文章编号:1004-0609(2008)10-1775-06

7039铝合金高温的热变形行为

蔡一鸣1,李慧中2, 3,梁霄鹏2, 3,汤国建1

(1. 国防科技大学 航天与材料工程学院,长沙 410073;

2. 中南大学 材料科学与工程学院,长沙 410083;

3. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083)

摘 要:采用圆柱试样在Gleeble-1500材料热模拟实验机上对7039铝合金进行高温等温压缩实验,研究了该合金在变形温度为300~500 ℃,应变速率为0.01~10 /s条件下的流变变形行为。结果表明:变形温度和应变速率对合金流变应力的大小有显著影响,流变应力随变形温度的升高而降低,随应变速率的增加而升高;在应变速率 <10 /s条件下合金表现出动态回复特征,而应变速率

<10 /s条件下合金表现出动态回复特征,而应变速率 =10 /s时,合金发生了局部动态再结晶。7039铝合金的高温流变行为可用Zener-Hollomon参数描述。从流变应力、应变速率和变形温度的相关性,得出了该合金高温变形时的四个材料常数。

=10 /s时,合金发生了局部动态再结晶。7039铝合金的高温流变行为可用Zener-Hollomon参数描述。从流变应力、应变速率和变形温度的相关性,得出了该合金高温变形时的四个材料常数。

关键词:7039铝合金;热压缩变形;流变应力;Zener-Hollomon参数;变形激活能

中图分类号:TG 146.2 文献标识码: A

Thermal deformation behavior for 7039 aluminum alloy at elevated temperature

CAI Yi-ming1, LI Hui-zhong2, 3, LIANG Xiao-peng2, 3, TANG Guo-jian1

(1. College of Aerospace and Material Engineering, National University of Defense Technology,

Changsha 410073, China;

2. School of Materials Science Engineering, Central South University, Changsha 410083, China;

3. Key Laboratory of Nonferrous Materials, Ministry of Education, Central South University, Changsha 410083, China)

Abstract: The flow stress features of 7039 aluminum alloy were studied by isothermal compression of cylindrical specimen at 300-500 ℃ and strain rate of 0.01-10 /s with Gleeble-1500 simulated machine. The results show that the flow stress is controlled by strain rate and deformation temperature. The flow stress increases with strain rate increasing and decreases with deformation temperature increasing. The 7039 aluminum alloy shows the phenomenal of dynamic recovery at the strain rates less than 10 /s; the alloy shows the phenomenal of partial dynamic recrystallization at the strain rates higher than 10 /s. The flow stress of 7039 aluminum alloy during high temperature deformation can be represented by Zener-Hollomon parameter. Four material constants of the alloy during plastic deformation at high temperature are derived from the interdependencies of flow stress, strain rate and temperature.

Key words: 7039 aluminum alloy; hot compression deformation; flow stress; Zener-Hollomon parameter; thermal deformation activation energy

7039铝合金是美国研制的一种中高强Al-Zn-Mg系铝合金,该具有优良的焊接性能与抗弹性能以及较好的加工成型性,目前作为炮架和装甲结构件被广泛应用[1-4] 。对该系列合金在焊接及抗应力腐蚀方面的研究已有报道[5-6]。流变应力是表征金属与合金塑性变形性能的一个最基本量,在实际塑性变形过程中,合金的流变应力值决定了变形时所需施加的载荷大小和所需消耗能量的多少[7]。对Al-Zn-Mg系铝合金热变形行为方面的研究已有较多的报道,CERRI等[8]对经不同预处理后的7012和7075铝合金的热加工性能进行了对比研究,并建立了相应的本构方程模型,林高用等[9]利用热模拟实验建立了7075铝合金的热变形流变应力方程。而对7039铝合金热加工流变应力行为的研究还未见报道。本文作者在Gleeble-1500热模拟试验机上对7039铝合金圆柱试样进行等温压缩,研究热变形时的流变应力与变形温度、应变速率的关系,采用一元线性回归法建立模型,并对热变形过程中的组织演化规律进行了分析,为优化该合金的热加工工艺提供理论依据。

1 实验

实验合金的化学成分(质量分数,%)为0.30Si、0.40Fe、4.50Zn、3.30Mg、0.15Cu、0.25Mn、0.20Zr、0.10Ti,余量为Al。将合金铸锭在460 ℃,均匀化退火24 h后加工成尺寸为d 10 mm×15 mm,两端带有d 8 mm×0.2 mm凹槽的Rastegaev的样品[10]。

将加工好的试样在Gleeble-1500材料热模拟试验机上进行等温压缩实验。压缩温度为300~500 ℃,应变速率为0.01~10/s,总压缩量为0.7(变形程度为50%),样品采用热模拟机电阻加热,升温速度为2 ℃/s,压缩前保温3 min,试样两端的凹槽内填充75%石墨+20%机油+5%硝酸三甲苯脂,以减少摩擦对应力的影响。压缩后的样品迅速水冷到室温以保留热变形时的组织,在TecnaiG220型透射电镜下对组织进行分析,样品先用机械方法减薄至0.1 mm的薄片,然后在MIT-Ⅱ型双喷电解仪上用30%HNO3+70%CH3OH(体积比)溶液双喷减薄,采用液氮冷却,双喷温度为-25 ℃,电压10~20 V,电流为80~100 mA。

2 实验结果

2.1 真应力—真应变曲线

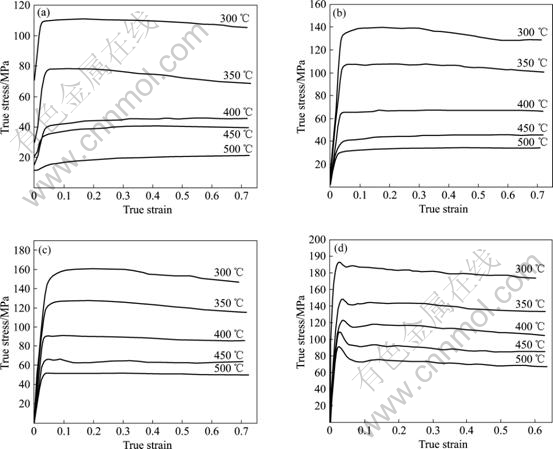

图1所示为7039铝合金热压缩变形时的真应力—真应变关系曲线。由图1可以看出合金在温度为300~500 ℃,应变速率为0.01~10 /s的变形条件范围内,合金存在明显的稳态流变特征,即当合金的变形小于一定的应变速率和变形温度时,真应力随着真应变的增大而迅速增大,当超过一定的变形条件范围时,真应变的增加对真应力变化的影响不大。在同一应变速率下,流变应力随着变形温度的升高而降低;在同一变形温度下,流变应力随着应变速率的增大而增大,说明在该实验条件下该合金具有正的应变速率敏感 性[11],即应变速率越大,温度越低,合金达到稳态变形越困难。当应变速率为10 /s时,合金变形时的应力—应变曲线上出现波浪峰,并且随着变形温度的升高,该波浪峰表现得越明显,该波浪形的出现是材料发生动态再结晶的表现[12]。

图1 7039铝合金热变形的正应力—真应变曲线

Fig.1 True stress-true strain curves of 7039 Aluminum alloy by hot compression: (a) 0.01 /s; (b) 0.1 /s; (c) 1 /s; (d) 10 /s

2.2 组织分析

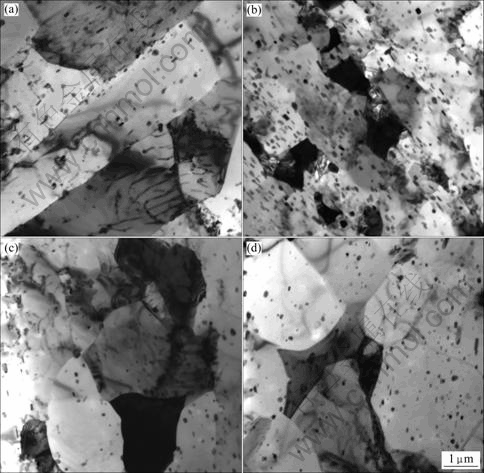

不同热变性条件下合金的透射电子显微组织如图2所示。合金在高温(500 ℃)变形时:当应变速率为0.01 /s时,组织中晶粒被拉长,位错在晶界聚集形成了平行的位错墙,这些位错墙为亚晶的形成提供了能量(图2(a));当应变速率为0.1 /s时,出现大量的亚晶组织,同时在晶界处有位错塞积(图2(b)),说明该条件下合金主要发生动态回复;在应变速率为10 /s时,亚晶合并已经完成,组织中晶界平直,清晰,由亚晶合并形成的晶粒内位错密度很低(图2(c)),说明此条件下发生了动态再结晶。而应变速率为10 /s, 变形温度为300 ℃时,合金发生了局部的动态再结晶,晶内的位错密度比500 ℃变形时高,这与图1(d)中300 ℃时的应力峰较500 ℃时的应力峰低是一致的。由以上的组织分析和图1所示的应力—应变关系可知,合金在应变速率为10 /s,变形温度大于300 ℃时,发生了动态再结晶。

图2 不同变形条件下合金的TEM组织

Fig.2 TEM microstructures of specimens after compressed under different conditions: (a) 500 ℃, 0.01/s; (b)500 ℃, 0.1/s; (c) 300 ℃, 10/s; (d) 500 ℃, 10/s

2.3 本构方程模型

金属的热变形和高温蠕变行为类似,都是一个受热激活控制的过程,因此金属的热变形可用高温蠕变时的应力—应变关系式进行描述,及变形过程中的应变速率 和温度T之间的关系可用Zener-Hollomon参数Z表示[7, 13]:

和温度T之间的关系可用Zener-Hollomon参数Z表示[7, 13]:

式中 σ为高温流变应力, 为应变速率,ε为真应变,T为变形温度,R为摩尔气体常数,Z为Zener-Hollomon参数,Q为热变形激活能,它反映材料热变形的难易程度,是材料在热变形过程中的重要参数。

为应变速率,ε为真应变,T为变形温度,R为摩尔气体常数,Z为Zener-Hollomon参数,Q为热变形激活能,它反映材料热变形的难易程度,是材料在热变形过程中的重要参数。

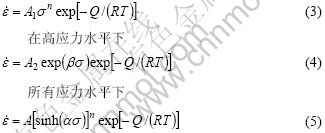

研究表明[14-16],Z与σ服从以下关系:

在低应力水平下

式中 A1、A2、A、α、β、n均为与温度无关的常数,且α、n、β满足:α=β/n。

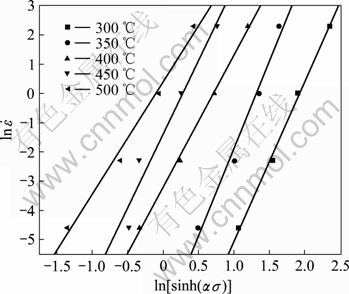

对式(3)和(4)两边取对数可知,当温度一定时,n和β分别为 —

— 和

和 —

— 曲线的斜率,采用一元线性回归处理,可得

曲线的斜率,采用一元线性回归处理,可得 —

— 和

和 —

— 的关系曲线,分别如图3(a)和图3(b)所示。

的关系曲线,分别如图3(a)和图3(b)所示。

由图3中的各温度下一元线性回归得到的斜率n和β可计算出不同温度下的α。

图3 应变速率与流变应力的关系

Fig.3 Relationships between strain rate and flow stress: (a)  —

— ; (b)

; (b)  —σ

—σ

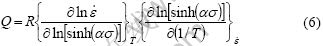

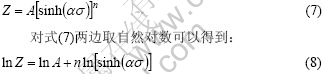

对式(5)两边取自然对数的微分可得:

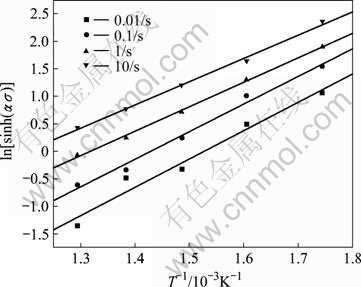

由式(6)可见,式中的第一项代表 —

— 关系曲线的斜率;第二项代表

关系曲线的斜率;第二项代表 —

— 关系曲线的斜率。将合金压缩变形时各变形条件下的峰值应力和不同温度下求得的α代入

关系曲线的斜率。将合金压缩变形时各变形条件下的峰值应力和不同温度下求得的α代入 ,对应相应的应变速率和温度,用线性回归绘制出

,对应相应的应变速率和温度,用线性回归绘制出 —

— 关系曲线(图4)和

关系曲线(图4)和 —

— 关系曲线(图5)。将所得斜率代入式(6),可得不同变形温度下的变形激活能,取其平均值为Q=202.6 kJ/mol。

关系曲线(图5)。将所得斜率代入式(6),可得不同变形温度下的变形激活能,取其平均值为Q=202.6 kJ/mol。

图4 流变应力与变形温度的关系

Fig.4 Relationships between flow stress and deformation temperature

图5 变形速率与流变应力的关系

Fig.5 Relationships between strain rate and flow stress

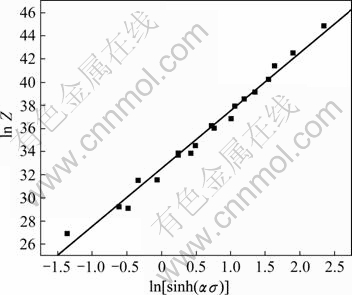

将式(5)代入式(2)可以得到:

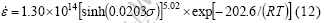

将所求的变形激活能Q=202.6 kJ/mol和不同变形温度下对应的应变速率代入式(2)可以得到不同的Z值,再与对应的α和峰值应力一起代入式(8),绘制出相应的 —

— 关系曲线,如图6所示。可见ln A和n分别为

关系曲线,如图6所示。可见ln A和n分别为 —

— 关系曲线中的截距和斜率,可得n=5.02,A=1.30×1014/s。由图3(b)可知:5条直线回归所得的斜率偏差很小,可认为β值是相同的,其平均值为β=0.101 8,将由图6所得的n=5.02代入α=β/n可得α=0.020 3/MPa。

关系曲线中的截距和斜率,可得n=5.02,A=1.30×1014/s。由图3(b)可知:5条直线回归所得的斜率偏差很小,可认为β值是相同的,其平均值为β=0.101 8,将由图6所得的n=5.02代入α=β/n可得α=0.020 3/MPa。

图6 流变应力与Z参数的关系

Fig.6 Relationship between Zener-Hollomon parameter and flow stress

将求得的Q、n、A和α等材料参数代入式(5),可得实验的应力—应变本构方程:

3 分析与讨论

由图1和式(12)可以看出,金属在高温压缩变形时,流变应力主要取决于应变速率和变形温度,真应变只在变形的极短时间内有影响,合金经历很小的应变即会达到峰值,然后进入稳态流变阶段,此时的流变应力完全取决于应变速率和变形温度。

7039铝合金的塑性变形行为与变形体内的位错密度紧密相关,在变形的开始阶段,随着应变量的增加,位错密度迅速增加,导致流变应力迅速增大,流变应力的增大同时为位错的起动提供了大量的能量,两者相互的促进作用导致了合金的流变应力迅速达到峰值;流变应力达到峰值以后,合金内部表现为加工硬化和动态软化相互作用的过程,加工硬化是由于外应力的作用下合金的体内的位错相互交割、缠绕,而导致位错运动受阻,在局部形成位错团或位错包。动态软化则是使位错密度的降低和位错重新排列成低能量状态的组织。流变应力达到稳态时的实质是位错的增值和位错间相互销毁和重组达到动态平衡,表现为强烈的动态回复。

合金在高应变速率下变形时,其应力—应变曲线上出现波浪形的峰值应力,主要是因为在高应变速率下变形时,变形的时间很短,螺形位错的交滑移和刃形位错的攀滑移所产生的动态回复有限,亚晶界未能很好的形成,晶内的位错密度仍然保持较高的水平,从而使金属内部的储能迅速增加,达到动态再结晶所需的驱动力,最终导致动态再结晶的发生。动态再结晶发生以后,为亚晶界的形成争取了时间,从而使稳态流变过程又处于一个加工硬化和动态软化的平衡过程,保持了稳态应变应力的相对稳定。

4 结论

1) 7039铝合金高温塑性变形时存在稳态流变 特征。

2) 7039铝合金的稳态流变应力随变形温度的升高而降低;随应变速率的增加而升高,合金在应变速率为10/s,温度大于300 ℃变形时发生动态再结晶。

3) 7039铝合金热变形条件下流变应力σ、应变速率 、变形温度T满足以下关系式:

、变形温度T满足以下关系式:

REFERENCES

[1] LEECH P W. Observations of adiabatic shear band formation in 7039 aluminum alloy[J]. Metallurgical Transactions A, 1985, 16(10): 1900-1903.

[2] 刘 瑛, 张新明, 李慧中, 刘 波, 高 慧, 李惠杰. 3种高强铝合金的低温拉伸力学性能研究[J]. 金属热处理, 2007, 32(1): 53-56.

LIU Ying, ZHANG Xin-ming, LI Hui-zhong, LIU Bo, GAO Hui, LI Hui-jie. Tensile properties of three kinds of aluminum alloys at low temperature[J]. Heat Treatment of Metals, 2007, 32(1): 53-56.

[3] 黄兰萍, 陈康华, 李 松, 刘红卫. 高温预析出对Al-Zn-Mg铝合金组织、力学性能和应力腐蚀性能的影响[J]. 中国有色金属学报, 2005, 15(5): 727-733.

HUANG Lan-ping, CHEN Kang-hua, LI Song, LIU Hong-wei. Effect of high-temperature pre-precipitation on micro-structure, mechanical property and stress corrosion cracking of Al-Zn-Mg aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(5): 727-733.

[4] 黄继武, 尹志民, 聂 波, 陈继强, 何振波. 7A52 铝合金原位加热过程中的物相转变与热膨胀系数测量[J]. 兵器材料科学与工程, 2007, 30(4): 9-12.

HUANG Ji-wu, YIN Zhi-min, NIE-bo, CHEN Ji-qiang, HE Zhen-bo. Investigation of phases and thermal expansivity of 7A52 alloy in in-situ heating[J]. Ordnance Material Science And Engineering, 2007, 30(4): 9-12.

[5] 周鹏展, 钟 掘, 贺地求. 7A52 铝合金厚板搅拌摩擦焊[J]. 中国有色金属学报, 2006, 16(6): 964-969.

ZHOU Peng-zhan, ZHONG Jue, HE Di-qiu. Friction-stir welding on thick plate of 7A52 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(6): 964-969.

[6] 陈康华, 黄兰萍, 郑 强, 胡化文. 高温预析出对7A52合金应力腐蚀性能的影响[J]. 中国有色金属学报, 2005, 15(3): 441-445.

CHEN Kang-hua, HUANG Lan-ping, ZHENG Qiang, HU Hua-wen. Effect of high-temperature pre-precipitation on stress corrosion cracking of 7A52 alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(3): 441-445.

[7] 李慧中, 张新明, 陈明安, 周卓平. 2519铝合金热变形行为[J]. 中国有色金属学报, 2005, 15(4): 621-625.

LI Hui-zhong, ZHANG Xin-ming, CHEN Ming-an, ZHOU Zhuo-ping. Hot deformation behavior of 2519 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(4): 621-625.

[8] CERRI E, EVANGELISTA E, FORCELESS A, MC QUEEN H J. Comparative hot workability of 7012 and 7075 alloys after different pretreatments[J]. Mater Sci Eng A, 1995, 197(1/2): 181-198.

[9] 林高用, 张 辉, 郭武超, 彭大暑. 7075铝合金热压缩变形流变应力[J]. 中国有色金属学报, 2001, 11(3): 412-415.

LIN Gao-yong, ZHANG Hui, GUO Wu-chao, PENG Da-shu. Flow stress of 7075 aluminum alloy during hot compression deformation[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(3): 412-415.

[10] 沈 健. 2091铝锂合金高温塑性变形行为的研究[D]. 长沙: 中南工业大学, 1996.

SHEN Jian. Study on the plastic deformation behavior of 2091 AI-Li alloy at elevated temperatures[D]. Changsha: Central South University of Technology, 1996.

[11] 关德林. 晶体的高温塑性变形[M]. 大连: 大连理工大学出版社, 1989.

GUAN De-lin. High-temperature plastic deformation of the crystal[M]. Dalian: Dalian University of Technology Press, 1989.

[12] 毛卫民, 赵新兵. 金属的再结晶与晶粒长大[M]. 北京: 冶金工业出版社, 1994.

MAO Wei-min, ZHAO Xin-bing. Metal recrystallization and grain growth[M]. Beijing: Metallurgical Industry Press. 1994.

[13] WANG Y, LIU D L, LAY C C. A correlation between tensile flow stress and Zenner-Hollomon factor in TiAl alloys at high tempera-tures[J]. J Mat Sci, 2000, 19: 1185-1188.

[14] YAO X X, ZAJAC S, HUTCHINSON B. The strain-rate sensitivity of flow stress and work- hardening rate in a hot deformed Al-1.0Mg alloy[J]. J Mat Sci, 2000, 19: 743-744.

[15] Castor-Femandez F R, SELLARS C M, WHITEMAN J A. Changes of flow stress and microstructure during hot deformation of Al-1Mg-1Mn[J]. Mater Sci Technol, 1990, 6: 453-460.

[16] SHI H, MCLAREN A J, SELLARS C M. Constitutive equations for high temperature flow stress of aluminum alloys[J]. Mater Sci Eng A, 1997, 13(3): 210-216.

基金项目:国家自然科学基金资助项目(50671121);中南大学博士后基金资助项目(2007-8);中国博士后基金资助项目(20070420828)

收稿日期:2008-02-18;修订日期:2008-06-19

通讯作者:李慧中,副教授,博士;电话:0731-8877949(O);E-mail: lhz606@mail.csu.edu.cn

(编辑 何学锋)