μm,T73处理的分别为19.21 μm和8.07 μm,RRA处理的分别为178.15 μm和15.38 μm。

参考文献:

[1] Leech P W. Observations of adiabatic shear band formation in 7039 aluminum alloy[J]. Metallurgical and Materials Transactions A, 1985, 16(10): 1900-1903.

[2] 刘 瑛, 张新明, 李慧中, 等. 3种高强铝合金的低温拉伸力学性能研究[J]. 金属热处理, 2007, 32(1):53-56.

LIU Ying, ZHANG Xin-ming, LI Hui-zhong, et al. Tensile properties of three kinds of aluminum alloys at low temperature[J]. Heat Treatment of Metals, 2007, 32(1): 53-56.

[3] 黄兰萍, 陈康华, 李 松, 等. 高温预析出对Al-Zn-Mg 铝合金组织、力学性能和应力腐蚀性能的影响[J]. 中国有色金属学报, 2005, 15(5): 727-733.

HUANG Lan-ping, CHEN Kang-hua, LI Song, et al. Effect of high- temperature pre-precipitation on micro- structure, mechanical property and stress corrosion cracking of Al-Zn-Mg aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(5): 727-733.

[4] LI Song, CHEN Kang-hua, LIU Hong-wei, et al. Effect of high-temperature pre-precipitation on mechanical properties and stress corrosion cracking of Al-Zn-Mg alloys[J]. Transactions of Nonferrous Metals Society of China, 2003, 13(3): 585-589.

[5] 陈康华, 黄兰萍, 郑 强, 等. 高温预析出对7A52合金应力腐蚀性能的影响[J]. 中国有色金属学报, 2005, 15(3): 441-445.

CHEN Kang-hua, HUANG Lan-ping, ZHENG Qiang, et al. Effect of high-temperature pre-precipitation on stress corrosion cracking of 7A52 alloy[J]. Transactions of Nonferrous Metals Society of China, 2005, 15(3): 441-445.

[6] 林高用, 张 颖, 杨立斌, 等. 时效制度对LC52铝合金组织与性能的影响[J]. 金属热处理, 2004, 29(10): 32-35.

LIN Gao-yong, ZHANG Ying, YANG Li-bin, et al. Effects of ageing treatment on structure and properties of LC52 aluminum alloy[J]. Heat Treatment of Metals, 2004, 29(10): 32-35.

[7] Srivatsan T S, Sriram S, Veeraraghavan D, et al. Microstructure, tensile deformation and fracture behavior of aluminum alloy 7055[J]. Journal of Materials Science, 1997, 32(11): 2883-2894.

[8] 张 坤, 刘志义, 郑青春, 等. 高Zn超高强铝合金的回归再时效处理[J]. 中南大学学报: 自然科学版, 2005, 36(2): 188-192.

ZHANG Kun, LIU Zhi-yi, ZHENG Qing-chun, et al. Effects of different retrogression and reaging heat treatment on high-zinc super-high aluminum alloy[J]. Journal of Central South University: Science and Technology, 2005, 36(2): 188-192.

[9] Gazda A, Warmuzek M, Wierzchowski W. DTA investigation of the retrogression and re-ageing in some AlZnMgCu alloys[J]. Thermochimica Acta, 1997, 303(2): 197-202.

[10] Loeffler H, Kovacs I, Lendvai J. Decomposition processes in Al-Zn-Mg alloys[J]. Journal of Materials Science, 1983, 18(8): 2215-2240.

[11] 华明建, 李春志, 王鸿渐. 微观组织对7075铝合金的屈服强度和抗应力腐蚀性能的影响[J]. 金属学报, 1988, 24(1): 46-51.

HUA Ming-jian, LI Chun-zhi, WANG Hong-jian. Effect of microstructures on the yield strength and SCC of 7075 aluminum alloy[J]. Acta Metallurgica Sinica, 1988, 24(1): 46-51.

[12] 李 海, 郑子樵, 王芝秀. 热处理制度对含Ag的7075铝合金断裂特征的影响[J]. 稀有金属材料与工程, 2005, 34(4): 612-616.

LI Hai, ZHENG Zi-qiao, WANG Zhi-xiu. Influence of heat treatment regime on microstructures and fracture characteristics of 7055 aluminum alloy containing Ag[J]. Rare Metal Materials and Engineering, 2005, 34(4): 612-616.

[13] Najjar D, Magnin T, Warner T J. Influence of critical surface defects and localized competition between anodic dissolution and hydrogen effects during stress corrosion cracking of a 7050 aluminum alloy[J]. Materials Science and Engineering A, 1997, 238(2): 293-302.

[14] 王祝堂, 田荣璋. 铝合金及其加工手册[M]. 长沙: 中南大学出版社, 2000.

WANG Zhu-tang, TIAN Rong-zhang. Handbook of aluminium alloy and its working[M]. Changsha: Central South University Press, 2000.

收稿日期:2009-01-25;修回日期:2009-04-09

基金项目:国家自然科学基金资助项目(50671121);湖南省科技计划项目(2009GK3038)

通信作者:李慧中(1968-),男,湖南衡阳人,博士,副教授,从事高强高韧铝合金研究;电话:0731-88830377;E-mail: lhz606@mail.csu.edu.cn